Sime OPEN HYBRID MEM-ECO 25-6 Manual

Fonderie SIME S.p.A. 6328233B - 06/2022 - R0

INSTALLATION AND MAINTENANCE MANUAL

OPEN HYBRID MEM-ECO

EN

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

To consult the documentation,

visit our website www.sime.it

2

SAFETY WARNINGS AND REGULATIONS

m

WARNINGS

–After having removed the packaging

make sure that the product supplied is

integral and complete in all its parts. If

this is not the case, please contact the

Dealer who sold the appliance.

–The appliance must be used

as intended by

Sime

who is not

responsible for any damage caused to

persons, animals or things, improper

installation, adjustment, maintenance

and improper use of the appliance.

–In the event of water leaks, disconnect

the appliance from the mains power

supply, close the water mains and

promptly inform professionally

qualified personnel.

–Periodically check that the operating

pressure of the water heating system

when cold is

1-1.2 bar

. If this is not the

case, increase the pressure or contact

professionally qualified personnel.

–If the appliance is not used for a long

period of time,

ONLY WHEN THERE IS

THE RISK OF FREEZING

, at least one

of the following operations must be

carried out:

-

set the main system switch to "OFF";

-

close the gas and water valves for the

water heating system.

–If there is the risk of freezing, leave

the gas valves open and ensure the

appliance is connected to the mains

power. This way the anti-freeze function

will remain active if set appropriately.

–In order to ensure optimal appliance

operations

Sime

recommends that

maintenance and checks are carried

out

ONCE A YEAR

.

–If the power cable is damaged, replace

it with a cable ordered as a spare part

with the same characteristics (type X).

Assembly must be by carried out by a

qualified professional.

m

WARNINGS

–

It is recommended that all operators

read this manual carefully in order to

use the appliance in a safe and rational

manner.

–

This manual

is an integral part of the

appliance. It must therefore be kept

for future reference and must always

accompany the appliance in the event

the appliance is transferred or sold to

another Owner or User or is installed

on another system.

–

Installation and maintenance

of this

appliance must be carried out by a

qualified company or by a professionally

qualified technician in accordance

with the instructions contained in the

manual. Once the work is complete,

the company or technician will issue a

declaration of conformity with national

and local technical standards and

legislation in force in the country where

the appliance will be used.

–

Any repairs on the appliance

must be

carried out solely by professionally

qualified personnel, using original

spare parts only. Failure to comply

with these instructions can jeopardise

the appliance’s safety and void the

warranty with immediate effect.

–

Fonderie SIME S.p.A.

reserves the

right to make improvements to

its products at any time without

prior notice, without compromising

their essential characteristics. The

graphic illustrations and/or images

in this document may show optional

accessories that vary according to the

country in which the appliance is used.

3

RESTRICTIONS

d

IT IS FORBIDDEN

–To allow children under the age of 8 to

use the appliance. The appliance can be

used by children no younger than 8 years

old, by people with physical or cognitive

disabilities, and by people lacking

experience or the necessary knowledge,

provided that they are supervised or

have been instructed on how to use

the appliance safely and that they

understand the risks associated with it.

–To allow children to play with the

appliance.

–To allow unsupervised children to

perform user maintenance and

cleaning.

–To use electrical devices or appliances

such as switches, electrical appliances etc

if you can smell fuel. If this should happen:

-

open the doors and windows to air the room;

-

close the gas isolation device;

-

promptly call for professional

assistance.

–To touch the appliance with bare feet or

with any wet part of the body.

–To carry out any technical intervention

or cleaning operation before having

disconnected the appliance from the

mains power by setting the main switch

to "OFF", and closing the gas supply.

d

IT IS FORBIDDEN

–To modify the safety or adjustment

devices without authorization and

instructions from the manufacturer.

–To block the condensate drain (if

present).

–To pull, detach or twist the electrical

cables coming out of the appliance

even if the appliance is disconnected

from the mains power supply.

–To block or reduce the size of the

ventilation openings of the room where

the appliance is installed, if present.

–Remove the mains power and gas

supply from the appliance if the

external temperature could fall below

ZERO (risk of freezing).

–To leave containers with flammable

substances in the room where the

appliance is installed.

–To dispose of the packaging material

irresponsibly as it could be dangerous.

Packaging must be disposed of as

specified by the legislation in force in the

country where the appliance will be used.

4

MANUAL STRUCTURE

This manual is organized as follows.

Dear Customer,

Thank you for purchasing a

Sime OPEN HYBRID MEM-ECO

boiler,

a new-generation modulating condensing device with technical

features and excellent performance, allowing you to satisfy your

heating and instant domestic hot water requirements with the

utmost safety and limited running costs.

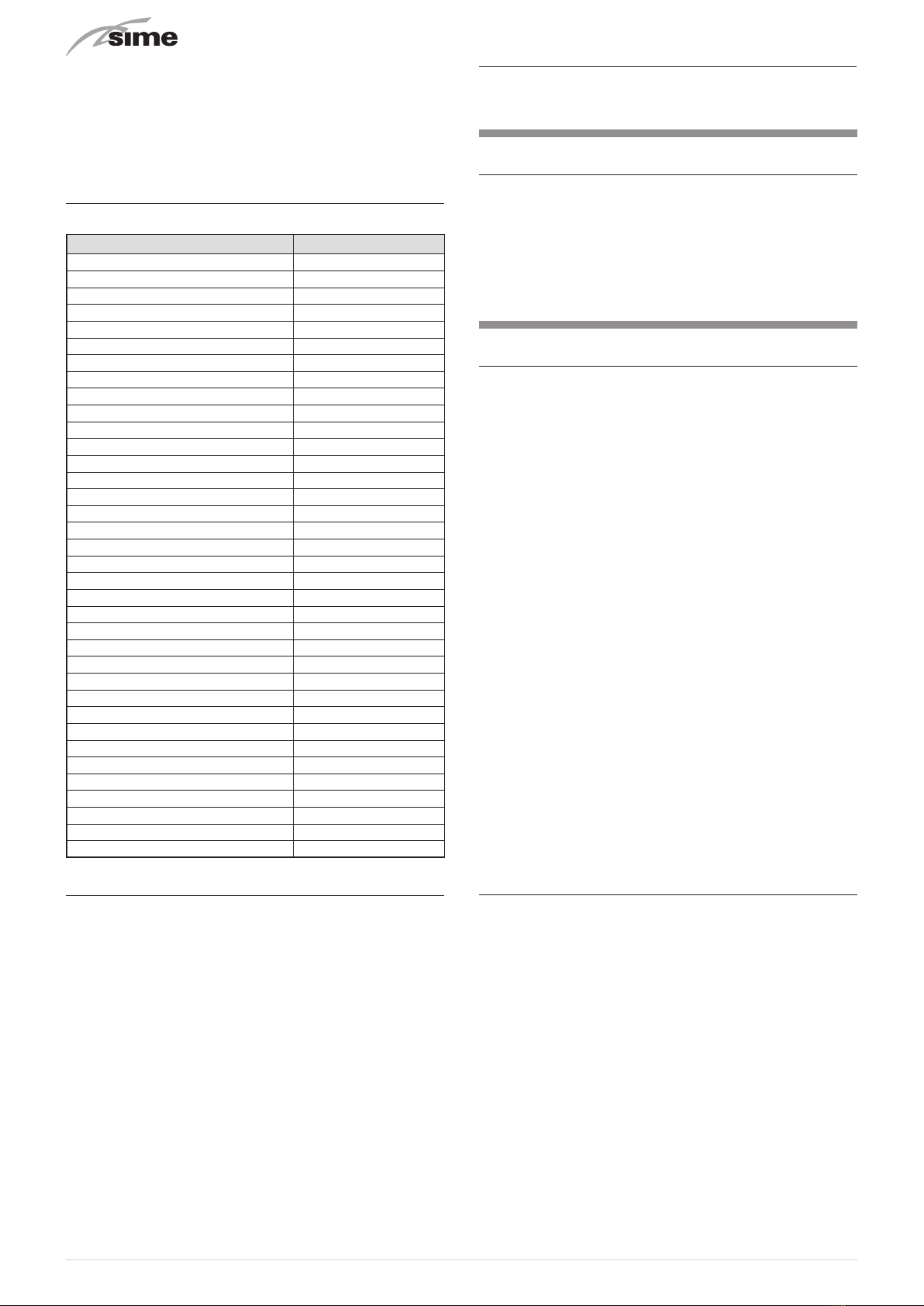

RANGE

MODEL CODE

OPEN HYBRID MEM-ECO 25-6 8117500

OPEN HYBRID MEM-ECO 25-6A 8118600

OPEN HYBRID MEM-ECO 25-8 8117501

OPEN HYBRID MEM-ECO 25-8A 8118601

OPEN HYBRID MEM-ECO 25-10 8117502

OPEN HYBRID MEM-ECO 25-12 8117503

OPEN HYBRID MEM ECO 30-6 8117504

OPEN HYBRID MEM ECO 30-6A 8118604

OPEN HYBRID MEM ECO 30-8 8117505

OPEN HYBRID MEM ECO 30-8A 8118605

OPEN HYBRID MEM ECO 30-10 8117506

OPEN HYBRID MEM ECO 30-12 8117507

OPEN HYBRID MEM ECO 35-6 8117508

OPEN HYBRID MEM ECO 35-6A 8118608

OPEN HYBRID MEM ECO 35-8 8117509

OPEN HYBRID MEM ECO 35-8A 8118609

OPEN HYBRID MEM ECO 35-10 8117510

OPEN HYBRID MEM ECO 35-12 8117511

OPEN HYBRID MEM-ECO 25-6 S 8117512

OPEN HYBRID MEM-ECO 25-6 S A 8118612

OPEN HYBRID MEM-ECO 25-8 S 8117513

OPEN HYBRID MEM-ECO 25-8 S A 8118613

OPEN HYBRID MEM-ECO 25-10 S 8117514

OPEN HYBRID MEM-ECO 25-12 S 8117515

OPEN HYBRID MEM ECO 30-6 S 8117516

OPEN HYBRID MEM ECO 30-6 S A 8118616

OPEN HYBRID MEM ECO 30-8 S 8117517

OPEN HYBRID MEM ECO 30-8 S A 8118617

OPEN HYBRID MEM ECO 30-10 S 8117518

OPEN HYBRID MEM ECO 30-12 S 8117519

OPEN HYBRID MEM ECO 35-6 S 8117520

OPEN HYBRID MEM ECO 35-6 S A 8118620

OPEN HYBRID MEM ECO 35-8 S 8117521

OPEN HYBRID MEM ECO 35-8 S A 8118621

OPEN HYBRID MEM ECO 35-10 S 8117522

OPEN HYBRID MEM ECO 35-12 S 8117523

COMPLIANCE

Our company declares that

OPEN HYBRID MEM-ECO

boilers

comply with the following directives:

–Gas Appliances EU Regulation 2016/426

–Low Voltage Directive 2014/35/EU

–Electromagnetic Compatibility Directive 2014/30/EU

–Ecodesign Directive 2009/125/EC

–Regulation (EU) No. 811/2013 - 813/2013

–Boiler Efficiency Directive 92/42/EEC

SYMBOLS

a

WARNING

To indicate actions which, if not carried out correctly,

can result in injury of a general nature or may damage

or cause the appliance to malfunction; these actions

therefore require particular caution and adequate

preparation.

f

ELECTRICAL HAZARD

To indicate actions which, if not carried out correctly,

could lead to injury of an electrical nature; these

actions therefore require particular caution and

adequate preparation.

d

IT IS FORBIDDEN

To indicate actions which MUST NOT BE carried out.

m

CAUTION

To indicate particularly important and useful

information.

OPEN HYBRID MEMECO SYSTEM

INDICE 5

1 SYSTEM description .................... 6

2 Installation........................... 19

3 Commissioning ....................... 32

4 Maintenance ......................... 48

5 Application diagrams .................. 51

6 Annexes ............................. 59

DESCRIPTION OF THE BOILER

TABLE OF CONTENTS 65

1 Description of the appliance ............ 66

2 Installation........................... 73

3 Commissioning ....................... 81

4 Maintenance ......................... 87

5 Annexes ............................. 90

5

OPEN HYBRID MEMECO SYSTEM

INDICE

1SYSTEM DESCRIPTION 6

1.1 Operation ......................................7

1.1.1 Domestic hot water . . . . . . . . . . . . . . . . . . . . 7

1.1.2 Heating .............................. 7

1.1.3 Cooling .............................. 8

1.1.4 Anti-freeze function .................... 8

1.1.5 Anti-blocking function .................. 8

1.1.6 Photovoltaic function ................... 8

1.1.7 Automatic filling function ............... 8

1.1.8 Automatic degassing function ........... 8

1.2 Structure ......................................9

1.3 Technical features ..............................10

1.3.1 Boiler ............................... 10

1.3.2 Heat pump........................... 11

1.4 Main water circuits .............................13

1.4.1 Open Hybrid MEM-ECO base ............ 13

1.4.2 Open Hybrid MEM-ECO base - High

Temperature kit....................... 13

1.4.3 Open Hybrid MEM-ECO base - High

Temperature Kit - Solar Kit ............. 14

1.5 Sensors.......................................15

1.6 Expansion vessels ..............................15

1.7 Circulation pump ..............................15

1.7.1 High temperature system pump ......... 15

1.7.2 Low temperature system pump.......... 15

1.7.3 Controlling operation of the pump ....... 15

1.8 Mem Remote Control ...........................16

1.9 Electrical panel ................................16

1.10 Wiring diagram ................................17

2INSTALLATION 19

2.1 Receiving the product ...........................19

2.2 Dimensions ...................................19

2.3 Handling ......................................19

2.4 Installation of the Open Hybrid MEM-ECO System....19

2.4.1 Heat pump installation................. 23

2.5 Smoke outlet and combustion air inlet .............24

2.5.1 Openings in the frame to allow the passage

of the smoke outlet.................... 24

2.5.2 Separate ducts (Ø 60/100mm) ........... 25

2.5.3 Separate ducts (Ø 60mm and Ø 80mm) ... 25

2.6 Mem Remote Control Installation .................26

2.7 Solar thermal storage tank connections............26

2.8 Position of the sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 Electrical connections...........................28

2.9.1 Connection to the mains ............... 28

2.9.2 Component connections................ 28

2.9.3 Boiler connections .................... 28

2.10 Filling operations...............................29

2.10.1 Automatic degassing function ........... 30

2.10.2 Setting boiler parameters .............. 30

2.11 Emptying operations ............................31

3COMMISSIONING 32

3.1 Preliminary operations ..........................32

3.2 Commissioning ................................32

3.3 Parameter setting and display ....................33

3.4 Complete list of parameters......................34

3.5 Parameter functions ............................37

3.5.1 General settings ...................... 37

3.5.2 Generation System Settings............. 38

3.5.3 Input and Output Configuration .......... 40

3.5.4 Heating ............................. 41

3.5.5 Cooling.............................. 43

3.5.6 DHW................................ 44

3.5.7 Energy Settings....................... 45

3.5.8 Communication....................... 46

3.6 Setting the circulation pump .....................47

3.6.1 Settings mode ........................ 47

3.6.2 Venting.............................. 47

3.6.3 Manual restart ....................... 47

3.6.4 Locking/unlocking the button ........... 47

3.6.5 Activating factory settings .............. 47

3.6.6 Manual restart ....................... 47

4MAINTENANCE 48

4.1 Adjustments...................................48

4.2 Alarms .......................................48

4.3 Pump troubleshooting...........................50

4.4 Pump troubleshooting...........................50

4.5 Alarm log .....................................50

5APPLICATION DIAGRAMS 51

6ANNEXES 59

6.1 Boiler product board ............................59

6

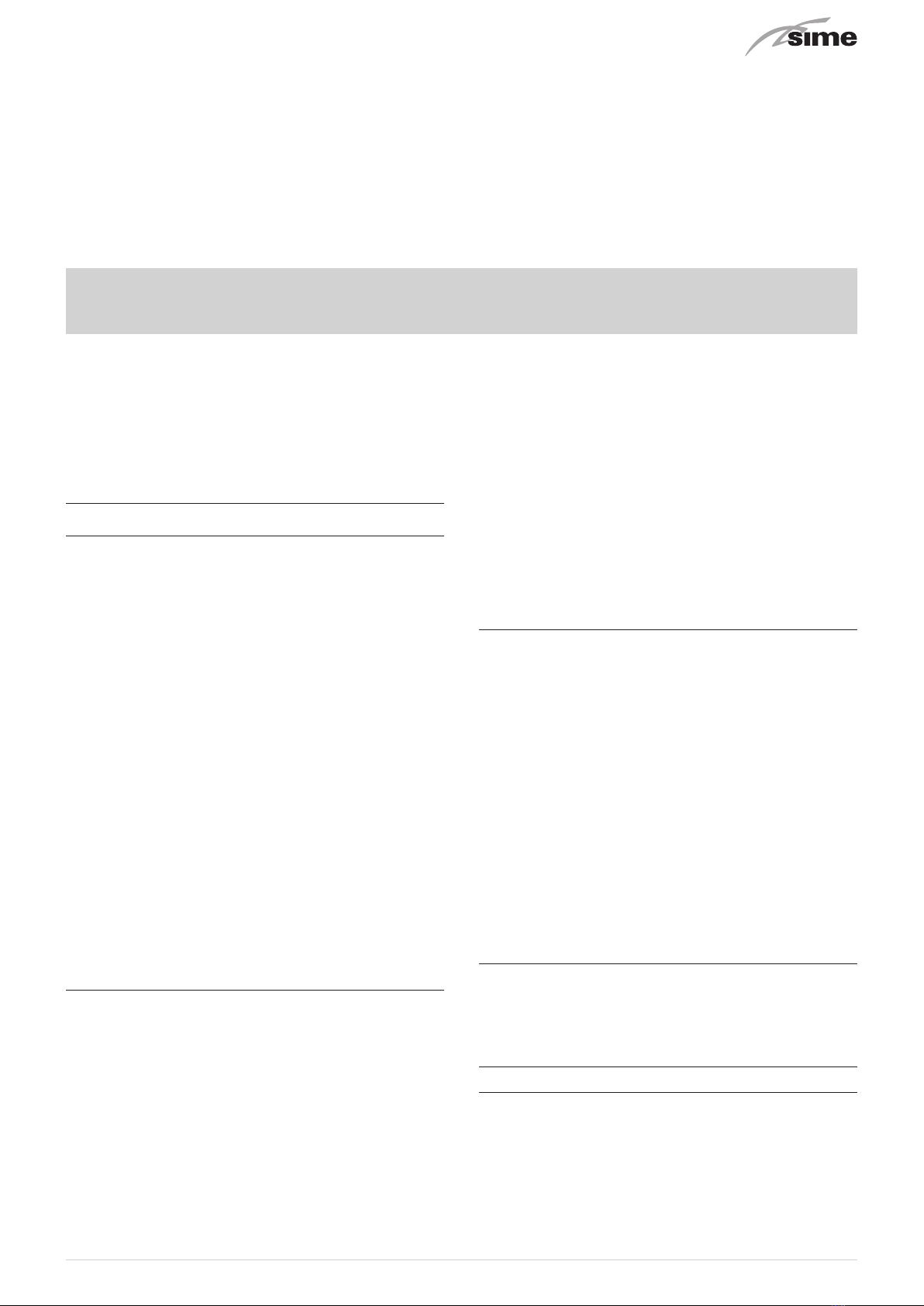

1 SYSTEM DESCRIPTION

OPEN HYBRID MEM-ECO

systems are built-in, “modular” sys-

tems for heating and cooling rooms and for the production of

domestic hot water. They can be "assembled" on the basis of

the system needs requested by the customer.

The basic

OPEN HYBRID MEM-ECO

structure consists of:

– Enclosure frame, fully recessed for outdoors, or in cabinet

for indoors. This must be ordered and installed before the

"components" are requested.

– Basic appliances/components (to be installed inside the

built-in housing structure):

– Hot water storage tank in stainless steel with a capacity

of 150 litres.

– 25, 30 or 35 kW hot water on-demand condensing boiler

– Main electrical panel.

– 8 litre hot water expansion vessel

– Relief valve and pump.

– Pipes for connecting all the appliances which make up

the system.

– A bag containing nuts, bolts and screws, the technical

data plate and the assembly instructions.

– Single column solar panel assembly complete with all the

water circuit elements needed for operating a solar ther-

mal circuit if installed (optional).

– Thermostatic mixer (optional)

– 12 litre solar thermal expansion vessel (optional)

Additional appliances/devices to complete the basic/mini-

mum structure:

–

Sime

SHP M ECO

heat pump to be selected on the basis of

system requirements

– MRM Remote Control to manage the entire system.

In the basic configuration,

OPEN HYBRID MEM-ECO

systems

provide hot water at a maximum delivery temperature of 60°C

and return temperature of 50°C, but they can also be integrat-

ed with the following optional kits:

– High temperature kit: to manage system terminals such as

radiators, fan convectors.

– Solar kit: to use the SIMESOL 182 solar panel to produce

domestic hot water maximising the use of alternative ener-

gy and limiting boiler usage.

m

WARNING

– With this appliance the USE OF THE EXTERNAL

SENSOR IS COMPULSORY for the boiler to work

with a sliding temperature (delivery temperature

varies automatically on the basis of the external

temperature detected), for the activation of the an-

ti-freeze function and to calculate the convenience

of the energy sources.

– Commissioning of the

Open Hybrid MEM-ECO

system

must be carried out by qualified technicians.

Fig. 1

7

1.1 Operation

1.1.1 Domestic hot water

The 150 litre hot water storage tank in STAINLESS STEEL is

made exclusively from renewable sources with the following

priorities:

1

Solar Thermal Energy (if present);

2

Heat pump.

The domestic hot water prepared in the storage tank always

remains in the boiler before being used. The boiler burner is

activated by the MEM only if the inlet temperature does not

reach the setpoint set by the user.

– Weekly programming from the MEM display for the prepa-

ration of the domestic hot water and therefore of the stor-

age tank.

– The solar thermal system (if present) can prepare the 150

litres of hot water in the storage tank at the maximum tem-

perature of 90°C. The actual energy ratio depends on the

solar rays which the solar collector is subject to. The solar

thermal pump is managed by the MEM on the basis of the

storage tank-collector and implements the ANTI-FREEZE

COLLECTOR, COOLING COLLECTOR).

– The heat pump can prepare 150 litres of hot water in the

storage tank up to the maximum temperature of 50°C.

Preparation by the heat pump only occurs in periods in

COMFORT mode. To allow for preparation when also in RE-

DUCED mode, act on the specific parameter.

– The amply dimensioned plate heat exchanger allows the

heat pump to operate with high COP values also for the

preparation of domestic hot water in addition to reduced

restore times. Management by the MEM includes activation

of the heat pump only when the storage tank is almost com-

pletely depleted of hot water in order to reduce the number

of start-ups to a minimum and to allow the heat pump to

operate at low temperatures (high COP).

– The actual preparation temperature of the storage tank by

the heat pump is calculated dynamically by the MEM on the

basis of the efficiency conditions (external temperature +

delivery temperature).

– The MEM manages the heat pump domestic hot water pri-

ority on the basis of some modifiable parameters:

–Priority in the summer (COOLING or DOMESTIC HOT WATER

with maximum time to be set). Default priority COOLING

– Priority in the winter (HEATING or DOMESTIC HOT WATER

with maximum time to be set). Default priority DOMESTIC

HOT WATER for no more than 30 minutes.

– The ANTI-LEGIONELLA function, if enabled, includes prepa-

ration of the storage tank at a temperature of 55°C (main-

tained for approximately 2 hours) once a week for bacteria

sanitisation.

1.1.2 Heating

– The heating request is made by means of the dry contact

(for example, a safety limit microswitch, etc..).

– The medium-low temperature heating circuit can reach a

maximum delivery temperature of 55°C with only the heat

pump operating. It is possible to reach a temperature of

60°C (return 50°C) with the combined heat pump - boiler

operation.

– The 30 litre inertial storage tank acts as a thermal flywheel

(needed by the heat pump) and hydraulic separator allow-

ing operation with any flow rate processed by the system.

Thanks to the specific design, the inertial tank always guar-

antees the best possible working conditions for the heat

pump making it work at the minimum temperature made

available by the system (no mixing of the return water inside

the inertial storage tank).

– The delivery setpoint can be set by the user at a fixed value

or it can be calculated dynamically by the MEM on the basis

of the external temperature and the selected climatic curve.

– System safety thermostat (50°C fixed calibration with the

option of deactivating the parameter) to protect the radiat-

ing system at low temperatures.

– In every operating condition, the MEM control unit calcu-

lates the heat pump COP (external temperature + delivery

temperature) and therefore whether the boiler or the heat

pump is most appropriate and it controls the subsequent

activation. If the most appropriate source is not sufficient to

cover the system needs, the other source can be activated

at the same time for the minimum energy needed to reach

the setpoint (this function can be set by the specific param-

eters). This way AND (simultaneous) operation is possible of

the sources allowing the heat pump to be activated even in

conditions in which it would normally be switched off as the

power output is less than the system requirements.

– The power modulation of the heat pump and the boiler is

always controlled by the MEM at the minimum level neces-

sary to meet the set system setpoint (there is no increase in

the generator setpoint in relation to the system if not nec-

essary).

–The defrost function of the heat pump is controlled by the MEM

eliminating almost all temporary comfort loss and compen-

sating the energy withdrawn from the system or the boiler.

– Using the MEM parameters, it is possible to set gas and

electrical energy costs to allow the dynamic calculation of

the financial advantage of using each individual source. If

this data is not available, the energy convenience will still

be calculated (primary energy equivalence).

– The high efficiency and high flow-head modulating pump

is able to guarantee the necessary flow rate to the system

adjusting the number of revolutions (and therefore the con-

sumption) on the basis of the instantaneous absorbed pow-

er of the system.

– Option of installing a HIGH TEMPERATURE KIT for an addi-

tional heating circuit with delivery temperature up to 80°C.

This circuit is used exclusively by the boiler as the temper-

atures are too high for the heat pump to operate. If the re-

quest is made for the boiler to operate together with the

high and low temperature circuits, the boiler generates with

a high temperature setpoint while the low-temperature cir-

cuit is adjusted by means of a distribution valve before mix-

ing inside the puffer to obtain the set temperature.

8

1.1.3 Cooling

– Setting the summer mode (cooling) from the remote display

or remote contact (option of installing a summer/winter se-

lector for the user's convenience - not supplied).

– The cooling request is made by means of the dry contact (for

example, a safety limit microswitch, etc..).

– Heat pump operation only in cool mode.

– Fixed system setpoint set by the user.

– Humidistat input (dry contact) for a second setpoint which

can be set by the installer for dehumidification (reduction)

or to prevent the formation of condensate in the radiating

system (increase).

– The power modulation of the heat pump is always controlled

by the MEM at the minimum level necessary to meet the set

system setpoint (there is no reduction in the heat pump set-

point in relation to the system if not necessary).

– 30 litre puffer and pipes with insulation present. The install-

er must complete the insulation of the connection points as

indicated in the installation manual.

1.1.4 Anti-freeze function

–Protection activated by the MEM with activation of the pumps,

valves and generators on the basis of the temperatures de-

tected by the sensors (electrical power is required). It is es-

sential that there is a correctly installed external sensor.

1.1.5 Anti-blocking function

– Function controlled by the MEM with the activation of all the

active organs after a period of inactivity to prevent blocking

(electrical power is required).

1.1.6 Photovoltaic function

– Function managed by the MEM to increase the amount of

auto-consumption of the electrical energy produced by a

photovoltaic system if installed.

1.1.7 Automatic filling function

– If system pressure drops with the subsequent intervention

of the low pressure alarm, it is possible to refill simply be

pressing a button on the display.

1.1.8 Automatic degassing function

– Function to be activated by the installer or technical per-

sonnel to allow rapid degassing of the air inside the system

during commissioning

– In any case, the system must be made according to the di-

agrams present in the installation manual and goose-neck

fittings are to be avoided.

– If they cannot be avoided, the installer must ensure that

there are bleed devices in the top sections.

9

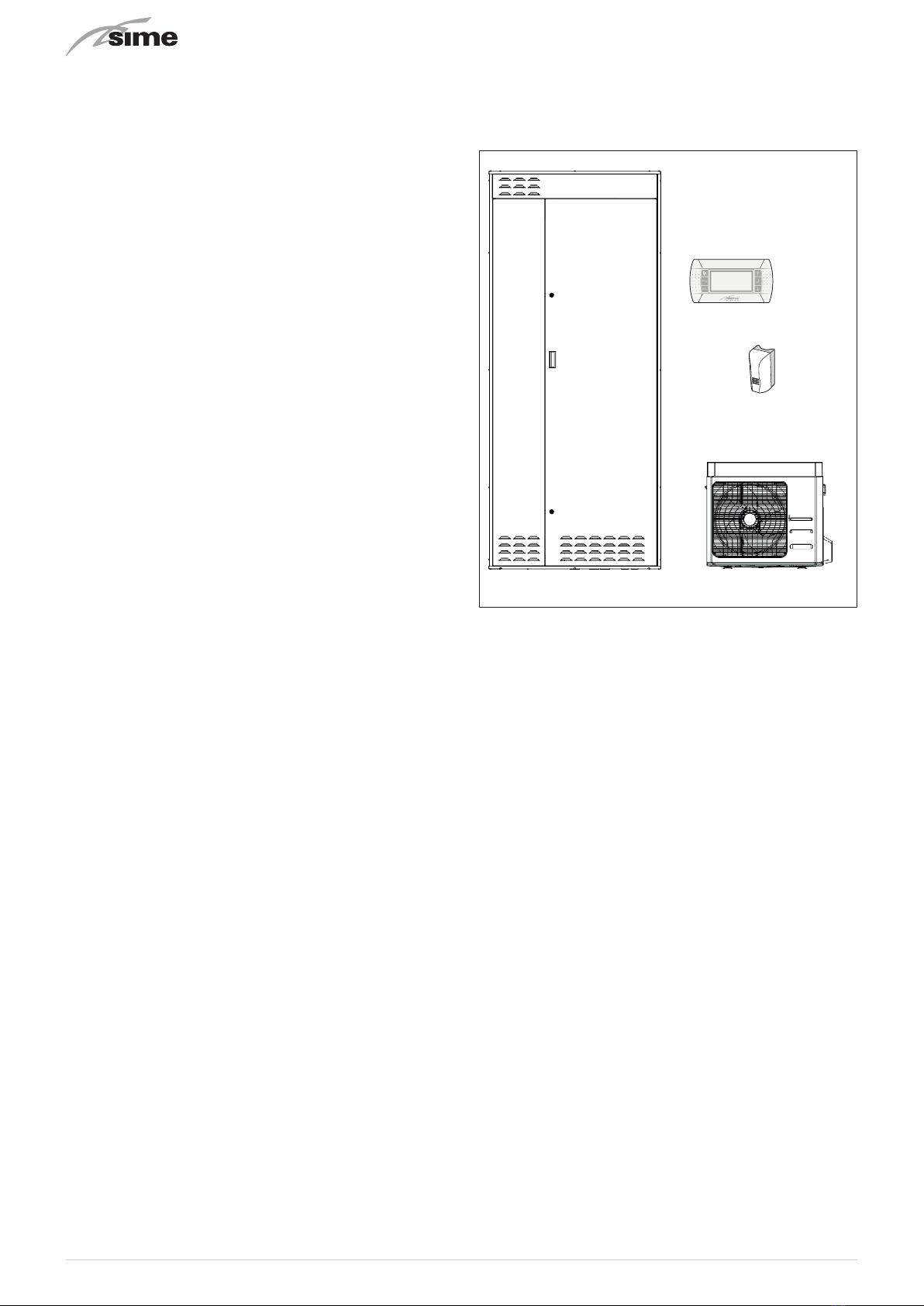

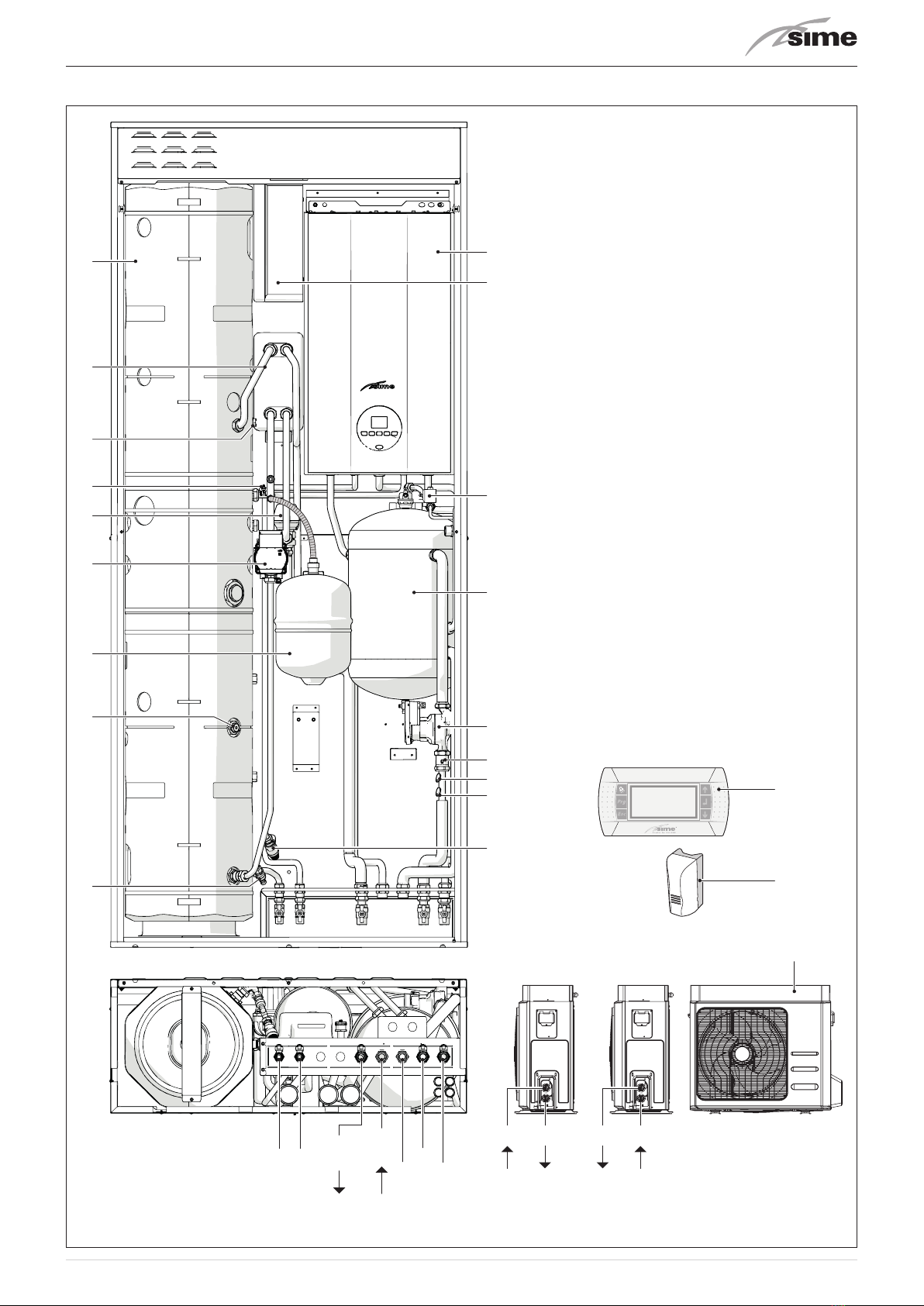

1.2 Structure

1

2

6

5

4

3

8

7

9

18

15

20

19

16

14

13

12

11

10

17

E U IN

PdC

OUT

PdC

Rbt

Mbt

G

OUT

SHP M ECO

006-008 SHP M ECO

010-012

IN

21

INOUT

Fig. 2

KEY

1

150 litre domestic hot water storage tank

2

Plate heat exchanger (

Sp

)

3

Sensor socket

B1

4

Sensor

B5

5

Diverter valve (

VD

)

6

Domestic hot water pump (

PS

)

7

Domestic hot water expansion vessel (

Ve

)

8

Sensor socket

B2

9

Domestic hot water storage tank drain valve (

Rs

)

10

Domestic hot water relief valve (

Vs

)

11

Sensor

B3

12

System safety thermostat (

TS

)

13

Check valve (

Vr

)

14

Low temperature system pump

(

PI

)

15

Inertial puffer

16

Automatic filling

(EV)

17

Electrical panel

18

Condensation boiler

19

Mem Remote control

20

External sensor (

SE

)

21 Sime

SHP M ECO heat pump

E

Domestic hot water inlet (Ø 1/2”)

U

Domestic hot water output (Ø 1/2”)

IN PdC

Heat pump return (Ø 3/4”)

OUT PdC

Heat pump delivery (Ø 3/4”)

Rbt

Low temperature system return (Ø 3/4”)

Mbt

Low temperature system delivery (Ø 3/4”)

G

Gas supply (Ø 3/4”)

IN

Heat pump inlet (Ø 1”)

OUT

Heat pump outlet (Ø 1”)

10

1.3 Technical features

1.3.1 Boiler

DESCRIPTION

OPEN HYBRID MEM-ECO OPEN HYBRID MEM ECO

25 30 35

CERTIFICATIONS

Country of intended installation IT – ES – PT – SI – PL

Fuel G20 / G31

PIN number II2HM3P - II2H3P

Category II2HM3P

Appliance classification B23P - B33P - B53P - C13 - C33 - C43 - C53 - C63 - C83 - C93 -

C(10)3

Class NOx (*) 6 (< 56 mg/kWh)

DHW rated useful heat output kW 24,0 28,0 34,8

HEATING PERFORMANCE

HEAT INPUT (**)

Nominal flow (Qn max) kW 24 24 30

Minimum flow (Qnw min) kW 4,8 4,8 6

HEAT OUTPUT

Nominal (80-60°C) (Pn max) kW 23,6 23,6 29,5

Nominal (50-30°C) (Pn max) kW 25,7 25,7 32,2

Minimum G20 (80-60°C) (Pn min) kW 4,7 4,7 5,9

Minimum G20 (50-30°C) (Pn min) kW 5,1 5,1 6,5

Minimum G31 (80-60°C) (Pn min) kW 4,7 4,7 5,9

Minimum G31 (50-30°C) (Pn min) kW 5,1 5,1 6,5

EFFICIENCY

Max useful efficiency (80-60°C) % 98,3 98,3 98,3

Min useful efficiency (80-60°C) % 97,9 97,9 98,3

Max useful efficiency (50-30°C) % 107,1 107,1 107,3

Min useful efficiency (50-30°C) % 106,3 106,3 108,3

Useful efficiency at 30% of load (40-30°C) % 108,5 108,5 108,5

Losses after shutdown at 50°C W 88 88 88

DOMESTIC HOT WATER PERFORMANCE

Nominal heat input (Qnw max) kW 24 28 34,8

Minimum heat input (Qnw min) kW 4,8 6

Specific D.H.W. flow rate ∆T 30°C (EN 13203) l/min 11,2 12,9 16,5

Continuous D.H.W. flow rate (∆T 25°C / ∆T 35°C) l/min 13,6 / 9,7 16,1 / 11,5 20 / 14,3

Minimum D.H.W. flow rate l/min 2 2 2

Max (PMW) / Min Pressure bar 7 / 0,5 7 / 0,5 7 / 0,5

kPa 700 / 50 700 / 50 700 / 50

ENERGY PERFORMANCE

HEATING

Heating seasonal energy efficiency class AAA

Heating seasonal energy efficiency % 93 93 93

Sound power dB(A) 53 53 50

DOMESTIC HOT WATER

Domestic hot water energy efficiency class AAA

Domestic hot water energy efficiency % 86 84 85

Stated domestic hot water profile load XL XL XL

ELECTRICAL SPECIFICATIONS

Power supply voltage V 230

Frequency Hz 50

Absorbed electrical power (Qn max) W 85 85 92

Absorbed electrical power at (Qn min) W 52 52 57

Absorbed electrical power in stand-by W 3,6 3,6 3,6

Electrical protection degree IP X5D

COMBUSTION DATA

Smoke temperature at Max/Min flow (80-60°C) °C 82 / 71 89 / 71 77 / 67

Smoke temperature at Max/Min flow (50-30°C) °C 59 / 51 71 / 51 58 / 49

Smoke flow Max/Min g/s 11,2 / 2,2 13,1 / 2,2 16,3 / 2,8

CO2 at Max/Min flow rate (G20) % 9,0 / 9,0 9,0 / 9,0 9,0 / 9,0

CO2 at Max/Min flow rate (G31) % 10,0 /10,0 10,0 /10,0 10,0 / 10,0

NOx measured mg/kWh 37 37 33

11

DESCRIPTION

OPEN HYBRID MEM-ECO OPEN HYBRID MEM ECO

25 30 35

NOZZLES GAS

Number of nozzles No. 1 1 1

Nozzle diameter (G20-G31) mm 5,3 5,3 6,5

Gas consumption at Max/Min flow rate (G20) m3/h 2,54 / 0,5 2,96 / 0,50 3,70 / 0,63

Gas consumption at Max/Min flow rate (G31) kg/h 1,87 / 0,37 2,17 / 0,37 2,71 / 0,46

Gas supply pressure (G20/G31) mbar 20 / 37 20 / 37 20 / 37

kPa 2 / 3,7 2 / 3,7 2 / 3,7

TEMPERATURE PRESSURE

Max operating temperature (T max) °C 85

Heating adjustment range °C 20÷80

Domestic hot water adjustment range °C 10÷60

Max operating pressure (PMS) bar 3

kPa 300

Water content in boiler l 4,75 4,75 4,95

(*) NOx class according to UNI EN 15502-1:2015

(**) Heat input calculated using the lower heat output (Hi)

Lower Heat Output (Hi)

G20 Hi.

9.45 kW/m

3

(15°C, 1013 mbar) -

G31 Hi.

12.87 kW/kg (15°C, 1013 mbar)

1.3.2 Heat pump

DESCRIPTION

SHP M ECO

06 06A 08 08A 10 12

COOLING

Cooling capacity (1) kW 3,20 / 5,02

/ 5,52 (*)

3,22 / 5,19

/ 5,71 (*)

3,80 / 6,08

/ 6,69 (*)

3,74 / 6,14

/ 6,65 (*)

4,66 / 7,53

/ 8,28 (*)

4,55 / 8,51

/ 9,36 (*)

Absorbed power (1) kW 1,60 1,64 1,99 1,97 2,39 2,79

E.E.R. (1) W/W 3,14 3,16 3,05 3,12 3,15 3,05

Cooling capacity (2) min/nom/max kW 4,82 / 6,18

/ 6,80 (*)

5,52 / 6,37

/ 6,72 (*)

4,91 / 7,72

/ 8,49 (*)

5,58 / 8,03

/ 8,67 (*)

6,22 / 9,50

/ 10,45 (*)

6,41 /

11,60 /

12,76 (*)

Absorbed power (2) kW 1,28 1,30 1,76 1,79 2,15 2,79

E.E.R. (2) W/W 4,82 4,90 4,38 4,49 4,41 4,16

SEER (5) W/W 4,12 4,42 4,25 4,51 4,15 4,25

Water flow rate (1) L/s 0,24 0,25 0,28 0,29 0,36 0,41

User-side heat exchanger head loss (1) kPa 2,0 3,2 2,8 5,3 6,9 8,8

HEATING

Heat Output (3) min/nom/max kW 3,95 / 6,08

/ 6,99 (*)

4,47 / 6,13

/ 7,48 (*)

3,95 / 7,81

/ 8,98 (*)

4,51 / 7,81

/ 9,42 (*)

5,33 /

10,10 /

11,62 (*)

5,33 /

11,80 /

13,57 (*)

Absorbed power (3) kW 1,35 1,25 1,78 1,71 2,28 2,73

C.O.P. (3) W/W 4,51 4,90 4,38 4,57 4,43 4,32

Heat Output (4) min/nom/max kW 3,82 / 5,88

/ 6,76 (*)

4,29 / 5,97

/ 7,03 (*)

3,80 / 7,58

/ 8,72 (*)

4,24 / 7,71

/ 8,99 (*)

5,18 / 9,76

/ 11,22 (*)

5,13 /

11,47 /

13,19 (*)

Absorbed power (4) kW 1,66 1,58 2,17 2,11 2,80 3,33

C.O.P. (4) W/W 3,54 3,78 3,50 3,65 3,48 3,44

SCOP (6) W/W 4,46 4,53 4,47

Water flow rate (4) L/s 0,28 0,29 0,37 0,37 0,47 0,55

User-side heat exchanger head loss (4) kPa 2,1 4,4 3,3 8,6 9,7 13,1

Water energy efficiency 35°C / 55°C Class A+++ / A++

COMPRESSOR

Type Twin Rotary DC Inverter

Refrigerating oil (type)

ESTEL

OIL RB

74A F

ESTEL

OIL VG74

ESTEL

OIL RB

74A F

ESTEL OIL VG74

Number of compressors 1

Oil charge (quantity) L 0,67 0,62 0,67 0,62 1

Cooling circuits 1

REFRIGERANT

Type R32

Refrigerant charge (7) kg 1,5 0,97 1,5 0,97 2,5

Quantity of refrigerant in tons of Co2 equivalent (7) ton 1,0 0,7 1,0 0,7 1,7

Design pressure (high/low) in heat pump mode bar 42,8 / 1,3

Design pressure (high/low) in chiller mode bar 42,8 / 3,5

(*) Activating the maximum Hz function.

12

DESCRIPTION

SHP M ECO

06 06A 08 08A 10 12

EXTERNAL ZONE FANS

Type DC Brushless Motor

Number 1

INTERNAL HEAT EXCHANGER

Type of internal heat exchanger Plate

No. of internal heat exchangers 1

Water content L 0,9 0,6 0,9 0,6 1,2

WATER CIRCUIT

Nominal useful head (1) kPa 78,8 74,9 76,0 71,0 68,9 63,4

Water content of the hydronic circuit L 1,4 1,14 1,4 1,14 1,8

Maximum pressure on water side bar 6

Plumbing connections inch 1” M

Minimum water volume L 40 50 60

Circulator pump maximum power kW 0,075 0,10 0,075 0,10 0,075

Circulator pump maximum current draw A 0,38 0,66 0,38 0,66 0,38

Energy Efficiency Index (EEI) circulator pump ≤ 0,21

NOISE LEVEL

Sound power Lw (8) dB(A) 64 65

Sound power at 1 m distance Lp1 (9) dB(A) 49,8 49,4 50,4

Sound power at 10 m distance Lp10 (9) dB(A) 32,8 32,7 33,7

ELECTRICAL SPECIFICATIONS

Power supply 230V/1/50Hz

Maximum absorbed power kW 3,5 3,4 3,9 4,1 4,6 5,1

Maximum absorbed current A 15,1 15,5 17,0 18,7 20,2 22,1

Maximum power absorption with anti-freeze kit kW 3,6 3,5 4,0 4,2 4,8 5,2

Maximum current absorption with anti-freeze kit A 15,6 15,9 17,6 19,1 20,7 22,7

Power supply unit 230V/1PH+PE/50Hz

On-board control circuit 12V/1/50Hz

Remote control circuit 12V/1/50Hz

Fan power supply 230V/1/50Hz

DIMENSION AND WEIGHTS

Dimensions (WxHxD) mm 924 x 828 x 377 1047 x 936 x 455

Max dimensions of package (WxHxD) mm 970 x 985 x 395 1080 x 1130 x 510

Shipping weight kg 84 110

Operating weight kg 72 96

Performance with the following conditions:

(1) COOLING: external air temperature 35°C; water temperature in/out 12/7°C..

(2) COOLING: external air temperature 35°C; water temperature in/out 23/18°C..

(3) Heating: external air temperature 7°C b.s. 6°C b.u.; water temperature in/out 30/35°C..

(4) Heating: external air temperature 7°C b.s. 6°C b.u.; water temperature in/out 40/45°C..

(5) COOLING: Input/output water temperature 7/12°C.

(6) Heating: average climatic conditions; Tbiv=-7°C; water temperature in/out 30/35°C.

(7) Indicative data subject to change. For the correct data, always refer to the technical label affixed to the unit.

(8) Sound power: condition heating mode (3); value determined based on measurements carried out in accordance with standard

UNI EN ISO 9614-2, in full compliance with the requirements of Eurovent certification.

(9) Sound pressure: value calculated from the sound power level using the ISO 3744:2010 standard.

13

1.4 Main water circuits

1.4.1 Open Hybrid MEM-ECO base

LOW

TEMPERATURE

SYSTEM

PUFFER

PI

Vr

Vr PS

Vs

Sp

Water mains

Water mains

DOMESTIC HOT WATER

STORAGE HEATER

VD

F

HEAT

PUMP

MU E R

SE

Vr

B2

B5

B3

TS

B1

Ve

VM

Fig. 3

1.4.2 Open Hybrid MEM-ECO base - High Temperature kit

1

LOW

TEMPERATURE

SYSTEM

PI

PS

Water mains

Water mains

Radiator

VD

F

HEAT

PUMP

MU E R

SE

B2

B5

B3

TS

B1

Ve

VM

VAT

PUFFER

DOMESTIC HOT WATER

STORAGE HEATER

Vr

Vr

Vs

Sp

Vr

Fig. 4

14

1.4.3 Open Hybrid MEM-ECO base - High Temperature Kit - Solar Kit

3

2

1

LOW

TEMPERATURE

SYSTEM

PI

Vr

Vr PS

Vs

Sp

Water

Mains

Water mains

Solar

unit

VeS Radiator

VD

F

HEAT

PUMP

SOLAR

COLLECTOR

MU E R

SE

Vr

B2

B5

B4

B3

TS

B1

Ve

VM

VAT

PUFFER

DOMESTIC HOT WATER

STORAGE HEATER

Fig. 5

KEY

Vr

Check valve

VD

Diverter valve

Vs

Relief valve

TS

Safety thermostat (low temperature system)

PS

Domestic hot water pump

PI

System pump (low temperature)

Sp

Plate heat exchanger

Ve

Domestic hot water expansion vessel

VeS

Solar expansion vessel (optional)

VM

Domestic hot water valve (optional)

VAT

High temperature valve (optional)

B1

Domestic Hot Water High Sensor

B2

Domestic Hot Water Low Sensor

B3

Low Temperature system delivery sensor

B4

Solar Collector Sensor (supplied with the Solar Kit)

B5

DHW Inlet O-ring sensor (in boiler)

SE

External sensor

F

Y Filter (not supplied, the responsibility of the installer)

M

Delivery

R

Return

U

DHW Output

E

DHW Inlet

1

HIGH TEMPERATURE KIT

2

SOLAR KIT

3

SOLAR PANEL

15

1.5 Sensors

The sensors installed have the following characteristics:

– B1 - Domestic Hot Water Storage Tank High Sensor NTC

R25°C; 10kΩ

– B2 - Domestic Hot Water Storage Tank Low Sensor NTC

R25°C; 10kΩ

– B3 - Low Temperature system delivery sensor NTC R25°C;

10kΩ

– B4 - Solar Collector Sensor (supplied with the Solar Kit)

PT1000

– B5 -DHW Inlet O-ring sensor (in boiler) NTC R25°C; 10kΩ

– SE - External sensor NTC R25°C; 10kΩ

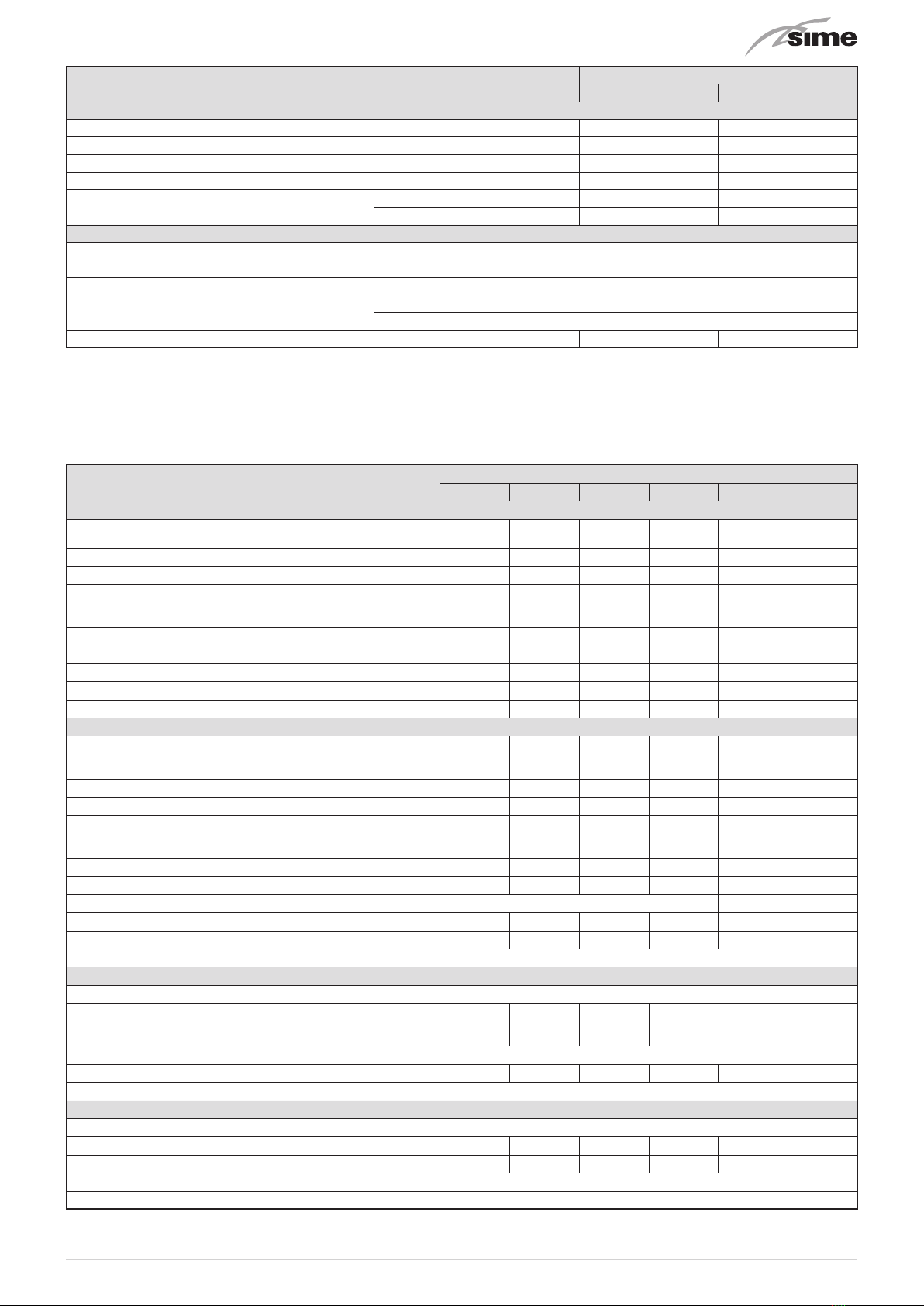

Correspondence of Temperature Detected/Resistance

Examples of reading:

TR=75°C → R=1925Ω

TR=80°C → R=1669Ω

TR

0°C 1°C 2°C 3°C 4°C 5°C 6°C 7°C 8°C 9°C

Resistenza R (Ω)

0°C

27279

17959

12090

8313

5828

4161

3021

2229

1669

1266

973

26135

17245

11634

8016

5630

4026

2928

2164

1622

1232

25044

16563

11199

7731

5440

3897

2839

2101

1577

1199

24004

15912

10781

7458

5258

3773

2753

2040

1534

1168

23014

15289

10382

7196

5082

3653

2669

1982

1491

1137

22069

14694

9999

6944

4913

3538

2589

1925

1451

1108

21168

14126

9633

6702

4751

3426

2512

1870

1411

1079

20309

13582

9281

6470

4595

3319

2437

1817

1373

1051

19489

13062

8945

6247

4444

3216

2365

1766

1336

1024

18706

12565

8622

6033

4300

3116

2296

1717

1300

998

10°C

20°C

30°C

40°C

50°C

60°C

70°C

80°C

90°C

100°C

1.6 Expansion vessels

The expansion vessel installed on the boilers has the following

characteristics:

Expansion vessel

Capacity (l) Prefilling

(kPa) (bar)

in boiler

9 100 1

domestic hot water

8 300 3

solar

12 250 2.5

(*) Conditions of:

Average operating temperature 70°C (with high tempera-

ture system 80/60°C)

Start temperature at system filling 10°C.

m

WARNING

– The difference in height between the relief valve

and the highest point of the system cannot exceed

6 metres. If the difference is greater than 6 metres,

increase the prefilling pressure of the expansion

vessel and the system when cold by 0.1 bar for each

meter increase.

1.7 Circulation pump

The flow-head performance curve for the pumps used in the

Open

Hybrid MEM-ECO

Systems are indicated in the following graphs:

1.7.1 High temperature system pump

RESIDUAL HEAD (mbar)

0

0 800 1000 1200600400200

100

200

300

400

500

600

30

25

35

FLOW (l/h)

Fig. 5

1.7.2 Low temperature system pump

Flow-head-Performance Diagram (Pump at max speed and

∆p constant).

00 800 1000 1200 1400 1600

1800

600400200

100

200

300

400

500

RESIDUAL HEAD (mbar)

FLOW (l/h)

600

700

800

Fig. 6

1.7.3 Controlling operation of the pump

1 2

34

Fig. 7

16

1

Operating LED: during normal operation, the LED lights

up green. In the event of a fault, it emits warning signals

as detailed below.

LED colour Status Troubleshooting

LED off No electrical power

Red/Green Flashing Anomaly in progress

Red Flashing Anomaly in progress

Red On Permanent safety shutdown

For “Pump troubleshooting” see the relevant section at the

end of the manual.

2

Selected settings mode: ∆p-v, ∆p-c and constant speed

3

Selected characteristic curve: I, II, III for the specific set-

tings mode

4

Command button to set the pump for exclusive use by the

installer or an authorised technician (for further informa-

tion, please see “Setting the circulation pump”.

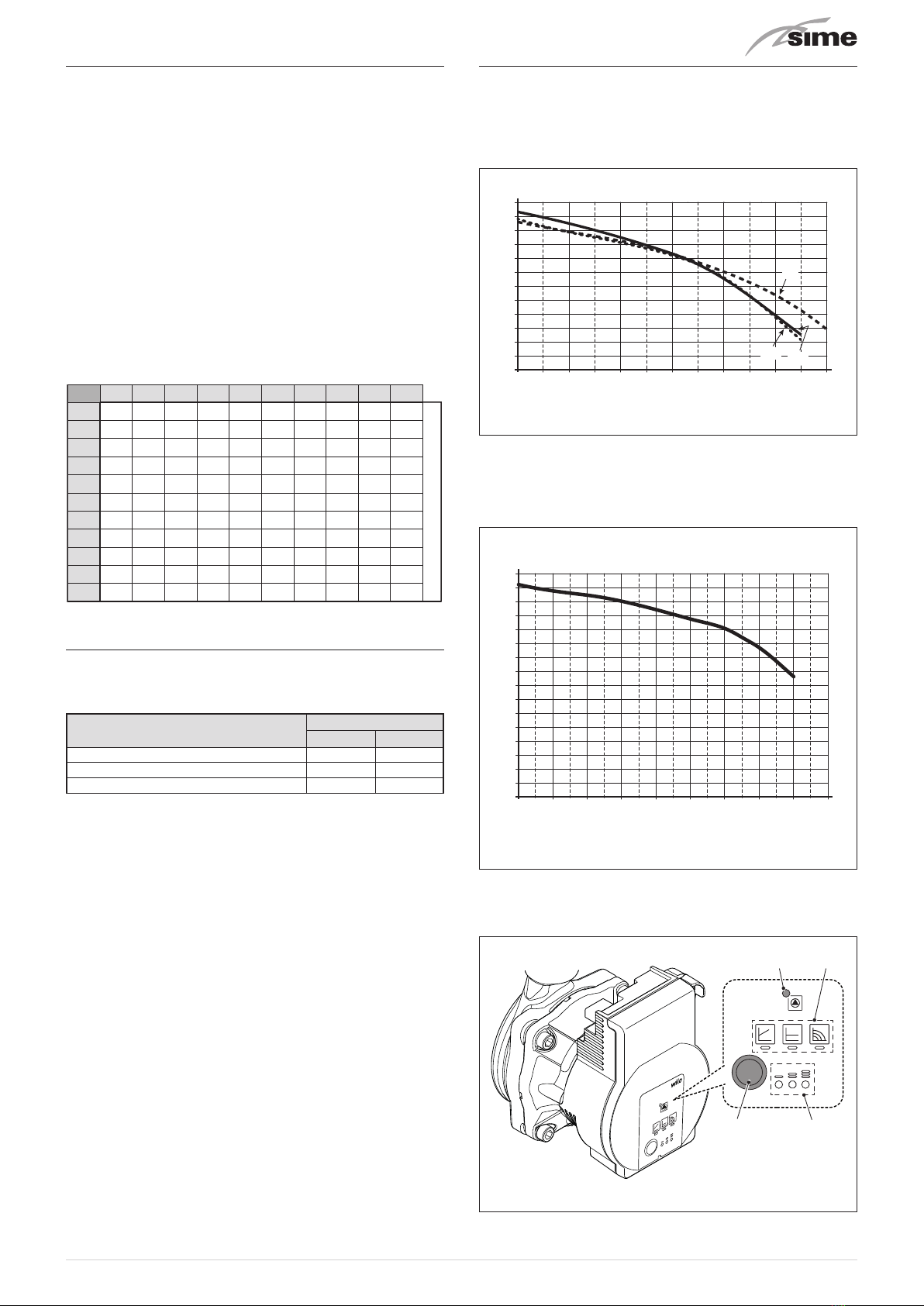

1.8 Mem Remote Control

The MEM Remote Control manages the entire system

OPEN HYBRID MEM-ECO.

Prg

Esc

156

Backlit display

82

31

Button Function

Alarm display (if present)

Red flashing light = alarm present

Access to parameters menu

(press and hold)

Return to previous menu or the Main screen

Scroll forwards

Confirm the selection of an item in the menu

or modification of value/data

Scroll backwards

Fig. 8

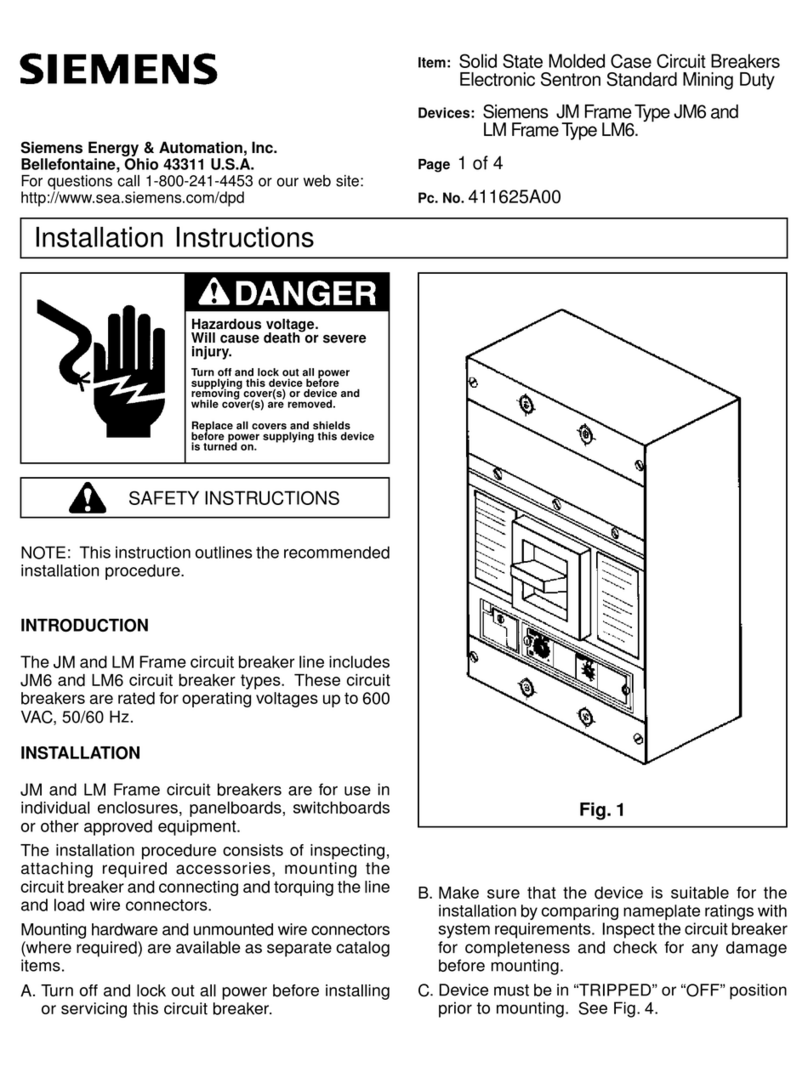

1.9 Electrical panel

To facilitate the electrical connections,it is recommended that

the panel is hooked to a clip on the domestic hot water stor-

age tank. The panel is equipped with the following pre-cabled

components which require connection.

1

3

6

2

4

5

7

KEY

5

Control unit

6

Communication bus converter

7

Transformer

8

Power supply terminals

9

Low voltage terminals

10

High voltage terminals

11

Fuses

Fig. 9

17

1.10 Wiring diagram

Y2

Y1

B -

A +

GNX

MOD-BUS

CONVERTOR

230V - 24V

TRANSFORMER

30VA

SP1

230V

0

230

GND

A

B

24

0

F2

T 2A

CABLE

SUPPLIED 6m

Extendable up to 50m

(RJ12 telephone cable)

24V

B4

B1

B2

B3

B5

B6

B8

ID1

GND

ID2

PE

L

N

N06

N07

N01

NA

LA

TS

MO3

MO1

12 3

LV system protection

(present in electrical panel)

CONTROL UNIT

EARTH

NODE

ELECTRICAL PANEL

FUI

T 6.3A

GND

Y2

C2

N02

N03

C3

G

G0

SYNC

SYNC

B1

B2

B3

B4

B5

B6

GND

+5Vref

+VDC

IDI

GND

CI

NCI

NOI

N04

N05

N06

N07

C3

GND

ID2

B7

B8

GND

TLAN

Y1

GNX

+

-

GND

+

-

N03

C3

N04

N05

N06

N07

C3

GND

ID2

B7

B8

MO2

N L N L

PE

N L

PE

M

236

M

DOMESTIC HOT WATER PUMP

LOW TEMPERATURE SYSTEM PUMP

AUTOMATIC FILLING VALVE

HEAT PUMP DIVERTER VALVE

on

12 3 4

BOILER

OT

SE

KEY

1 Control unit

2 Mod-bus converter

3 Transformer

MO1/3

Electrical panel terminal board

OT OpenTherm Connection

B1 Domestic Hot Water High Sensor

B2 Domestic Hot Water Low Sensor

B3 Low Temperature system delivery sensor

B4 Solar Collector Sensor

B5 DHW Inlet O-ring sensor in boiler

18

Electrical wiring diagram

NANO1

NALA

NALA

LA

NA

L

N

NANO6

PE PE

PE PE

GND

GND

GND

GND

GND

NANO7

ELECTRICAL PANEL TERMINAL BOARD (Open Hybrid Mem ECO)

MO1

GNX

2

6

3

GND

GND BLUE

BLACK

BROWN

123456

T

BOILER TERMINAL BOARD

ID2

ID1

B6

B4

B8

24 V

Y2

Y1

B -

FU2

FU1

A +

HEAT PUMP TERMINAL BOARD

ELECTRICAL PANEL CONTROL UNIT

MEM REMOTE CONTROL

M

EXTERNAL SENSOR - AS STANDARD

(cable not supplied 2x0.5mm²)

RJ12 TELEPHONE CABLE supplied as

standard L=6m extendable up to 50m

HEAT PUMP - MODBUS

(cable not supplied shielded 3x0.5mm²)

BOILER - POWER SUPPLY

(boiler output cable supplied as standard)

SOLAR PUMP - OPTIONAL KIT

(cable supplied in optional kit)

COLD MODE

(230Vac 1A max - cable not supplied 2x1.5mm²)

HIGH TEMPERATURE CIRCUIT VALVE - OPTIONAL KIT

(cable supplied in optional kit)

HIGH TEMPERATURE CIRCUIT REQUEST (*)

LOW TEMPERATURE CIRCUIT REQUEST (*)

HUMIDISTAT REQUEST (*)

MULTIFUNCTION DIGITAL INPUT (*)

SOLAR COLLECTOR SENSOR - OPTIONAL KIT (*)

L

N

PE

IG1

PE

POWER SUPPLY

230 V - 50 Hz

OT (Cable from electrical panel supplied as standard)

T

(*) cable not supplied 2x0.5mm²

ANTI-FREEZE RESISTOR - OPTIONAL KIT

(cable supplied in optional kit)

L

N

L

N

KA

MO3

MO2

N

L

PE

IG2

HEAT PUMP

POWER SUPPLY

230 V - 50 Hz

X-1

N

L

X-5.2

X-5.1

X-4.1

19

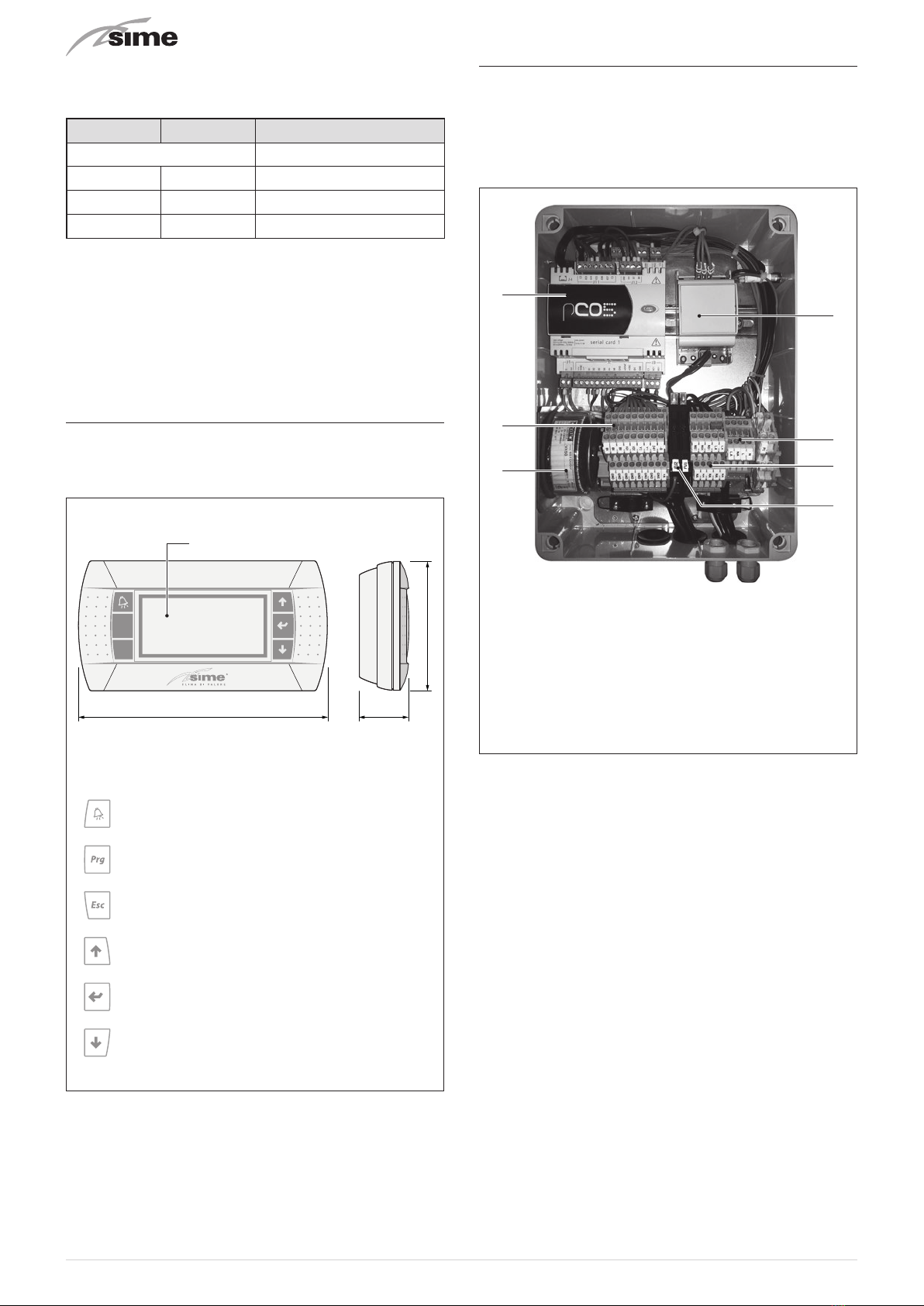

2 INSTALLATION

m

CAUTION

The appliance must be installed by the Sime Techni-

cal Service only, or by a qualified professional.

2.1 Receiving the product

The OPEN HYBRID MEM-ECO systems are supplied with the

following packages:

1

2

4

3

Fig. 10

m

WARNING

Package 2 contains the Pipe Kit, the Mem Remote Control,

the sensors and the insulation parts to be used after filling.

2.2 Dimensions

Description W (mm) D (mm) H (mm)

1 -

Domestic Hot Water Storage Tank

370 375 2100

2 - Plumbing system kit 500 380 1235

3 - Boiler 450 280 780

4- SHP M ECO 006 heat pump 925 380 769

4- SHP M ECO 006A heat pump 1023 423 1000

4- SHP M ECO 008 heat pump 925 380 769

4- SHP M ECO 008A heat pump 1023 423 1000

4- SHP M ECO 010 heat pump 1047 465 898

4- SHP M ECO 012 heat pump 1047 465 898

2.3 Handling

Handling of the

Sime

OPEN HYBRID MEM-ECO system is to be

carried out with equipment which is suitable for the dimen-

sions and weights of the parts using suitable accident preven-

tion protection.

When handling is not carried out manually, operators must

ensure that the maximum weight per person is not exceeded.

a

WARNING

Use suitable tools and accident prevention protec-

tion when removing the packaging and when han-

dling the appliance.

d

IT IS FORBIDDEN

Do not leave packaging material around or near

children since it could be dangerous. Dispose of it as

prescribed by legislation in force.

2.4 Installation of the Open Hybrid MEM-ECO

System

The OPEN HYBRID MEM-ECO system is to be assembled in

the following sequence:

– Domestic hot water storage tank

– Boiler

– Plumbing system kit

INSTALLATION OF THE DOMESTIC HOT WATER STORAGE TANK

Lift the domestic hot water storage tank and hook onto the frame

bracket (A), place the upper slot on the storage tank onto the pre-

arranged pun (B) and secure using the nut and washer supplied.

The storage tank can only be made secure when it is hooked

to the frame bracket.

A

B

C

Fig. 11

– Mount the 3/8”-3/4” reducer (supplied) on the water mains con-

nection fitting (C) using sealant or teflon to ensure tightness.

20

BOILER INSTALLATION

Position the boiler inside the built-in frame hanging it by plac-

ing the slots on the two prearranged pins. Secure using the

nuts and washers supplied.

Fig. 12

m

WARNING

The installer must ensure that a condensate outlet

pipe is fitted. The pipe must not have any siphons

or horizontal sections to prevent ice from forming if

there is condensate inside.

WATER SYSTEM KIT INSTALLATION

m

WARNING

Always place a seal on every joint and tighten the

swivel joints only when all operations have been

completed.

Premise

Check that the connections have already been fitted on the

fitting template

– Connect the pipe (1) code 6277844 (cold water inlet from

mains) to the connection (E- mains inlet) of the fitting tem-

plate and to the domestic hot water storage tank

– Connect the pipe (2) code 6277821 to the plate heat exchang-

er (Sp) and rest it on the shelf (M) in the built-in frame. Con-

nect the pipe (2) to the domestic hot water storage tank

m

WARNING

Prestare attenzione a collegare il tubo (2) cod.

6277821 nel senso mostrato in figura, in modo da

non compromettere il montaggio dei restanti tubi e

il posizionamento finale dello scambiatore a piastre

(Sp).

2

MSp

1

E

YES

NO

Fig. 13

– Mount the assembly consisting of: pipe (3) code 6277855,

domestic hot water pump (PS), pipe (4) code 6277856, relief

valve (Vs) and cock (Rs)

m

WARNING

– To facilitate the installation/tightening operations,

it is recommended that the assembly is connected

after having fitted the pipes.

– Fit the domestic hot water pump (PS) with the ar-

row facing upwards.

3

4

Rs

Vs

PS

Sp

Fig. 14

This manual suits for next models

71

Table of contents

Other Sime Industrial Equipment manuals