- 3 -

Before Using the Product

(Be sure to read this, and handle this product with due care.)

To ensure correct use, read this operation manual thoroughly before handling

this product. In addition, keep this manual in an easily accessible location.

△ Install this product horizontally at a stable location.

△ Be sure to connect the power cord grounding wire.

△ This product is not explosion-proofed, so do not use it in the vicinity of combustible or

flammable substances.

△ [Modifications and Repairs Are Prohibited] Never disassemble or modify this product, as

doing so will void the warranty with Sibata. Doing so may also result in unforeseen faults and

accidents.

△ If a fault occurs, request repairs immediately. Never leave the fault as is, or attempt your own

repairs, as subsequent use may result in unforeseen accidents.

△ If the product becomes dirty, wipe away the dirt with a soft cloth (soaked in detergent if there

is significant dirt).

△ If the product emits smoke, or the motor becomes very hot, or the product makes a strange

noise, stop using it immediately. Turn OFF the power switch, remove the power plug from the

power outlet, and request repairs.

△ When removing the power plug from the outlet, hold the cord by the power plug to avoid

pulling on the power cord. Be sure your hands are dry before handling the power cord.

Otherwise, there is a risk of electric shocks.

△ Do not bend, stretch, or twist the cord. Do not connect it to a different cord.

△ If you notice that the cord has become damaged, or broken, or the plug does not connect

properly, stop using it immediately, and request repairs.

Contents of Package

Check the package for the following items before using the product.

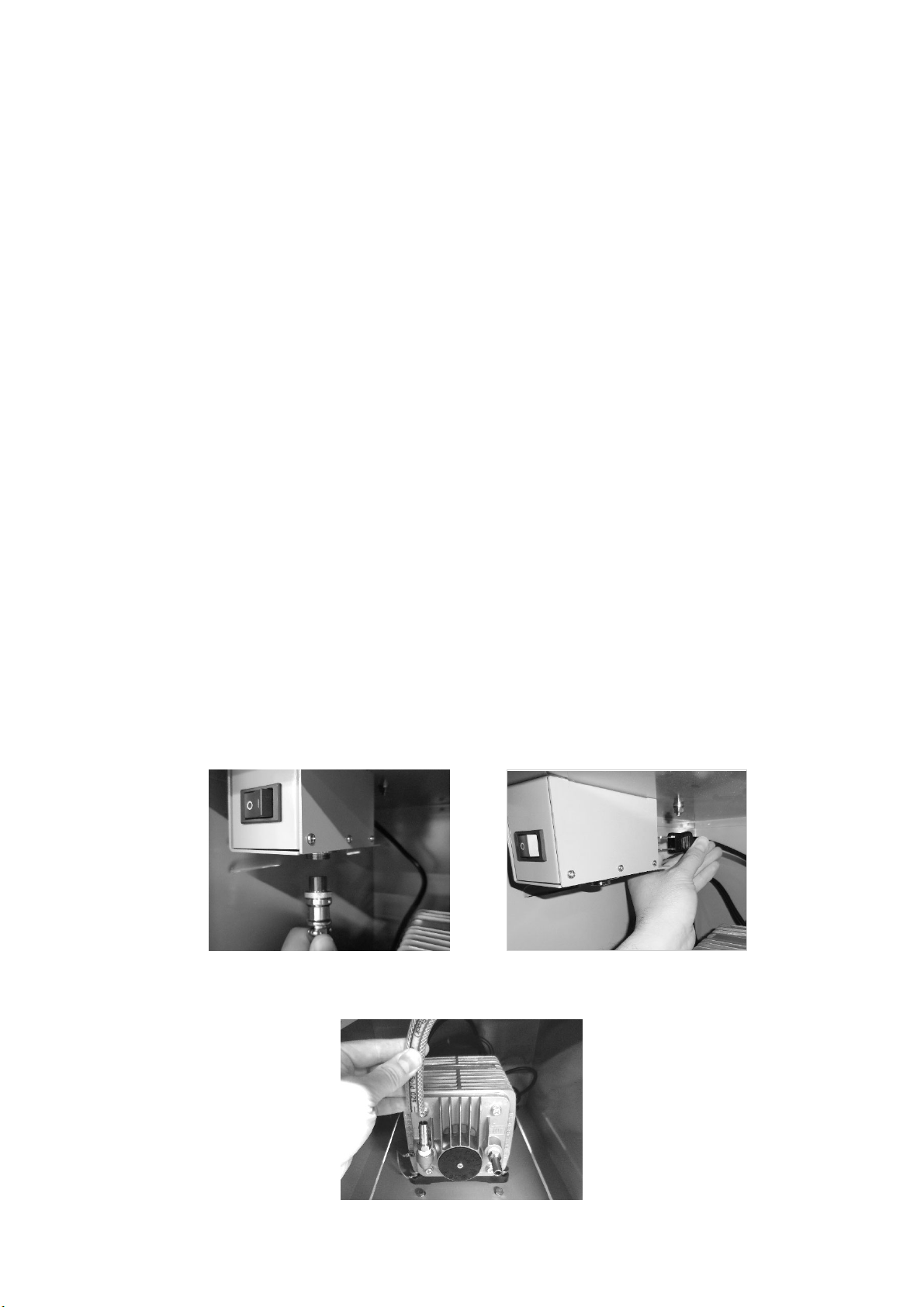

●Shelter for Andersen sampler < Item code 080040-011 >

Shelter (Suction pump, PVC hose 1m)···································1

Power cord······································································1

Operation manual (This document) ·······································1

Warranty·········································································1

●Andersen Sampler AN-200 < Item code 080040-012 >

Andersen Sampler AN-200 main unit·····································1

Glass collection plate, 82.5 mm dia. ···························10 sheets

Aluminum filter plate, t = 1.6, 82.5 mm dia. ··················· 8 sheets

Stainless steel collection plate, t = 0.1, 80 mm dia. ········10 sheets

Styrol sample holder························································ 10

Flowrate calibration table····················································1

Operation manual (This document) ·······································1

Warranty·········································································1

●Glass fiber filters, PTFE binding, TF98R, 80 mm dia., 100 sheets

< Item code 080130-098080 >

Andersen Sampler AN-200 Set < Item code 080040-01 >