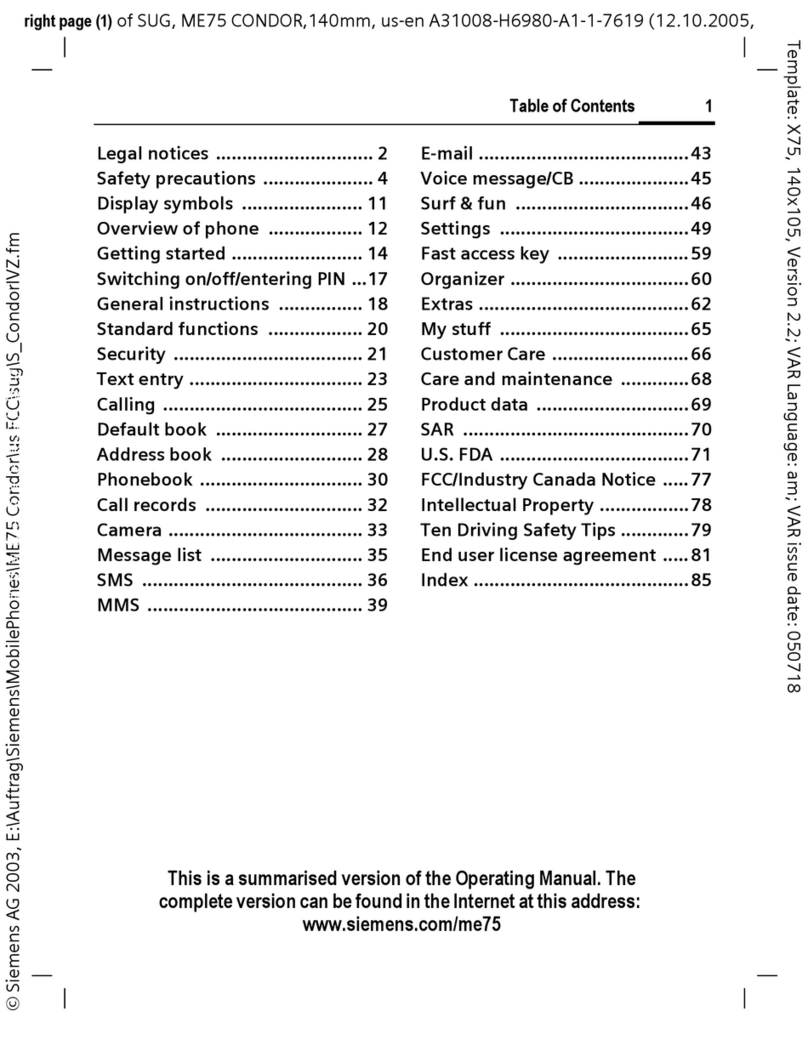

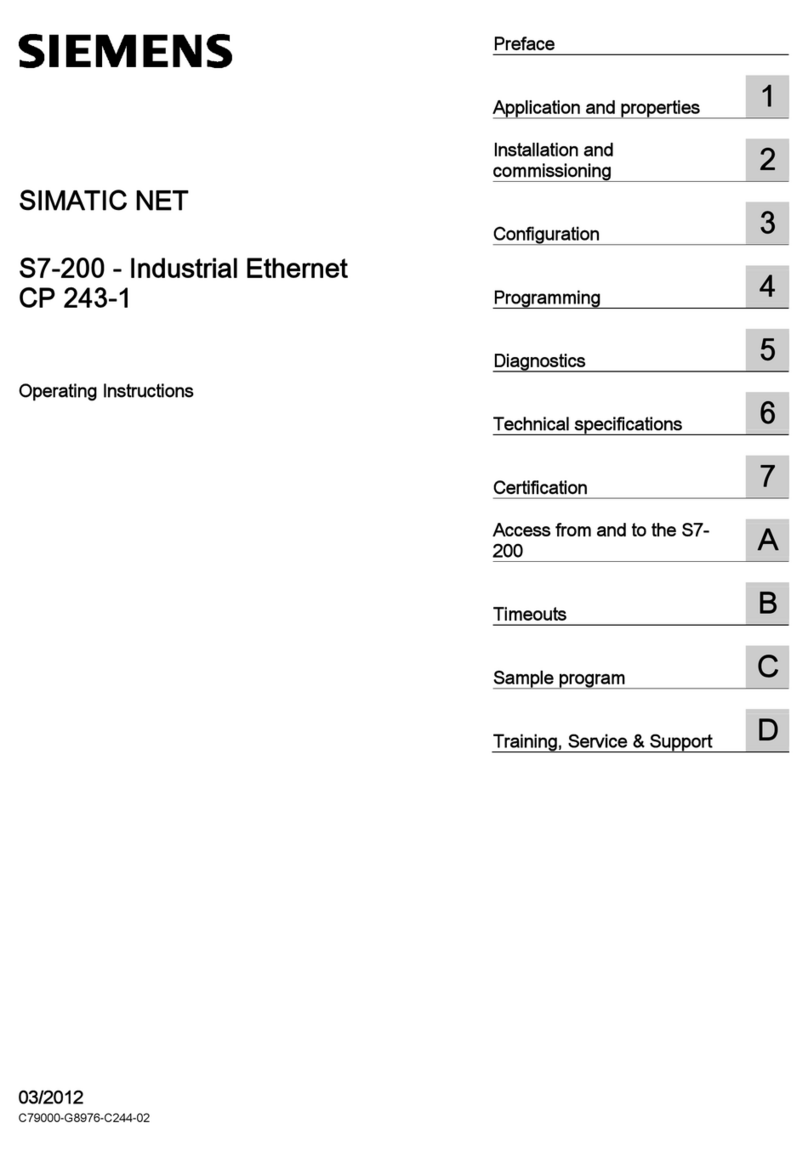

Table of contents

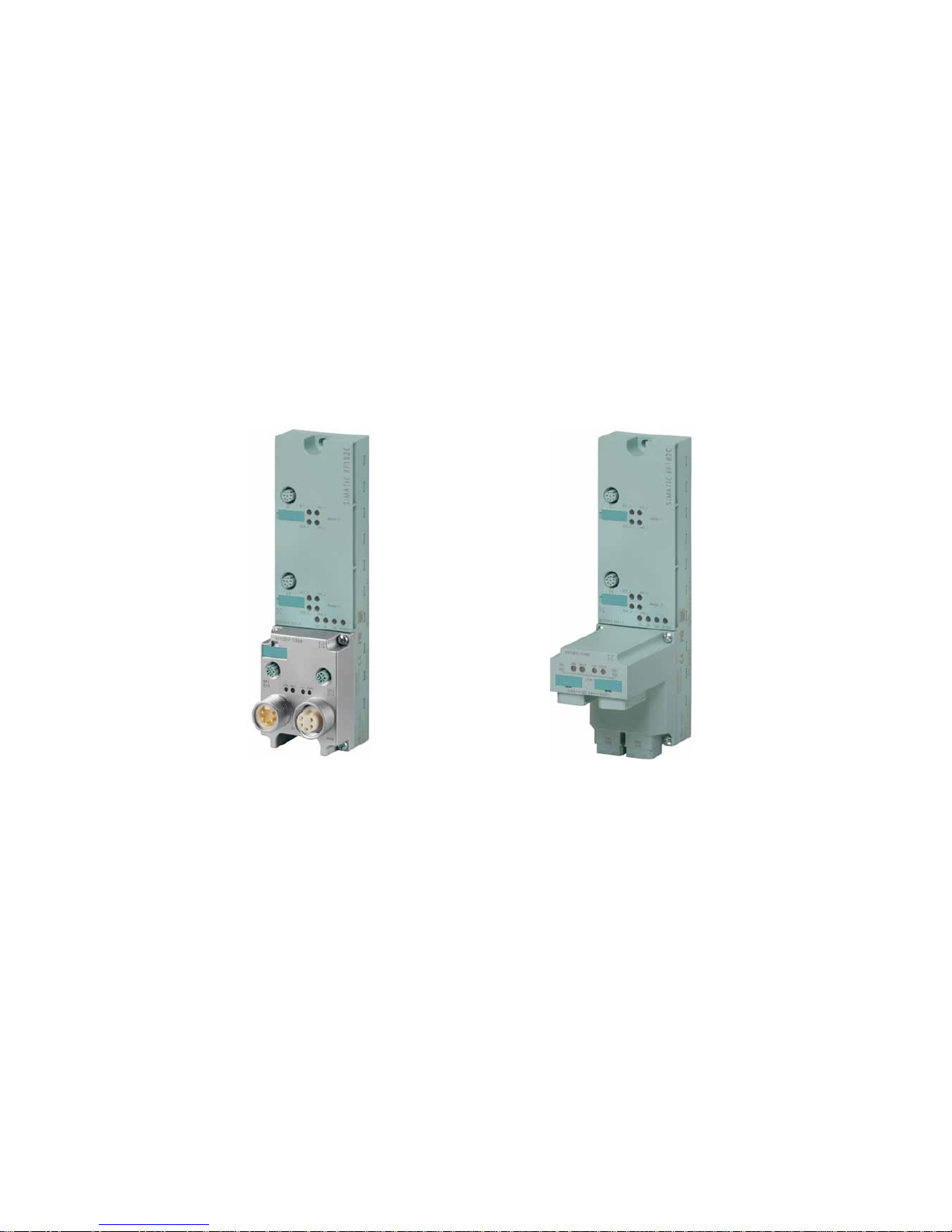

RF182C communication module

4 Operating Instructions, 10/2010

6.5 Asynchronous message frames.................................................................................................. 60

6.5.1 tagPresent................................................................................................................................... 60

6.5.2 alarm ........................................................................................................................................... 61

7 Maintenance and Service ........................................................................................................................ 63

7.1 Replacing the RF182C communication module.......................................................................... 63

7.2 Firmware update ......................................................................................................................... 65

7.3 Reader update ............................................................................................................................ 65

8 Diagnostics .............................................................................................................................................. 67

8.1 Diagnostics using LEDs .............................................................................................................. 67

9 Error messages ....................................................................................................................................... 71

9.1 Response without error entry...................................................................................................... 71

9.2 Response with error entry........................................................................................................... 71

9.3 Error messages of the RF182C .................................................................................................. 72

9.4 Diagnostics via Web server......................................................................................................... 78

9.4.1 Saving/reading of I&M data records............................................................................................ 78

9.4.2 Communication status query....................................................................................................... 79

9.4.3 Event and message frame overview........................................................................................... 80

10 Examples/applications ............................................................................................................................. 81

10.1 Basic principles of socket programming, exemplary in C ........................................................... 81

10.1.1 Socket programming requirements............................................................................................. 81

10.1.2 Basic client/server principle......................................................................................................... 82

10.1.3 Important basic commands......................................................................................................... 82

10.1.4 Partial programming example of a client in C/Windows operating system................................. 83

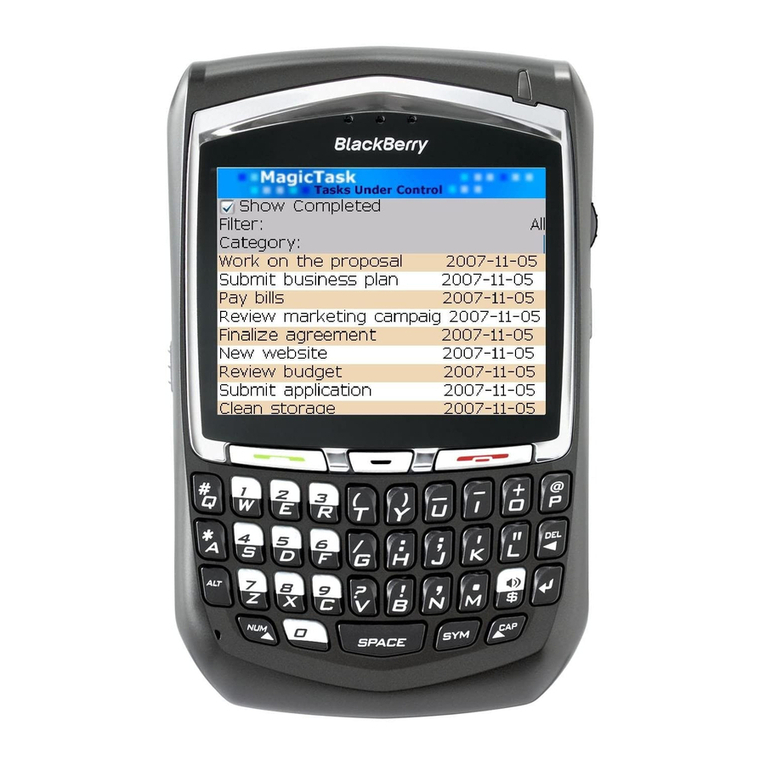

10.2 RF182C user application............................................................................................................. 85

10.2.1 User interface layout ................................................................................................................... 86

10.2.2 Extracts example code of the user application in C#.................................................................. 87

10.2.3 Functions of the RF182C applications ........................................................................................ 95

10.3 Example application for a PLC according to DIN IEC 61131...................................................... 99

11 Technical data ....................................................................................................................................... 101

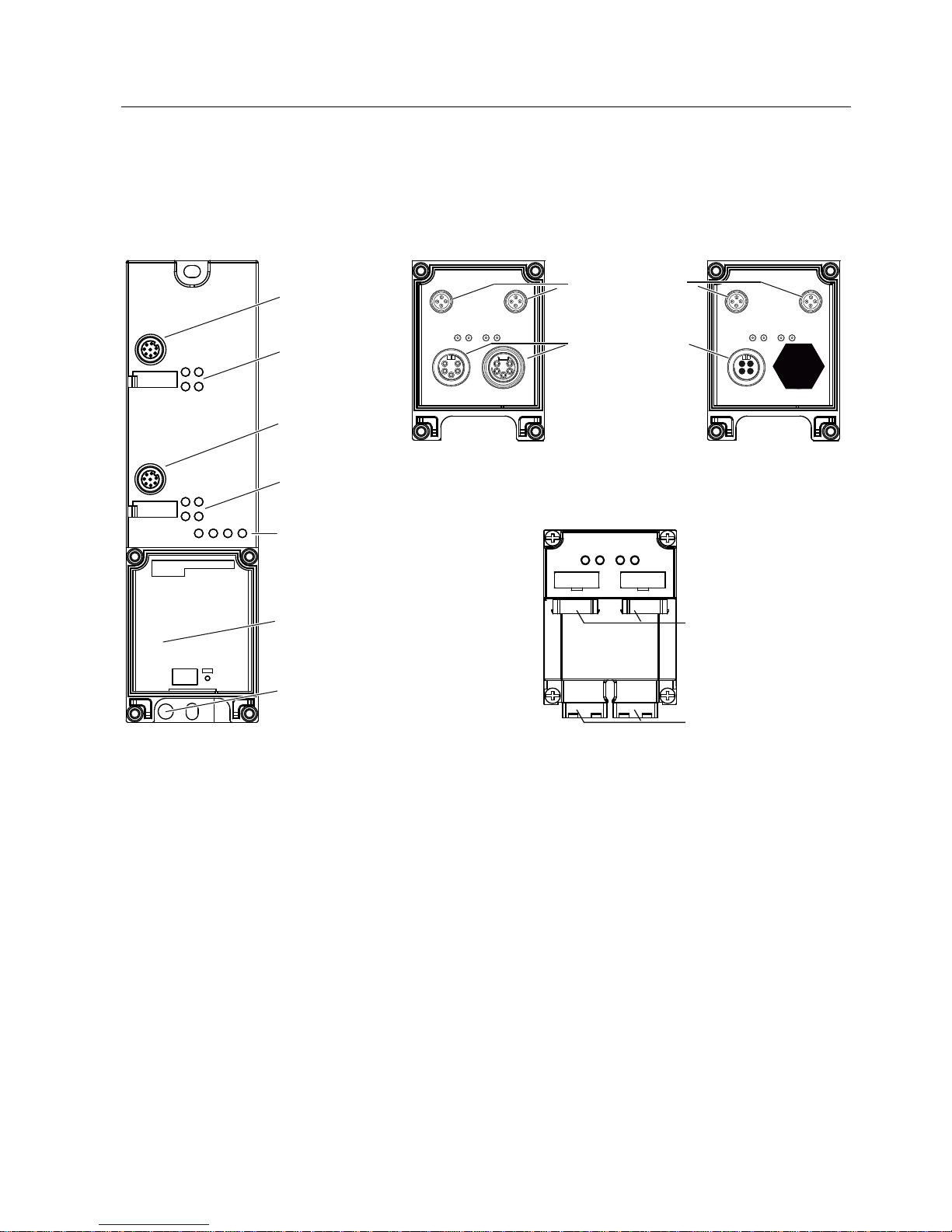

12 Dimension drawings .............................................................................................................................. 103

12.1 Dimension drawing for RF182C with fixing holes ..................................................................... 103

13 Connecting cable to the reader/SLG...................................................................................................... 105

13.1 Routing of standard cables ....................................................................................................... 105

13.2 Self-assembled cable................................................................................................................ 107

14 Ordering data......................................................................................................................................... 109

A Command and acknowledgement telegrams......................................................................................... 111

B Addressing of the RFID tags.................................................................................................................. 123

C Transfer scheme for hexadecimal tag data via XML .............................................................................. 125

D Service & support .................................................................................................................................. 127