Company Confidential s Com

Copyright 2005© Siemens AG

Page 2of 9

TI_Repair_L2.5l_A62_A65_A70_A75_R1.2.pdf Release 1.2

Introduction

This Service Repair Documentation is intended to carry out repairs on Siemens repair level

2.5. The described failures shall be repaired in Siemens authorized local workshops only.

All repairs have to be carried out in an ESD protected environment and with ESD protected

equipment/tools. For all activities the international ESD regulations have to be considered.

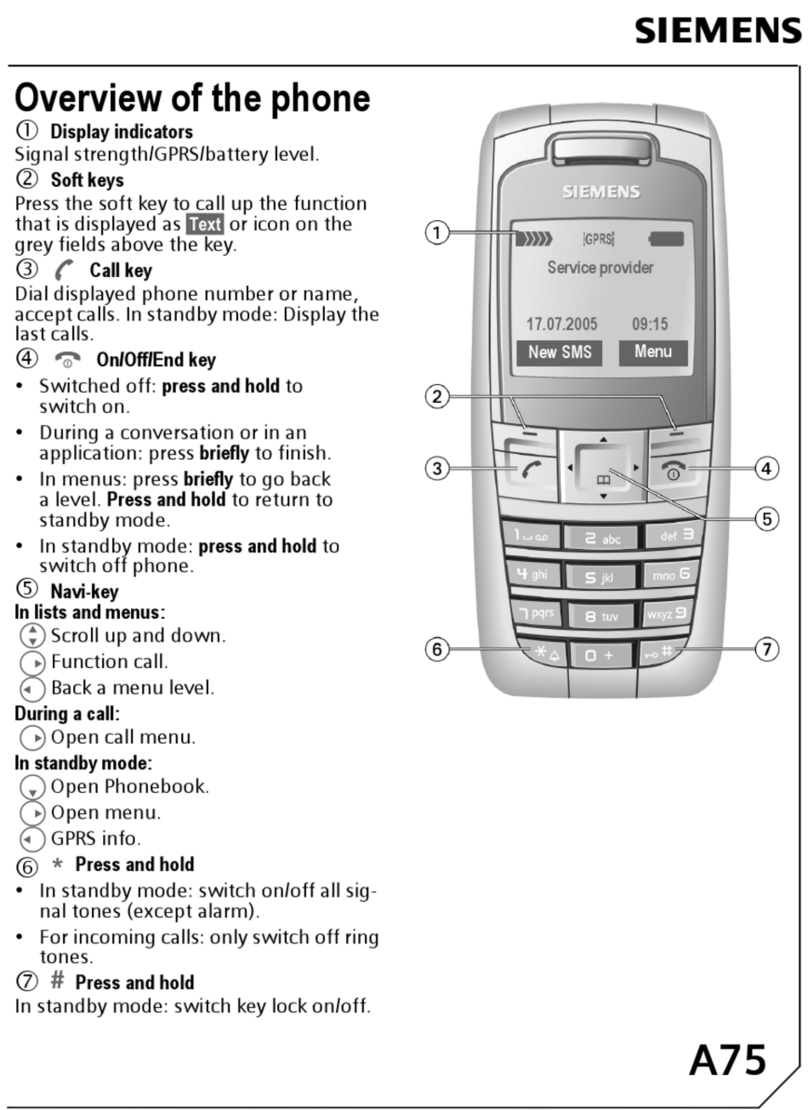

Assembling/disassembling has to be done according to the latest A62, A65, A70 & A75

Level 2 repair documentation. It has to be ensured that every repaired mobile Phone is

checked according to the latest released General Test Instruction document (both

documents are available in the Technical Support section of the C-market).

Check at least weekly C-market for updates and consider all A62, A65, A70 & A75 related

Customer Care Information, and Repair Information who are relevant for A62, A65, A70 &

A75.

A62 Partnumber on IMEI label: S30880-S5890-#xxx

A65 Partnumber on IMEI label: S30880-S5810-#xxx

A70 Partnumber on IMEI label: S30880-S2770-#xxx

A75 Partnumber on IMEI label: S30880-S2790-#xxx

, while # may be any letter (A-Z) and xxx may be any number from 100, 101, 102....

Scrap Handling: All Scrap information given in this manual are related to the

SCRAP-Rules and instructions.

Attention: Consider the new "LEAD-FREE" soldering rules (A70 and A75 affected)

(available in the communication market), avoid excessive heat.

If you have any questions regarding the repair procedures or technical questions spare not

hesitate to contact our technical support team in Kamp-Lintfort, Germany:

Tel.: +49 2842 95 4666

Fax: +49 2842 95 4302