- 2 -

Contents

Before Use.......................................................................................................................3

Safety Precautions...........................................................................................................4

Product Overview.............................................................................................................7

Features...........................................................................................................................7

Names of Parts ................................................................................................................8

Installation......................................................................................................................10

Conveyance............................................................................................................10

Assembly and Installation Procedure...................................................................... 11

Wiring Methods.......................................................................................................13

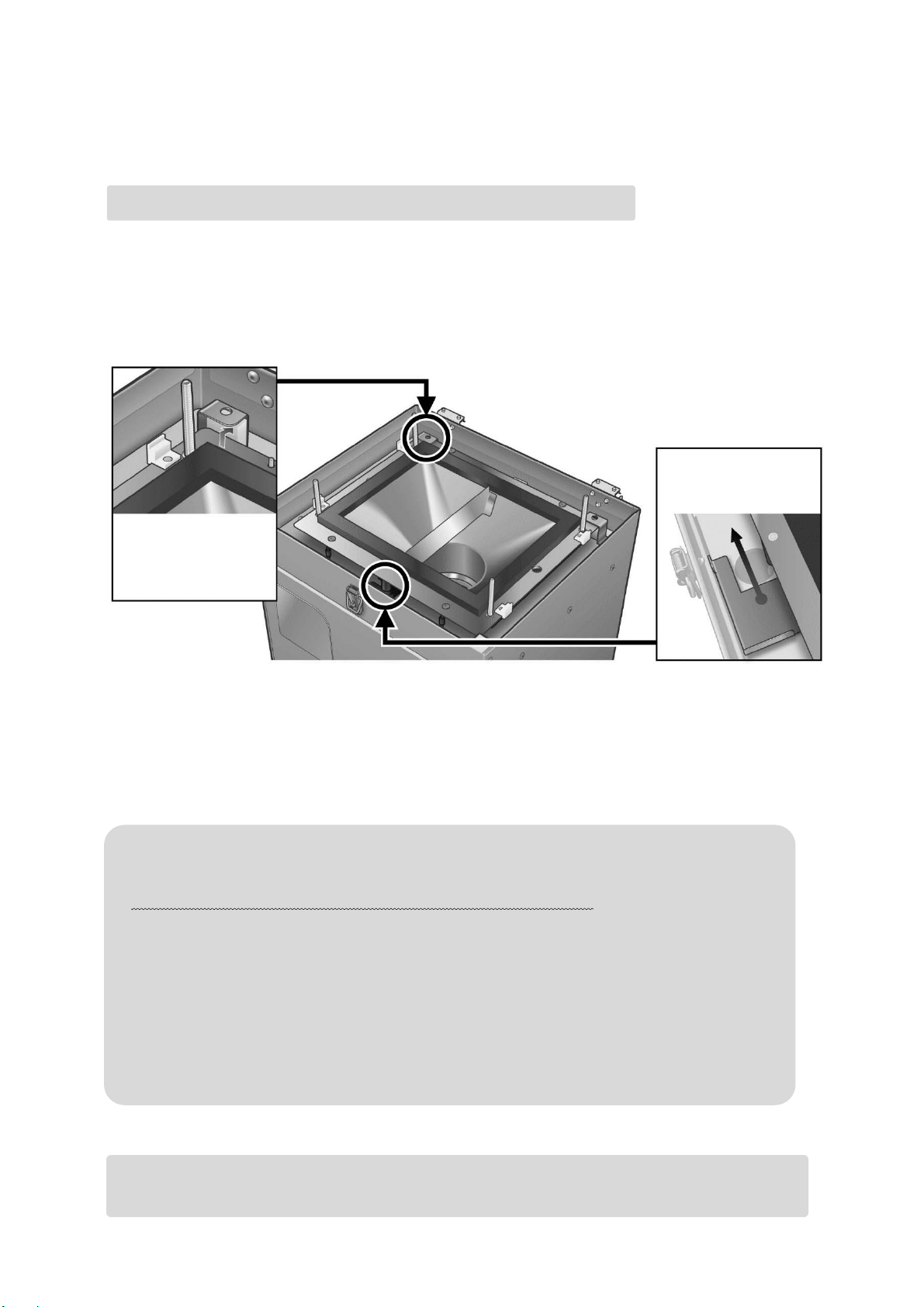

Attaching the Shuttle Tube......................................................................................14

Attaching the Filter Case.........................................................................................15

Capability of This Product..............................................................................................16

Product Limitations.........................................................................................................16

Touch Panel ...................................................................................................................17

Main Screen...................................................................................................................18

Sampling Method...........................................................................................................19

Setting the Flow Rate..............................................................................................19

Setting the Operation Start Timer ...........................................................................20

Setting the Operation End Timer.............................................................................22

Starting Operations.................................................................................................24

During Operation.....................................................................................................25

Error Displays .........................................................................................................26

Power Outages ..............................................................................................................27

Mode Display .................................................................................................................28

Menu..............................................................................................................................30

Toggling the Flow Rate Correction Method.............................................................30

Sampling Data ........................................................................................................31

Detailed Error Display.............................................................................................33

Setting the Time......................................................................................................34

Setting the Screen ..................................................................................................35

Setting the Serial Number.......................................................................................35

Setting the Error......................................................................................................36

Calibration Mode.....................................................................................................37

Leak Check.............................................................................................................38

Calibration Methods.......................................................................................................39

Flow Rate Calibration Method.................................................................................39

Atmospheric Temperature Calibration Method........................................................39

Atmospheric Pressure Calibration ..........................................................................40

Flow Rate Correction Method ........................................................................................41

Communications ............................................................................................................41

Maintenance...................................................................................................................42

Troubleshooting..............................................................................................................43

Main Specifications........................................................................................................44

Spare Parts....................................................................................................................45

Consumables.................................................................................................................45

Options...........................................................................................................................45

Warranty and Repair......................................................................................................46

Disposal of the Product..................................................................................................46

Inquiries..........................................................................................................................46

Trouble Notification Sheet..............................................................................................47