Use the table below as a guide while using the worksheet on the next page to record your notes.

NOTE! Please read the entire quick-start procedure before beginning installation.

TM500

TM500

9

Introduction

3 PULSE (+)

4 PULSE (-)

5 Tx/Rx (+)

2 SWITCH INPUT (-)

1 SWITCH INPUT (+)

POWER (+) 1

POWER (-) 2

4-20mA #1 (+) 3

4-20mA #1 (-) 4

4-20mA #2 (+) 5

4-20mA #2 (-) 6

TS2

TS1

F1

0.75A

TP1

TP2

POWER

#4

#6

#3

#5

#2

Cable Shield

Electronics Enclosure

RED WHT

BLU YEL

Probe Sensor Wired By Fox

SENSOR

Remote Enclosure

#7

#8

#1

Splice

Green Wire

Shield Wire (insulate)

F1 F2 F3 F4

Initializing...

F1 F2 F3 F4

Initializing...

3 PULSE (+)

4 PULSE (-)

7 COMMON

6 Tx/Rx (-)

5 Tx/Rx (+)

2 SWITCH INPUT (-)

1 SWITCH INPUT (+)

POWER (+) 1

POWER (-) 2

4-20mA #1 (+) 3

4-20mA #1 (-) 4

4-20mA #2 (+) 5

4-20mA #2 (-) 6

TS2

TS1

F1

0.75A

TP1

TP2

TM500Customer PLC or DCS

+12 TO 24VDC

PULSE OR ALARM OUTPUT

12 TO 24VDC RETURN

+

-

2.4K OHM TYPICAL WITH 24VDC POWER

1.2K OHM TYPICAL WITH 12VDC POWER

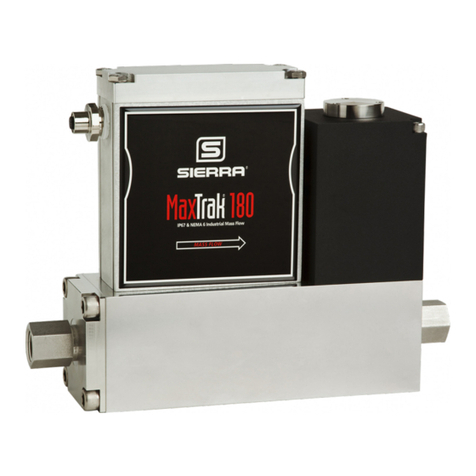

ID OUTER

DIAMETER

FLOW

4X = INLINE

8X = INLINE

15X = INSERTION

PIPE ID MIN.

INDICATOR:

- POINT IN DIRECTION

OF FLOW

- LOOSEN SET SCREWS TO

ROTATE HOUSING ±90º, ±180º

- TIGHTEN SET SCREWS

WHEN DONE

FLOW

FLOW

0.73"

(18.5 mm)

L

C

F1 F2 F3 F4

ACCESS THE

DISPLAY BY

UNSCREWING

COVER

REMOVE SCREWS

ON DISPLAY TO

ROTATE DISPLAY

±180°

1. Record inside diameter (ID). Ensure the actual pipe ID

matches the pipe ID shown on the factory calibration

certificate. If IDs do not match, refer to "Pipe Diameter" on

page 61.

2.

Record up/downstream straight-pipe requirements based on

Pipe ID and meter style (insertion or inline). [refer to p. 23]

3.

The Flow Direction Indicator must point in the direction of

flow.

The housing can be rotated for a better view of the meter's

display. Note that the 2 set screws must be loosened before

the housing will turn. [refer to p. 29]

4.

Ensure correct probe depth setting. If using 1 ½" size pipe,

please see note on p. 26.

5.

If needed, the orientation of display can be rotated in 90°

increments for a better view.

[refer to p. 30 for more information]

6. Ensure power wiring [p. 37] and 4-20mA wiring [p. 39 -

p. 40] properly connected. [refer to Wiring section p. 35

for more information]

7.

Ensure remote wiring is correct if remote option ordered.

[refer to p. 46 - p. 48 for more information]

8.

Verify you have the proper output signal wiring

[refer to p. 39 - p. 45 for more information]

9.

Apply power to the flow meter.

10. Check the remaining flow meter settings by accessing the meter settings either through the front panel of the

display or by using the TM500-ViewTM software. Record the settings in the spaces given for items A - F on

the following page.

Quick Start Guide