$ESIGN6%6

# ' #

$ESIGN

!RRANGEMENTS

$EPENDING ON THE APPLICATION TWO BASIC MODELS ARE

AVAILABLE

&OR PARALLELING ASYNCHRONOUS OR

SYNCHRONOUS VOLTAGE SOURCES WITH

TWO SELECTABLE PARAMETER BLOCKS 6%

&OR PARALLELING ASYNCHRONOUS OR

SYNCHRONOUS VOLTAGE SOURCES WITH

SIX SELECTABLE PARAMETER BLOCKS

WITH FREQUENCY AND VOLTAGE BALANCER 6%

)N THE 6% ALL FUNCTIONS INCLUDING DCDC CONVER

TER ARE ACCOMMODATED ON ONE BASIC PLUG IN MOD

ULE OF $OUBLE %UROPA &ORMAT )N THE 6% AN AD

DITIONAL PLUG IN MODULE IS ADDED TO THE BASIC MOD

ULE )N THE FOLLOWING THE DATA APPLYING TO THE 6%

ARE GIVEN IN SHOULD THEY DEVIATE FROM THE 6%

MODEL

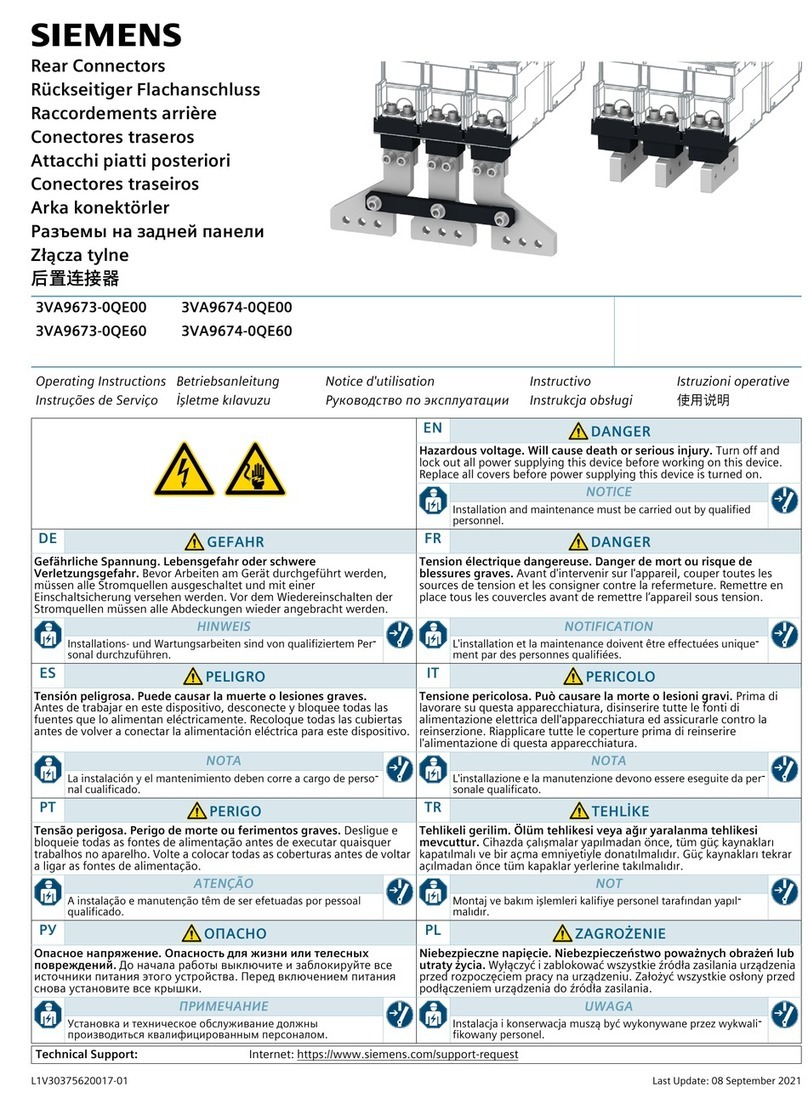

4HE MODULES ARE INSTALLED IN A HOUSING 80 4WO

DIFFERENT TYPES OF HOUSINGS CAN BE DELIVERED

6%JJ J$JJJ IN HOUSING 80

80 FOR PANEL SURFACE MOUNTING

4HE HOUSING HAS FULL SHEET METAL COVERS AS WELL

AS A REMOVABLE FRONT COVER WITH TRANSPARENT PLAS

TIC WINDOW

0LASTIC GUIDE RAILS ARE BUILT IN FOR THE SUPPORT OF

PLUG IN MODULES .EXT TO THE GUIDE RAIL AT THE BOT

TOM ON THE LEFT HAND SIDE OF EACH MODULE A CON

TACT AREA WHICH IS ELECTRICALLY CONNECTED TO THE

HOUSING IS INSTALLED TO MATE WITH THE EARTHING

SPRING OF THE MODULE #ONNECTION TO EARTH IS MADE

BEFORE THE PLUGS MAKE CONTACT %ARTHING SCREWS

HAVE BEEN PROVIDED ON THE LEFT HAND SIDE OF THE

HOUSING !DDITIONALLY TERMINAL IS CON

NECTED TO THE CASE

!LL EXTERNAL SIGNALS ARE CONNECTED TO

SCREWED TERMINALS WHICH ARE ARRANGED OVER CUT

OUTS ON THE TOP AND BOTTOM COVERS 4HE TERMINALS

ARE NUMBERED CONSECUTIVELY FROM LEFT TO RIGHT AT

THE BOTTOM AND TOP

4HE DEGREE OF PROTECTION FOR THE HOUSING IS )0

FOR THE TERMINALS )0 &OR DIMENSIONS PLEASE RE

FER TO &IGURE

6%JJ J#JJJ IN HOUSING 80

80 FOR PANEL FLUSH MOUNTING OR

6%JJ J%JJJ FOR CUBICLE INSTALLATION

4HE HOUSING HAS FULL SHEET METAL COVERS AS WELL

AS A REMOVABLE FRONT COVER WITH TRANSPARENT PLAS

TIC WINDOW FOR PANEL MOUNTING

0LASTIC GUIDE RAILS ARE BUILT IN FOR THE SUPPORT OF

PLUG IN MODULES .EXT TO THE GUIDE RAIL AT THE BOT

TOM ON THE LEFT HAND SIDE OF EACH MODULE A CON

TACT AREA WHICH IS ELECTRICALLY CONNECTED TO THE

HOUSING IS INSTALLED TO MATE WITH THE EARTHING

SPRING OF THE MODULE #ONNECTION TO EARTH IS MADE

BEFORE THE PLUGS MAKE CONTACT %ARTHING SCREWS

HAVE BEEN PROVIDED ON THE REAR WALL OF THE HOUS

ING

!LL EXTERNAL SIGNALS ARE CONNECTED TO CONNECTOR

MODULES WHICH ARE MOUNTED ON THE REAR COVER

OVER CUT OUTS &OR EACH ELECTRICAL CONNECTION

ONE SCREWED TERMINAL AND ONE PARALLEL SNAP IN

TERMINAL ARE PROVIDED &OR FIELD WIRING THE USE OF

THE SCREWED TERMINALS IS RECOMMENDED SNAP IN

CONNECTION REQUIRES SPECIAL TOOLS

4HE PLUG MODULES ARE LABELLED ACCORDING TO THEIR

MOUNTING POSITION BY MEANS OF A GRID SYSTEM EG

! 4HE INDIVIDUAL CONNECTIONS WITHIN A MODULE

ARE NUMBERED CONSECUTIVELY FROM LEFT TO RIGHT

WHEN VIEWED FROM THE REAR EG ! REFER TO

&IGURE

$EGREE OF PROTECTION FOR THE HOUSING IS )0 FOR

CUBICLE INSTALLATION )0 FOR THE TERMINALS )0

&OR DIMENSIONS PLEASE REFER TO &IGURE