Siemens Building Technologies CA2N1655E / 11.1998

Landis & Staefa Division 3/4

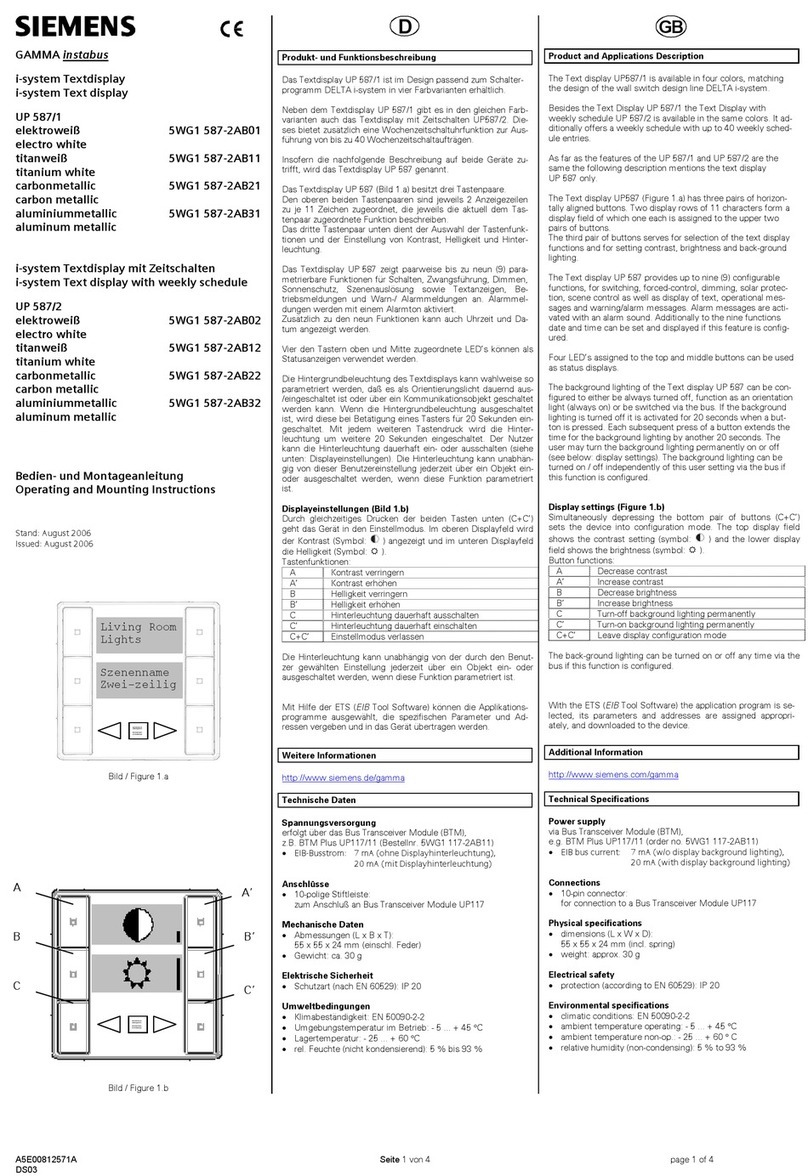

Important:

On no account must Step 2

(‘Calibrating the display’) be

omitted.

Switch S4

Display in °C (factory setting)

Display in °F

Service (for PRONTO IRC controllers only)

To set the PRONTO IRC controller parameters and read controller data, the

ZS1 service terminal may be connected to the FCC telephone socket on the

room operating unit (see page 1). It is then possible to set the parameters

of all controllers connected to the same trunk.

Initialisation is only possible with the ZS1 connected directly to the

relevant controller.

If there is no requirement for communication with the controllers from

the room operating unit, there is no need to wire the service bus (see

“Terminal layout”, page 2).

Commissioning

The PBC room operating unit is commissioned as follows:

1. Select temperature scale for display (°C or °F)

The preferred scale for the temperature display can be selected on switch

S4 before fitting the PBC electronic assembly to the PB2 base unit.

2. Calibrating the display

With PRONTO IRC PRU/A, PRFB.., PRVU and SMART SMVU

• Connect the ZS1 service terminal to the service socket (1) on the PBC

• Use CMD 01 on the ZS1 to display the measured room temperature

• If the LCD display (2) differs from the measured value:

1. Depress button (3) with a small screwdriver: →

°

Cor

°

Fwill flash

2. Use the rotary knob (4) to match the LCD display (2) to the measured

temperature

3. If the adjustment range is not wide enough, wait until flashing stops

(approx. 10 s), turn the rotary knob back and repeat steps 1 and 2.

• If the temperature now displayed deviates from the actual room

temperature (as measured by a separate thermometer), the displayed

value can be re-calibrated with the trimmer potentiometer accessible

from the bottom of the unit (see diagram on page 1 for position).

See Manual P6 for a description of the ZS1 service terminal.

With INTEGRAL RS NRU.., NRK..:

• With the NBRN operator terminal read the temperature at the

corresponding input of the NRU.. or NRK.. RS module

• If the LCD display (2) differs from the measured value:

1. Depress button (3) with a small screwdriver: →

°

Cor

°

Fwill flash

2. Use the rotary knob (4) to match the LCD display (2) to the measured

temperature

3. If the adjustment range is not wide enough, wait until flashing stops

(approx. 10 s), turn the rotary knob back and repeat steps 1 and 2.

• If the temperature now displayed deviates from the actual room

temperature (as measured by a separate thermometer), the displayed

value can be re-calibrated with the trimmer potentiometer accessible

from the bottom of the unit (see diagram on page 1 for position).

See Manual K23 for a description of the NBRN operator terminal.

With PRONTO PRFA..:

1. Use a separate thermometer to establish the room temperature

2. Depress button (3) with a small screwdriver: →

°

Cor

°

Fwill flash

3. Use the rotary knob (4) to match the LCD display (2) to the measured

temperature

4. If the adjustment range is not wide enough, wait until flashing stops

(approx. 10 s), turn the rotary knob back and repeat steps 2 and 3.

Recalibration with the trimmer potentiometer does not apply in this case.