instabus EIB

Technical product information

August 2010

Venetian blind switch N 523/02 5WG1 523-1AB02

4 x 230 V AC / 6 A

Siemens AG N 523/02, 4 pages Technical manual

Industry Sector, Building Technologies

Electrical Installation Technology © Siemens AG 2010 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D-93009 Regensburg Subject to change without further notice

2.10.1.13/1

Product and functional description

The Venetian blind switch N 523/02 is a DIN rail mounted

device in N-system dimensions with a width of 4 module

units. Only one AC 230V drive (motor) with electro-

mechanical limit switches or with integrated electronics

for disconnection at the limit positions can be connected

to a channel of the 4-fold Venetian blind switch

N 523/02. The parallel operation of several drives on one

channel requires the intermediate switching of a special

relay. Apart from moving the sun/anti-glare protection

into one of the two limit positions, the Venetian blind

can also be stopped and the slats can be adjusted step-

wise.

The power supply of the Venetian blind switch elec-

tronics is carried out via an integrated power supply unit,

which is fed via the mains connection L1 for channels A

and B. The mains connection of channels C and D is car-

ried out via the connection L2. This enables two channels

to be connected to different external conductors. If this is

not required, one of the terminals L1 must be linked to

one of the terminals L2 via a wiring jumper.

For direct operation (also in the event of communi-

cations failure or if EIB communication has not yet been

put into operation), four pairs of push buttons are avail-

able on the top of the device. For direct operation, both

AC 230 V and bus voltage must be applied at the actua-

tor. Moreover, the actuator must be switched to direct

operation via the appropriate push button with an LED.

In direct operation mode, an output remains switched on

while the associated push button is pressed. As the direct

operation is completely isolated from the bus communi-

cation, any active safety alarm or protection mode (for

blocking the raising or lowering of the sun/anti-glare pro-

tection) is not taken into account.

Application program

The sunblind switch N 523/02 only works together with

the application program 25 A4 Sunblind switch 980103.

Due to its two 1 bit command objects which are always

available per channel, the program enables the move-

ment of a Venetian blind into the upper or lower limit

position, stopping the movement of the Venetian blind

as well as the stepwise adjustment of the slats. The ad-

justable period for gradually opening the slats or gradu-

ally raising the sunblind again once it has reached the

lower limit position only becomes into effect if the sun-

blind has been lowered from the upper limit position

without any interruptions.

When commissioning the sunblind switch the following

objects can be added to all the channels :

-one object “Move-up blockade On/Off“

(required e.g. for cleaning)

-one object “Move-down blockade On/Off”

(required e.g. for interior sun protection and when

the window is open)

-two 1 bit objects for saving/restoring two Venetian

blind/slat positions

-two 8 bit status objects (Venetian blind and slat posi-

tion as percentage values).

In connection with a weather station, in the event of a

wind or rain alarm it is ensured via an alarm object that

the sun/anti-glare protection is for example raised auto-

matically and that the lowering of it via the EIB is pre-

vented when there is an alarm.

It can further be selected whether the parameterisation

is adopted for all the channels or whether each channel

should be configured individually.

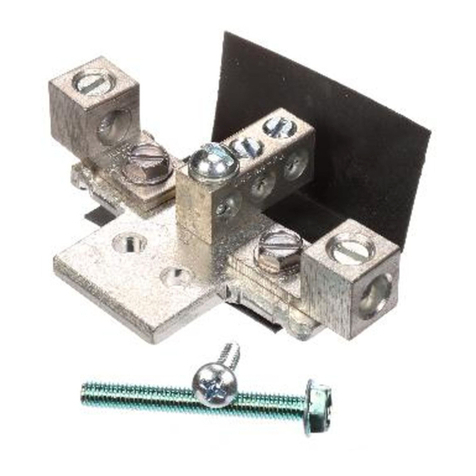

Connection example

Venetian blind switch N 523/02

instabusEIB

Bus coupling unit

venetian blind drives

venetian

blind

channel

D

venetian

blind

channel

C

venetian

blind

channel

B

venetian

blind

channel

A

K1

up

K2

down

K3

up

K4

down

K5

up

K6

down

K7

up

K8

down

L2

L1 N

power supply