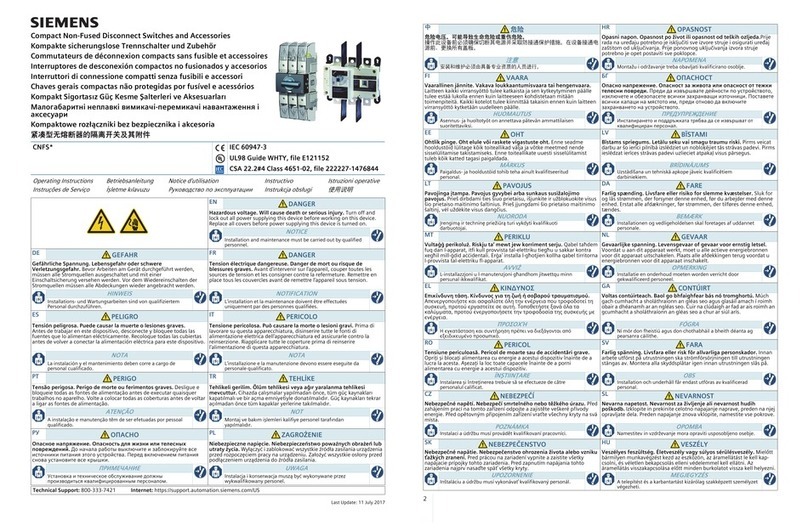

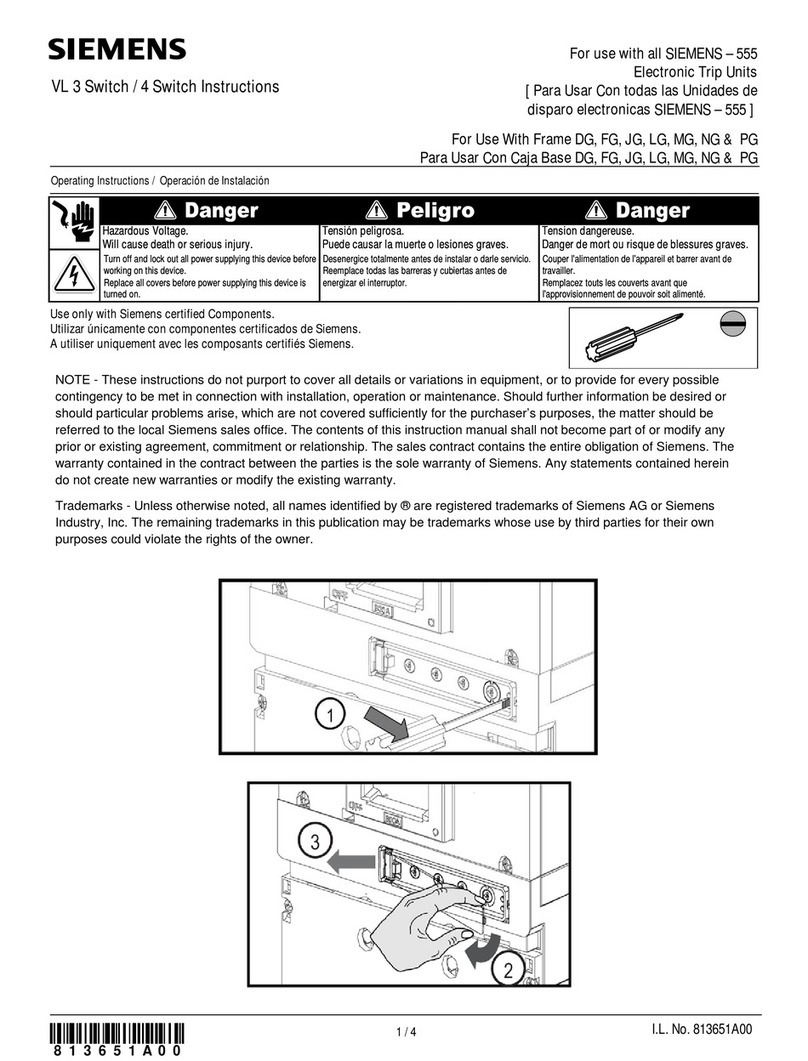

HazardousVoltage.

Will cause death or serious injury.

Turn off and lock out all power supplying this device before

removing cover(s) or device and while cover(s) are removed.

Wire connector shield no. NDTS must be installed when

pressure wire connectors 3TA2K8750, 3TA4P8500,

3TA2N8750, 3TA3N8750, 3TA4N8500 or crimp connectors

CCM800K2, CCM800K3, CCN1200K2, CNN1200K3 are used.

Replace the covers and shields before power supplying this

device is turned on.

NOTE: This instruction outlines the recommended

installation procedure.

INTRODUCTION

The MD and ND Frame circuit breaker line includes types

MD6, MDX6, HMD6, HMXD6, CMD6, ND6, NXD6, HND6

HNXD6 and CND6 circuit breaker types; MD6 ETI, and CMD6

ETI motor circuit interrupters; types MXD6 and NXD6 molded

case switches. These devices are rated for operating voltages

up to 600 VAC, 50/60 Hz and 500 VDC.

INSTALLATION

MD and ND Frame devices are for use in individual

enclosures, panel boards, switchboards or other approved

equipment.

The installation procedure consists of inspecting, attaching

required accessories, mounting the device and connecting

and torquing the line and load wire connectors.

Mounting hardware and unmounted wire connectors (where

required) are available as separate catalog items.

Note: Trip unit and accessory installation should be

completed before the device is mounted and connected. (See

installation instructions supplied with trip unit and accessory

before proceeding).

Note: Motor circuit interrupters and molded case switches

are supplied as complete devices only.

Note: Molded case switches do not have a PUSH-TO-TRIP

button.

A. Turn off and lock out all power before installing or servicing.

B. Make sure that the device is suitable for the installation

by comparing nameplate ratings with system require-

ments. Inspect the device for completeness and check for

any damage before mounting.

SAFETY INSTRUCTIONS

Installation Instructions

Peligro

Tensión Peligrosa.

Puede causar daños serio o la muerte.

Desenergice totalmente antes de instalar o darle servicio.

Protector del alambre NDTS debe ser instalado cuano se

utilizan los conectadores 3TA2K8750, 3TA4P8500,

3TA2N8750, 3TA3N8750, 3TA4N8500 o connectodores

CCM800K2, CCM800K3, CCN1200K2, CNN1200K3 del alambre

de la presión de la encrespadura.

Reemplace todas las barreras y cubiertas antes de energizer

el interruptor.

INSTRUCCIONES DE SEGURIDAD

Lea cuidadosamente este instructivo, con ello obtendrá la

completa seguridad en el uso de estos equipos para su montaje.

1 Información Técnica

Generalidades

La línea de interruptores termomagnéticos Tipo- MD6, MDX6,

HMD6, HMXD6, CMD6, ND6, NXD6, HND6 HNXD6 y

CND6; Interruptores Tipo-MD6 ETI, y CMD6 ETI; y Interrup-

tores mobibles, Tipo-MXD6 y NXD6, para corrientes nominales

desde 700 hasta 800 A, son adecuados para operar en tensiones

hasta 600 V C.A. 50/60 Hz. La línea de interruptores

termomagnéticos NXD6, para corrientes nominales desde 1000

hasta 1200 A, son adecuados para operar en tensiones hasta 600 V

C.A. 50/60 Hz.

2 Instalación.

Los interruptores termomagnéticos MXD6 y NXD6, están

previstos para alojarse en gabinetes individuales, tableros de

distribución, tableros de maniobra y otros gabinetes aprobados.

El procedimiento para la instalación consiste de: inspección de los

accesorios requeridos, montaje del interruptor y conexión de los

conductores del lado de línea y de carga. Montaje de los

conectores para cable o solerás (Cuando se requieran).

La unidad de disparo y los accesorios de instalación, deben estar

completas antes que el interruptor sea instalado y conectado.

Cuando el interruptor es de unidad de disparo

intercambiable, esta se suministra junto con los accesorios

necesarios.

A. Desenergice totalmente antes de instalarlo o darle mantenimiento.

B. Asegúrese que el interruptor sea el adecuado para la protección

del circuito en el que se intercala, consultando las especificaciones

en la placa de características.

Interruptores termomagnéticos Marco MD, Tipo-MD6,

MXD6, HMD6, HMXD6, y CMD6, Marco ND, ND6,

NXD6, HND6, HNXD6 y CND6; Interruptores Tipo-

MD6 ETI y CMD6 ETI; y Interruptores mobibles, Tipo-

MXD6 y NXD6.

Siemens Energy & Automation, Inc.

Bellefontaine, OH 43311 U.S.A.

Devices: MD Frame Types MD6, MXD6, HMD6, HMXD6, and

CMD6, ND Frame Types ND6, NXD6, HND6, HNXD6

and CND6 Circuit Breakers, Types MD6 ETI and CMD6

ETI Motor Circuit Interrupters, and Types MXD6 and

NXD6 Molded Case Switches.

Page 1 of 4

Pc. No. 83432A03

Instructivo de Instalación y Operación