Sifos Technologies PowerSync PSA100-SA Product manual

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

1

Sifos Technologies

PowerSync®Service Analyzer

PSA100-SA

Technical Reference

Manual

Version 3.4

Revised February, 2010

Copyright © 2010 Sifos Technologies

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

2

Disclaimer

The information contained in this manual is the property of Sifos Technologies, Inc., and is furnished for use by recipient

only for the purpose stated in the Software License Agreement accompanying the user documentation. Except as permitted

by such License Agreement, no part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, without the prior written permission of Sifos Technologies, Inc.

Information contained in the user documentation is subject to change without notice and does not represent a commitment

on the part of Sifos Technologies, Inc. Sifos Technologies, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in the user documentation.

Warrantee

Sifos Technologies Inc., warrants to recipient that hardware (“Hardware”) and the tangible media on which it supplies

Software will be free from significant defects in materials and workmanship for a period of 12 months from the date of

delivery (the “Warrantee Period”), under normal and intended use and conditions. Sifos also warrants that during the

Warranty Period, the Software that it supplies will operate substantially in accordance with the specifications supplied by

Sifos for such Software. Sifos does not warrant that the functions contained in the Software will meet a specific

requirement or that the operation will be uninterrupted or error free. Sifos shall have no warranty obligations whatsoever

with respect to any Software which has been modified in any manner by any third party.

Defective Product under warranty shall be, at Sifos’ discretion, repaired or replaced or a credit issued for an amount equal to the

price paid for such Product provided that: (a) such Product is returned to Sifos Technologies after first obtaining a return

authorization number and shipping instructions, freight prepaid, to Sifos’ location in the United States; (b) Recipient provides an

explanation of the defect or Software failure claimed; and (c) the claimed defect actually exists and was not caused by fault,

neglect, accident, misuse, improper storage, improper installation, improper repair (other than by Sifos or its agents), fire,

flood, lightning, power surges, earthquake or alteration (unless such alteration performed by Sifos or its agents). Sifos will

ship repaired Products to recipient, freight prepaid, within ten (10) working days after receipt of defective Product. Except as

otherwise stated, any claim on account of defective materials or for any other cause whatsoever will conclusively be

deemed waived by recipient unless written notice thereof is given to Sifos Technologies, Inc. within the Warrantee Period.

Product will be subject to Sifos Technologies’ standard tolerances for variations.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, ALL IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO IMPLIED WARRANTEES OF MERCHANTABILITY, NONINFRINGEMENT AND FITNESS FOR A

PARTICULAR PURPOSE, ARE HEREBY EXCLUDED, AND THE LIABILITY OF SIFOS, IF ANY FOR DAMAGES

RELATING TO ANY ALLEGEDLY DEFECTIVE PRODUCT SHALL BE LIMITED TO THE ACTUAL PRICE PAID

BY THE PURCHASER FOR SUCH PRODUCT. IN NO EVENT WILL SIFOS TECHNOLOGIES BE LIABLE FOR

COSTS OF PROCUREMENT OF SUBSTITUTE PRODUCTS OR SERVICES, LOST PROFITS, OR ANY SPECIAL

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES, HOWEVER CAUSED AND ON ANY

THEORY OF LIABILITY, ARISING IN ANY WAY OUT OF THE SALE AND/OR LICENSE OF PRODUCTS OR

SERVICES TO RECIPIENT EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES AND

NOTWITHSTANDING ANY FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY.

Safety Precautions

To prevent electric shock, do not remove the cover of the PSA-100-SA. No user serviceable parts are inside. Service

should be referred to qualified personnel.

The PSA-100-SA is for connection only to the isolated intra-corporate or private Ethernet networks.

The PSA should be powered via the supplied AC Power Adapter, which includes an Earthing Conductor. The ground

terminal of the plug should not be modified, since this could result in a product that is not properly earthed. When placing

the equipment in its final configuration, the equipment should be placed such that it is easy to access the power cord; this

will allow the cord to be pulled out of the unit in the event that it is necessary to remove power. THE PSA-100-SA

SHOULD ONLY BE OPERATED WITH THE POWER SUPPLY THAT WAS PROVIDED WITH THAT PRODUCT.

Note! The PSA-100-SA may be powered from 5V battery modules. This power configuration has not been tested for

CSA certifications. The PSA-100_SA is CSA certified when powered from the AC Power Adapter.

THERE ARE VENTILATION HOLES ON THE SIDES AND TOP OC THE PSA-100. THESE SHOULD NOT BE

BLOCKED OR OTHERWISE OBSTRUCTED.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

3

Table of Contents

1. Introduction....................................................................................................5

2. PoE and the PowerSync Analyzer................................................................7

2.1. IEEE 802.3af / 802.3at Overview .........................................................................................................7

2.1.1. The Power Connection....................................................................................................................................... 7

2.1.2. PD Detection...................................................................................................................................................... 8

2.1.3. PD Classification................................................................................................................................................ 8

2.1.4. Power-Up ........................................................................................................................................................... 9

2.1.5. Power Removal................................................................................................................................................ 10

2.2. Power Sourcing Equipment Characteristics...................................................................................10

2.2.1. Signaling Variations......................................................................................................................................... 10

2.2.2. Connection Alternatives................................................................................................................................... 11

2.2.3. MPS Behaviors ................................................................................................................................................ 11

2.2.4. Legacy Modes and Proprietary Detection Schemes ......................................................................................... 11

2.3. System Hardware Overview..............................................................................................................12

2.3.1. Port Switch and Detection Subsystem.............................................................................................................. 12

2.3.2. Triggers............................................................................................................................................................ 13

2.3.3. Loads and Load Transients .............................................................................................................................. 14

2.3.4. DC Meters........................................................................................................................................................ 14

2.3.5. AC Meter ......................................................................................................................................................... 14

2.3.6. Time Interval Meter ......................................................................................................................................... 14

2.3.7. LAN Test “Data OUT” Ports ........................................................................................................................... 14

2.4. System Software Overview..............................................................................................................15

2.4.1. PSA Interactive ................................................................................................................................................ 15

2.4.2. PowerShell Scripting Environment .................................................................................................................. 15

2.4.3. PSE Automated Test Suites.............................................................................................................................. 16

2.4.4. PowerSync Analyzer Configuration Files ........................................................................................................ 16

2.4.5. Directory and File Organization – Microsoft Windows ................................................................................... 18

2.4.6. Directory and File Organization – Linux and Unix......................................................................................... 18

2.4.7. TK/TCL Requirements & Resources ............................................................................................................... 19

2.5. (Section Omitted)...............................................................................................................................20

2.6. (Section Omitted)...............................................................................................................................20

2.7. Technical Specifications...................................................................................................................20

2.7.1. Port Configuration............................................................................................................................................ 20

2.7.2. Measurements .................................................................................................................................................. 20

2.7.3. Triggering ........................................................................................................................................................ 21

2.7.4. Programming and Control................................................................................................................................ 21

2.7.5. Physical and Environmental............................................................................................................................. 21

2.7.6. Certifications.................................................................................................................................................... 22

3. PoE Service Analyzer Tests........................................................................23

3.1. PoE Service Test Suite......................................................................................................................23

3.1.1. Basic Service Tests .......................................................................................................................................... 23

3.1.2. Parametric (Interoperability) Tests................................................................................................................... 24

3.1.3. Classification Service and Interoperability Tests ............................................................................................. 25

3.1.4. PoE Service Test Suite Reporting .................................................................................................................... 25

3.2. PoE Monitoring Test..........................................................................................................................26

3.3. PoE Scope Trace ...............................................................................................................................27

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

4

4. PoE Service Test Configurations ...............................................................28

5. PSA Interactive for the PoE Service Analyzer...........................................29

6. Accessing the PoE Service Analyzer from PowerShell............................30

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

5

1. Introduction

The PSA-100-SA is a special adaptation of the PowerSync Analyzer (PSA), the network industry’s most popular

instrument for Power-Over-Ethernet (PoE) design validation and Power Sourcing Equipment (PSE) systems testing. The

PSA-100-SA leverages the PSA Compact hardware platform and adds a specialized application aimed at comprehensive

qualification of PoE Service at the Powered Device (PD) interface. The PSA-100-SA connects in place of a PD to

automatically analyze and report on all critical parameters of the PoE service including power capacity, power

management, and numerous interoperability parameters.

This manual provides a detailed overview of the PSA-100-SA and is organized as follows:

Section 2 will introduce basic PoE technology, PSE product characteristics, and the capabilities of the PowerSync

Analyzer.

Section 3 will cover the PSA-100-SA Service Analyzer automated test suite including Basic Service tests, Parametric

Interoperability tests, Classification Service tests, Line Monitoring tests, and signal viewing capabilities.

Section 4 will describe fundamental configurations and hook-up options for the PSA-100-SA Service Analyzer.

Section 5 will cover the PSA Interactive user interface for the PSA-100-SA.

Section 6 will introduce PowerShell and automated scripting capabilities available with the PSA-100-SA.

The PowerSync Analyzer family from Sifos Technologies also includes the following products:

• PSA-1200: Chassis-based analyzer with capacity to test up to 24 PSE ports. The PSA-1200 fully supports

optional modules including the PSE Conformance Test Suite and the PSE Multi-Port Test Suite.

• PSA-2400: The PSA-2400 “RackPack” bundles 48 test ports in 2 chassis’ with equivalent options and

capabilities as the PSA-1200.

• PSA-100: The PSA-100 Compact is a 2-port, portable versions of the PSA-1200 optionally offering full support

of the PSE Conformance Test Suite. The PSA-100 is fully software compatible with the PSA-1200 and

PSA-2400 chassis-based platforms.

• PSA-PL: The PSA-PL (Programmable Load) is a low cost per-port version of the PSA-1200 aimed at PoE

testing in a production environment. The PSA-PL supports a portion of the automated Multi-Port (System)

Test Suite for the PSA-1200 and also supports upward compatible automation scripting with the PSA

family.

• PDA-100: The PDA-100 is a stand-alone analyzer for assessing Powered Devices (PD) and their expected

interoperability with a broad range of PSE’s. It is also useful for PD design analysis and parametric

reporting.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

6

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

7

2. PoE and the PowerSync Analyzer

2.1. IEEE 802.3af / 802.3at Overview

The 802.3af specification was designed to create an environment whereby Powered Devices (PD’s) from numerous

different manufacturers could be interconnected to Power Sourcing inter-networking equipment (PSE) including switches,

routers, and hubs produced by many different networking equipment manufacturers. It is envisioned that such

interoperability will lead to lower cost and higher proliferation among both the sourcing equipment and the networked

PD’s. The ongoing emergence of VoIP telephony combined with ramp-up in TCP-IP networked devices show that this is

a fast growing market. There are numerous new PD functions such as security, inventory management, environmental

management, and other applications.

The basic features of 802.3af PoE are:

• 48V DC Supply to PD’s

• Guaranteed 15.4 Watts of Power Consumption per network connection (PD and cabling)

• Power Sourcing from both “End-Point” switches/routers as well as “Mid-Span” power “adder” devices.

• Safety “interlocks” to prevent powering when no PD’s are connected and to assure prompt power removal when

PD’s are disconnected as well as to limit DC current flow at all voltage levels.

• Physical layer mechanism for PSE’s to characterize power demands of individual PD’s and thus manage power

delivered per port.

The 802.3at specification will expand upon 802.3af is several key areas:

• Guaranteed up to 30 Watts of Power Consumption per network connection (PD and cabling)

• Optional LLDP (MAC Layer) based protocol for negotiating power demands with a PD with granularity of 0.1

watts.

• PoE End-Point and Mid-Span PSE’s with full gigabit Ethernet support

2.1.1. The Power Connection

Under the 802.3af specification, DC power must be carried on 2 of the 4 pairs of a LAN (e.g. category 5) cable. Either

+48V or –48V DC is carried on one pair (common mode) and reference (zero volts) is carried on a second pair. ALT A

(alternative A) refers to the case where power is sourced on Pairs 2 and 3 (referring to EIA/TIA 568B), the data

transmission pairs for 10/100BaseT. ALT B refers to the case where power is carried on Pairs 1 and 4 which are otherwise

unused in 10/100BaseT. Mid-Span PSE’s MUST apply power on the “ALT B” pairs while End-Point PSE’s may use

either, though typically will use ALT A. This allows both End-Point and Mid-Span PSE’s to coexist on the same cable.

Power may be applied by the PSE in either an MDI or MDI-X (crossover) port configuration. This means that from the

PD’s point of view, the incoming voltage may look either like +48 VDC (MDI) or –48 VDC (MDI-X) since in the latter

configuration, pairs 2 and 3 (as well as 1 and 4) are crossed. PD’s are required to be completely insensitive to whether

power is furnished on the ALT A or ALT B pairs and whether power is positive polarity or negative polarity.

Each PSE port is responsible for managing 4 basic aspects (or phases) of PoE:

1. PD Detection

2. PD Classification

3. Power-Up

4. Power-Removal

802.3at compliant PSE’s will source at least 50 VDC and will readily differentiate between PD’s that are high power

(802.3at) versus normal power (802.3af) type PD’s. PSE’s, including Mid-Spans, can furnish power on any pair (ALT A

or ALT B) and an option may exist to allow powering of all 4 pairs under 802.3at.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

8

2.1.2. PD Detection

A PoE enabled PSE port provides a low power signaling mechanism that constantly monitors for an 802.3af Powered

Device to appear at the end of the LAN cable. If a non-powered network device is connected, the PSE port can function

just as would a non-PoE port and link to the networked device. However, if an 802.3af PD is connected, the PSE port will

quickly recognize this and begin the process of powering up the PD.

The primary means of detection is a measurement of PD

port electrical resistance performed by the PSE port.

802.3af specifies that compliant PDs will present a load

resistance at the PSE between 19 KΩand 26.5 KΩgiven an

input voltage under 10 VDC. It further specifies that the

method of resistance measurement shall allow for an

unknown voltage drop up to 2.8 volts associated with one or

more diode junctions in series with this load resistance.

This implies that the resistance must be determined from a

[ΔV / ΔI] measurement performed at 2 (or more) voltage

levels and that the minimum detection voltage must be at

least 2.8 VDC.

Some of the relevant specifications affecting the detection

process are:

Characteristic Minimum Maximum Units

Unterminated (Open Circuit) Detection Voltage 30 VDC

Terminated Detection Voltages 2.8 10 VDC

Detection Current Limit (compliance) 5 mA

[ΔV / ΔI ] Voltage Step 1 7.2 VDC

Maximum Acceptable Load Resistance 26.5 33 KΩ

Minimum Acceptable Load Resistance 15 19 KΩ

Maximum Acceptable Load Capacitance 0.15 10 μF

Slew Rate of Voltage Step 0.1 V / μsec

Detection Duration 500 mSec

Detection Backoff (following unsuccessful detection)

(does not apply to End-Point PSE’s)

2 Sec

It should be noted that despite the various requirements described for PD Detection signaling in the 802.3 specification, that

there is considerable room for design variation and that in practice, detection pulses and detection measurement schemes do

vary significantly across PSE interface technologies. The 802.3af and 802.3at standards do not prohibit the use of

complementary schemes that might improve detection accuracy and speed while also reducing risk of possible damage to

non-PoE capable end station equipment.

2.1.3. PD Classification

802.3af allows for PD’s to communicate their power demands to a PSE port via a “Classification” process. From the

perspective of a PSE port, PD’s can be classified as follows:

Type (802.3at) Classification Guaranteed Power Minimum Power Units

Class 0 15.4 ~ 0.5

Class 1 4.0 ~ 0.5

Class 2 7.0 ~ 4.0

Type-1

Class 3 15.4 ~ 7.0

Type-2 Class 4 30.0 (802.3at)~ 15.4

Watts

A Type-1 PSE has the option not to classify the PD in which case the PD must be assumed to require Class 0 power.

Classification is performed by applying a voltage in the band from 15.5V to 20.5V and measuring the fixed DC current

load presented by the PD. The magnitude of measured current is then translated into a classification as follows:

Figure 2.1 802.3af Detection

802.3af Detection Pulses

10

2.8

30 No Load (> 2MΩ)

Volts DC

Loaded (< 33KΩ)

ΔVstep

Vslew

Tdbo Tdet

Vvalid

802.3af Detection Pulses

10

2.8

30 No Load (> 2MΩ)

Volts DC

Loaded (< 33KΩ)

ΔVstep

Vslew

Tdbo Tdet

Vvalid

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

9

Minimum Current Maximum Current Units Classification

0 5 mA Class 0

8 13 mA Class 1

16 21 mA Class 2

25 31 mA Class 3

35 45 mA Class 4

The PSE is free to make decisions regarding current

measurements that fall between the above bands. Classification

must be completed in 75 mSec, so typically classification

involves a short duration pulse with amplitude between 15.5 and

20.5 Volts. A “single-event” class pulse (see Figure 2.2) may

return to zero or may hold its value (or anything in between)

following completion of classification.

The 802.3at specification requires that all compliant PSE’s

perform classification and it adds an expanded classification

measurement option that allows PSE’s to “signal” their 802.3at

high power capability to a powered device while reading the

power demand of the powered device. The “2-event”

classification (see Figure 2.2) involves 2 successive

classification current measurements separated by a “mark” region. The 802.3at PD must be capable of discharging the

class voltage in order to “see” this mark region and thereby detect the presence of an 802.3at capable PSE. The 2-event

classification cannot ever drop below 2.8V, or the PD will reset and forget that the PSE is 802.3at capable.

802.3at PSE’s may use either single-event or 2-event PD classification. Those that use single event method are required to

us MAC layer LLDP protocol to negotiate power with an 802.3at PD following initial PD power-up.

2.1.4. Power-Up

Following classification, assuming the PSE performs

this step, the PSE will apply power (voltage and

current) to the PD. A PSE is required to furnish

between 44 V (50 V for Type-2 PSE’s) and 57 V to

at the PSE interface. There are two timing criteria of

interest: Time from end-of-detection until power-up

is complete and the rise time of the PoE voltage.

The first parameter includes classification time and

must be under 400 mSec. The power-on rise time is

required to be longer than 15 μsec.

Other parameters of interest during the power-on

event are the initial (in-rush) current and the peak-to-

peak ripple and noise amplitude. PSE’s are required

to clamp in-rush current to 450 mA regardless of the

transient load provided by a PD. AC ripple

(including AC MPS signals) under 500 Hz in frequency should not exceed 500 mVpp. AC noise in the region below 150

KHz should not exceed 200 mVpp.

While the PSE is furnishing power to the PD, the PSE is responsible for regulating total power delivered to the PD.

802.3af compliant PSE ports must have capability of furnishing a minimum of 15.4 watts given connection to a “Class 0”

PD. High Power 802.3at compliant PSE ports must have capability to furnish at least 30 watts given connection to a “Class

4” PD. The maximum power capacity of a PSE port is limited by a current ceiling defined as Icut in the 802.3

specification. Given the ceilings specified, an 802.3af compliant PSE might theoretically furnish a maximum of 22.7 watts

while a 2-pair, high power, 802.3at compliant PSE might theoretically supply up to 38.9 watts continuous power.

Practically speaking, typical port power capacity will be relatively close to the minimum required values.

802.3 Classification Pulses

15.5

20.5

Volts DC

Vclass Tpdc

Single Event

Class Pulse 2-Event

Class Pulse

10.0

7.0

Vmark

Tcle

Tme

802.3 Classification Pulses

15.5

20.5

Volts DC

Vclass Tpdc

Single Event

Class Pulse 2-Event

Class Pulse

10.0

7.0

Vmark

Tcle

Tme

Figure 2.2 802.3af & 802.3at Classification

Figure 2.3 802.3af Power-Up

802.3 Power-Up

20

44

Detection

Volts DC

10

Classification

Tpon

57

Vport Inrush Load

Vpp

Trise

802.3 Power-Up

20

44

Detection

Volts DC

10

Classification

Tpon

57

Vport Inrush Load

Vpp

Trise

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

10

2.1.5. Power Removal

802.3 compliant PSE’s offer one of two means to determine that a Powered Device has been disconnected, and therefore

DC power should be removed. By implication, the two different mechanisms are mutually exclusive, though the

specification allows for what effectively would be an impractical combination of both methods.

The AC MPS method involves the

superposition of a low level, relatively low

frequency signal on the DC power rail. The

AC signal is sourced from a high output

impedance such that when exposed to a

nominal load resistance of 25 KΩ, the

amplitude of the signal is attenuated to well

below 500 mVp-p. Typically it will be well

below 200 mVp-p. When the 25 KΩ

signature load is removed, the AC signal

amplitude increases and can be detected on

the PSE output. The PSE must then wait for

an interval of at least 300 mSec, but not

longer than 400 mSec to remove power. The

main advantage of the AC MPS method over

the DC MPS method is the ability to tolerate

well below 10mA of load current indefinitely

so long as the AC MPS load impedance of 25

KΩis detected.

The DC MPS method relies on a continuous measurement of DC load current. When the DC load current drops below 10

mA, the PSE has the “right” to remove DC power. When the DC load current drops below 5 mA, the PSE must remove

DC power. As with AC MPS, the timing of the low-load current is such that the PSE must tolerate 300 mSec of low load,

but not longer than 400 mSec of this condition. Additionally, the specification makes allowance for the DC MPS signature

to be intermittent so long as it is present for a continous 60 msec out of every 360 msec interval. The main advantage of

DC MPS is that it does not add any noise onto the power rail.

2.2. Power Sourcing Equipment Characteristics

The 802.3af specification leaves considerable room for implementation dependent behaviors. Additionally, many vendors

of Power Sourcing Equipment (PSE) will choose to go outside the 802.3 specification in ways that will not affect the ability

to power and maintain pure 802.3 Power Devices (PD). This high degree of variation will add a number of challenges to

the generation and performance of PSE specification conformance tests.

2.2.1. Signaling Variations

One area of implementation variation relates to the signaling utilized prior and during power-up. The following table

describes some of the possible variations in the area of signaling.

Signal Type Variants

Amplitude: 2 – 30 VDC

Course Detection Range: Any Detection Signature > 33 KΩ

Course Detection Method: Not strictly specified – may use 802.3af ΔV/ΔI Steps

Open Circuit Detection

Measurement Timing: No firm requirements, just recommendations

Amplitude: 2.8 – 10 VDC (given valid PD signature from 19 to 26.5 KΩ)

Pulse Duration: 20 – 500 mSec Step Magnitude: 1 – 7.2 V

ΔV/ΔI Steps: 1 or more Pulse End: RZ or NRZ

Connected Detection

Signature

Step Edge: Rising, Falling, Both Pulse Separation: >0 (>2 Midspan) sec

Amplitude: 15.5 – 20.5 VDC Duration: 15 to 70 mSecClassification

Classification Pulse Count: > 1 Pulse End: RZ or NRZ

Waveform: CW or PulsedAC MPS Signal

Frequency: 20 to 500 Hz

Removal: Before, During, After

Power-Down (or Never ?)

AC MPS Threshold: 27 KΩto 1.98

MΩ

Power-Down

DC MPS Threshold: 5 – 10 mA

Dissipation: PD Load, PSE Shunt, or

Active PSE Discharge

Figure 2.4 802.3af Power-Down

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

11

2.2.2. Connection Alternatives

PSE’s will generally be configured to source power on EITHER the data pairs (10/100BaseT) OR the unused pairs. For

any given PSE port implementation, this should be a design constant. Within the 802.3af specification, Mid-Span PSE’s

MUST utilize the unused 10/100BaseT pairs. The 802.3at specification allows for Mid-Span PSE’s that power either pair

and support 1000BaseT where all 4 pairs are used for data transmission.

PSEs can provide EITHER polarity (+48V or –48V) to which PDs must be insensitive. Some PSE’s may offer

programmability in configuring their ports for MDI or MDI-X which in turn may affect voltage polarity.

2.2.3. MPS Behaviors

Generally, a PSE will be designed to utilize either the AC or DC MPS method for determining a PD disconnect. Hence,

this is one fundamental characterization of each PSE port that affects both the types of tests and the method of controlling a

PSE port through PD emulation. Those ports supporting DC MPS need to see a low current condition (below 10 mA) in

order to remove power. Those ports supporting AC MPS need to see an effective load impedance in excess of 1.98 MΩin

order to remove power, with a PSE-dependent load threshold ranging from 27 KΩto 1.98 MΩ! These PSE’s will tolerate a

PD operating at less than 0.1 watt indefinitely since a DC load current of 2 mA (assuming port voltage of 48 VDC)

translates to effective 24KΩresistive load.

2.2.4. Legacy Modes and Proprietary Detection Schemes

Prior to 802.3af, a considerable amount of “legacy” PoE equipment including first-generation VoIP phones utilized

proprietary technology to generate and manage power over LAN. Typical legacy powered devices include a low

frequency coupling circuit between data transmission pairs and/or the existence of a large capacitance seen by common

mode measurements across either data or spare pairs. These features could be sensed by the power sourcing equipment

using proprietary techniques. Protocols for determining power requirements of the PD were also proprietary and conducted

at the MAC layer.

With the volume of legacy PD’s in the

marketplace, many new generation PSE’s seek to

utilize BOTH 802.3 signaling and legacy detection

methods simultaneously so that either type of PD

can be recognized and powered. This “hybrid”

detection behavior may violate 802.3 specifications

when detection signaling is compliant with

relevant 802.3af criteria including signal levels,

source impedance, and slew rates. However,

assuming this hybrid behavior does not damage

802.3 compliant PD’s, it is desirable to customers

who want maximum flexibility in their PSE.

Hybrid detection schemes may also include coarse

measurements to assess possible PD connections

prior to performing more refined 802.3 detection.

These proprietary techniques may help to prevent damage to ordinary Ethernet interfaces (non-PD) or they may be

beneficial in determining possible legacy PD connections. On the other hand, the added complexity complicates testing by

adding ambiguity as to exactly how a PSE is detecting either an 802.3 or other type of PD.

Figure 2.5 Hybrid Proprietary Detection Methods

Special Detection Schemes

10

50

Volts DC

Proprietary

Legacy

Detection

Pulses

802.3

Detection

Measurement

Proprietary

Course

Detection

Measurent

Special Detection Schemes

10

50

Volts DC

Proprietary

Legacy

Detection

Pulses

802.3

Detection

Measurement

Proprietary

Course

Detection

Measurent

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

12

2.3. System Hardware Overview

The diagram below shows a block diagram of a single PowerSync Analyzer (PSA) test port. Each PSA test blade (or

PSA100 instrument) contains two of these measurement circuits, which are electrically isolated from each other and from

the chassis control circuitry.

The PSE input connector is connected to a PSE device under test. The DC power and related common mode control and

classification signals are tapped off and fed to the measurement subsystems. The DC voltage and very low frequency,

common mode PoE signals are not visible at the output port. The data signal is passed directly to the output connector, and

can be used for data-related measurements with other test equipment.

At the front end of the test port, there are two sets of switches. These are implemented with electro-mechanical relays. The

ALT-A/B switch selects which wire pair is connected to the PSA test resources. The Polarity switch selects the polarity of

the power supplied by the device under test. ALT-A/B and Polarity settings will depend upon the characteristics of the

equipment being tested. Incorrect settings of either switch will not damage the instrument.

The paragraphs that follow will cover each test subsystem in greater detail.

2.3.1. Port Switch and Detection Subsystem

The Port Switch and Detection Passives subsystem provides the detection loading required for a PSE under test to

recognize a Powered Device (PD) “signature” so that it can turn on and supply power. It also provides an AC Maintain

Power Signature (MPS) resistive loading that is visible to a powered-up PSE. This load value is at the top of the range

where PSE’s must interpret a valid load signature.

The Port switch is used to connect the passive detection loads to the PSE under test. On initial power-up of the PSA-1200,

this switch is typically in the open (or “isolated”) position. This switch closes and opens under software control, and within

all PowerSync Analyzers excluding the PSA-PL, may be used as a triggering event for many single-shot measurements of

detection and MPS behaviors.

The Detection Passives are affected by an internal disconnect feature that is dependent only upon the PSE voltage level.

When the PSE voltage reaches approximately 11 volts, the passive R-C Detection signature is removed and the MPS

signature R-C circuit is inserted thus presenting a valid AC MPS signature following PSE power-up for as long as the Port

Switch is closed (or connected).

PSA1200 Test Port Resources

PSE IN DATA Out

Resistance

9–39KΩ

Capacitance

.1, 4.8, 6.9,

11.6, 47*, 52*,

54*, 58* uF

AC MPS R

24 KΩ, 11 V

Activation

Port

Switch

Trig1, Trig2

•Rising

•Falling

•0 – 64 V

•.25V Res.

Static Load

•0 – 510 mA,

•0.5 mA Res.

•15V Activate

2-Step Trans.

•200 msec –

1 sec/step

•0 – 510 mA

•Opt. 2nd step

“hold”

•Triggers

Volt & Current

•Average

•Min. Peak

•Max. Peak

•Trace

Meas. Period

•10msec–10sec

Triggers

•Immediate

•Trig1

•Ext. Trigger

Low Band

•16Hz – 5KHz

•4Vpp full scale

•10msec – 5sec

High Band

•5KHz – 300KHz

•1Vpp full scale

•10msec – 5 sec

Meas. Period

•10msec – 5sec

Load

Current

*“Type 2” or “Type 3” PSA Test Blades Only

ALT A/B Select

Polarity Select

Detection and

MPS Passives Triggers Active Load DC Meters TI Meter

AC P-P Meter

Time Interval

•20 μsec – 6.5

sec range

•1 msec or

1μsec Res.

Start Trigger

•Trig1

•External

Stop Trigger

•Trig2

PSA1200 Test Port Resources

PSE IN DATA Out

Resistance

9–39KΩ

Capacitance

.1, 4.8, 6.9,

11.6, 47*, 52*,

54*, 58* uF

AC MPS R

24 KΩ, 11 V

Activation

Port

Switch

Trig1, Trig2

•Rising

•Falling

•0 – 64 V

•.25V Res.

Static Load

•0 – 510 mA,

•0.5 mA Res.

•15V Activate

2-Step Trans.

•200 msec –

1 sec/step

•0 – 510 mA

•Opt. 2nd step

“hold”

•Triggers

Volt & Current

•Average

•Min. Peak

•Max. Peak

•Trace

Meas. Period

•10msec–10sec

Triggers

•Immediate

•Trig1

•Ext. Trigger

Low Band

•16Hz – 5KHz

•4Vpp full scale

•10msec – 5sec

High Band

•5KHz – 300KHz

•1Vpp full scale

•10msec – 5 sec

Meas. Period

•10msec – 5sec

Load

Current

*“Type 2” or “Type 3” PSA Test Blades Only

ALT A/B Select

Polarity Select

Detection and

MPS Passives Triggers Active Load DC Meters TI Meter

AC P-P Meter

Time Interval

•20 μsec – 6.5

sec range

•1 msec or

1μsec Res.

Start Trigger

•Trig1

•External

Stop Trigger

•Trig2

Figure 2.6 PSA Test Port Resources

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

13

The Detection resistance and capacitance ranges in the Detection subsystem are 9 KΩ-39 KΩOhms, and nominally 0, 5, 7,

and 11μF respectively. Newer “Type 2” or “Type 3” PSE Test Blades add capacitance values of 47, 52, 54, and 58 μF to

aid with legacy PD emulation needs. The AC MPS signature consists of 24 KΩ in parallel with 0.1 μF that becomes

visible above 11 volts – the same level where Detection Signature passives are removed and become invisible. Because of

the 11 volt activation floor, the effective DC resistance of the AC MPS signature is significantly greater than 24 KΩuntil

the port voltage significantly exceeds 11V. This means that neither the Detection Signature nor the AC MPS signature

will produce any measurable error to Classification Signature loads created by the Active Load module.

There are 2 forward-biased diodes that the signal must pass through before entering the Detection and MPS passives

circuitry. These model typical PD bridge characteristics and are commensurate with recommended circuitry as described in

the 802.3 PoE standard.

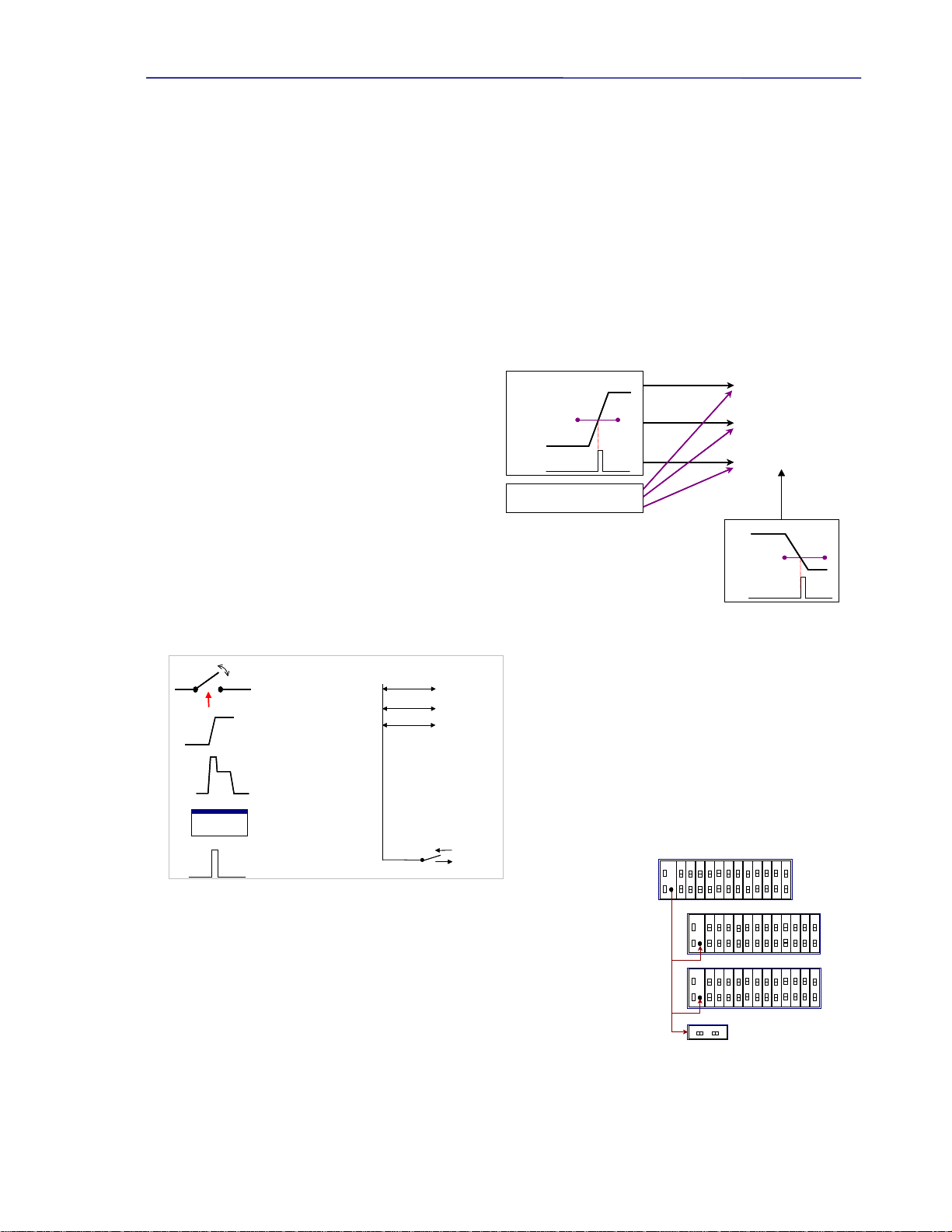

2.3.2. Triggers

The PowerSync Analyzer has extensive triggering capabilities, which are divided into 2 categories: internal (or waveform)

and external (or event). The instrument also has the ability to perform non-triggered measurements. The triggering types

are depicted in Figures 2.7 and 2.8. Also depicted in

Figure 2.7 are trigger applications including the DC

meters, time-interval measurement, and load current

transient, each of which can be initiated with those

triggers.

Internal (or waveform) triggering is derived from the

common mode voltage levels received from the PSE

under test. For most measurements, this triggering is

based upon the trigger levels and directions (rising or

falling) set for Trigger 1. A second trigger, Trigger 2 is

used exclusively for terminating time interval

measurements. Trigger 2 offers identical

programmability as Trigger 1 (levels and edge polarities).

External (or Event) triggering is also used to initiate measurements or actions, and is initiated by either a user command, an

action that is programmed to send out an external trigger, or

through an external event that appears on the trigger bus.

The trigger bus is a trigger signal connection that is shared by

all ports within a system, and by the Trig Out BNC connector

on each PowerSync Analyzer. Figure 2.8 shows the sources

used to generate External (or event) triggers on the left, and

shows the external bus configuration on the right.

Any External trigger

in the system will

appear on this bus, and

will trigger any port

which is waiting for an

external trigger event. This enables cross-triggering across ports and triggering via

externally generated signals. It also enables the user to use the trigger output for

other purposes, such as monitoring data throughput during PSE powering or load

transients.

The BNC trigger connector on the Chassis Controller front panel can be configured

as an output or an input. As an output, it directly mirrors the External trigger bus.

Output triggers will appear as a 3.3V, 10 mSec pulse. When set as an input, it can

drive the external trigger bus inside the PSA chassis. This enables triggering across

multiple instruments, which may be desirable when testing equipment with more than 24 ports.

Voltage

Trigger 1

Level

DC Meters

Current Transient

Time Interval Meter

Internal Trigger

External Trigger

Voltage

Trigger 2

Level

Trigger 2

Voltage

Trigger 1

Level

DC Meters

Current Transient

Time Interval Meter

Internal Trigger

External Trigger

Voltage

Trigger 2

Level

Trigger 2

Figure 2.7 Test Port Triggering

Port Switch

(Connect or Isolate)

Current

Current

Static Load Change

Load Transient

Software “TrigOut”

(or Send Trigger)

> trigout

Another Port

5 Sources External

Trigger Bus Slot1, Port1

Slot1, Port2

Slot2, Port1

…..

Chassis

Ext. Trigger

(Optional)

(Optional)

(Optional)

Port Switch

(Connect or Isolate)

Current

Current

Static Load Change

Load Transient

Software “TrigOut”

(or Send Trigger)

> trigout> trigout

Another Port

5 Sources External

Trigger Bus Slot1, Port1

Slot1, Port2

Slot2, Port1

…..

Chassis

Ext. Trigger

(Optional)

(Optional)

(Optional)

Figure 2.8 PSA Test Port Trigger Sources

PSA #1

PSA #2

PSA #3

PSA #4

External Trigger

PSA #1

PSA #2

PSA #3

PSA #4

PSA #1

PSA #2

PSA #3

PSA #4

External Trigger

Figure 2.9 External Trigger Bus

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

14

For example, the Figure 2.9 shows cross triggering across instruments. The trigger direction on PSA #1 is set as an output,

and the other PSA’s are set as inputs. This set-up can be used to perform measurements, or initiate a load current change

across 96 or more PoE ports simultaneously.

2.3.3. Loads and Load Transients

The load and load transients subsystem uses an active programmable current load. This current load is activated for port

voltages in excess of 15V from the PSE under test. Similarly, the load is deactivated when the port voltage drops below

15VDC. The current load has a programmable range from 0 through 511 mA, in 0.5 mA steps. The PowerSync

Analyzer’s active load may also be configured to produce a programmable 2-step transient current load, where both current

level and load step durations can be set. The durations are programmable from 200 μSecs to 1 second per step. The second

step can optionally be held indefinitely thus becoming the new static DC load. The load transient can be triggered via

either Trigger 1 (waveform) or Externally (event), and it is also capable of generating an Event Trigger at the beginning of

the transient. The load circuitry is automatically switched out of the circuit for input voltages lower than 15V.

2.3.4. DC Meters

The DC Meter subsystem is capable of measuring PSE voltages and sensing actual load currents. Measurement

capabilities include average, maximum peak, minimum peak, and trace capture of either voltage or current. Each of these

measurements uses configurable measurement periods from 10 mSecs to 10 seconds. The sampling rates scale with

measurement period, and range from 40us to 40 mSecs for 10 mSec and 10 second measurement periods respectively.

All DC Meter measurements can be user initiated, triggered with a designated voltage transition and level, or triggered via

an external event (see Section 2.3.2). Only one DC measurement can be performed at a time on a each test port. Triggered

measurements across multiple test ports may be configured to run simultaneously however using either port-specific

waveform triggering or shared external triggering.

2.3.5. AC Meter

The AC Meter is used to measure ripple voltage on the DC signal supplied by the PSE under test. This measurement is

always initiated upon receipt of the AC measurement command.

The AC Meter is capable of measuring ripple in either a 16 Hz – 5K Hz band, or in a 5K – 300K Hz band (3dB BW). This

measurement is a peak-to-peak voltage measurement, based upon a sample rate of approximately 20K-samples per second.

Since this is a peak-to-peak measurement of ripple on a steady state voltage, there are no triggers associated with this

measurement. Integration period can be programmed from 10msec to 5 seconds in 1,2,5 scale increments.

2.3.6. Time Interval Meter

The time interval meter measures time duration between a Trigger 1 edge transition or an External Trigger event, and a

Trigger 2 edge transition. This measurement is configured either to 1 mSec or 1 μSec resolution scale, and can be used for

measurements of reaction times, rise times, pulse widths, and other time-critical events.

If the timing measurement exceeds the maximum capacity of the counters, an “overflow” condition will be returned. The

maximum measurable time intervals are 52.4 mSecs and 6.7 seconds for the 1 µSec and 1 mSec scales respectively. The

resolution for the mSec range is 0.1 mSec and the resolution for the µSec range is 1 µSec. The minimum measurable time

interval is 20 µSec.

2.3.7. LAN Test “Data OUT” Ports

Each test port provides a passively de-coupled “output” to enable the testing of LAN packet throughput either with or

without PoE loads applied. Testing under conditions of PoE load can be used to resolve any significant contribution of

PoE voltage and current toward packet transmission impairment. Such testing can be performed using 10BaseT

(Ethernet), 100BaseT (Fast Ethernet), and 1000BaseT (Gigabit Ethernet) signals. Packet transmission latency through a

PSA Test Port will be negligible owing to the simple passive coupling.

Because the primary purpose of the instrument is to accurately resolve numerous Power-over-Ethernet behaviors, the LAN

pass-thru channel is not optimized for LAN transmission per applicable IEEE 802.3 and ANSI/EIA/TIA standards. Users

should expect that the PSA test port will add a small degree of impairment, particularly affecting low frequency response of

the LAN channel. This impairment may lead to very low levels of packet loss depending upon characteristics of connected

LAN PHY’s. Such characteristics may either worsen or help overcome effects of baseline wander and low frequency

response. Sifos does not specify any particular level of performance for the Data OUT port because performance is

strongly influenced by physical layer design characteristics of LAN ports (e.g. packet data testers, PSE ports) that are

connected to the PSA Test Ports.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

15

Also, because many LAN terminations include various methods of EMI suppression (e.g. “Bob Smith termination”), Sifos

recommends that the OUT port not be connected to a LAN analyzer or other Ethernet device when running precision PoE

signaling measurements including the optional PSE Conformance Test Suite available for PSA-1200 platforms since

these can devices can present unpredictable AC loads and impairments that will negatively affect those PoE signals.

2.4. System Software Overview

PowerSync Analyzers require externally hosted software in order

to operate. PSA software is primarily designed for the Microsoft

Windows operating environment. A version is also available for

Linux and Unix based hosts. PSA software consists of several

distinct subsystems:

PSA Interactive: A graphical user interface designed to

promote interactive use of the PSA1200 or PSA-PL instrument.

PowerShell: A scripting and application program development

environment for creating and executing automated test

sequences. The PowerShell script development environment is

built upon the Tcl/Tk scripting language.

PSE Conformance Test Suite: A series of applications

developed specifically for conformance testing PSE ports to the

802.3 PoE specification given an PSA-1200 platform.

PSE Multi-Port Test Suite: A series of applications developed specifically for system performance testing PSE power

management, capacity, and multi-port decision behaviors.

PoE Service Analyzer: A set of applications and tools for in-depth analysis of PoE Service characteristics at the PD

interface available for the PSA-1200 platform.

PowerShell includes a robust set of commands added into Tcl/Tk that create the Application Programming Interface (API)

for the PowerSync Analyzer family of instruments. Both PSA Interactive and each of the test suites fully utilize the

PowerShell API to control and monitor the PSA. This assures complete uniformity of behaviors when the instrument is

configured from either the PowerShell interface or from PSA Interactive.

2.4.1. PSA Interactive

PSA Interactive is a Tcl/Tk based graphical user interface (GUI) constructed on top of the PowerShell API. It offers robust

control of most PowerSync Analyzer functions. It is intended for users who intermittently or regularly use the PowerSync

Analyzer for PD emulation and PSE measurements as well as for PSE Conformance (PSA-1200) and PSE Multi-Port

(PSA-1200 and PSA-PL) testing.

2.4.2. PowerShell Scripting Environment

PowerShell provides command level access to the PowerSync Analyzer. It consists of the full Tcl/Tk programming shells

(Tcl and Wish) combined with numerous extensions specific to the PowerSync Analyzer.

Tcl/Tk offers two shell programs for interactive command / query execution and scripting development. The “classic” Tcl

shell is an interpretive development environment for Tcl command and script execution. In Windows, the Tcl shell is

typically the Windows command shell with the full range of Tcl libraries (command set) packaged in.

Many operating system (e.g. “MS DOS”, Linux “Bash”) commands also execute in this shell.

The Wish shell enables Tk extensions useful for developing graphical user interfaces. As a shell program, Wish is more

“Windows-like” in its support of a mouse controlled cursor as well as its cut and paste editing capabilities. It does impose

certain limitations in the handling of “standard input” (interactive user prompting) however.

For the most part, PowerShell commands and scripts run equivalently in either the Tcl Shell or the Wish Shell, so users are

generally free to use the shell that best suits their needs. When PSA software is installed, certain configuration files will be

placed such that opening either the Tcl Shell or the Wish Shell will automatically integrate all of the PowerShell resources.

Figure 2.10 PSA Host Software Architecture

PSA Interactive

Graphical User

Interface Software PSE Test Suites

Conformance Suite

(excluding PSA-PL)

Multi-Port Suite

PoE Service Analyzer

(excluding PSA-PL)

PowerShell

TK/Tcl Based Application

Development Environment

10/100BaseT

Tk/Tcl 8.4.5

API

Tk/Tcl

Libraries

PowerSync Analyzer Software

Config

File(s)

Reports

PowerSync Analyzer

PSA Interactive

Graphical User

Interface Software PSE Test Suites

Conformance Suite

(excluding PSA-PL)

Multi-Port Suite

PoE Service Analyzer

(excluding PSA-PL)

PowerShell

TK/Tcl Based Application

Development Environment

10/100BaseT

Tk/Tcl 8.4.5

API

Tk/Tcl

Libraries

PowerSync Analyzer Software

Config

File(s)

ReportsReports

PowerSync Analyzer

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

16

Many test engineers will want to integrate PowerShell API into pre-existing script environments to support test automation

involving several instruments including DUT control interaction. The final chapter of this manual addresses PowerShell

features designed to enable this possibility.

2.4.3. PSE Automated Test Suites

The PSE Conformance Test Suite is an optional feature of the PSA-1200 (including PSA-100, PSA-2400) consisting of

23 tests and associated utilities that run in PowerShell and can be accessed and sequenced from either PowerShell or from

PSA Interactive. These tests are designed to assess 802.3af and 802.3at compliance of one or more PSE ports. The tests

cover detection, classification, power-up, power management, MPS, and power-down behaviors of PSE ports. The tests

have been constructed to work as generally as possible given the wide range of signaling and other PSE characteristics

described above in Section 2.2. Each test returns one or more specification parameters relating to the 802.3 PoE

specification.

The PSE Multi-Port Test Suite is an optional feature of the PSA-1200 (including PSA-2400) and PSA-PL consisting of

16 tests that automatically analyze PSE system powering characteristics including bulk power-on, power-down, and

overload processing characteristics as well as power management, power capacity, and stress test behaviors. Each test

returns a variety of multi-port statistics and offers the capability to generate detailed logs of PSE port interactions and

timing behaviors.

The PoE Service Analyzer is the aimed at qualifying PoE service delivered to a PD at the PD interface point. It evaluates

basic service capabilities, many interoperability parameters, and classification or power management behaviors of the PoE

service. This feature is available on all PSA-1200, PSA-100, and PSA-2400 platforms.

Each test suite includes a test sequencer and several report generation options including automatic Microsoft Excel

spreadsheet that reports test results, test statistics, test limits, and pass/fail results on one or more cycles of testing.

2.4.4. PowerSync Analyzer Configuration Files

PowerSync Analyzer software utilizes two local configuration files that can be adapted for a number of characteristics that

are “local” to a user’s setup and testing requirements. These files are located as follows:

Operating System Config Directory Location

Windows NT – Windows XP \Program Files\Sifos\PSA1200\Config\

Windows Vista & Windows 7 \Users\Public\Sifos\PSA1200\Config\

Linux & Unix $HOME/Sifos/PSA1200/Config/

The PSA Environment local configuration file is named psa_env.txt. This file is found in the subdirectory \env\ (or /env/

for Linux) beneath the above mentioned Config directory location. Only one instance of this configuration can exist in the

host computer. It contains system environment related parameters as described in the following table:

Parameter Type Parameter Values

Default_PSA_Address: <current PSA IP address>

PSA_Addresses: {<TCL List of known PSA IP addresses>}

Default_Conf_Test_List_AF: {<TCL List PSE Conformance Tests>}

Default_Conf_Test_List_AT: {<TCL List PSE Conformance Tests>}

Default_Test_Results_Path: {<TCL string of default path location for all test result files>}

Excel_Path_Location: {<TCL string of path route to MS Excel>}| “N/A”

Emulation_Mode: ON or OFF

I/O_Routing: psa

Default_PSA_Address: The PSA chassis to initially be controlled by the PowerShell and PSA Interactive when those

applications open up. This chassis will be automatically “inventoried” upon application initialization and initial PSA

connection. The address will be updated in this file whenever Select Chassis is performed via PSA Interactive or when the

psa command is executed in PowerShell assuming that the new address is valid and present.

PSA_Addresses: A (Tcl) list of “known” PSA Chassis addresses on the network. A Tcl list is enclosed in braces and uses

spaces to separate different elements (e.g. IP addresses). This list will evolve as new chassis are connected and selected by

either PSA Interactive or PowerShell.

Default_Conf_Test_List_AF: A (Tcl) list of available standard tests within the Version 3.4 PSE Conformance Test Suite

for 802.3af and pre-802.3at standard high power PSE’s.

Default_Conf_Test_List_AT: A (Tcl) list of available standard tests within the Version 4.0 PSE Conformance Test Suite

for 802.3at compliant PSE’s. Note: These tests are only available for the PSA-3000 platform.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

17

Default_Test_Results_Path: Path to where test results from the sequencer will be stored. This has the default value of

“c:/Program Files/Sifos/PSA1200/Results/<chassis IP Address>” when PSA software is initially installed. Note that PSE-

specific local configuration files may override this default (see below).

Excel_Path_Location: Path where Microsoft Excel application is stored. This is formed during installation.

Emulation_Mode: A control that allows software operation in the absence of a PowerSync Analyzer instrument. It is also

referred to as “Demo Mode”. This control should be normally set to “OFF”.

I/O_Routing: A control that should be normally set to “psa”.

A second type of configuration file is the Local PSE Configuration File for specific PSEs. These files generally (though

not necessarily) reside in the Config directory location described above. They must have .txt file extensions. There may

be more than one local configuration file, for example there may be one Local PSE Configuration File for each type of PSE

that a user plans to test.

The PSE Local Configuration file consists of the following settings:

Parameter Type Parameter Values Status

Default_PSE_Class: EndSpan or MidSpan Required

Default_PSE_MPS_Type: AC or DC Required

Default_ALT_Setting: Aor BRequired

Default_POL_Setting: MDI or MDI-X Required

PSE_High_Pwr_Grant: NONE or PHY or LLDP

PSE_Test_Results_Path: {<TCL string of path location for results files>}Optional

PSE_Conf_Test_Report: {<Non-standard Conformance Report template file>} Optional

PSE_MP_Test_Report: {<Non-standard Multi-Port Report template file>} Optional

Default_PSE_Class: Specifies whether the PSE is EndSpan or MidSpan equipment . This setting will be affected by the

PSE Type declaration in the PSE Conformance Test menus in PSA Interactive software and may also be configured in

PowerShell using the psaPseClass global variable. The PSE Class or Type is used to limit certain other PSE descriptors

(e.g. “LLDP” High Power Grant) and is fed to the PSE Conformance Standard Report for test limit processing.

Default_PSE_MPS_Type: Specifies whether PSE utilizes AC or DC MPS method to remove power from a PD. This

setting will be affected by the “DC MPS” vs “AC MPS” PSE Description controls in the PSA Interactive PSE

Conformance Test menus and Multi-Port Test Menus (see Section 3.3).

Default_ALT_Setting: Specifies how to initialize all ports within the PowerSync Programmable Load for ALT pair

selection. Initialization is performed ONLY when the local configuration file is loaded via the [File] [Load] operation in

PSA interactive or via the psa_pse ( = psa_getConfig) command in PowerShell. The [File] [Save] operation in PSA

Interactive or the psa_saveConfig command in PowerShell will store these settings using current PSA port configuration.

Initialization will automatically include all PSA chassis’ that make up a PSA-2400 RackPack PSA.

Default_POL_Setting: Specifies how to initialize all ports within the PowerSync Analyzer for PoE polarity (MDI vs

MDI-X). Initialization is performed ONLY when the local configuration file is loaded via the [File] [Load] operation in

PSA interactive or via the psa_pse ( = psa_getConfig) command in PowerShell. The [File] [Save] operation in PSA

Interactive or the psa_saveConfig command in PowerShell will save these settings using current PSA port configuration.

Initialization will automatically include all PSA chassis’ that make up a PSA-2400 RackPack PSA.

PSE_High_Pwr_Grant: Specifies the method used by a Type-2 PSE (as defined in IEEE 802.3at) to grant full power to a

Type-2 PD. Type-1, or 802.3af generation PSE’s must therefore specify NONE for this parameter since they are not

capable of delivering 30 Watts of power. Some PSE’s, such as Type-2 MidSpans, will specify PHY to indicate that they

use 2-event classification in response to a PD Class 4 signature to grant access to full power. Many Type-2 EndSpan

PSE’s may use Link Layer Discovery Protocol (LLDP) defined under 802.3at to grant access to full power – those PSE’s

will therefore use the LLDP setting. This setting is available under the PSE Conformance Test Menus in PSA Interactive

and may also be configured in PowerShell using the global psaPseHpGrant. As a setting it is used to gate access to high

power tests using Type-2 PD emulation, it is used to make decisions inside automated tests, and it is used by the

Conformance Test Standard Report in configuring test limits.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

18

PSE_Test_Results_Path: This parameter, if provided, will override the default test reporting path found in the

psa_env.txt environment file and guide all test results and reports to the specified directory path that can be PSE type or

model specific. NOTE: This setting can only be changed by editing the PSE local configuration file directly – the

setting is retained whenever a local configuration file is “loaded”, then “saved” by PSA Interactive or PowerShell.

PSE_Conf_Test_Report: Specifies a non-standard PSE Conformance Test template (spreadsheet) file for use by the PSE

Conformance Test Suite running on a PSA-1200 (or PSA-100, PSA-2400). An example might be a re-named copy of

psa_report.xls that has modified test limits for a particular PSE type. NOTE: This setting can only be changed by editing

the configuration file directly – the setting is retained whenever a local configuration file is “saved” by PSA Interactive

or PowerShell. See Section 5.10 of the PSA-1200 manual for further information.

PSE_MP_Test_Report: Specifies a non-standard PSE Multi-Port Test template (spreadsheet) file. An example might be

a re-named copy of mp_report.xls that has modified test limits for a particular PSE type. NOTE: This setting can only be

changed by editing the configuration file directly – the setting is retained whenever a local configuration file is “saved”

by PSA Interactive or PowerShell. See Section 6.11 for further information.

Note that changes to PSE Local Configuration Files required to make existing files compatible with PSA 3.4 Version

software will occur automatically after software is updated and those PSE Local Configuration Files are loaded or saved.

2.4.5. Directory and File Organization – Microsoft Windows

When PowerSync Analyzer software is installed to a Microsoft Windows®PC, files will be populated to particular

directories as described in the following table.

Directory Path Directory Files

PowerShell Script Library

PowerShell Wish and PowerShell Tcl Executables

PSA Initialization Script

PowerShell Wish and PowerShell Tcl resource files

\documentation\ Various PSA reference documents

C: \Program Files\Sifos\PSA1200

\PSA Interactive\ PSA Interactive Script Library and various library sub-

directories to support PSA Interactive functions (plotchart,

tkprint1.1, tbcload14, etc.).

PSA Interactive Executable

PSA Interactive resource file

\Config\ PSA (local) Configuration Files including \Config\env

environment file sub-directory.

\Results\ PSA Test Report Files

Including psa_report.xls, mp_report.xls, and

service_report.xls template report spreadsheets and the

psa_trace.xls trace display spreadsheet. Chassis-specific

subdirectories under \Results will automatically be created as

needed by PowerSync Analyzer software.

\Emul\ Files only used when PSAsoftware is placed in “Demo Mode”

(also called Emulation Mode).

Windows NT – Windows XP

C: \Program Files\Sifos\PSA1200

Windows Vista – Windows 7

C:\Users\Public\Sifos\PSA1200

\Contrib\ Tcl scripts stored in this directory will automatically source

into PowerShell. This directory includes various sample

scripts at installation.

Version information concerning individual PowerSync Analyzer software libraries is available from PSA Interactive under

the [Help] menu as well as from PowerShell using the psa_version command.

2.4.6. Directory and File Organization – Linux and Unix

PSA Software installs into Linux and Unix in a manner that separates and organizes files into 3 categories:

Category File Locations

Compiled Software and Libraries /usr/local/Sifos/PSA1200

Configuration and User Data <User’s Home Directory>/ Sifos/PSA1200

Shell Scripts (Program Launchers) <User’s Home Directory>/bin

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

19

This organization allows various users in a shared computing or NFS type of environment to maintain local user

information independent from other users and independent of the actual shared software modules and libraries.

Installation of PSA Software requires that the user have full permissions to add the application into the /usr/local/ directory

path while the installation takes place. After installation, those permissions may be removed.

The following table provides greater detail regarding files and file locations after PSA software installation is completed.

Directory Path Directory Files

PowerShell Application Programs & Script Libraries

PowerShell Wish and PowerShell Tcl resource files

(unused copies)

/usr/local/Sifos/PSA1200

/PSA

Interactive/

PSA Interactive Application Programs & Script

Libraries

Shared Library Directories with binaries and scripts

used by PowerShell and PSA Interactive

Copy of PSA Interactive initialization resource file

PowerShell Wish and PowerShell Tcl resource files

(used by shell scripts to initialize PSA software)

/Config/ PSE (local) Configuration Files including /Config/env

environment file sub-directory.

/Results/ PSA Test Report Files

Including psa_report.xls, mp_report.xls, and

service_report.xls template report spreadsheets and

the psa_trace.xls trace display spreadsheet. Chassis-

specific subdirectories under \Results will

automatically be created as needed by PowerSync

Analyzer software.

/documentation/ Various PSA reference documents

/Emul/ Files only used when PSA software is placed in “Demo

Mode” (also called Emulation Mode).

<User Home Path>/

Sifos/PSA1200

/Contrib/ Tcl scripts stored in this directory will automatically

source into PowerShell. This directory includes

various sample scripts at installation.

<User Home Path>/ bin Shell scripts to launch:

PowerShell TCL (PowerShell_TCL.sh),

PowerShell Wish (PowerShell_Wish.sh)

PSA Interactive PL (PSA_Interactive.sh).

PSA Software Installer and Removal Scripts.

Version information concerning individual PowerSync Analyzer software libraries is available from PSA Interactive PL

under the Help menu as well as from PowerShell using the psa_version command.

2.4.7. TK/TCL Requirements & Resources

PowerSync Analyzer software was developed utilizing Tcl/Tk version 8.4.5. Generally, there should not be a problem with

using newer versions of Tcl/Tk. PSA software is distributed with an installer for Tcl/Tk 8.4.5 on Microsoft Windows

platforms. If Tcl/Tk is not present on the host PC system or if a version older than 8.4.5 is found, PSA installation software

will install version 8.4.5 Tcl. If a newer version (e.g. ActiveState Tcl 8.4.9) is already on the host system, PSA software

will utilize that version. (Note: This does not apply to Linux systems where the user is responsible for pre-installing a

satisfactory version of Tcl/Tk.)

While there are no requirements as to where the user installs Tcl/Tk, it is recommended that the install be done in the

c:\Program Files\tcl directory on Microsoft Windows systems and in /usr/local/ on Linux systems. Users should beware

that older or specially modified versions of Tcl present from installations of various LAN analyzer software tools and

applications could interfere with PSA software behavior.

PowerShell software includes four “resource” files: tclshrc.tcl, tclshrc_psapi.tcl, wishrc.tcl and wishrc_psapi.tcl.

These files are utilized by PowerShell during initialization and should remain in the directories where they are initially

installed. Sections 8.3 and 8.4 of this manual provide further information regarding PowerShell API integration into native

TCL shells as well as the use of these files to enable remote access to PowerShell.

PowerSync Service Analyzer Reference Manual

February 8, 2010 Sifos Technologies page

20

There are a number of valuable resources to help programmers and test engineers get acquainted with Tcl. First, the help

software that comes with Tcl/Tk is very robust and easy to work with. Also, there are several books available including

“Practical Programming in Tcl and Tk” by Brent B. Welch. On the Web, there are numerous “notes” sites with

correspondence on Tcl and Tk programming owing to Tcl’s popularity in academic and commercial enterprises.

2.5. (Section Omitted)

2.6. (Section Omitted)

2.7. Technical Specifications

2.7.1. Port Configuration

Input/Output Ports 1 & 2 RJ45, 10/100/1000BaseT 100ΩBalanced

Pair Connectivity Ports 1 & 2 Alt. A or Alt. B

Polarity Ports 1 & 2 MDI or MDI-X

Detection Resistance Ports 1 & 2 Range 8 to 39 KΩ

Resolution 1KΩ

Accuracy 1%

Detection Capacitance Ports 1 & 2 Range 0.14, 5.14, 7.14, 11.14, 47,

52, 54, and 58 μF

Accuracy 5%

Load Current Ports 1 & 2 Range 0 to 511 mA

Resolution 0.5 mA

Error +

1.8% +1.1 mA

Activation Voltage 15.5V

Configurable Load Ports 1 & 2 Load Steps 2

Transient Range 200µs to 1sec

Resolution 100µs

2.7.2. Measurements

DC Voltage Pair-to-Pair Type Peak, Average, or Trace

Range 0 to 60V

Resolution 64mV

Error +

1.2% +13 mV

Peak Types Max or Min

Trace Length 256 Samples

Triggers Immediate, Internal, External

DC Current Powered Pair Type Peak, Average, or Trace

Range 0 to 511 mA

Resolution 0.5 mA

Error +

1.2% + .25mA

Peak Types Max or Min

Trace Length 256 Samples

Triggers Immediate, Internal, External

Voltage Ripple Pair-to-Pair Range 0 to 2Vpp

16Hz - 5kHz Resolution 4mV

Error TBD

%

Table of contents

Other Sifos Technologies Measuring Instrument manuals

Sifos Technologies

Sifos Technologies PSA-3000 User manual

Sifos Technologies

Sifos Technologies PowerSync PSA100 Product manual

Sifos Technologies

Sifos Technologies PowerSync PDA-300 User manual

Sifos Technologies

Sifos Technologies PowerSync PSA-3002-SA Product manual

Sifos Technologies

Sifos Technologies PowerSync PDA-300 Product manual

Sifos Technologies

Sifos Technologies PhyView PVA-3000 User manual

Sifos Technologies

Sifos Technologies PowerSync Series User manual

Sifos Technologies

Sifos Technologies PowerSync PSA100 User manual