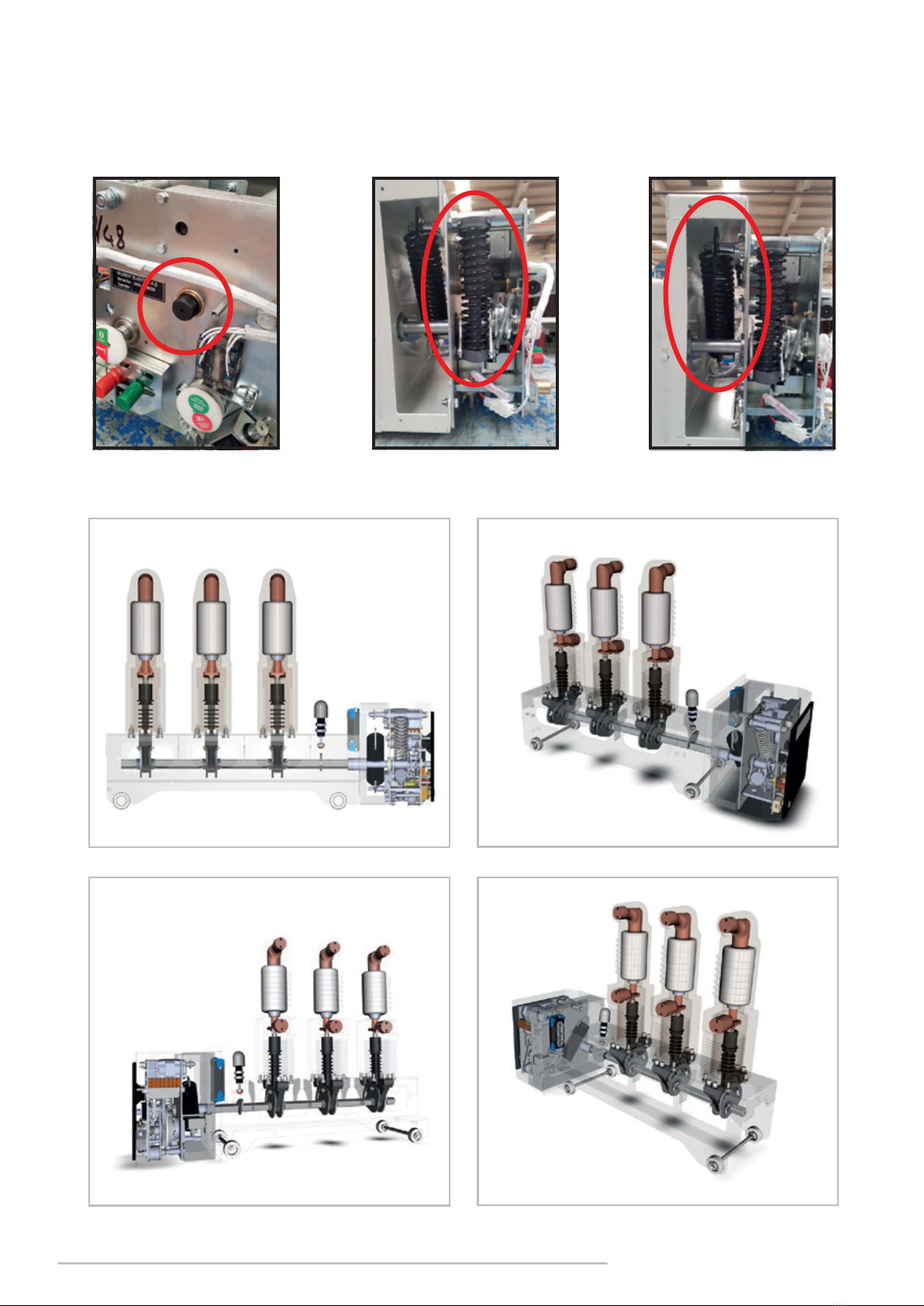

Eaton RVU Series User manual

Other Eaton Circuit Breaker manuals

Eaton

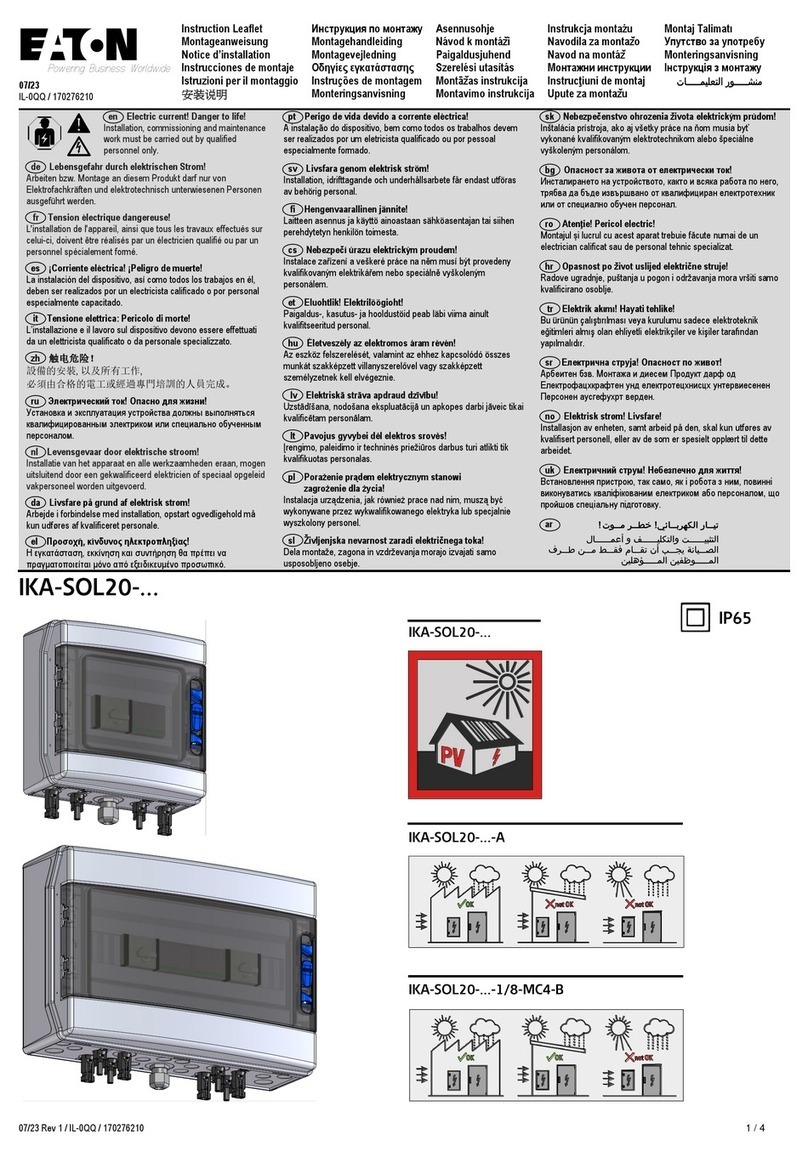

Eaton IKA-SOL20 Series Manual

Eaton

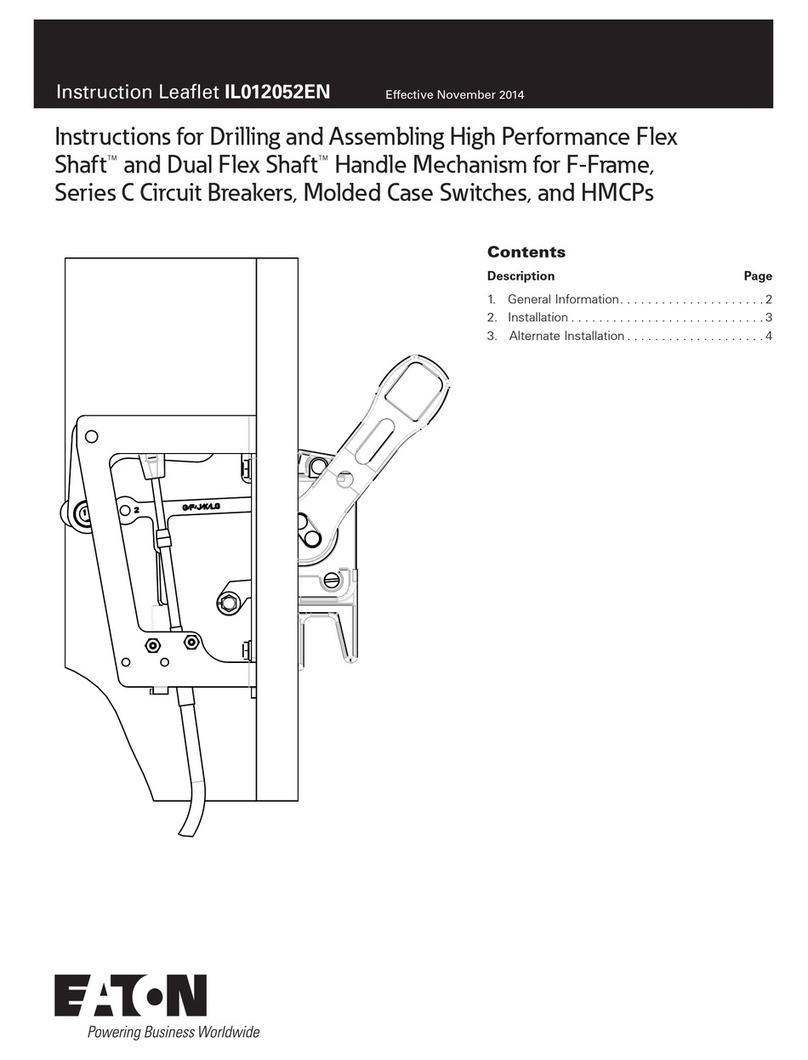

Eaton Flex Shaft Manual

Eaton

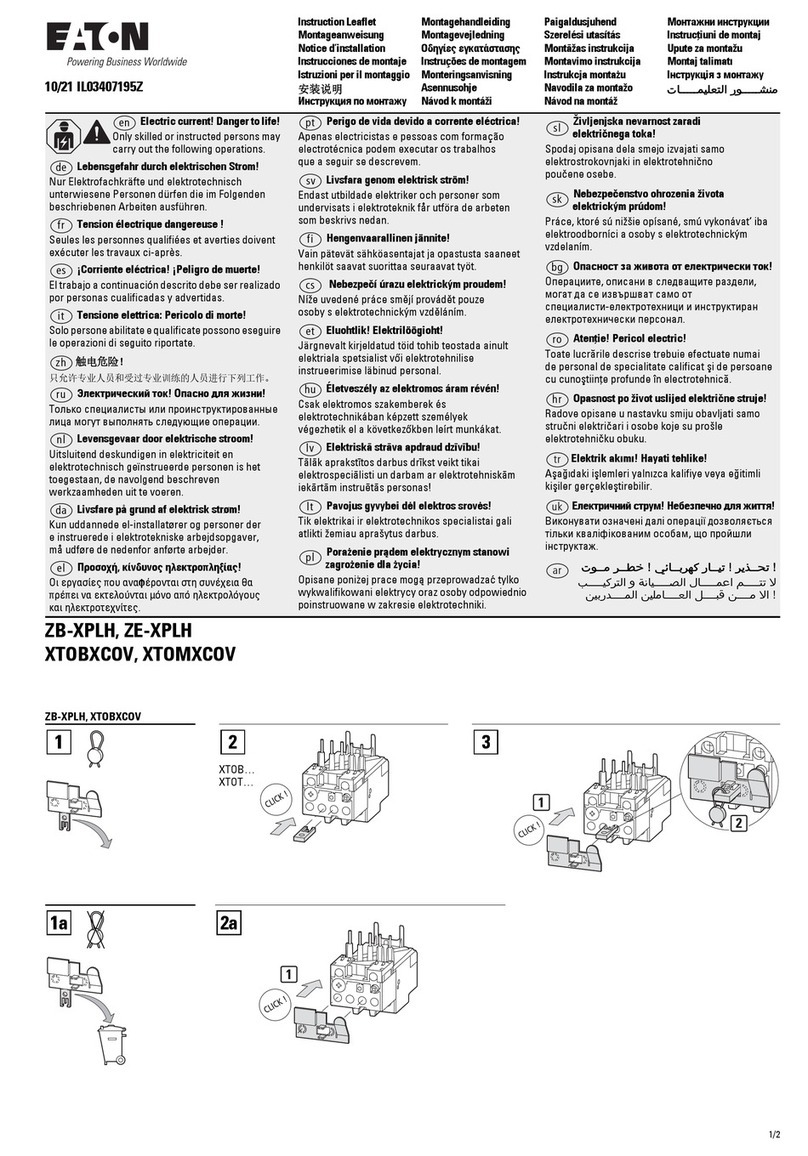

Eaton ZB-XPLH Manual

Eaton

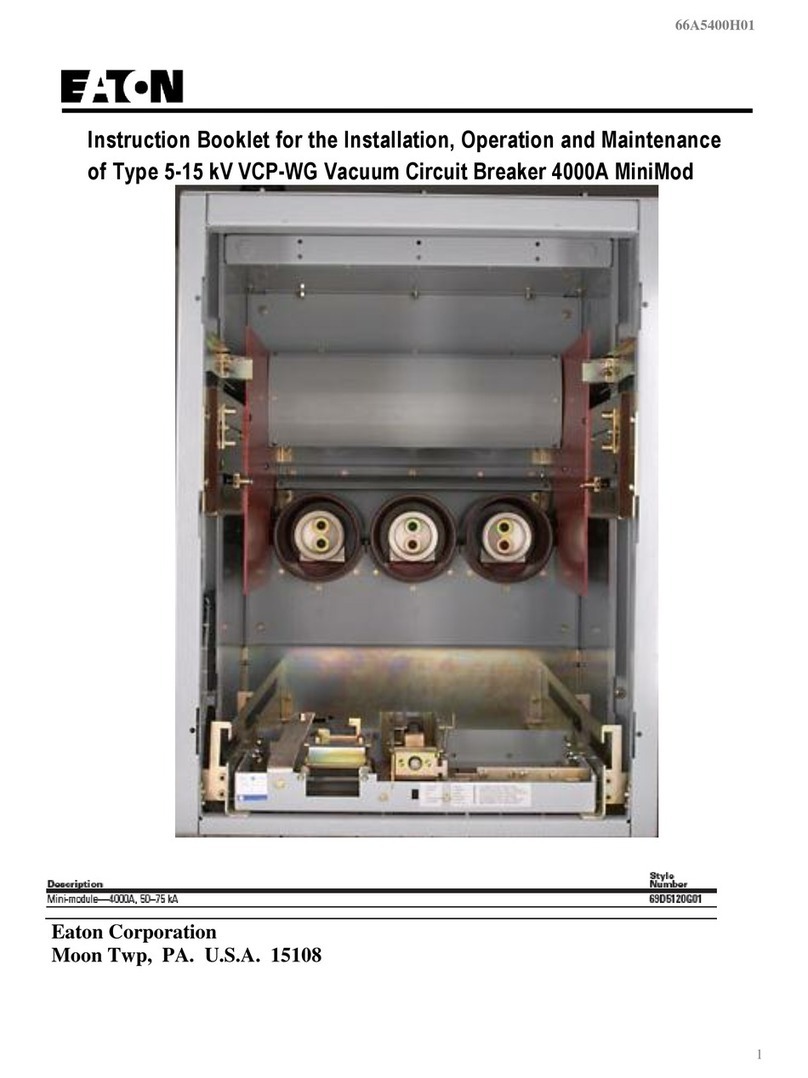

Eaton 4000A MiniMod User manual

Eaton

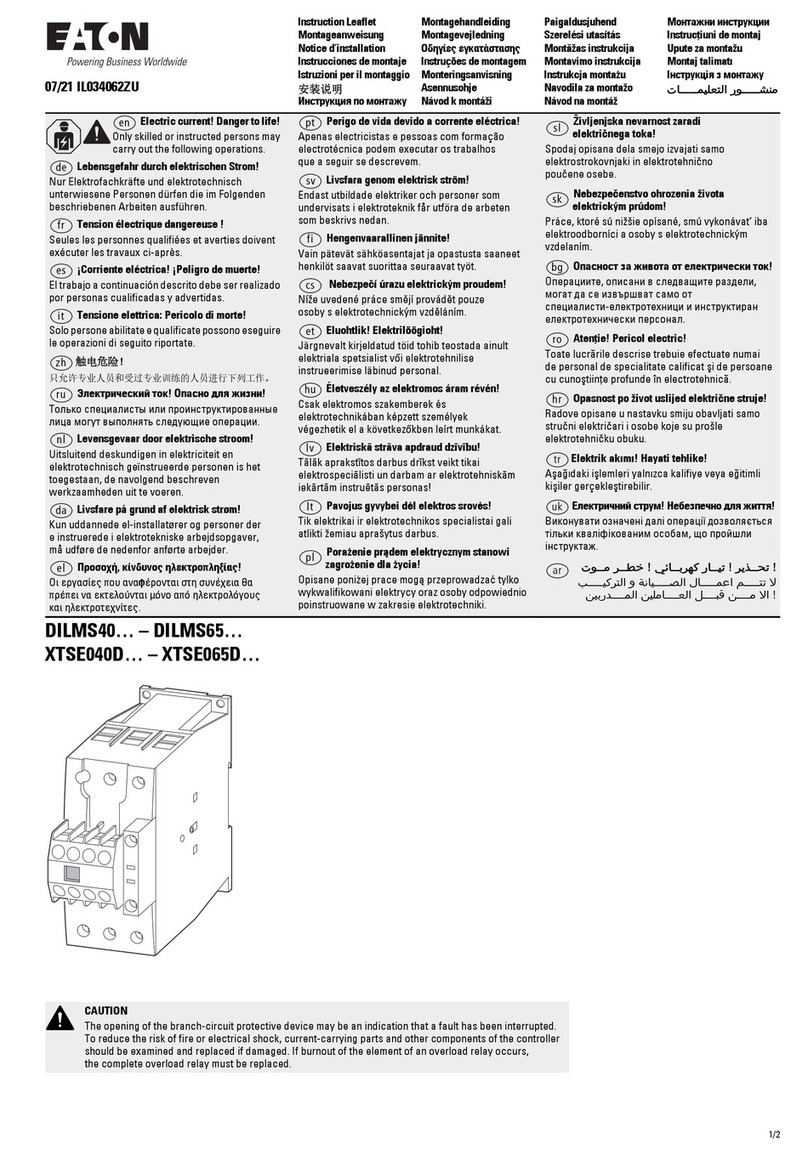

Eaton DILMS40-DILMS65 Series Manual

Eaton

Eaton VCP-W Series User manual

Eaton

Eaton 50 DHP User manual

Eaton

Eaton PKZM4/XTPR DC1 Series User manual

Eaton

Eaton PKE65/AK/XTU-65-SP User manual

Eaton

Eaton NZM2-XSRM-LR Manual

Eaton

Eaton XNH1-A Series Manual

Eaton

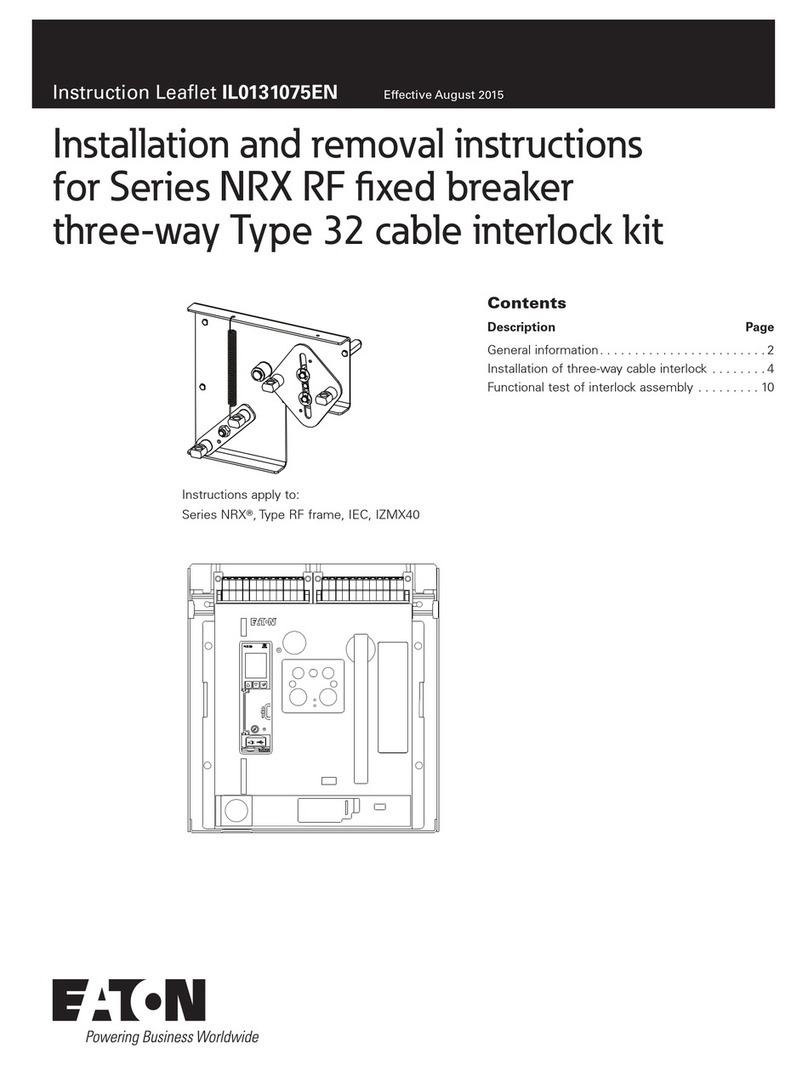

Eaton Series NRX Manual

Eaton

Eaton DILM-XMV XTCEXML Series Manual

Eaton

Eaton Moeller DIL-SWD-32-001 Manual

Eaton

Eaton ND Series User manual

Eaton

Eaton PKE12 Series User manual

Eaton

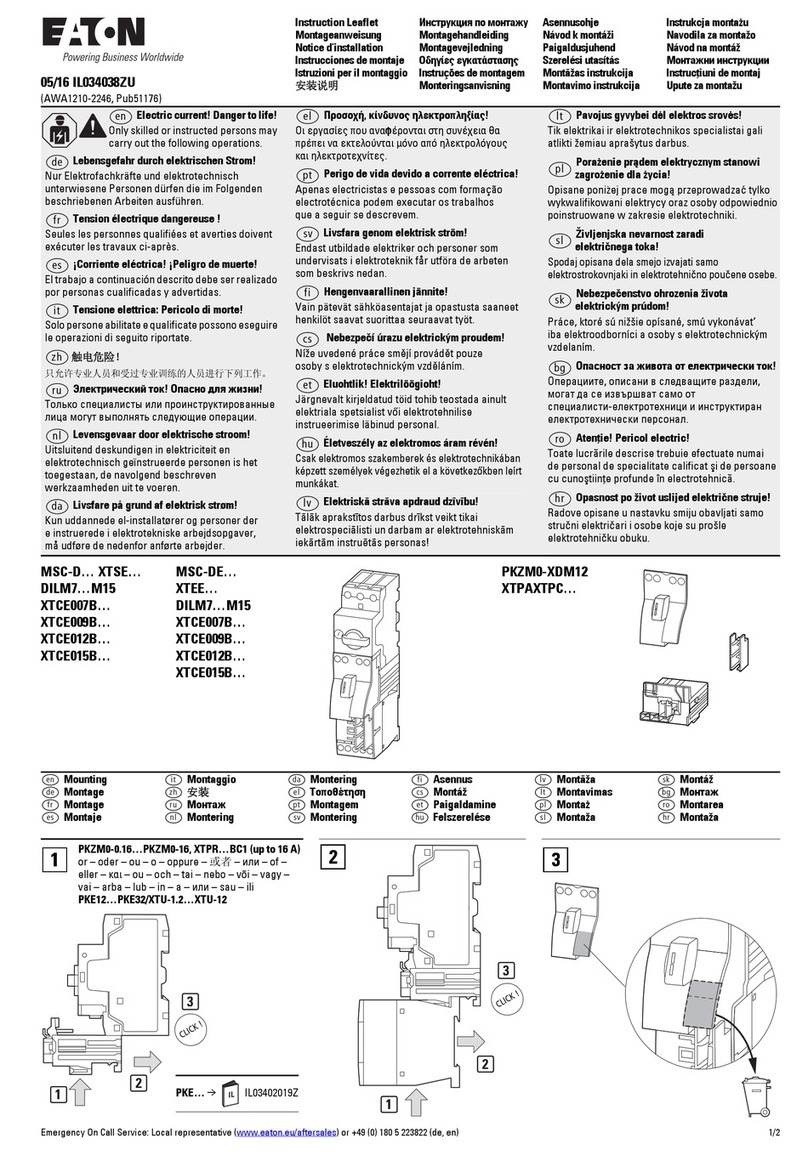

Eaton MSC-D XTSE Series Manual

Eaton

Eaton EASY256-HCI Manual

Eaton

Eaton Power Defense 32-NF Manual

Eaton

Eaton Cutler-Hammer VCP-W Programming manual

Popular Circuit Breaker manuals by other brands

OEZ

OEZ LFN Instructions for use

Bticino

Bticino L4412CM2 quick start guide

OEZ

OEZ 3VA9-RS-4VBH1 Installation, service and maintenance instructions

Siemens

Siemens PSR Instructions, Installation, Operation, Maintenance

Rockwell Automation

Rockwell Automation Allen-Bradley 140G-G manual

FuseBox

FuseBox AFDD060630B Technical data