Simpson Lawrence Pacific C1250 Guide

1

pacific

C12 50 CA PS TA N

C1250STD

in sta lla tio n, o per a tio n & m a in tena nce i ns tr u ct io n s

contents

..............................................................................................................................

sim ps o n -la w ren ce

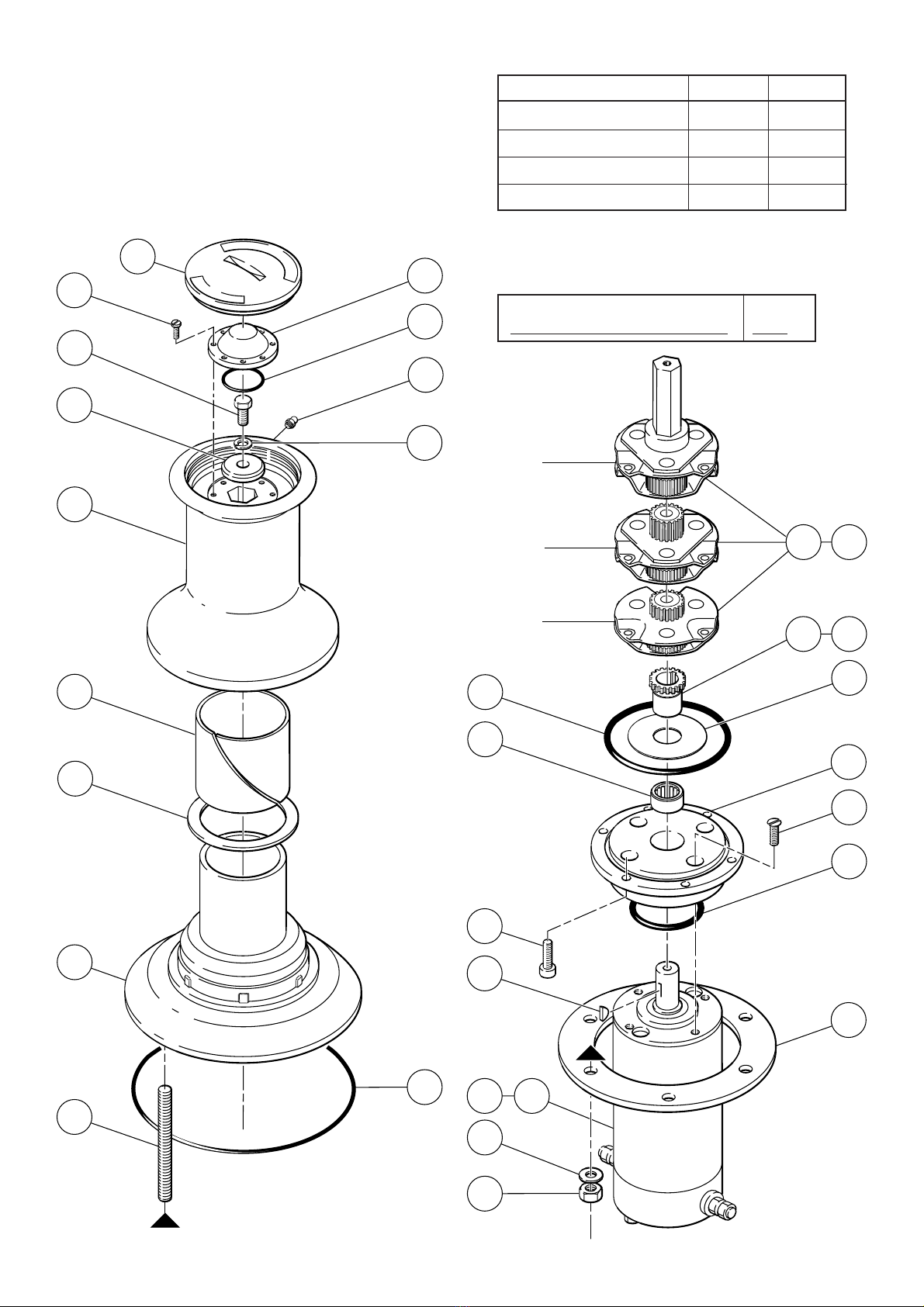

1.0 P AR T S

1.1 E xploded Diagram

1.2 F or F uture R eference

1.3 P arts List

2.0 P L ANNING THE INS T AL L A TION

2.1 P ackage C ontents

2.2 Additional R equirements

2.3 E lectric C able S election

3.0 AC C E S S OR IE S

4.0 S P E C IF IC ATION

4.1 P erformance Data

4.2 Materials

5.0 INS TAL L A TION

5.1 F itting C aps tan to Deck

5.2 Wiring

5.3 Test

5.4 P rotection of B elow Deck P arts

5.5 Wiring Diagrams

6.0 OP E R AT ING INS T R UC T IONS

6.1 S afety F irs t!

6.2 Hauling In

7.0 IMP O R T A NT US E R INF OR MA TION

8.0 MAINTE NA NC E

8.1 G eneral R ecommendations

8.2 Winter Laying Up

9.0 WA R R A NTY

SIM PSON

LAW RENCE

2

13

27

33

30

32

10

18

26

31

3

28

24a24

27a

26a

23

12

S tage 3

S tage 2

S tage 1

1.2.1 Identify your model

Type List No. Tick

12V P acific C1250 Anchoring 0032010

24V P acific C1250 Anchoring 0032020

1.2.2 P leas e note your serial number and voltage. (P rinted on motor

label). T his information is es sential when ordering spares.

V

1.0 P AR T S

1.1 E xploded Diagram

1.2.0 F or F uture R eferenc e

After you have read this instruction booklet, please keep it safe

on board your vess el for future reference.

9

11

4

2

6

5

7

15

22

16

8

17

19

25

3

1.3 PARTS LIST

Item Part No. Part Description Quantity

C1250 C1250

Anchoring Anchoring

2 P103064 Shim Bearing - Main 1

3 P103036 Shim Bearing - Gears 1

4 P103037 Shim W asher - Drum 1

5 P106003 Drum 1

6 P106200 Cap - T op 1

7 P106210 Cap - Inner Seal 1

8 P106215 Cap - Lock 1

9 P109003 Deck Housing 1

10 P109301 Deck Clamp 1

11 P154000 Stud 6

12 P339017 Nut 6

13 P342000 O Ring 1

15 P342050 O Ring 1

16 P342435 O Ring 1

17 P354101 Screw 6

18 P354014 Screw 6

19 P354231 Screw 1

22 P366042 Washer 1

23 P366045 Washer 6

24 P418201 Gearset (Complete) 1

24a - Gearset (Complete) -

25 P418100 Grease Nipple 1

26 P336040HMS Motor 12V 1

26a P336041HMS Motor 24V 1

27 P118012 Pinion 1

27a - Pinion -

28 P303104 Spragg Clutch 1

30 P354325 Screw 4

31 P113020 Key 1

32 P342030 O Ring 1

33 P136007 Flange 1

4

2.0 PLANNING THE INSTALLATION

2.1 Package Contents

Capstan

Mounting Studs, Washers, Nuts & 'O' Ring

Clamping Plate

Mounting Template

Safety Instructions

Installation Warning Label

Instruction Manual

2.2 Additional Requirements

Each capstan installation requires :

a. A solenoid for a single direction installation. (Unless the

High Load Foot Switch only is used)

b. A control switch (or switches) by preference.

c. A breaker/isolator for overload protection which can also be

used as a main isolating switch. (Simpson-Lawrence

recommend the breaker/isolators listed under 3.0

Accessories)

d. The following tools:

Capstan Installation

Flat Blade Screwdriver

10mm (3/8") Diameter Drill

13mm A/F (1/2") Spanner (Wrench)

Jig Saw or Trepanning Tool

Wiring Installation

Flat Blade Screwdriver

Crimping Pliers / Wire Stripper

13mm A/F (1/2") Spanner or Socket

8mm A/F (5/16") Spanner or Socket

e. Marine grade silicone sealant. DO NOT use permanent

adhesive/sealant.

f. Suitable electrical cable and crimp terminals.

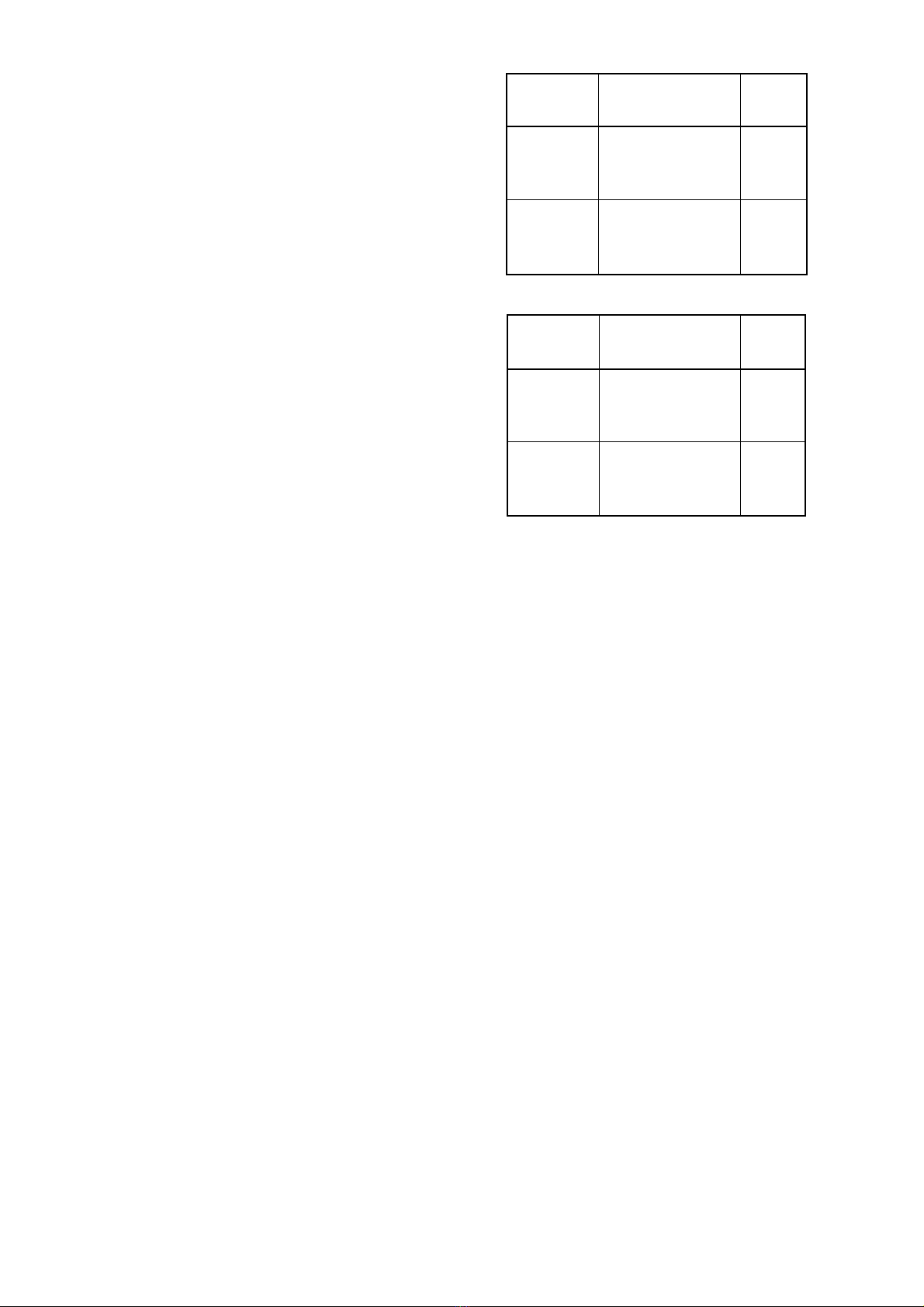

2.3 Electric Cable Selection

To achieve the best performance and safeguard your electrical

system, it is essential that any electric capstan is fitted with

sufficiently large diameter cable to cope with the current draw

imposed upon it and, to keep the voltage drop within acceptable

limits. In any circumstance, voltage drop due entirely to cable

resistance should not exceed 5%, roughly 0·5V for a 12V

installation and 1·0V for a 24V one.

The following tables give recommended cable sizes. The

recommendations are based on the total length of cable

required, from the battery to the capstan and back to the

battery, following the route of the cables. (See the Wiring

Diagram for the definition.)

DO NOT confuse Cable Length with the length of the vessel!

3.0 ACCESSORIES

Item List Number

Breaker/Isolator (70 Amp) 12V Installation 0050711

Breaker/Isolator (50 Amp) 24V Installation 0050710

12 Volt Solenoid Single direction 0052505

24 Volt Solenoid Single direction 0052506

Foot Switch Single direction 0052514

High Load Foot Switch Single direction 0052516

USA list number for above (Black) LEWP49C

USA list number for above (White) LEWP49CW

METRIC or STARTER CABLE

Voltage Cable Length Size

m(ft.) (mm²)

18.0m (60ft.) 25

12 27.0m (90ft.) 35

37.0m (120ft.) 50

18.0m (60ft.) 6

24 27.0m (90ft.) 10

37.0m (120ft.) 16

AMERICAN CABLE

Voltage Cable Length Size

m (ft.) (AWG)

18.0m (60ft.) 2

12 27.0m (90ft.) 1

37.0m (120ft.) 1/0

18.0m (60ft.) 8

24 27.0m (90ft.) 8

37.0m (120ft.) 6

Thin wire of 1·5mm² cross sectional area, 21/0·30 PVC covered

(American equivalent 14 AWG) is required for the control switch

circuits. This is used to connect the switch(es) to the

solenoid(s).

5

8.2

5.1.6 Longer Studs

For thicker than standard decks, simply fit longer studs as

appropriate (Thread M8 x 1.25). Studs to special lengths may

be obtained from Simpson-Lawrence Engineering Limited.

5.2.0 Wiring

5.2.1 General Recommendations

Warning! Carefully check to ensure that the capstan motor is

wired to correct polarity. It is possible to damage the gearbox

if the motor is wired to the wrong polarity.

The wiring system should be of the two cable fully insulated

return type, which avoids possible electrolytic corrosion

problems. Most modern installations are negative return

(negative earth) but polarity should be checked.

Solenoids should be mounted as close to the battery as

possible, in a dry location using the mounting holes provided.

Under no circumstances should solenoids or solenoid control

boxes be installed in chain lockers or similar damp or semi

exposed areas.

Overload protection must be built into the capstan wiring

circuit. This protects the wiring and prevents undue damage to

the capstan motor, in the event of it being stalled by an

excessive load in service. It is advisable to site the Breaker/

Isolator in a dry, readily accessible place, as it must be

manually reset should an overload occur that causes it to trip

to the OFF position.

If you are NOT using the Breaker/Isolator recommended, an

alternative MUST have identical characteristics.

NB: Crimp terminals should be used on all wire ends for good

electrical connections.

5.2.2 Control Switch Installation

Follow the mounting instructions supplied with the switch.

Remember when using more than one control switch, it is

important to their correct operation, that they are wired in a

parallel circuit.

5.3 Test

Immediately after installation, it is recommended that the

capstan is tested to ensure it functions correctly in all modes,

e.g., forward, reverse and manual operations should be tested.

5.4 Protection of Below Deck Parts

Check all terminals or connections are firmly secured. Coat

ALL below deck surfaces, including the terminals, with rubber

or plastic type paint (automotive underseal is one convenient

way) OR wrap completely in self amalgamating tape OR coat/

protect in a similar way with some other system suitable for a

marine environment.

4.0 SPECIFICATION

4.1 Performance Data:

Typical Working Figures (12V/24V) Warping

Load Speed Current Draw

110kg(220lb) 8.0m(26ft)/min 80 Amp - 12V

110kg(220lb) 8.0m(26ft)/min 40 Amp - 24V

Typical Working Figures (12V/24V) Anchoring

Load Speed Current Draw

110kg(220lb) 18.0m(59ft)/min 80 Amp -12V

110kg(220lb) 18.0m(59ft)/min 40 Amp - 24V

Motor 4 Pole Permanent Magnet

Weight 10kg (22lb)

5.0 INSTALLATION

5.1.0 Fitting Capstan To Deck

5.1.1 Preparation

The capstan must always be mounted vertically. DO NOT

mount capstan in a horizontal direction as oil will leak from the

gearbox and the capstan will wear out prematurely. If the deck

top is uneven a suitable mounting pad may be required to take

up camber or sheer. Decks which are thin, of foam or balsa

laminate construction, will require a backing piece in order to

spread the load which will be applied locally to the deck while

the capstan is in use. Care must be taken if the deck is of

uneven thickness and a mounting pad and/or backing piece

fitted that the top and bottom surfaces are parallel for optimum

clamping.

5.1.2 Position of Capstan

Select a site for the capstan on the deck that is a comfortable

position for the operator to tail rope off the drum and preferably

feed rope straight into the storage area. A position for the

switch should be found that makes it accessible to the capstan

operator’s foot or knee.

5.1.3 Access

Allow for access to the top of the drum during maintenance.

5.1.4 Mounting Template

Place the mounting template in the desired position. Drill a

clearance hole for the motor to pass through as detailed and

six 10mm (3/8") holes for the studs. The studs supplied suit

decks and mounting pads up to 75mm (3") thickness.

5.1.5 Fitting

Place the capstan and studs through the holes in the deck,

when satisfied that all is correct, fit any packing, the clamping

ring, the nuts and washers, and tighten evenly and firmly using

a 150mm (6") long spanner.

Table of contents

Other Simpson Lawrence Marine Equipment manuals