Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.1.1 Related applicable documents............................................... 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Cybersecurity............................................................................................ 7

2.4 Limitation of liability................................................................................. 7

2.5 Modifications and conversions................................................................ 8

2.6 Requirements for skilled persons and operating personnel.................. 8

2.7 Operational safety and specific hazards................................................. 8

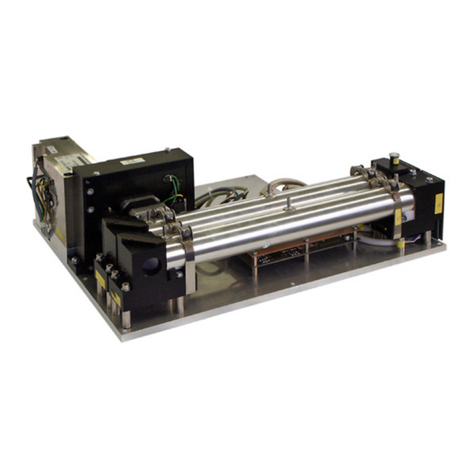

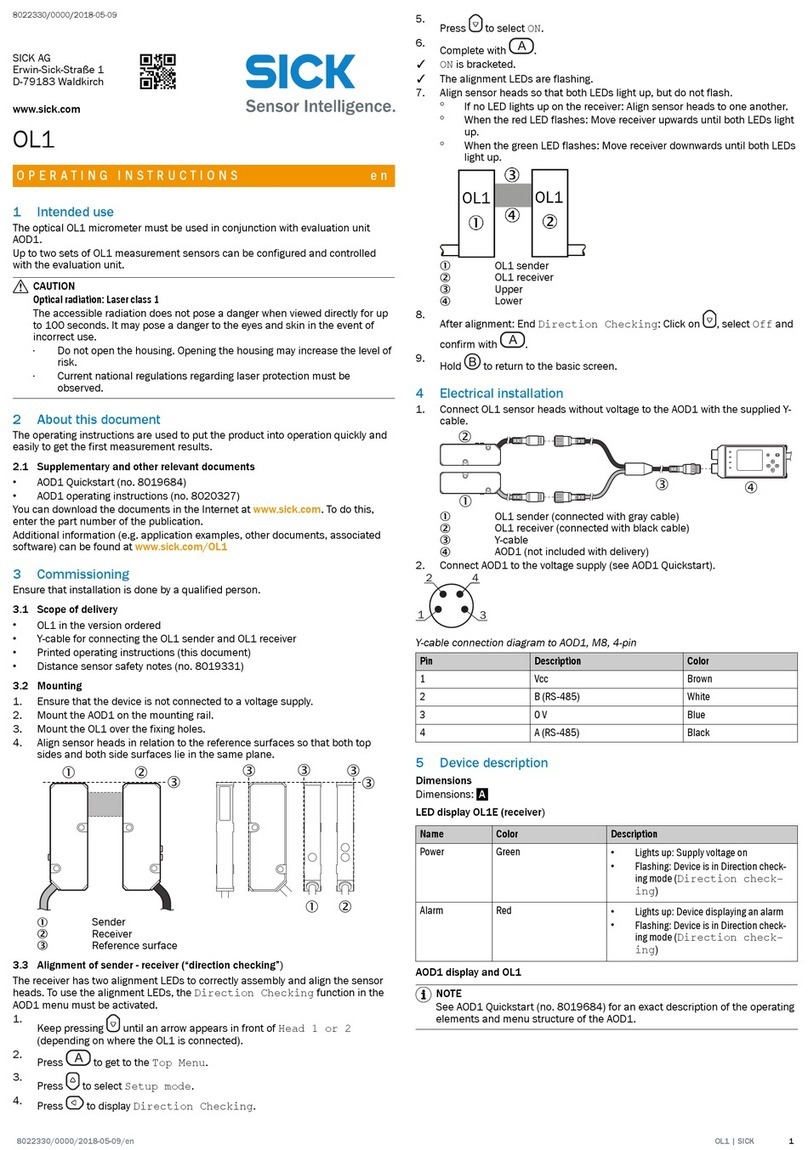

3 Product description........................................................................... 9

3.1 Scope of delivery....................................................................................... 9

3.2 Function and use...................................................................................... 9

3.3 Positioning mark....................................................................................... 10

3.4 Target region............................................................................................. 11

3.5 Single-deep rack storage.......................................................................... 11

3.6 Single- and double-deep rack storage.................................................... 12

4 Mounting............................................................................................. 13

4.1 Mounting requirements............................................................................ 13

4.2 Mounting the polarizing filter................................................................... 14

4.3 Mounting the device................................................................................. 16

5 Electrical installation........................................................................ 17

5.1 Notes on electrical installation................................................................ 17

5.2 Ethernet interface..................................................................................... 17

5.3 Digital inputs and digital outputs............................................................. 17

6 Commissioning.................................................................................. 18

6.1 Software.................................................................................................... 18

6.1.1 SICK AppManager.................................................................... 18

6.1.2 SOPASair.................................................................................. 18

6.2 SICK AppManager user interface............................................................ 18

6.3 Changing the IP address.......................................................................... 19

6.4 Establishing a PROFINET connection...................................................... 19

6.5 Parameterization using SOPASair............................................................ 20

6.5.1 SOPASair user interface.......................................................... 20

6.5.2 Opening the SOPASair user interface..................................... 20

6.5.3 User levels................................................................................ 20

6.5.4 Setting the user interface language....................................... 21

CONTENTS

8024534/1DQ8/2022-01-14 | SICK O P E R A T I N G I N S T R U C T I O N S | InspectorP Rack Fine Positioning 3

Subject to change without notice