PowerSync Analyzer Reference Manual

March 9, 2010 Sifos Technologies page

iv

3.1.8. DC Meters............................................................................................................................................................ 33

3.1.9. Triggered Measurements...................................................................................................................................... 34

3.1.10. The O-Scope Display........................................................................................................................................... 35

3.1.11. The Event Control Panel...................................................................................................................................... 36

3.1.12. AC Meter ............................................................................................................................................................. 37

3.1.13. Time Interval Meter ............................................................................................................................................. 38

3.1.14. Waveforms Menu ................................................................................................................................................ 39

3.1.15. PSA Interactive Help Menus................................................................................................................................ 41

3.2. PSE Conformance Test Suite Menus.............................................................................................................................42

3.2.1. PSE Conformance Tests Menu ............................................................................................................................ 42

3.2.2. PSE Conformance Test Sequencer Menu and PSE Conformance Reporting....................................................... 43

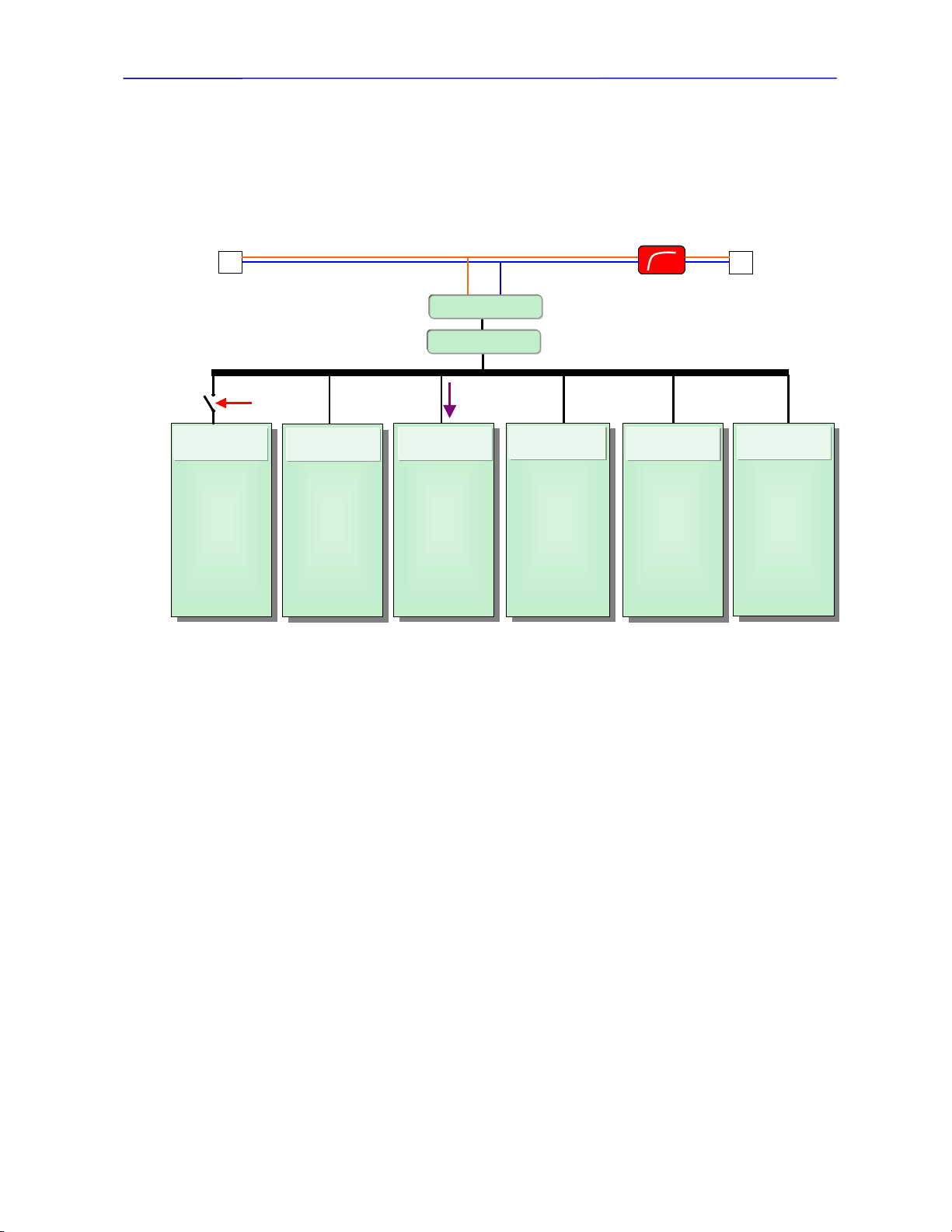

3.3. PSE Multi-Port Test Suite Menus...................................................................................................................................45

3.3.1. PSE Multi-Port Configure Resources Menu ........................................................................................................ 45

3.3.2. Multi-Port PSE Test Menu................................................................................................................................... 46

3.3.3. Multi-Port Test Sequencer Menu and Multi-Port Reporting................................................................................ 48

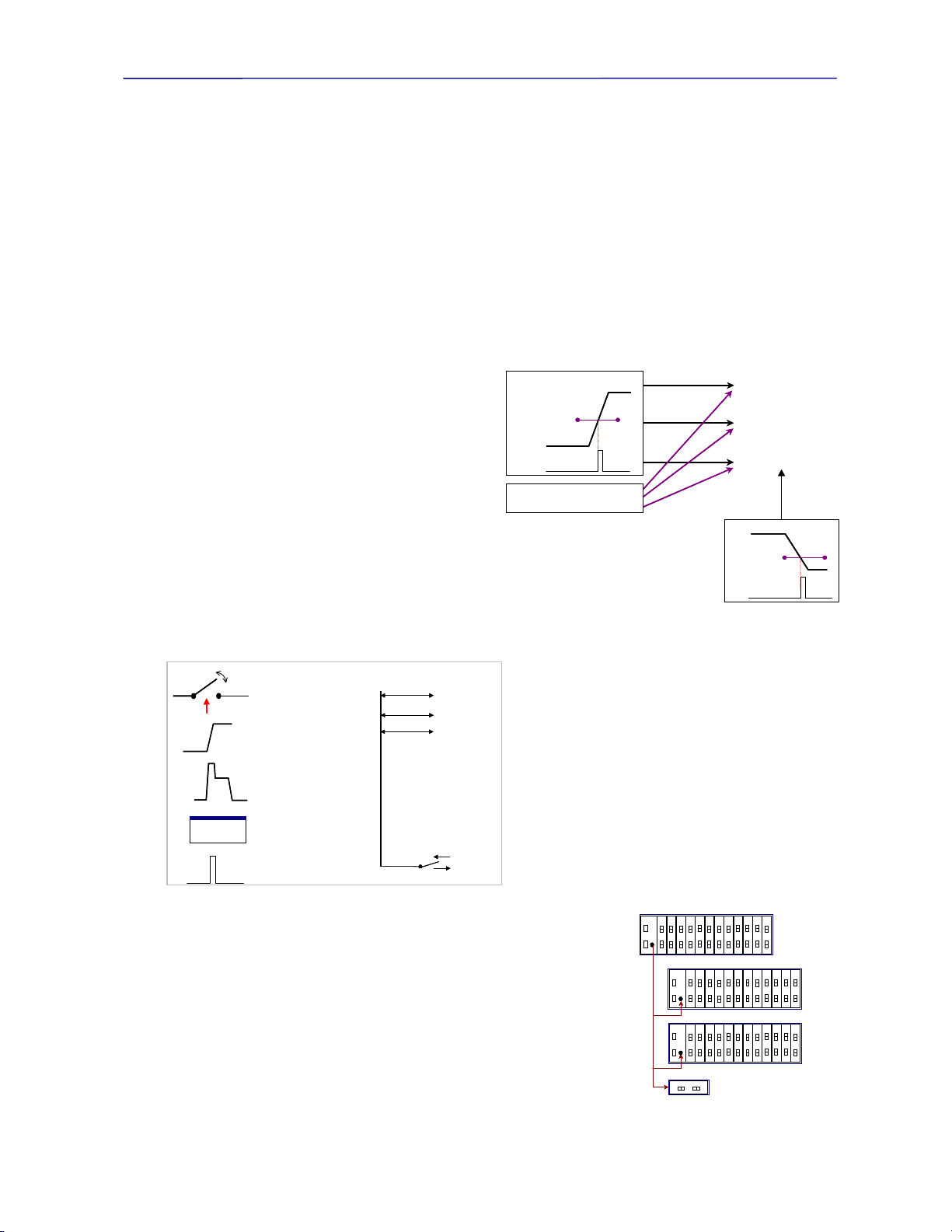

3.4. PSA Interactive Task Examples .....................................................................................................................................50

3.4.1. Observe a Class 1 Power-Up Sequence on Test Port 3,2 for an ALT A, MDI-X PSE Port ................................. 50

3.4.2. Repeat 3.2.1 Without using the Waveform Viewer.............................................................................................. 51

3.4.3. Measure Peak Detection Voltage on Port 1,2 with ALT A, MDI PSE................................................................. 51

3.4.4. Measuring Power-Up Slew Rate on ALT A, MDI-X PSE Port 5,1 using Class 0 PSE....................................... 53

3.4.5. Measuring Inrush Current during Class 3 Power-Up with ALT A, MDI PSE on Port 1,1................................... 54

3.5. Enabling PSA Interactive for the PSA2400 ...................................................................................................................55

4. PowerShell Scripting Environment...............................................................................................57

4.1. TCL and Wish Shells.......................................................................................................................................................57

4.1.1. Tcl Versus Wish in the PC Windows Environment ............................................................................................. 57

4.2. PSA Connection Dialog ..................................................................................................................................................57

4.3. PowerShell Syntax Conventions....................................................................................................................................58

4.4. PowerShell Help Capabilities .........................................................................................................................................58

4.5. PowerShell Connection and Configuration Commands..............................................................................................59

4.6. Test Port Configuration Commands..............................................................................................................................60

4.7. Test Port Measurement Commands..............................................................................................................................62

4.8. PowerShell Test Support Utilities..................................................................................................................................66

4.9. PowerShell Trace Display and Analysis Commands...................................................................................................69

4.10. PowerShell PSE Conformance Test Support Commands...........................................................................................71

4.11. PowerShell System & Chassis Commands ..................................................................................................................71

4.12. PowerShell Scripting Examples.....................................................................................................................................73

4.12.1. Capturing a Power-Up Trace to a Class 1 PD on Port 3,2.................................................................................... 73

4.12.2. Measure Peak Detection Voltage on Port 1,2....................................................................................................... 74

4.12.3. Power-Up Slew Rate Command Sequence .......................................................................................................... 75

4.12.4. Measure Class 3 Power-Up Current Inrush.......................................................................................................... 76

4.13. PowerShell PSE Conformance Test Commands..........................................................................................................77

4.14. PowerShell PSE Multi-Port Test Commands ................................................................................................................80

4.15. PowerShell Multi-Port Helper Commands.....................................................................................................................83

5. PSE Conformance Test Suite........................................................................................................85

5.1. PSE Conformance Test Suite Overview........................................................................................................................85

5.2. Global PSE Description Parameters..............................................................................................................................85

5.3. Conformance Test Documentation Conventions.........................................................................................................86

5.4. PSE Conformance Tests – Detection Processes .........................................................................................................86