Siei ARTDriveG User manual

.....Instruction Manual

ARTDriveG

General-PurposeInverter

230/400/460V Class

575VClass

ARTDriveG

Thank you for choosing this SIEI product.

We will be glad to receive any possible information which could help us improving this manual. The e-mail address is the

following:[email protected] .

Before using the product, read the safety instruction section carefully.

Keepthemanualinasafe placeandavailableto engineeringandinstallationpersonnel duringtheproductfunctioning period.

SIEI S.p.A has the right to modify products, data and dimensions without notice.

The data can only be used for the product description and they can not be understood as legally stated properties.

Thismanualisupdatedaccordingto firmware version V03.02.

Allrightsreserved

ARTDriveG Instruction Manual Table of Contents • 3

Table of Contents

Safety Symbol Legend - Precautions de securité...................................................................... 6

Chapter 1 - Safety Precautions..................................................................................................7

1.1PowerSupplyandGrounding ........................................................................................................................................................ 10

Chapter 2 - General................................................................................................................... 11

Features ............................................................................................................................................................................................12

Accessories/Options ........................................................................................................................................................................12

Chapter 3 - Inspection Procedure, Component Identification and Standard Specification .... 13

3.1UponDeliveryInspectionProcedures............................................................................................................................................ 13

3.1.1General .....................................................................................................................................................................................13

3.1.2InverterTypeDesignation ..........................................................................................................................................................13

3.1.3Nameplate ................................................................................................................................................................................14

3.2ComponentIdentification .............................................................................................................................................................. 15

3.3StandardSpecifications ................................................................................................................................................................ 16

3.3.1PermissibleEnvironmentalConditions .......................................................................................................................................16

Disposalof the Device ...............................................................................................................................................................17

3.3.2MainsConnectionandInverterOutput .......................................................................................................................................17

3.3.3ACInputCurrent ........................................................................................................................................................................20

3.3.4ACOutput..................................................................................................................................................................................20

3.3.5Open-LoopandClosed-LoopControlSection ..............................................................................................................................21

3.3.6Accuracy ..................................................................................................................................................................................21

Chapter 4 - Installation Guidelines ........................................................................................... 23

4.1MechanicalSpecification.............................................................................................................................................................. 23

4.2WattsLoss,HeatDissipation,InternalFansandMinimumCabinetOpeningSuggestedfortheCooling ........................................ 27

4.2.1CoolingFansPowerSupply.......................................................................................................................................................28

4.3InstallationMountingClearance.................................................................................................................................................... 29

4.4MotorsandEncoder ...................................................................................................................................................................... 30

4.4.1.ACInductionMotors.................................................................................................................................................................30

4.4.2Encoder ....................................................................................................................................................................................31

Chapter 5 - Wiring Procedure................................................................................................... 33

5.1AccessingtotheConnectors ........................................................................................................................................................ 33

5.2PowerSection .............................................................................................................................................................................. 35

5.2.1MaximumCableCrossSectionforPowerTerminals ..................................................................................................................36

5.2.2 RectificationandIntermediate(D.C.)Circuit ..............................................................................................................................37

5.2.3Inverter .....................................................................................................................................................................................38

5.3RegulationSection ........................................................................................................................................................................ 39

5.3.1R-AGyRegulationCard..............................................................................................................................................................39

5.3.2TerminalAssignmentsonRegulationSection .............................................................................................................................40

5.4SerialInterface ............................................................................................................................................................................. 41

5.4.1InGeneral .................................................................................................................................................................................41

5.4.2RS485SerialInterfaceConnectorDescription...........................................................................................................................42

5.5Typical ConnectionDiagrams ........................................................................................................................................................ 43

5.5.1AGyConnection ........................................................................................................................................................................43

5.5.2EngineeringNotes .....................................................................................................................................................................44

5.5.3.ParallelConnectionontheAC(Input)andDC(IntermediateCircuit)SideofSeveralInverters ...................................................45

5.6CircuitProtection .......................................................................................................................................................................... 46

5.6.1ExternalFusesofthePowerSection ..........................................................................................................................................46

5.6.2 ExternalFusesofthePowerSectionDCInputSide....................................................................................................................47

5.6.3InternalFuses............................................................................................................................................................................48

5.7Chokes/Filters(Optional) ............................................................................................................................................................ 48

5.7.1ACInputChokes ........................................................................................................................................................................49

5.7.2OutputChokes ...........................................................................................................................................................................49

4 • Table of Contents ARTDriveG Instruction Manual

5.7.3InterferenceSuppressionFilters ................................................................................................................................................50

5.7.3.1EMIfilterconnectionsforSizes1007...3150(230V...480V) ..............................................................................................52

5.7.3.2EMIfilterconnectionsforSizes4220...71320(230V...480V).............................................................................................53

5.8BrakingintheAGySystem ........................................................................................................................................................... 54

5.8.1BrakingUnit ..............................................................................................................................................................................54

5.8.1.1ExternalBrakingResistor ...............................................................................................................................................56

5.8.2D.C.Braking ..............................................................................................................................................................................59

5.9DischargeTimeoftheDC-Link ..................................................................................................................................................... 59

Chapter 6 - Drive Keypad Operation......................................................................................... 60

6.1Keypad ......................................................................................................................................................................................... 60

6.2LanguageSelection ....................................................................................................................................................................... 62

6.3MovingThroughtheDriveMainMenu .......................................................................................................................................... 62

6.4Scrolling ThroughtheDrive Parameters ........................................................................................................................................ 63

6.5ParametersModification .............................................................................................................................................................. 63

6.6QuickstartProcedure .................................................................................................................................................................... 64

Chapter 7 - Parameter Description .......................................................................................... 65

7.1ParametersList ............................................................................................................................................................................ 65

7.2 Menud-DISPLAY ....................................................................................................................................................................... 92

Basic.................................................................................................................................................................................................92

Overload............................................................................................................................................................................................92

Inputs/Outputs....................................................................................................................................................................................93

Encoder.............................................................................................................................................................................................96

Option................................................................................................................................................................................................97

Pid ....................................................................................................................................................................................................97

Alarmlist...........................................................................................................................................................................................98

DriveIdentification.............................................................................................................................................................................98

Utility.................................................................................................................................................................................................99

7.3 MenuS-START-UP....................................................................................................................................................................100

PowerSupply.................................................................................................................................................................................. 100

V/F Characteristic........................................................................................................................................................................... 100

MotorData ...................................................................................................................................................................................... 101

Commands&Referencies ................................................................................................................................................................ 102

Functions......................................................................................................................................................................................... 104

Utility............................................................................................................................................................................................... 105

7.4 MenuI-INTERFACE...................................................................................................................................................................106

DigitalInputsRegulationBoard ........................................................................................................................................................ 106

DigitalInputsExpansionBoard ......................................................................................................................................................... 107

DigitalOuputsRegulationBoard ....................................................................................................................................................... 108

DigitalOutputsExpansionBoard ....................................................................................................................................................... 109

AnalogInputsRegulationBoard ....................................................................................................................................................... 110

AnalogOutputsRegulationBoard ..................................................................................................................................................... 114

AnalogOutputsExpBoard ................................................................................................................................................................ 117

EnablingVirtualI/O .......................................................................................................................................................................... 118

EncoderConfiguration...................................................................................................................................................................... 122

SerialConfiguration ......................................................................................................................................................................... 123

OptionsConfiguration....................................................................................................................................................................... 125

SBIConfiguration............................................................................................................................................................................. 126

7.5 Menu F-FREQ&RAMPS ...........................................................................................................................................................128

Motorpotentiometer ......................................................................................................................................................................... 128

ReferenceLimits .............................................................................................................................................................................. 130

ReferenceSources .......................................................................................................................................................................... 131

MultispeedFunction ........................................................................................................................................................................ 132

RampConfiguration ......................................................................................................................................................................... 134

JumpFrequencies ........................................................................................................................................................................... 136

7.6 MenuP-PARAMETERS..............................................................................................................................................................138

Commands ...................................................................................................................................................................................... 138

PowerSupply.................................................................................................................................................................................. 144

MotorData ...................................................................................................................................................................................... 144

V/F Curve ........................................................................................................................................................................................ 145

ARTDriveG Instruction Manual Table of Contents • 5

OuputFrequencyLimit ..................................................................................................................................................................... 147

SlipCompensation........................................................................................................................................................................... 147

Boost............................................................................................................................................................................................... 148

AutomaticFluxRegulation................................................................................................................................................................ 149

AntiOscillationFunction .................................................................................................................................................................. 149

SWCurrentClamp........................................................................................................................................................................... 149

CurrentLimit .................................................................................................................................................................................... 150

DCLinkLimit .................................................................................................................................................................................... 152

OverTorqueAlarmConfiguration...................................................................................................................................................... 153

MotorOverloadConfiguration .......................................................................................................................................................... 154

BUConfiguration.............................................................................................................................................................................. 154

DCBrakeConfiguration .................................................................................................................................................................... 155

Autocapturefunction........................................................................................................................................................................ 156

UndervoltageConfiguration.............................................................................................................................................................. 158

OvervoltageConfiguration................................................................................................................................................................ 162

AutoresetConfiguration.................................................................................................................................................................... 163

ExternalFaultConfiguration ............................................................................................................................................................. 164

PhaseLossDetection ....................................................................................................................................................................... 164

VoltageReductionConfiguration ...................................................................................................................................................... 165

FrequencyThreshold ....................................................................................................................................................................... 166

SteadyStateSignalling.................................................................................................................................................................... 168

HeatsinkTemperatureThreshold....................................................................................................................................................... 168

PWMSetting................................................................................................................................................................................... 169

DeadTimeCompensation................................................................................................................................................................. 170

DisplaySetting ................................................................................................................................................................................ 170

Protection........................................................................................................................................................................................ 171

7.7 MenuA- APPLICATION .............................................................................................................................................................172

PIDSetting ...................................................................................................................................................................................... 172

PIDGains......................................................................................................................................................................................... 176

PIDLimits ........................................................................................................................................................................................ 176

7.8 MenuC-COMMANDS...............................................................................................................................................................181

Basic............................................................................................................................................................................................... 181

AlarmRegisterReset ....................................................................................................................................................................... 181

ExternalKey .................................................................................................................................................................................... 181

Tuning ............................................................................................................................................................................................. 182

7.9 MenuH- HIDDEN ......................................................................................................................................................................183

VirtualI/OCommands ...................................................................................................................................................................... 183

ProfidriveParameters...................................................................................................................................................................... 184

DriveStatus..................................................................................................................................................................................... 185

ParametersReadingExtension ......................................................................................................................................................... 185

RemoteI/OsControl ......................................................................................................................................................................... 186

SerialLinkCommands...................................................................................................................................................................... 187

Chapter 8 - Serial Protocol ..................................................................................................... 189

8.1ModbusRTUProtocolforAGydrives...........................................................................................................................................189

8.1.1Introduction............................................................................................................................................................................. 189

8.1.2TheMODBUSProtocol ............................................................................................................................................................ 189

8.1.3Messageformat ...................................................................................................................................................................... 189

8.1.3.1Theaddress ................................................................................................................................................................... 189

8.1.3.2Thefunctioncode........................................................................................................................................................... 189

8.1.3.3CRC16 ............................................................................................................................................................................ 190

8.1.3.4Messagesynchronization .............................................................................................................................................. 190

8.1.3.5Serial line setting........................................................................................................................................................... 190

8.1.4Modbusfunctionsforthedrive ................................................................................................................................................ 191

8.1.4.1ReadOutputRegisters(03) ............................................................................................................................................ 191

8.1.4.2ReadInputRegisters(04) .............................................................................................................................................. 191

8.1.4.3PresetSingleRegister (06) ............................................................................................................................................ 192

8.1.4.4ReadStatus(07)............................................................................................................................................................ 192

8.1.4.5PresetMultiple Registers (16) ....................................................................................................................................... 193

8.1.5Errormanagement................................................................................................................................................................... 193

8.1.5.1Exceptioncodes ............................................................................................................................................................ 194

8.1.6Systemconfiguration............................................................................................................................................................... 194

8.2Proprietaryprotocol .....................................................................................................................................................................195

6 • Table of Contents ARTDriveG Instruction Manual

Safety Symbol Legend - Precautions de securité

Indicates a procedure, condition, or statement that, if not strictly observed, could result in perso-

nal injury or death.

Indique le mode d'utilisation, la procédure et la condition d'exploitation. Si ces consignes ne sont pas

strictement respectées, il y a des risques de blessures corporelles ou de mort.

Indicatesa procedure, condition, or statement that, if not strictlyobserved, could result in damage

to or destruction of equipment.

Indique et le mode d'utilisation, la procédure et la condition d'exploitation. Si ces consignes ne sont pas

strictement respectées, il y a des risques de détérioration ou de destruction des appareils

Indicates a procedure, condition, or statement that should be strictly followed in order to optimize

these applications.

Indique le mode d'utilisation, la procédure et la condition d'exploitation. Ces consignes doivent être

rigoureusementrespectéespour optimiser ces applications..

Warning!

Caution

Attention

NOTE!Indicatesan essential or important procedure, condition,or statement.

Indiqueunmode d'utilisation, de procédure etde condition d'exploitation essentiels ouimportants

8.2.1Introduction............................................................................................................................................................................. 195

8.2.2Messageformat ...................................................................................................................................................................... 195

8.2.3Address................................................................................................................................................................................... 196

8.2.4Controlcode ........................................................................................................................................................................... 196

8.2.5Functions ................................................................................................................................................................................ 196

8.2.6MsgSlavemeaning ................................................................................................................................................................ 197

Chapter 9 - Troubleshooting ................................................................................................... 199

9.1Drive AlarmCondition ..................................................................................................................................................................199

9.2AlarmReset.................................................................................................................................................................................199

9.3ListofDriveAlarmEvents ...........................................................................................................................................................200

Chapter 10 - EMC Directive, Declarations of EC-Conformity................................................ 201

Index Parameters ................................................................................................................... 204

ARTDriveG Instruction manual Chapter 1 - Safety • 7

Chapter 1 - Safety Precautions

Accordingto the EEC standards theARTDRiveG and accessories must beused only after checking

that the machine has been produced using those safety devices required by the 89/392/EEC set

ofrules, as faras the machine industryis concerned. These standardsdo not applyin the Americas,

but may need to be considered in equipment being shipped to Europe.

Drive systems cause mechanical motion. It is the responsibility of the user to insure that any

such motion does not result in an unsafe condition. Factory provided interlocks and operating

limits should not be bypassed or modified.

Selon les normes EEC, les drives ARTDRiveG et leurs accessoires doivent être employés seulement

après avoir verifié que la machine ait été produit avec les même dispositifs de sécurité demandés par la

réglementation 89/392/EEC concernant le secteur de l’industrie.

Les systèmes provoquent des mouvements mécaniques. L’utilisateur est responsable de la sécurité

concernantlesmouvements mécaniques. Les dispositifs desécuritéprévues par l’usine et les limitations

operationelles ne doivent être dépassés ou modifiés.

Electrical Shock and Burn Hazard:

When using instruments such as oscilloscopes to work on live equipment, the oscilloscope’s

chassis should be grounded and a differential amplifier input should be used. Care should be

used in the selection of probes and leads and in the adjustment of the oscilloscope so that

accurate readings may be made. See instrument manufacturer’s instruction book for proper

operation and adjustments to the instrument.

Décharge Èlectrique et Risque de Brúlure :

Lors de l’utilisation d’instruments (par example oscilloscope) sur des systémes en marche, le chassis de

l’oscilloscope doit être relié à la terre et un amplificateur différentiel devrait être utilisé en entrée.

Lessondes et conducteurs doivent être choissis avec soinpour effectuer les meilleures mesures à l’aide

d’un oscilloscope. Voir le manuel d’instruction pour une utilisation correcte des instruments.

Fire and Explosion Hazard:

Fires or explosions might result from mounting Drives in hazardous areas such as locations where

flammable or combustible vapors or dusts are present. Drives should be installed away from

hazardous areas, even if used with motors suitable for use in these locations.

Risque d’incendies et d’explosions:

L’utilisation des drives dans des zônes à risques (présence de vapeurs ou de poussières inflammables),

peut provoquer des incendies ou des explosions. Les drives doivent être installés loin des zônes

dangeureuses, et équipés de moteurs appropriés.

Strain Hazard:

Improper lifting practices can cause serious or fatal injury. Lift only with adequate equipment and

trained personnel.

Attention à l’Élévation:

Une élévation inappropriée peut causer des dommages sérieux ou fatals. Il doit être élevé seulement

avec des moyens appropriés et par du personnel qualifié.

Drives and motors must be ground connected according to the NEC.

Tous les moteurs et les drives doivent être misà la terreselon le CodeElectrique National ouéquivalent.

Replace all covers before applying power to the Drive. Failure to do so may result in death or

serious injury.

Remettre tous les capots avant de mettre sous tension le drive. Des erreurs peuvent provoquer de

sérieux accidents ou même la mort.

Adjustable frequency drives are electrical apparatus for use in industrial installations. Parts of the

Drivesareenergized duringoperation. Theelectrical installationandthe openingof thedevice should

therefore only be carried out by qualified personnel. Improper installation of motors or Drives may

therefore cause the failure of the device as well as serious injury to persons or material damage.

Driveisnotequippedwithmotoroverspeedprotectionlogicotherthanthatcontrolledbysoftware.Follow

the instructions given in this manual and observe the local and national safety regulations applicable.

Les drives à fréquence variable sont des dispositifs électriques utilisés dans des installations industriels.

Une partie des drives sont sous tension pendant l’operation. L’installation électrique et l’ouverture des

drives devrait être executé uniquement par du personel qualifié. De mauvaises installations de moteurs

Warning!

8 • Chapter 1 - Safety ARTDriveG Instruction manual

ou de drives peuvent provoquer des dommages materiels ou blesser des personnes.On doit suivir les

instructions donneés dans ce manuel et observer les régles nationales de sécurité.

Always connect the Drive to the protective ground (PE) via the marked connection terminals

(PE2) and the housing (PE1). AGy Drives and AC Input filters have ground discharge currents

greater than 3.5 mA. EN 50178 specifies that with discharge currents greater than 3.5 mA the

protective conductor ground connection (PE1) must be fixed type and doubled for redundancy.

Il faut toujours connecter le variateur à la terre (PE) par les des bornes (PE2) et le châssis (PE1). Le

courant de dispersion vers la terre est supérieur à 3,5 mA sur les variateurs Brushless et sur les filtres à

courant alterné (CA). Les normes EN 50178 spécifient qu'en cas de courant de dispersion vers la terre,

supérieur à 3,5 ma, la mise à la terre (PE1) doit avoir une double connexion pour la redondance.

The drive may cause accidental motion in the event of a failure, even if it is disabled, unless it has

been disconnected from the AC input feeder.

En cas de panne, le variateur peut causer une mise en marche accidentelle, même s'il est désactivé,

sauf s'il a été débranché de l'alimentateur à courant alterné.

Never open the device or covers while the AC Input power supply is switched on. Minimum time

to wait before working on the terminals or inside the device is listed in section 5.9 on Instruction

manual .

Nejamais ouvrir l’appareillorsqu’ilestsuns tension. Letempsminimumd’attente avant depouvoirtravailler

sur les bornes ou bien à l’intérieur de l’appareil est indiqué dans la section 5.9.

If the front plate has to be removed because of ambient temperature higher than 40 degrees, the

user has to ensure that no occasional contact with live parts may occur.

Si la plaque frontale doit être enlevée pour un fonctionnement avec la température de l’environnement

plushauteque40°C,l’utilisateurdoits’assurer, par des moyens opportuns, qu’aucun contactoccasionnel

ne puisse arriver avec les parties sous tension.

Do not connect power supply voltage that exceeds the standard specification voltage fluctuation

permissible. If excessive voltage is applied to the Drive, damage to the internal components will

result.

Ne pas raccorder de tension d’alimentation dépassant la fluctuation de tension permise par les normes.

Dansle casd’une alimentationentensionexcessive, descomposantsinternes peuventêtreendommagés.

Do not operate the Drive without the ground wire connected. The motor chassis should be grounded to

earth through a ground lead separate from all other equipment ground leads to prevent noise coupling.

Nepasfairefonctionnerledrivesansprisedeterre.Lechassisdumoteurdoit êtremisàlaterreàl’aided’un

connecteur de terre separé des autres pour éviter le couplage des perturbations. Le connecteur de terre

devrait être dimensionné selon la norme NEC ou le Canadian Electrical code.

The grounding connector shall be sized in accordance with the NEC or Canadian Electrical Code.

The connection shall be made by a UL listed or CSA certified closed-loop terminal connector

sized for the wire gauge involved. The connector is to be fixed using the crimp tool specified by

the connector manufacturer.

Le raccordement devrait être fait par un connecteur certifié et mentionné à boucle fermé par les

normes CSA et UL et dimensionné pour l’épaisseur du cable correspondant. Le connecteur doit être

fixé a l’aide d’un instrument de serrage specifié par le producteur du connecteur.

Do not perform a megger test between the Drive terminals or on the control circuit terminals.

Ne pas exécuter un test megger entre les bornes du drive ou entre les bornes du circuit de contrôle.

Because the ambient temperature greatly affects Drive life and reliability, do not install the

Drive in any location that exceeds the allowable temperature. Leave the ventilation cover

attached for temperatures of 104° F (40° C) or below.

Étant donné que la température ambiante influe sur la vie et la fiabilité du drive, on ne devrait pas

installer le drive dans des places ou la temperature permise est dépassée. Laisser le capot de

ventilation en place pour températures de 104°F (40°C) ou inférieures.

Warning!

Caution

ARTDriveG Instruction manual Chapter 1 - Safety • 9

If the Drive’s Fault Alarm is activated, consult the TROUBLESHOOTING section of this instruction

book, and after correcting the problem, resume operation. Do not reset the alarm automatically

by external sequence, etc.

Si la Fault Alarm du drive est activée, consulter la section du manuel concernant les défauts et après avoir

corrigél’erreur,reprendrel’opération.Nepasréiniliatiserl’alarmeautomatiquementparuneséquenceexterne,

etc.

Be sure to remove the desicant dryer packet(s) when unpacking the Drive. (If not removed these

packets may become lodged in the fan or air passages and cause the Drive to overheat).

Lorsdu déballage dudrive, retirer le sachet déshydraté. (Si celui-ci n’est pas retiré, il empêche laventilation

et provoque une surchauffe du drive).

The Drive must be mounted on a wall that is constructed of heat resistant material. While the

Drive is operating, the temperature of the Drive's cooling fins can rise to a temperature of 194° F

(90°C).

Le drive doit être monté sur un mur construit avec des matériaux résistants à la chaleur. Pendant le

fonctionnementdu drive, la température desailettes du dissipateur thermiquepeut arriver à 194°F(90°).

Do not touch or damage any components when handling the device. The changing of the isolation

gaps or the removing of the isolation and covers is not permissible.

Manipulerl’appareilde façon à ne pas toucher ou endommager des parties. Iln’estpaspermisdechanger

les distances d’isolement ou bien d’enlever des matériaux isolants ou des capots.

Protectthe device fromimpermissible environmentalconditions(temperature, humidity,shock etc.)

Protéger l’appareil contre des effets extérieurs non permis (température, humidité, chocs etc.).

No voltage should be connected to the output of the drive (terminals U2, V2 W2). The parallel connection

of several drives via the outputs and the direct connection of the inputs and outputs (bypass) are not

permissible.

Aucune tension ne doit être appliquée sur la sortie du convertisseur (bornes U2, V2 et W2). Il n’est pas

permisderaccorderlasortiede plusieurs convertisseurs en parallèle, ni d’effectuer une connexion directe

de l’entrée avec la sortie du convertisseur (Bypass).

A capacitative load (e.g. Var compensation capacitors) should not be connected to the output of

the drive (terminals U2, V2, W2).

Aucunecharge capacitive ne doit être connectée àlasortieduconvertisseur(bornesU2, V2 et W2) (par exemple

des condensateurs de mise en phase).

The electrical commissioning should only be carried out by qualified personnel, who are also

responsible for the provision of a suitable ground connection and a protected power supply

feeder in accordance with the local and national regulations. The motor must be protected against

overloads.

La mise en service électrique doit être effectuée par un personnel qualifié. Ce dernier est responsable de

l’existence d’une connexion de terre adéquate et d’une protection des câbles d’alimentation selon les

prescriptions locales et nationales. Le moteur doit être protégé contre la surcharge

No dielectric tests should be carried out on parts of the drive. A suitable measuring instrument

(internal resistance of at least 10 kΩΩ

ΩΩ

Ω//

//

/V) should be used for measuring the signal voltages.

Il ne faut pas éxécuter de tests de rigidité diélectrique sur des parties du convertisseurs. Pour mesurer les

tensions,des signaux, ilfaut utiliser desinstruments de mesure appropriés (résistance interne minimale 10

k

Ω

/V).

Caution

NOTE!Ifthe Drives havebeen stored for longer than twoyears, the operation of theDClink capacitors may be impaired

and must be “reformed”.

Before commissioning devices that have been stored for long periods, connect them to a power supply for two

hours with no load connected in order to regenerate the capacitors, (the input voltage has to be applied without

enabling the drive).

Encasde stockage des variateurs pendant plus de deux ans,ilestconseillédecontrôlerl'étatdescondensateurs

CC avant d'en effectuer le branchement. Avant la mise en service des appareils, ayant été stockés pendant

longtemps,ilfautalimentervariateurs à vide pendant deux heures, pour régénérerlescondensateurs:appliquer

une tension d'alimentation sans actionner le variateur .

NOTE!The terms “Inverter”, “Controller” and “Drive” are sometimes used interchangably throughout the industry. We

will use the term “Drive” in this document.

Les mots “Inverter”, “Controller” et “Drive” sont interchangeables dans le domaine industriel. Nous utiliserons

dans ce manuel seulement le mot “Drive”.

10 • Chapter 1 - Safety ARTDriveG Instruction manual

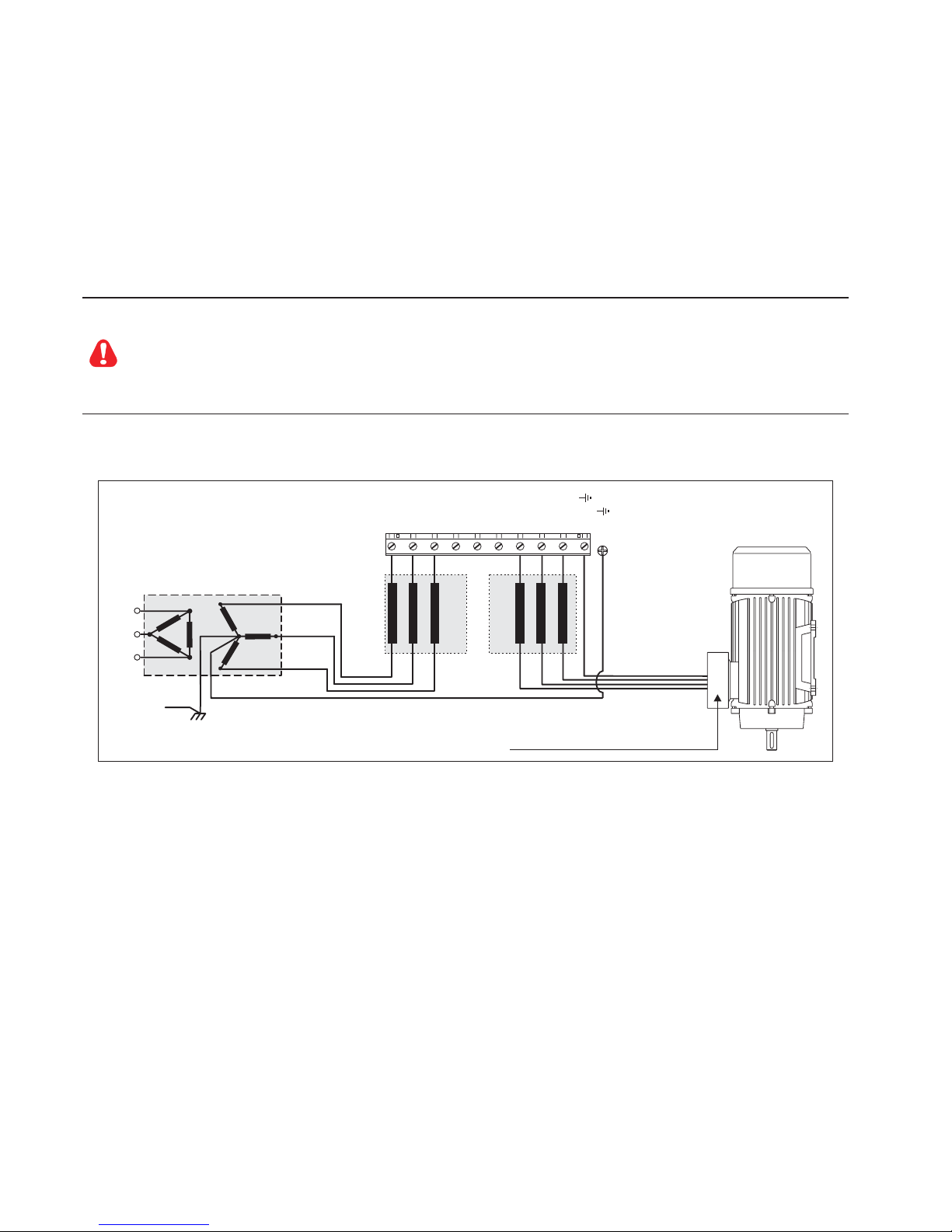

1.1 Power Supply and Grounding

1) SIEI drives are designedto be powered from standardthree phase lines thatare electrically symmetrical with

respecttoground(TNorTTnetwork).

Lesvariateurs SIEI sont prévuspour être alimentés par unréseau triphasé équilibré avecun régime de neutre

standard(TNou TT).

2) In case of supply with IT network, the use of delta/wye transformer is mandatory, with a secondary three phase

wiringreferred to ground.

Si le régime de neutre est IT, nous vous recommendons d'utiliser un tranformateur triangle/étoile avec point milieu

ramenéàla terre.

In case of a three phase supply not symmetrical to ground, an insulation loss of one of the devices

connected to the same network can cause functional problem to the drive, if the use of a delta/wye

transformeris avoided.

Si le réseau n'est pas équilibré par rapport à la terre et qu'il n'y a pas de transformateur raingle/étoile,

une mauvaise isolation d'un appareil électrique connecté au même réseau que le variateur peut lui

causer des troubles de fonctionnement.

Please refer to the following connection sample.

Safety

ground

L1

L2

L3

Earth

U1/L1

V1/L2

W1/L3

U2/T1

V2/T2

W2/T3

PE2/

All wires (including motor ground) must

be connected inside the motor terminal box

AC OUTPUT

CHOKE

AC Main Supply

AC INPUT

CHOKE

PE1/

Warning!

ARTDriveG Instruction manual Chapter 2 - General • 11

Chapter 2 - General

ARTDriveG(AGy) isanAC DigitalInverters forthevariation of the speed ofthree-phasemotors.TheAGy canbesupplied

with a power range from 0.75Kw up to 132Kw (230V...480V) and from 2Hp up to 75Hp (575V).

Anintermediate voltage is generatedfromtherectifiedACvoltage. The Inverter bridgethenproduces,fromthisintermediate

voltage,power supplywithvariable voltageand frequency,by means of sinusoidal evaluated pulse-widthmodulation.This

power supply provides motors with excellent running characteristics, even in a lower range.

The power supply voltage of the various cards is obtained through a switching from the intermediate circuit voltage.

The inverter power part is based on IGBTcomponent (Insulated Gate Bipolar Transistor).The output is protected against

short-circuits and earth faults. It is possible to switch motors on and off during the Inverter operation (see chapter 5.2.3)

If AC motors that are not specially manufactured to operate with an inverter are used, a reduction of 5...10% in supplied

current must be taken into account. In case that the rated torque is requested even in the low frequency range, further

reductions of the heat will be obtained by an external fan. If no assisted ventilation is available, oversizing of the power of

the motor will be necessary. In both cases we suggest to consult the motor manufacturer.

For mechanical reasons (bearings, unbalanced mass, etc.) the motor manufacturer should be consulted when the motor

is operated above the rated frequency.

AGy Inverters can be controlled in different ways:

- via terminal strip on the drive

- via an operator keypad

- via a standard PC program through RS 485 interface

ARTDriveG allows a smooth open-loop control and by using QUIX-ENC option closed-loop control. With closed-loop

control, an encoder (a pulse generator) provides speed feedback information.

Thepowersection and the control electronicsare galvanically isolated.

12 • Chapter 2 - General ARTDriveG Instruction manual

Features

- Supplyvoltagesgenerated by switching starting fromtheintermediate circuit voltage.

- Reduction of motor noise is achieved by the use of a special PWM control procedure.

- Theoutput of the Inverteris protected against shortcircuits and earth faults.

- Motorscan be switched onand off at theInverter output (see chapter5.2.4 of the manual).

- TheInverter isprotectedagainstovercurrents,undervoltages andovervoltages.

- Voltagedips(upto15msfor the power section) can bebridged;forthecontrolsection (see chapter 7.6 for theautomatic

restartprogrammation).

- Sinusoidaloutputcurrentgeneratedbymeansof sinusoidally evaluated pulse-width modulation

- Excellentmotorrunning characteristics, even in the lowerfrequencyrange.

- Programmableslip compensation reduces load-initiated changesinspeed to a minimum.

- Voltagecanbe boosted in the lowerfrequency range, either manuallyor automatically (boost).

- Automaticvoltageandfrequencyadjustmentunderanoverloadensuresthe Inverter cannot stall.

- Parameters can be set either via a keypad or via an RS 485 interface.

- Reference value in the form of an analog signal 0...10 V, -10...10V, 0...20 mA, 4...20 mAas a frequency or via a serial

interface.

- Ramp function generator with linear or S-shaped ramp.

- Direct current braking by commands:

a - thru digital input;

b - automatic injection below a set frequency;

c - Before starting the motor; used with pump and fan drives which are driven by the medium or by the air and are

already turning before the drive is started. D.C. braking prevents the Inverter being switched on when already

turning.

- A range of voltage-frequency characteristics can be selected.

- Overload control.

- Thelast alarm 4 messages canbe stored.Alarm messages areretainedeven afterpower failure.

- Open-looporclosed-loopoperation,asdesired.

- Indication via a potential-free contact and via the interface when a preselected speed is exceeded. Example of an

application: indication of stationary drive.

- Control via an RS 485 serial interface.

- Internal brake unit.

Accessories/Options

- Driveversion (“-C”) withCANopen/DeviceNet integrated.

- External EMC input filters.

- External Input / Output chokes.

- Externalbrakingresistors (connected between terminals Cand BR1).

- Encoderexpansion card: QUIX-ENC (codeS6F36)

- Remote keypad kit (code S5WW5).

-E

2PROM key: PRG-KEY (code S6F38).

- I/Oexpansioncard:EXP-D6A1R1-AGy (code S524L).

- 120Vacdigital input interface card:EXP-D8-120 (code S520L).

- Profibusinterfacecard:SBI-PDP-AGy(codeS5H28).

ARTDriveG Instruction manual Chapter 3 Inspection Procedure, Component Identification and Standard Specification • 13

Chapter 3 - Inspection Procedure, Component Identification

and Standard Specification

3.1 Upon Delivery Inspection Procedures

3.1.1General

Ahigh degree of care is taken in packing theAGy Drives and preparing them for delivery. They should only be transported

with suitable transport equipment (see weight data). Observe the instructions printed on the packaging. This also applies

when the device is unpacked and installed in the control cabinet.

Upon delivery, check the following:

- the packaging for any external damage

- whether the delivery note matches your order.

Open the packaging with suitable tools. Check whether:

- any parts were damaged during transport

- the device type corresponds to your order

Intheeventofanydamageorofanincompleteorincorrectdeliverypleasenotifytheresponsiblesalesoffices immediately.

The devices should only be stored in dry rooms within the specified temperature ranges .

NOTE!A certain degree of moisture condensation is permissible if this arises from changes in temperature (see

section 3.4.1, “Permissible Environmental Conditions”).This does not, however, apply when the devices

are in operation. Always ensure that there is no moisture condensation in devices that are connected to

the power supply!

3.1.2 Inverter Type Designation

The technical specification of the AGy Drive is stated in the type code. Example:

AGy 2 040-KB X-X -X

AGy Drive series

Drive mechanical dimension

Drive kW rating or Hp (for 575V series)

K=keypad included

X=Software standard

B=Integrated braking unit; X= NOT Integrated braking unit

Mains Supply Type

[Blank]=NOT integrated CANopen/DeviceNet

The AGy Drive selected depends on the rated current of the motor. The rated output current at the appropriate service

conditions must be greater than or equal to the motor current required.

Thespeed of the three-phasemotor is determined bythe number of polepairs and the frequency(nameplate, data sheet)

of the motor concerned. Operation above the rated frequency and speed of the motor must take into account the

specificationsgivenbythe manufacturer losses (bearings, unbalance etc.).Thisalsoapplies to temperature specifications

for continuous operation under 20 Hz (poor motor ventilation, not applicable to motors with external ventilation).

14 • Chapter 3 IInspection Procedure, Component Identification and Standard Specification ARTDriveG Instruction manual

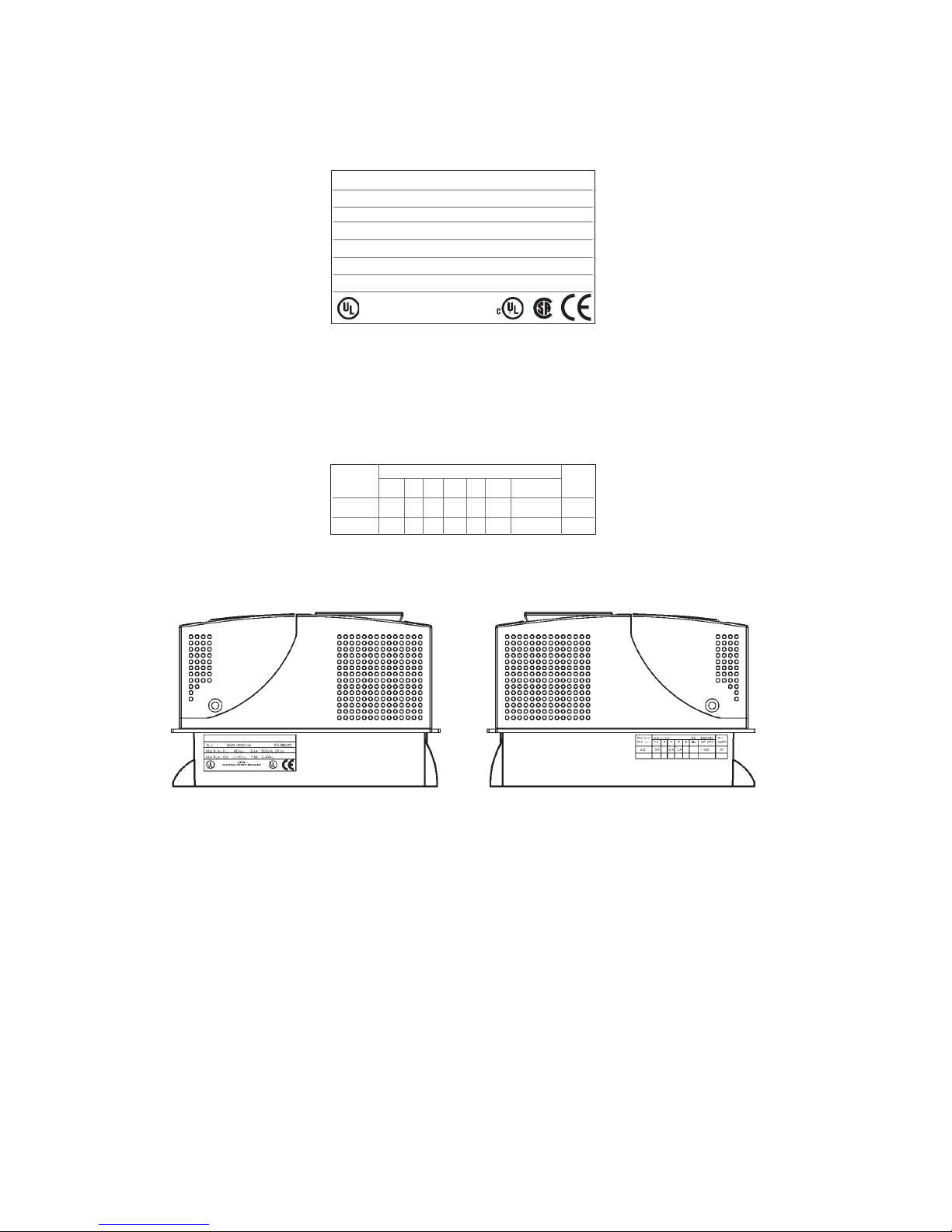

3.1.3Nameplate

Check that all the data stated in the nameplate enclosed to the inverter correspond to what has been ordered.

Figure3.1.3.1:Identification Nameplate (example for 575V series)

Type : AGy 2003 -KBX-5 Inverter Drive S/N 02135387

Inp: 575 Vac 50/60Hz 3Ph Zmin=1%

4.5A@575Vac With Line Choke

Out : 0-575Vac 400Hz 3Ph 3Hp @ 575Vac

4.1A@575V Ovld. 150% 60s

LISTED

INDUSTRIAL CONTROL EQUIPMENT

SIEI SPA

®

Type: Inverter model

S/N: Serial number

Main Power In: Power supply voltage - AC Input current - Frequency

Main Power Out: Output voltage - Output current - Output frequency

Figure3.1.3.2:Firmware&CardRevision Level Nameplate

Firmware HW release S/N 0162330 Prod.

R elease D F P R S BU SW . CFG CONF

C 2.03 A -.A -.- 1.000 A1

Figure 3.1.3.3: Nameplates Position

ARTDriveG Instruction manual Chapter 3 Inspection Procedure, Component Identification and Standard Specification • 15

3.2 Component Identification

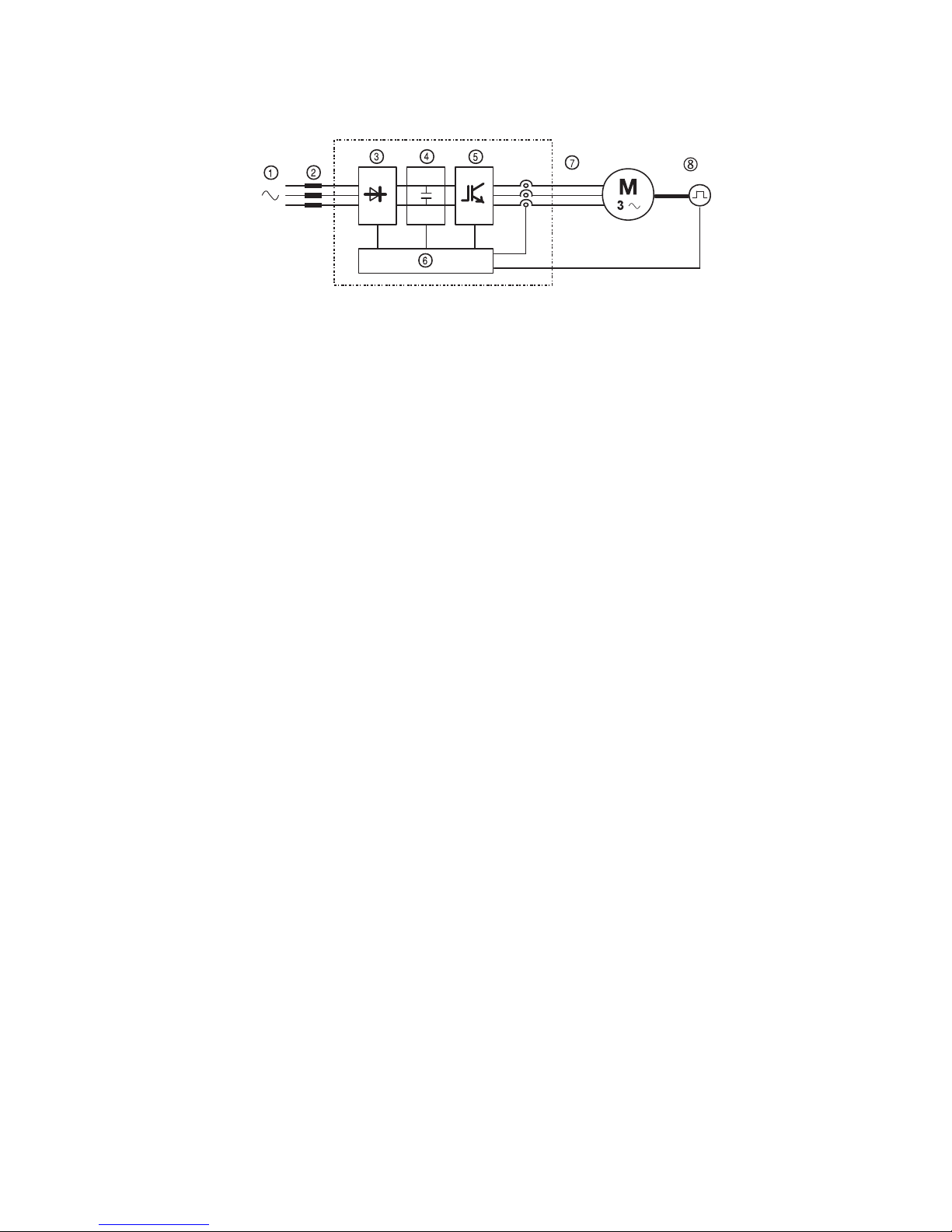

Figure 3.2.1: Basic Setup of Frequency Inverter

An AGy Drive converts the constant voltage and frequency of a three-phase power supply into a direct voltage and then

converts this direct voltage into a new three-phase power supply with a variable voltage and frequency. This variable

three-phase power supply can be used for the infinitely variable adjustment of the speed of three-phase asynchronous

motors.

1 AC Input supply voltage: 230V ... 480V for “AGy...-4 and 575V for “AGy...-5”.

2 AC Mains choke (see section 5.7.1).

3 Three-phase rectifier bridge

Converts the alternating current into direct current using a three phase full wave bridge.

4 DC intermediate circuit

With charging resistor and smoothing capacitor.

Direct voltage (UDC) = √2 x Mains voltage (ULN)

5 IGBT inverter

Converts direct voltage to a variable three-phase alternating voltage with variable frequency.

6 Configurable control section

Modules for open-loop and closed-loop control of the power section. This is used for processing control commands,

reference values and actual values.

7 Outputvoltage:

Three-phase, variable alternating voltage from 0 up to 94% of Mains voltage (ULN).

8 Encoder(option)

For speed feedback (see section 4.4.2).

16 • Chapter 3 IInspection Procedure, Component Identification and Standard Specification ARTDriveG Instruction manual

3.3 Standard Specifications

3.3.1PermissibleEnvironmentalConditions

Table 3.3.1.1: Environmental Specification

[°C] 0 … +40; +40…+50 with derating

[°F] 32 … +104; +104…+122 with derating

Installation location

Installation altitude

Temperature:

operation

1)

operation

2)

storage

transport

Air humidity:

operation

storage

transport

Air pressure:

operation [kPa] 86 to 106 (class 3K3 as per EN50178)

storage [kPa] 86 to 106 (class 1K4 as per EN50178)

transport [kPa] 70 to 106 (class 2K3 as per EN50178)

General standards

Safety

Climatic conditions

Clearance and creepage

Vibration

EMC compatibility

Rated input voltages

Approvals

TGy0020

-20…+60°C (-4…+140°F), for devices with keypad

IP20 according to EN 60529

IP54 for the cabinet with externally mounted heatsink; only for sizes from 1007 to 3150 (230V…480V) and

from 2002 to 3020 (575V)

EN 50178, UL508C, UL840. Overvoltage category for mains connected circuits: III; degree of pollution 2

EN 60068-2-6, test Fc.

-20…+55°C (-4…+131°F), for devices with keypad

CE, UL, cUL, CSA

ENVIRONMENT

STANDARD

Pollution degree 2 or better (free from direct sunligth, vibration, dust, corrosive or inflammable gases, fog,

vapour oil and dripped water, avoid saline environment)

Up to 1000m (3281 feet) above sea level; for higher altitudes a current reduction of 1.2% for every 100m (328

feet) of additional height applies .

A light condensation of moisture may occur for a short time occasionally if the device is not in operation (class 2K3 as per

EN50178)

EN61800-3 (see “EMC Guidelines” instruction book)

IEC 60038

-25…+70°C (-13…+158°F), class 2K3 per EN50178

T

A

Ambient temperature

0…40°C (32°…104°F)

0…50°C (32°…122°F)

-25…+55°C (-13…+131°F), class 1K4 per EN50178

Protection degree

95 %

3)

60 g/m

4)

EN 61800-1, IEC 143-1-1.

5 % to 85 %, 1 g/m

3

to 25 g/m

3

without moisture condensation or icing (Class 3K3 as per EN50178)

5% to 95 %, 1 g/m

3

to 29 g/m

3

(Class 1K3 as per EN50178)

EN 50178, UL 508C

EN 60721-3-3, class 3K3. EN 60068-2-2, test Bd.

1) Over40°C(104°F):

- current reduction of 2% of rated output current per K

-remove front plate (betterthan class 3K3 as perEN50178)

2) Currentderatedto0.8 rated ouput current

Over40°C(104°F): removalof the top cover (better thanclass3K3as per EN50178)

3) Greatestrelativeairhumidityoccurswiththetemperature@40°C (104°F) or if the temperature of the device is brought

suddenlyfrom-25...+30°C(-13°...+86°F).

4) Greatestabsoluteair humidity if the deviceis brought suddenly from 70...15°C(158°...59°F).

ARTDriveG Instruction manual Chapter 3 Inspection Procedure, Component Identification and Standard Specification • 17

Disposal of the Device

The AGy Drive can be disposed as electronic scraps in accordance with the currently valid national regulations for the

disposal of electronic parts.

The plastic covering of the Drives are recyclable: the material used is >ABS+PC< .

3.3.2 Mains Connection and Inverter Output

The AGy Drive must be connected to an AC mains supply capable of delivering a symmetrical short circuit current lower

or equal to the values indicated on table 3.3.2.1. For the use of an AC input choke see paragraph 5.7.1.

Note from the table of paragraph 3.3.2.1. the allowable mains voltages. The cycle direction of the phases is free.

Voltages lower than the min. tolerance values can cause the block of the inverter.

Itis possible toobtainthe automatical restart of theinverter, afteranother failure has occured (For further information, see

paragraph7.6,Autoreset Configurationsection).

NOTE!In some cases AC Input chokes, and possibly noise suppression filters should be fitted on the AC

Input side of the device. See chapter “Chokes/Filters”.

AdjustableFrequencyDrivesandAC Input filters have ground discharge currents greater than 3.5mA.EN50178specifies

that with discharge currents greater than 3.5 mA the protective conductor ground connection (PE1) must be fixed type.

18 • Chapter 3 IInspection Procedure, Component Identification and Standard Specification ARTDriveG Instruction manual

Table 3.3.2.1-A: AC Input/Output Specifications for 230V...480V Drive Kw/Hp Rating

1007 1015 1022 1030 2040 2055 2075 3110 3150 4220 4300 4370 5450 5550 6750 7900 71100 71320

Inverter Output (IEC 146 class1), Continuous service

(@ 400Vac)

[kVA] 1.6 2.7 3.8 5 6.5 8.5 12 16.8 22.4 32 42 55 64 79 98 128 145 173

Inverter Output (IEC 146 class2),150% overload for

60s (@ 400Vac)

[kVA] 1.4 2.4 3.4 4.5 5.9 7.7 10.9 15.3 20.3 29 38.2 50 58.3 72 89.2 116.5 132 157.5

PNmot (recommended motor output):

@U

LN=230Vac; fSW=default; IEC 146 class 1

[kW] 0.37 0.75 1.1 1.5 2.2 3 4 5.5 7.5 11 18.5 22 22 30 37 55 55 75

@U

LN=230Vac; fSW=default; IEC 146 class 2

[kW] 0.37 0.75 1.1 1.5 2.2 3 4 5.5 7.5 11 15 18.5 22 30 37 45 55 55

@U

LN=230Vac; fSW=default; IEC 146 class 1

[Hp] 0.50 1 1.5 2 3 4 5 7.5 10 15 25 30 30 40 50 75 75 100

@U

LN=230Vac; fSW=default; IEC 146 class 2

[Hp] 0.50 1 1.5 2 3 4 5 7.5 10 15 20 25 30 40 50 60 75 75

@U

LN=400Vac; fSW=default; IEC 146 class 1

[kW] 0.75 1.5 2.2 3 4 5.5 7.5 11 15 22 30 37 45 55 75 90 110 132

@U

LN=400Vac; fSW=default; IEC 146 class 2

[kW] 0.75 1.5 2.2 3 4 5.5 7.5 11 15 22 30 37 45 55 55 90 90 110

@U

LN=460Vac; fSW=default; IEC 146 class 1

[Hp] 123357.51015203040506075100125150150

@U

LN=460Vac; fSW=default; IEC 146 class 2

[Hp] 0.75 1.5 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150

U2Max output voltage

[V]

f2Max output frequency

[Hz]

I2N Rated output current :

@U

LN=230-400Vac; fSW= default; IEC 146 class 1

[A] 2.4 4 5.6 7.5 9.6 12.6 17.7 24.8 33 47 63 79 93 114 142 185 210 250

@U

LN=230-400Vac; fSW=default; IEC 146 class 2

[A] 2.2 3.6 5.1 6.8 8.7 11.5 16.1 22.5 30 43 58 72 85 104 129 169 191 227

@U

LN=460Vac; fSW=default; IEC 146 class 1

[A] 2.1 3.5 4.9 6.5 8.3 11 15.4 21.6 28.7 40 54 68 81 99 124 160 183 217

@U

LN=460Vac; fSW=default; IEC 146 class 2

[A] 1.9 3.2 4.4 5.9 7.6 10 14 19.6 26 36 50 62 74 90 112 146 166 198

fSW switching frequency (Default)

[kHz]

fSW switching frequency (Higher)

[kHz]

Derating factor:

Voltage Factor KVat 460 Vac **

0.87 0.87 0.87 0.86 0.86 0.87 0.87 0.87 0.78 0.76 0.79 0.78 0.79 0.79 0.78 0.78 0.78 0.78

Temp. Factor K Tfor ambient temperature

Switching frequency KF

ULN AC Input voltage

[V]

AC Input frequency

[Hz]

INAC Input current for continuous service :

- Connection with 3-phase reactor

@ 230Vac; IEC 146 class1

[A] 1.7 2.9 4 5.5 * 7 9.5 14 * 18.2 25 * 39 55 69 84 98 122 158 192 220

@ 400Vac; IEC 146 class1

[A] 1.9 3.3 4.5 6.2 * 7.9 10.7 15.8 * 20.4 28.2 * 44 62 77 94 110 137 177 216 247

@ 460Vac; IEC 146 class1

[A] 1.7 2.9 3.9 5.4 * 7 9.3 13.8 * 17.8 24.5 * 37 53 66 82 96 120 153 188 214

- Connection without 3-phase reactor

@ 230Vac; IEC 146 class1

[A] 3.6 4.4 6.8 7.9 * 11 15.5 21.5 * 27.9 35.4 *

@ 400Vac; IEC 146 class1

[A] 3.9 4.8 7.4 9 * 12 16.9 24.2 * 30.3 40 *

@ 460Vac; IEC 146 class1

[A] 3.4 4.2 6.4 7.8 * 10.4 14.7 21 * 26.4 34.8 *

Max short circuit power without line reactor (Zmin=1%) [kVA] 160 270 380 500 650 850 1200 1700 2250 3200 4200 5500 6400 7900 9800 12800 14500 17300

Overvoltage threshold

[V]

Undervoltage threshold

[V]

Braking IGBT Unit

Standard internal (with external resistor);

MAX Braking torque :

TGy0031

For these types an external inductance is recommended

0.8 @ 50°C (122°F)

300500

8

8

4

16

150% 70%

410VDC (for 230VAC mains), 800VDC (for 400VAC mains), 800VDC (for 460VAC mains)

230VDC (for 230VAC mains), 380VDC (for 400VAC mains), 415VDC (for 460VAC mains)

150% 120%

AGy Drive Type - Kw rating

OUTPUT

90% Option internal (with external

resistor); Braking torque 150% External braking unit (optional)

INPUT

0.94 x ULN (AC Input voltage)

0.7 for higher f

sw

50/60 Hz ±5%

230 V -15% … 480 V +10%, 3Ph

*: For the specified power sizes, the external reactor is strongly recommended

**: Linear shapes for KV, KT, respectively in the ranges [400, 460] Vac, [40, 50]°C, (104, 122)°F.

Example: for AC mains = 440VAC, 400V/440V = 0.90 = KV

ARTDriveG Instruction manual Chapter 3 Inspection Procedure, Component Identification and Standard Specification • 19

Table 3.3.2.1-B: AC Input/Output Specifications for 575VDrive Hp Rating

AGy Drive Type - Hp rating 2002 2003 2005 3007 3010 3015 3020 4025 4030 4040 5050 5060 5075 6100 7125 7150 8200

Inverter Output (IEC 146 class1), Continuous service

[kVA]

3.8 4.5 7.0 10.8 13.7 18.6 24.1 30 36 46 58 69 86 109 136 157 210

Inverter Output (IEC 146 class2), 150% overload for

60s

[kVA]

3.4 4.1 6.3 9.8 12.5 16.9 21.9 27 33 42 53 63 78 99 124 143 191

PNmot (recommended motor output):

@U

LN=575Vac; fSW=default; IEC 146 class 1

[Hp]

2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200

@U

LN=575Vac; fSW=default; IEC 146 class 2

[Hp]

2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200

U2Max output voltage

[V]

f2Max output frequency (*)

[Hz]

I2N Rated output current :

@U

LN=575Vac; fSW= default; IEC 146 class 1

[A]

3.8 4.5 7.0 10.8 13.8 18.7 24.2 30 36 46 58 69 86 109 137 158 211

@U

LN=575Vac; fSW=default; IEC 146 class 2

[A]

3.5 4.1 6.4 9.8 12.6 17.0 22.0 27 33 42 53 63 78 99 125 144 192

fSW switching frequency (Default)

[kHz]

fSW switching frequency (Higher)

[kHz]

2

Derating factor:

KTfor ambient temperature

KFfor switching frequency 0.87 0.64 0.87 t.b.d.

ULN AC Input voltage

[V]

AC Input frequency

[Hz]

INAC Input current for continuous service :

- Connection with 3-phase reactor

@ 575Vac; IEC 146 class1

[A]

3.8 4.7 7.4 11.7 15 19.8 25.9 31 35 46 60 68 85 114 146 163 220

- Connection without 3-phase reactor

@ 575Vac; IEC 146 class1

[A]

5.3 6.1 9.9 17 20.7 27.6 33.9

Max short circuit power without line reactor (Zmin=1%)

[kVA]

380 450 700 1080 1370 1860 2410 3000 3600 4600 5800 6900 8600 10900 13700 15700 21000

Overvoltage threshold

[V]

Undervoltage threshold

[V]

Braking IGBT Unit (standard drive)

TGy0030

DC choke integrated

0.94 x ULN (AC Input voltage)

8

200

16

8

1000 VDC

565 VDC (for 575 VAC mains)

External braking unit (optional)

Optional internal braking unit (with external

resistor); braking torque 150%

Standard internal (with external resistor); Braking torque

150%

INPUT

0.7 for higher f

SW

400

42

4

t.b.d.

0.8 for higher f

SW

OUTPUT

0.8 @ 50°C (122°F)

500 -10% / 575V ±10%, 3Ph

50/60 Hz ±5%

20 • Chapter 3 IInspection Procedure, Component Identification and Standard Specification ARTDriveG Instruction manual

3.3.3ACInput Current

NOTE!The Input current of the Drive depends on the operating state of the connected motor. The tables

3.3.2.1 shows the values corresponding to rated continuous service, keeping into account typical

output power factor for each size

3.3.4 AC Output

The output of the AGy Drive is ground fault and phase to phase output short protected.

NOTE!Theconnectionofan external voltagetotheoutput terminals oftheDriveisnot permissible!Itisallowed to

disconnect the motor from the Drive output, after the Drive has been disabled.

Therated value of directcurrent output ( ICONT ) dependson the supply voltage( KV), the ambient temperature( KT) and the

switching frequency (KF) if higher than the default setting:

ICONT = I2N x KVx KT(Values of derating factor are the listed on tables 3.3.2.1) with an overload capacity IMAX = 1.5 x ICONT

for 60 seconds.

Recommended motor outputs

The coordination of the motor rated powers with the Drive type presented in the table 3.3.2.1 refers to the use of standard

motors with a rated voltage equal to the rated voltage of the input supply.

As for those motors with different voltages, the type of Drive to use is determined by the rated current of the motor.

NOTE!Max allowed overload:

136% . I2N cl.1 ≡150% . I2N cl.2

Table 3.3.4.1 shows nominal current values for typical service profiles (Ambient temperature =40°C

[104°F],standardswitchingfrequency).

Similarcriteriaapply for operation with additional deratingfactors.

Table 3.3.4.1: Nominal Drive Current

I2N (1) I2N (2) I2N (3) I2N (4) I2N (5) I2N (6)

[A] [A] [A] [A] [A] [A]

1007 2.4 2.2 2.1 1.9 2002 3.8 3.4

1015 4 3.6 3.5 3.2 2003 4.5 4.1

1022 5.6 5.1 4.9 4.4 2005 7.0 6.3

1030 7.5 6.8 6.5 5.9 3007 10.8 9.8

2040 9.6 8.7 8.3 7.6 3010 13.7 12.5

2055 12.6 11.5 11 10 3015 18.6 16.9

2075 17.7 16.1 15.4 14 3020 24.1 21.9

3110 24.8 22.5 21.6 19.5 4025 30 27

3150 33 29.9 25.7 23 4030 36 33

4220 47 42.6 35.7 32.3 4040 46 42

4300 63 57.1 49.7 45 5050 58 53

4370 79 71.6 61.6 55.8 5060 69 63

5450 93 84.3 73 66.6 5075 86 78

5550 114 103.4 89 80.6 6100 109 99

6750 142 129 110.7 100 7125 136 124

7900 185 169 144 132 7150 157 143

71100 210 191 163.8 149 8200 210 191

71320 250 227 195 177

TGy0040

AGy…-4 (230V…480V)

Drive

Type

Drive

Type

AGy…-5 (575V)

(1): I2N Rated output current (@ ULN=230-400Vac),

Continuous service, no overload (IEC 146 class 1)

(2): I2N Rated output current (@ ULN=230-400Vac), Overload

service150%x60s followed by IN,min.cycletime360s(IEC

146 class 2).

(3): I2N x kV Rated output current (@ ULN=460-480Vac),

Continuous service, no overload (IEC 146 class 1)

(4): I2N x kV Rated output current (@ ULN=460-480Vac),

Overload service 150%x60s followed by IN, min.cycle time

360s (IEC 146 class 2).

(5) I2N Rated output current (@ ULN=575Vac), continuous

service, no overload (IEC 146 classe 1).

(6) I2N Rated output current (@ ULN=575Vac), overload

service 150%x60s followed by IN, min. cycle time 360s

(IEC 146 classe 2).

Table of contents

Other Siei Inverter manuals

Popular Inverter manuals by other brands

Olimpia splendid

Olimpia splendid DC 18 HP Instructions for installation, use and maintenance

Thermal Arc

Thermal Arc FABRICATOR 181i Service manual

Tsun

Tsun TITAN TSOL-MP3000 Quick installation guide

GE

GE HOME NERATOR 7000 WATT Installation and start-up manual

Advanced Energy

Advanced Energy AE 600 user manual

Victron energy

Victron energy RS Smart manual