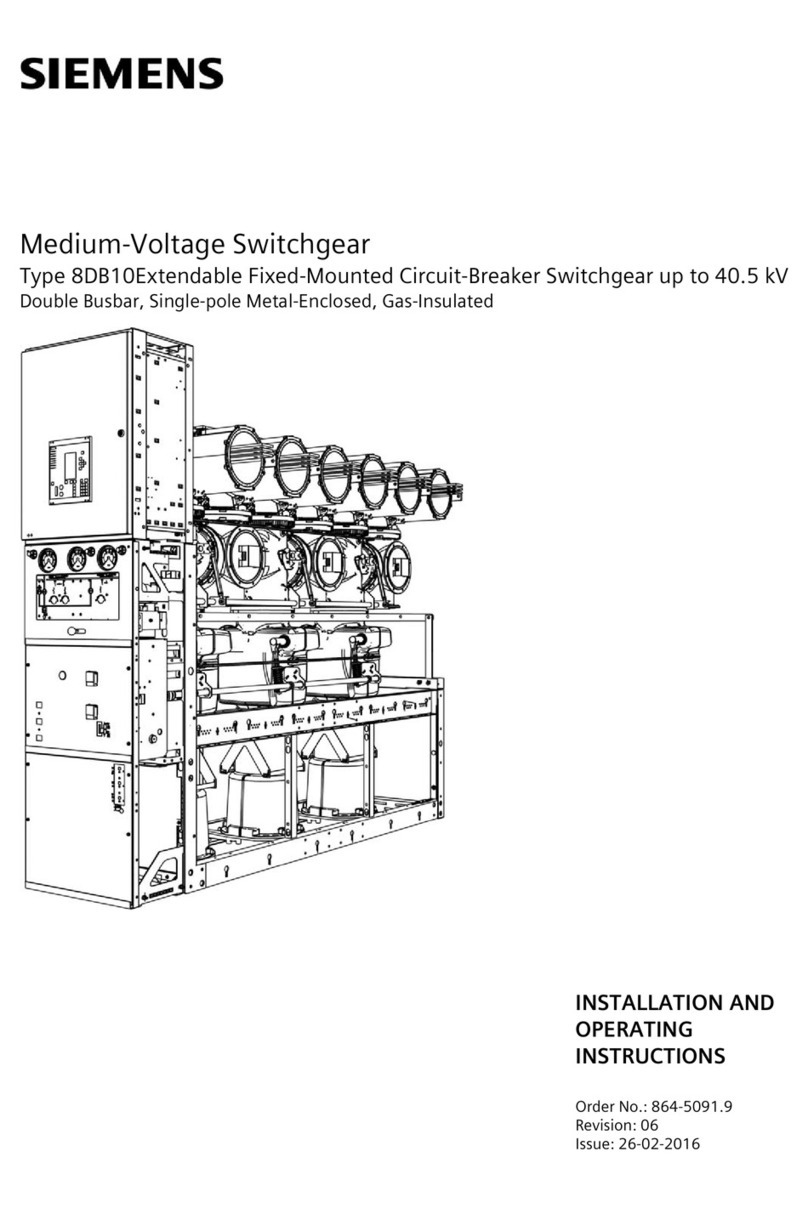

Siemens GMI Series User manual

Other Siemens Circuit Breaker manuals

Siemens

Siemens 5SV1 User manual

Siemens

Siemens MEMOSKOP 2 SUB Operating instructions

Siemens

Siemens 3VA967 0WA00 Series User manual

Siemens

Siemens 3VL31 KN Series User manual

Siemens

Siemens SIMATIC ET 200SP HA Technical Document

Siemens

Siemens Sentron WL User manual

Siemens

Siemens 3WL10 0 Series User manual

Siemens

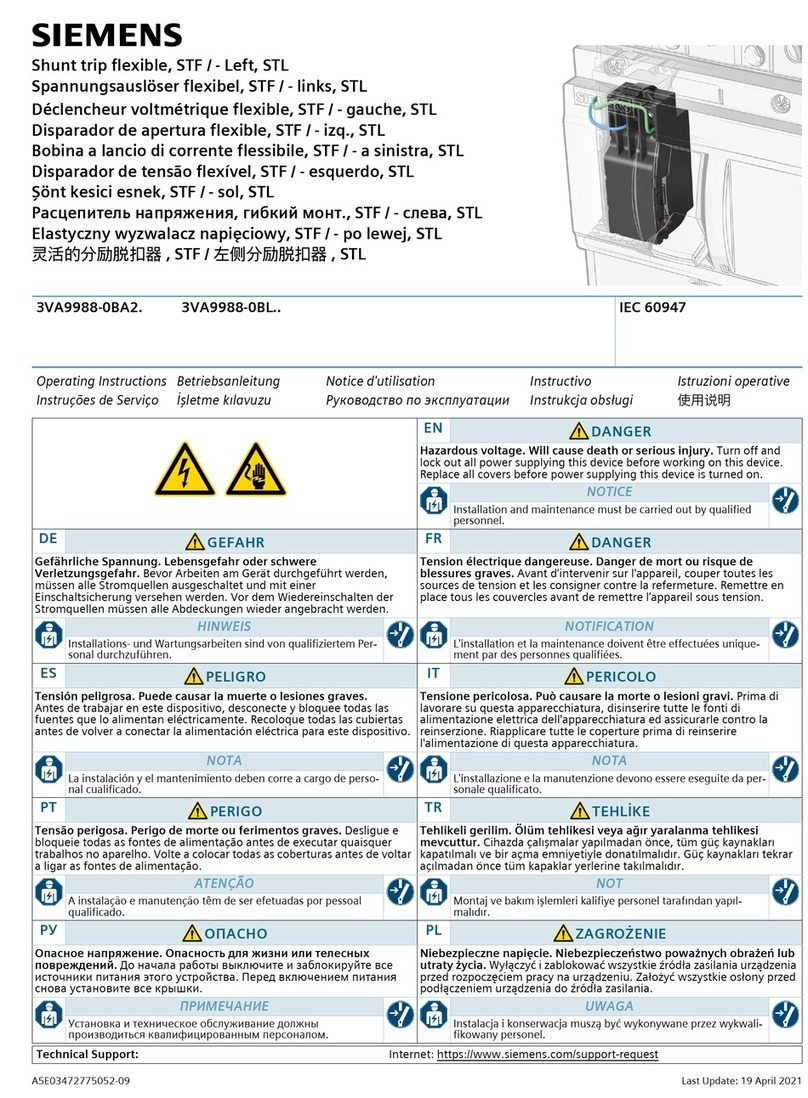

Siemens Sentron 3VA9988-0BA2 Series User manual

Siemens

Siemens SION 3AE5 User manual

Siemens

Siemens 3 Series User manual

Siemens

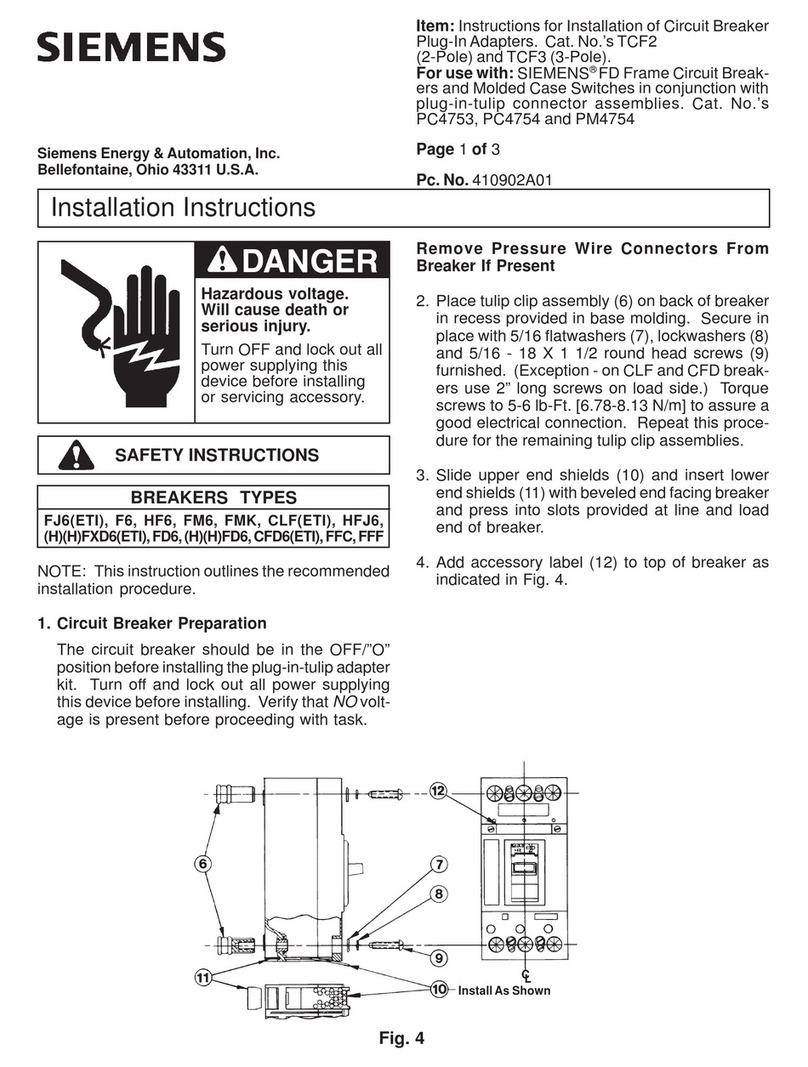

Siemens TCF2 User manual

Siemens

Siemens 555 User manual

Siemens

Siemens PCBMRC3 User manual

Siemens

Siemens SIRIUS 3RV1 3 Series User manual

Siemens

Siemens 8DA10 User manual

Siemens

Siemens 3WX3653-1J 00 Series User manual

Siemens

Siemens 3VA52-EC.1 Series User manual

Siemens

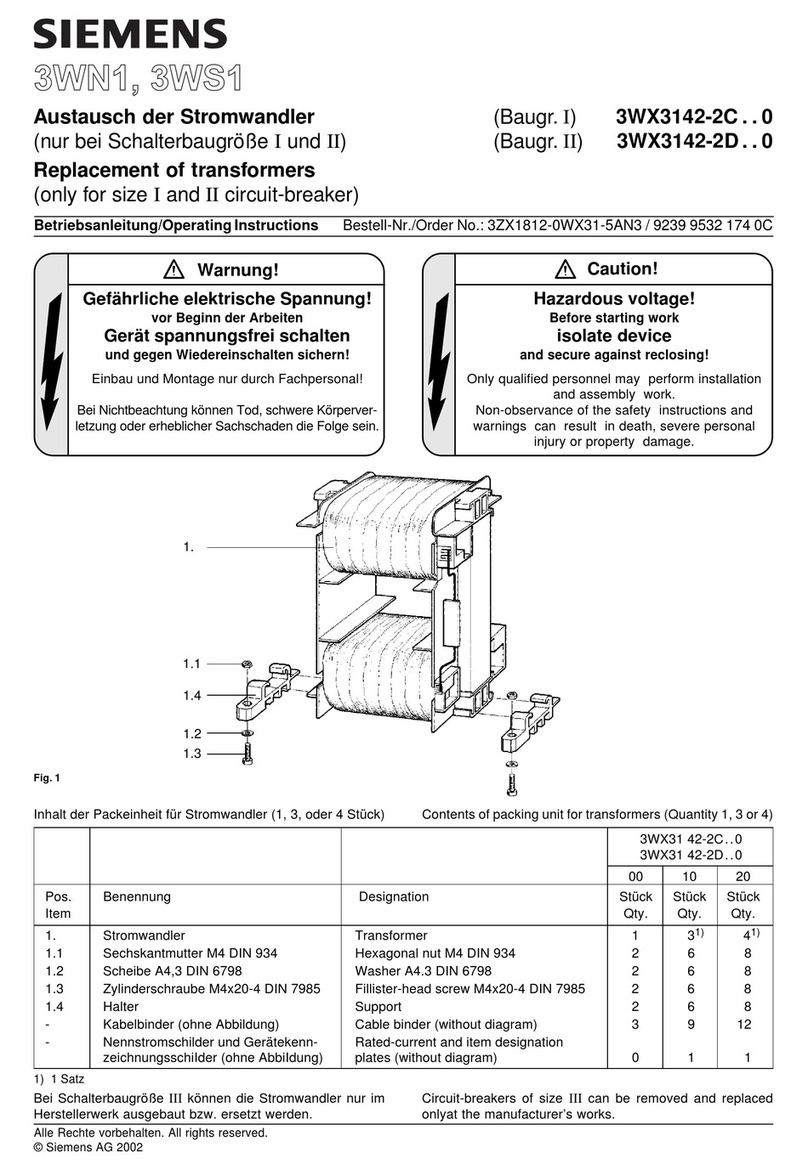

Siemens 3WN1 User manual

Siemens

Siemens 3WX3641-0JB00 User manual

Siemens

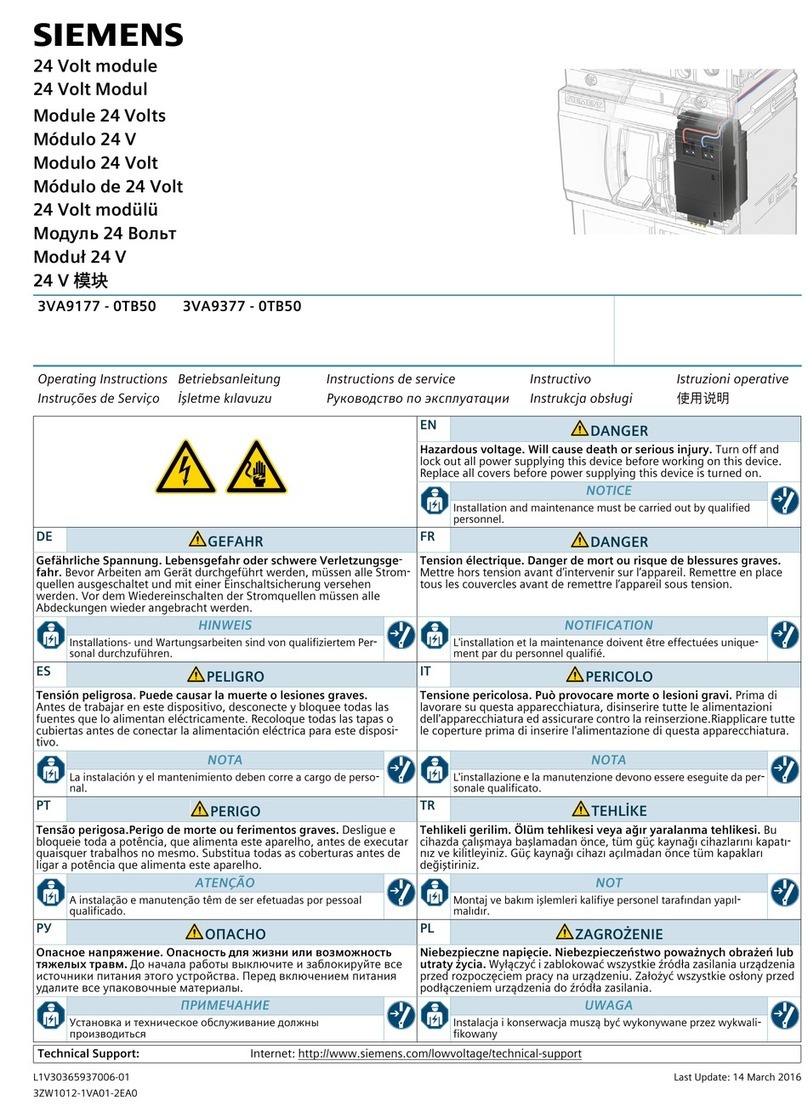

Siemens 3VA9177-0TB50 User manual