Operating instructions

8028999:

OPERATING INSTRUCTIONS en

1 About this document

1.1 Information on the operating instructions

Read these operating instructions carefully before starting any work in order to

familiarize yourself with the product and its functions.

The operating instructions are an integral part of the product and should remain

accessible to the personnel at all times. When handing this product over to a third

party, include these operating instructions.

These operating instructions do not provide information on the handling and safe

operation of the machine or system in which the product is integrated. Information

on this can be found in the operating instructions for the machine or system.

1.2 Scope

This document applies to the following products:

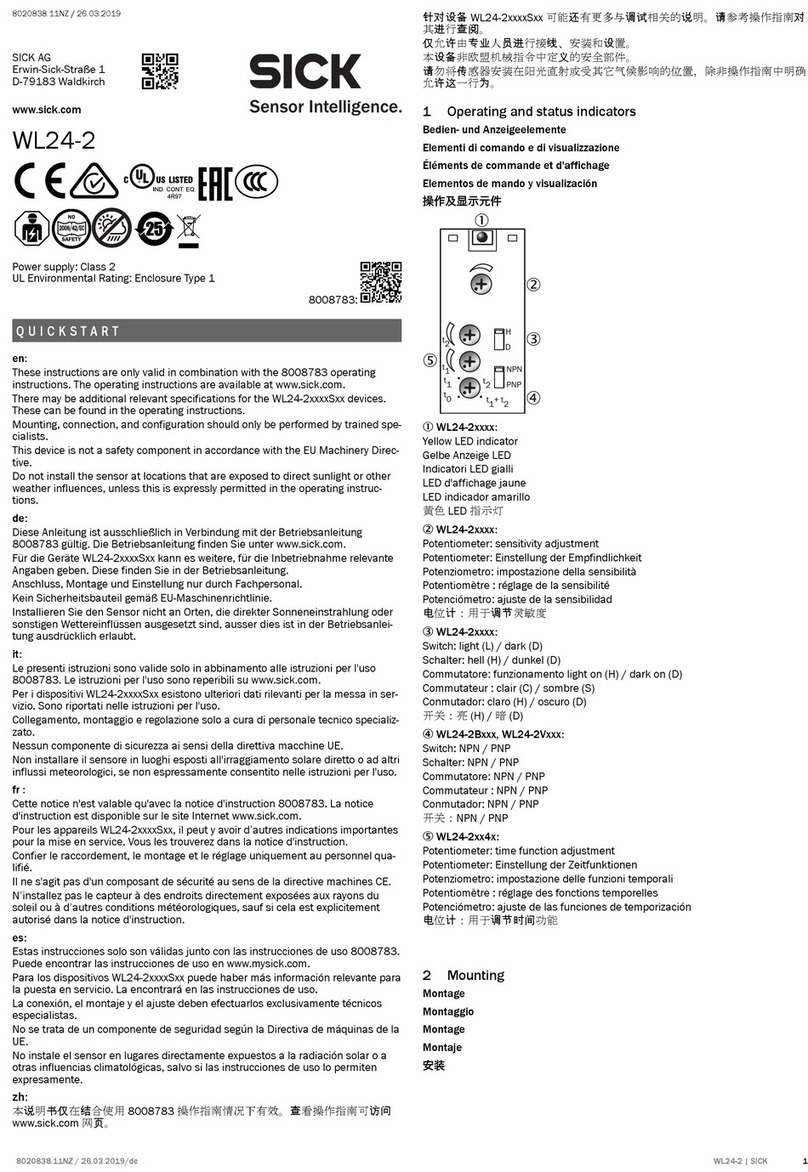

•ELS35/ELM35

1.3 Target group

This document is intended for persons who commission, install, operate and

maintain the product.

1.4 Further information

You can find the product page with further information via the SICK Product ID:

pid.sick.com/{P/N}/{S/N}

(see Product identification via the SICK product ID).

The following information is available depending on the product:

•This document in all available language versions

•Data sheets

•Other publications

•CAD files and dimensional drawings

•Certificates (e.g., declaration of conformity)

•Software

•Accessories

1.5 Related applicable documents

Related applicable documents from SICK

Document Title Part num‐

ber

Source

Technical

information

Technical Information for

BiSS-C

8028999 www.sick.com/8028999

1.6 Symbols and document conventions

Warnings and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or

serious injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or

serious injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate

or minor injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property

damage if not prevented.

NOTE

Highlights useful tips and recommendations as well as information for effi‐

cient and trouble-free operation.

Instructions to action

bThe arrow denotes instructions to action.

1. The sequence of instructions is numbered.

2. Follow the order in which the numbered instructions are given.

✓The tick denotes the results of an action.

2 Safety information

2.1 Basic safety notes

Please observe the safety notes and the warnings listed here and in other sec‐

tions of this product documentation to reduce the possibility of risks to health and

avoid dangerous situations.

CAUTION

Failure to observe the relevant work safety regulations may lead to physical

injury or cause damage to the system.

Mounting and electrical installation

DANGER

Death or severe injury due to electrical voltage and/or an unexpected startup

of the machine

bMake sure that the machine is (and remains) disconnected from the

voltage supply during mounting and electrical installation.

bMake sure that the dangerous state of the machine is and remains

switched off.

Integrating the product

DANGER

The product can not offer the expected protection if it is integrated incorrectly.

bPlan the integration of the product in accordance with the machine

requirements (project planning).

bImplement the integration of the product in accordance with the project

planning.

Repairs and modifications

DANGER

Improper work on the product

A modified product may not offer the expected protection if it is integrated

incorrectly.

bApart from the procedures described in this document, do not repair,

open, manipulate or otherwise modify the product.

The motor feedback system housing is to be connected to the customer’s flange

arrangement with fixing screws so that it cannot rotate. The more precise the

centering of the motor feedback system, the less the angle and shaft offset

during mounting.

From an EMC perspective, it is essential to connect the housing or encoder to

ground. In the case of the ELS35-0/ELM35-0, the direct contact with the motor

flange ensures that the encoder housing is at the same potential as the motor

housing.

WARNING

To ensure fault-free operation, the motor shielding must be connected prop‐

erly.

2.2 Qualification of personnel

Any work on the product may only be carried out by personnel qualified and

authorized to do so.

Qualified personnel are able to perform tasks assigned to them and can inde‐

pendently recognize and avoid any potential hazards. This requires, for example:

•technical training

•experience

•knowledge of the applicable regulations and standards

3 Product description

3.1 Product description

Encoders of type ELS35/ELM35 are motor feedback systems that are designed

for the dynamic and precise operation of servo-control circuits due to their equip‐

ment.

The overall system, which consists of a motor feedback system, evaluation sys‐

tem, servo controller, and motor forms a control circuit. Actual values for commu‐

tation, rotational speed, direction of rotation, and position are derived from the

encoder signals. The sensor signals are transmitted to the evaluation system via a

BiSS-C interface.

WARNING

The ELS35/ELM35 motor feedback system is not a safety component.

4 Mounting

4.1 Mounting instruction

WARNING

The product must be mounted in an ESD protected area.

8029004/2023/11/07/en ELS35/ELM35 | SICK 1

8029004/2023/11/07

www.sick.com

ELS35/ELM35