-4-

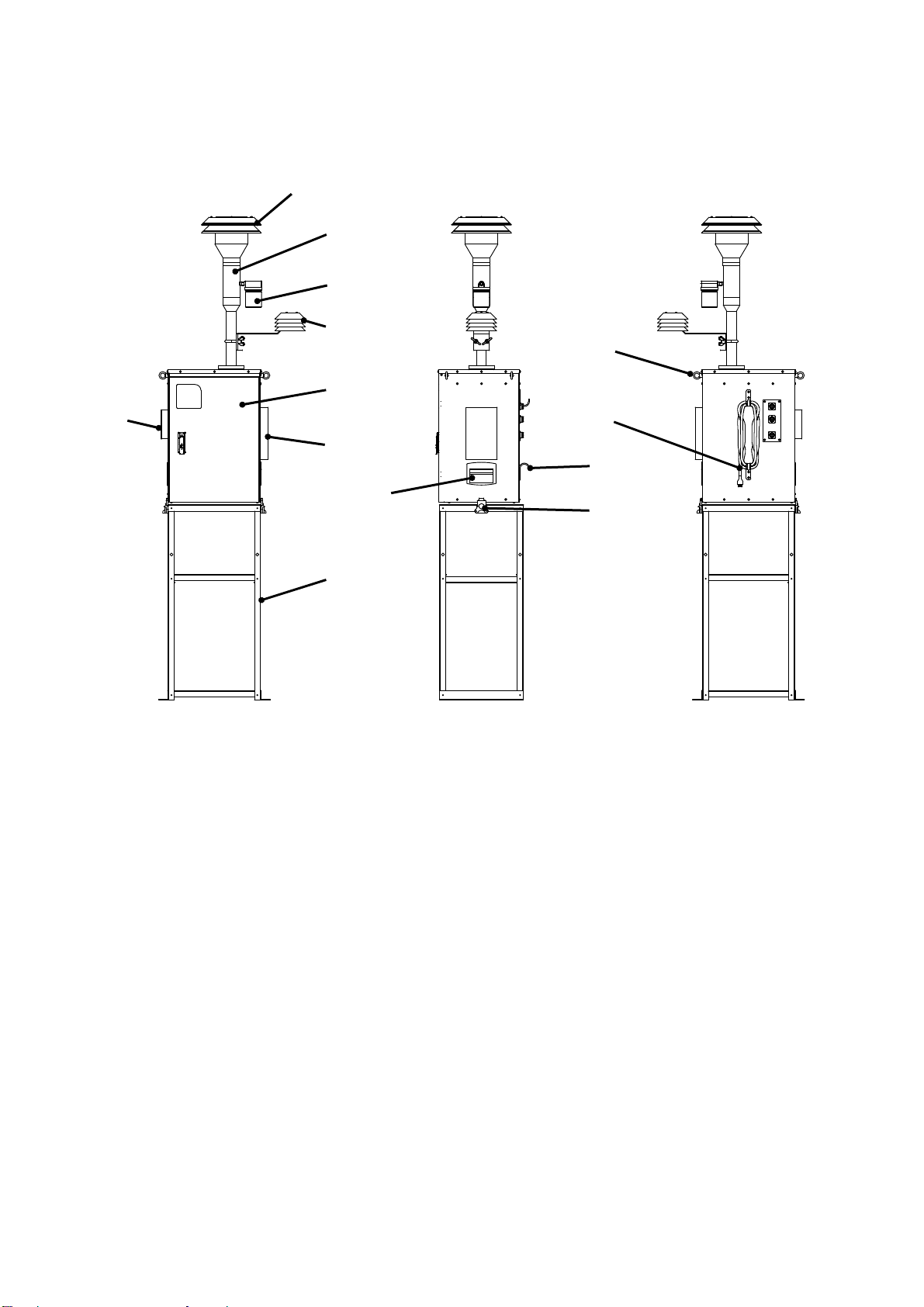

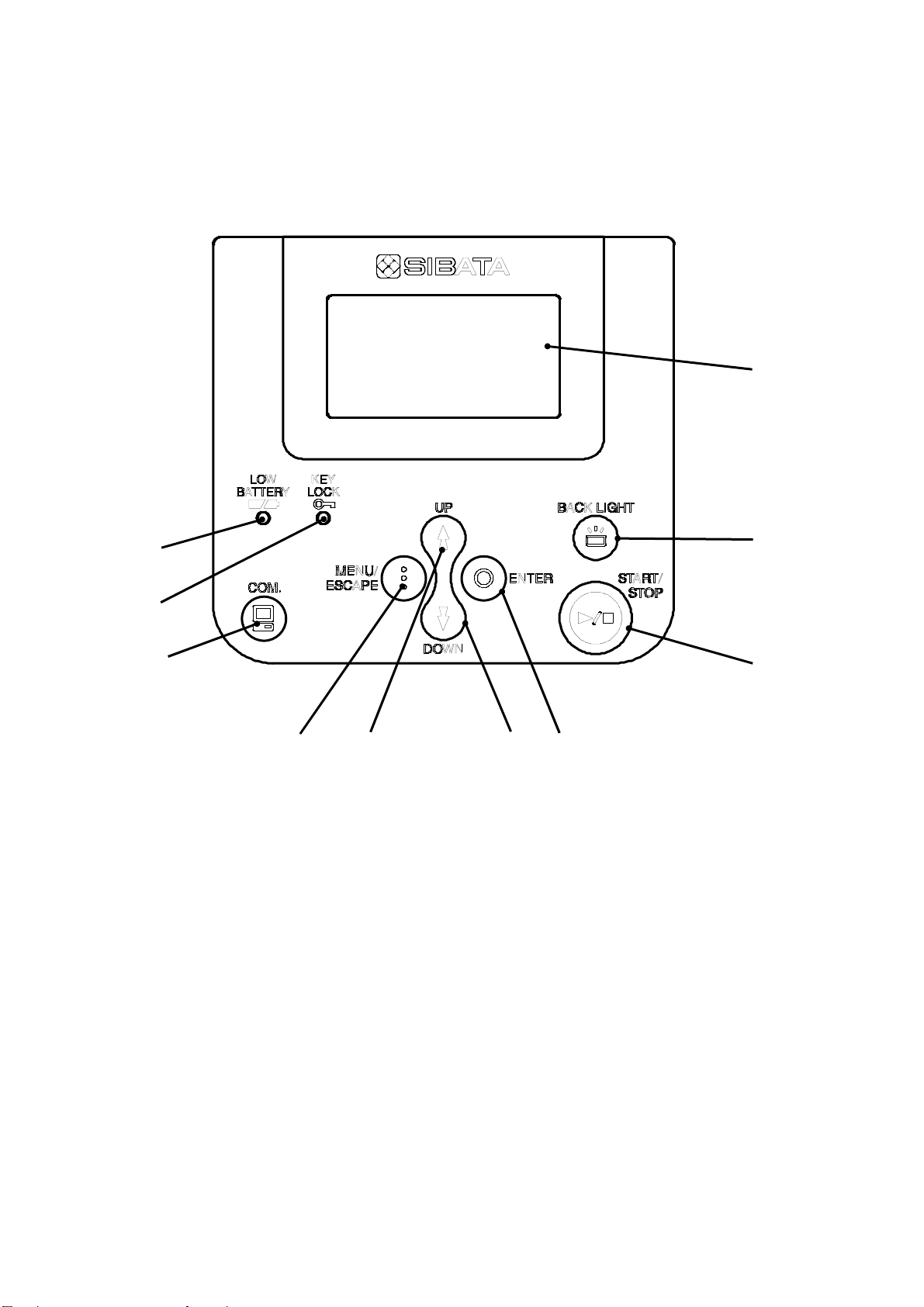

This product is an air sampler. Do not use the product for any purpose not described in this

manual. Doing so might cause malfunction.

Do not store this product where it will be exposed to direct sunlight, or near fire. Doing so might

cause abnormal operation or malfunction.

If this product is exposed to strong sunlight, the product may become hot. When handling it, be

careful to avoid burning your hands.

When assembling this product, be careful not to get your hands caught in the equipment, or to

bump into the equipment.

Never transport the equipment with the main unit attached to the stand. There is a risk that the

twist fasteners will be damaged.

Do not place objects on top of this product. Doing so might cause the product to tip over or

deform the product, resulting in accident or malfunction.

Before cleaning or inspecting this product, disconnect the power plug from the power outlet.

Failure to do so might cause electric shock, electric leak or other abnormalities.

Do not use chemicals to wipe down unspecified parts of this product. Also, do not use

unspecified chemicals. Doing so might cause malfunction.

The main unit can be used with a single-phase 100 V to 240 V (85 V to 264 V) power source,

but the power outlet is only designed for 100 V. Contact your Sibata representative or the

vendor if you will be using the equipment at a voltage outside of these specifications.

When not using this product, disconnect the power plug from the power outlet. Failure to do so

might cause fire or malfunction.

When disconnecting the power plug, be sure to hold the power cord by the power plug. Pulling

the cord might damage it and cause electric shock or fire.

Before use, check the sheath of the power adapter cord for scratches or other abnormalities.

Also, do not place heavy objects or step on the power cord. Use in an abnormal state might

cause fire or electric shock.

Do not use wires, other metallic objects, or any other connection method not specified in this

manual. Doing so might cause malfunction.

Do not allow water and other liquids, and gases other than air to be sucked in. Also, do not

allow corrosive gases (e.g. salt air) or chemicals to be sucked in. Doing so might cause

malfunction or fire.

Be sure to install a backup filter in the main unit interior before operating the product.

Malfunction might result from direct, long term intake of air.

Do not insert screws or other foreign objects into the suction and exhaust ports. Doing so might

cause malfunction. Should foreign objects get inside this product, immediately turn the power

switch OFF, disconnect the power plug, and contact your Sibata agent.

The operating temperature and humidity ranges of this product are 0 to 40 °C and 10 to 90 % rh

(no condensation), respectively. Use of this product outside of these ranges might impair its

performance and service life, resulting in malfunction.

Do not bring this product close to equipment that generates electrical noise. Also, do not install

it at locations subject to string magnetic fields, or lots of dust or humidity. Doing so might

damage the hardware, for example.

Note that, should some nonconformity occur, Sibata does not assume any liability whatsoever

for compensation of data or content that could not be acquired or logged as a result, loss of data

or other content, and other direct and indirect damages relating to the preceding. Periodically

back up data as a precaution against malfunction or accidents.