Simu (X) 200 TRAN202 User manual

LIT DATE

RC200 S435 01-01-2001

MODEL SERIES

(X) 200

LINE

433MHz RADIO MOTOR CONTROL

Troubleshooting

- Check fuse

- Conrm that 120VAC is supplied to terminals 3 and 4

- Conrm that the receiver code has been memorized (see MEMORIZING

TRANSMITTER CODES WITH THE RECEIVER on reverse side of this page)

- Make sure you have generated a code for that button on the transmitter (see SETTING CODES IN

THE TRANSMITTERS on the reverse side of this page)

- Make sure the jumper is in terminals 8-9 if no safety device is used.

- If the jumper is in terminals 8-9 and the receiver still switches in just one direction, the transmitter

code may have been memorized as either an up or down signal. Delete the transmitter’s code

from the receiver memory (see ERRASING RECEIVER MEMORY on the reverse side of this page).

Then with dip switch 1 and 2 on, have the receiver memorize the transmitter’s code again (see

MEMORIZING TRANSMITTER CODES WITH THE RECEIVER on the reverse side of this page)

- Check limit settings on the motor.

- The timed run on the receiver is set too low. Increase the run time by

following the instructions in the paragraph“Run time programming (SW1) on page 2.

- Make sure the transmitter has generated a code for that button (see SETTING CODES IN

THE TRANSMITTER on the reverse side of this page)

- If the led LD is on continuosly, the receiver memory is full (has 24 codes memorized). Delete

some of the codes (see ERASING RECEIVER MEMORY on the reverse side of this page)

- Make sure the receiver is as far as possible from other receivers, metal objects, EMI

sources (oresent lights, transformers, computers, etc...) Try the receiver in dierent locations if

possible before hard wiring.

- If the receiver is mounted in a metal enclosure or in a remote location from where the

transmitters will be used with metal or other dense material in the line of sight, the receiver’s

antenna can be remotely located nearer to the area the transmitters will be used in (see

Installation on this page).

Problem: No response from the receiver

Solutions if led PW is o

Soultions if led PW is on

Problem: Receiver only switches in one direction

Solutions

Problem: Motor stops/receiver turns o before the motor reaches the limit.

Solution

Problem: The receiver will not memorize a code from a button on the transmitter

Solutions

Problem: Range is poor

Solutions

TRAN202

TRAN204

TRAN212

TRANWS200

RC200

SIMU U.S Inc.,

6100 Broken Sound Parkway N.W., #14

Boca Raton, FL 33487

Phone: 561-995-0335 FAX: 561-995-7502

Description

Use

Transmitters

Receivers

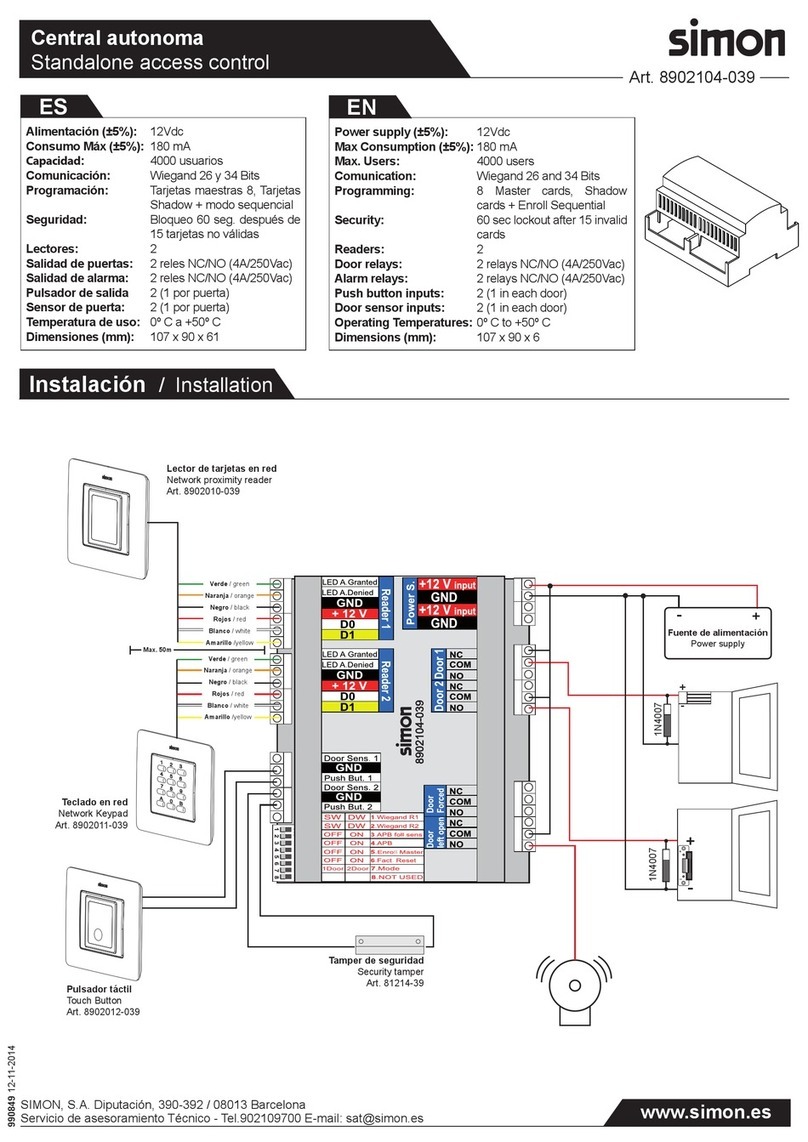

Installation

Electrical connections

-

Terminals

TECHNICAL SPECIFICATIONS

Receiver

Transmitter

The (X) 200 radio control system consists of one or more transmitters and one or more receivers

which can be combined to meet the specic needs of a wide variety of systems.

The (X) 200 control has a highly reliable and system that uses an algorithm to

recognize only specic variations of the original transmitted code. The receiver is able to memorize

This allows a receiver to be activated by multiple

transmitters.

The (x) 200 radio control can be used with Type 3.5, Type 5 and Type 6 120VAC SIMU motors. One

RC200 is required for each motor unless used with SIMU group control relays (RI2, RI3, and GI2).

Each RC200 receiver can be controlled individually from 1 channel (1 button on a transmitter)

when the code is programmed into the RC200 in sequencing mode (open-stop-close-stop..). using

dip switch SW1(on/on). Groups of RC200 receivers can be controlled together by programming

one button as an open for all receivers in a group using dip switch SW1 (on/o ) and one button on

the transmitter as close using dip switch SW1 (o/on).

TRAN202 Two channel transmitter 2 Buttons

TRAN204 Four channel transmitter 4 Buttons

TRAN212 Twelve channel transmitter 4 Buttons and A-B-C slide switch

TRANWS200 Four channel wall-switch transmitter 4 Buttons

RC200 Motor control receiver in surface external box

RC210 Motor control receiver recessable in plastic 3 gang switch box (interior only)

RC201 12/24VDC 2 channel dry contact output receiver

Disconnect power before installing.

- High voltage 120VAC wires must pass through the holes marked “A”(see g. 9)

- Low voltage wires must pass through the holes marked “B” (see g. 9) and must be routed

separately from the high voltage wires.

secure rolling code

24 dierent codes in its non volatile memory.

IMPORTANT : For installation by a qualied electrician in accordance with local

electrical codes.

- CAUTION: RISK OF ELECTRICAL SHOCK.

The receiver bracket should be mounted to the wall with the included screws. The receiver can then

be slid onto the bracket. If mounted in an exposed location, the receiver must be mounted with

holes marked A and B (see g. 9) facing down. Receivers should not be mounted within 5 feet of

each other. Do not mount the receiver in a metal box, near metal, or near EMI sources. It is

recommended that the range of the unit be tested before permanently wiring the receiver. If range is

poor, often relocating the receiver by a few feet can drastically improve the reception. If the

receiver must be installed in a metal box or located in a remote location, the antenna can be

remotely located. Connect the shield of a coaxial cable to terminal 12 and the center conductor

to terminal 13. Run the cable to a clear location near where the transmitter will be used and strip

the shielding o the last 17cm (exact length of antenna supplied with unit)

!

1-2 Ground (Motor Green)

3 Hot 120 VAC 60HZ

4 Neutral

5 Motor direction 1 (Motor Black)

6 Motor direction 2 (Motor Red)

7 Motor common (Motor White)

8-9 N.C. low voltage input for safety device. Jumper must be installed if safety device not used

10-11 N.O. low voltage input with sequencing function (open-stop-close-stop-open...) for single

throw, single pole low voltage switch (Ref# SPBS.W)

12 Antenna ground

13 Antenna connection for 17cm wire supplied with receiver. The antenna can be remotely

located using 50 Ohm coaxial cable as described above in“Installation”

- Reception frequency........................................................................................................433.92MHz

- Local emission..........................................................................................................................<2nW

- Antenna input impedance..................................................................................................50 Ohms

- Sensitivity.......................................................................................................................................1uV

- Power supply............................................................................................................120VAC 50-60Hz

- Operating temperature range.....................................................................................-20 C...+60 C

- Carrier frequency.............................................................................................................433.92MHz

- Carrier frequency tolerance.................................................................................................+75MHz

- Band width............................................................................................................................>25kHz

- Power supply (alkaline battery GP23A)......................................................................12V+10%

- Maximum power consumption..................................................................................................25mA

- Operating temperature range....................................................................................-10 C...+55 C

NOTE: This equipment LH8TX-S435 and LH8RP-S435 has been tested and found to comply with limits for a

These limits are designed to provide reasonable protection

against harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment o and on, the user is advised to try and correct the

situation by taking one or more of the following measures:

D Reorientate the receiving device

A Increase the distance between the equipment and the receiver

S Connect the equipment to a socket which is on a dierent branch circuit than the receiver

S Consult your dealer or an experienced radio/TV technician for help

ZVL408.01-P1 Mod: 18-04-2008

class B digital device, according to part 15 of FCC rules.

*8&9: N. C. Reversing Sensor

10&11: Remote Override Switch (SPBS)

12: Coax Antenna Connection (not supplied)

13: Standard Antenna (supplied with unit)

* NOTE: If you are not using a safety device a

jumper wire must be connected to

terminals 8 & 9.

Do not cut antenna wire supplied with this unit.

RC200 Receiver

PW

POWER IN 120VAC

HOT

NEUTRAL

GROUND

Antenna

*JUMPER

MN.O. SINGLE POLE

SINGLE THROW SWITCH

(REF#SPBS)

GREEN

RED

WHITE

BLACK

LD

1 2

CODE

MEMORY

8910 11

12 13

1

234 5 67

SW1 P1 P2

MEMO DELETE

ON

A

B

C

EXTERNAL DIMENSIONS

BATTERY REPLACEMENT

SETTING THE TRANSMITTER CODE

WIRING DIAGRAM (fig. 9)

A: Entry holes for 120VAC

B: Entry holes for low voltage wiring and antenna

D: Hole plugs

PW: Power light

SW : Function selection switch

P1: Memorize button

LD: Signal LED

P2: Delete button

1: Ground (Green)

2: Ground (Green)

3: Hot 120VAC

4: Neutral

5: Direction 1 ( Black )

6: Direction 2 (Red)

7: Common (White)

1

2

N

O

1

2

N

O

1

2

N

O

1

2

N

O

PROGRAMMING

SETTING CODES IN THE TRANSMITTERS (Fig. 1-6)

MEMORIZING TRANSMITTER CODES WITH THE RECEIVER

1) Open the access door (Fig. 1)

2) (Only on 12 channel transmitter) Select block of channels

with ABC slide switch Y1 (Fig.2)

Y1 in position A = channels 1-4

Y1 in position B = channels 5-8

Y1 in position C = channels 9-12

3) Press button J1 (Fig3)

4) While holding down button J1, press one of the transmitter

buttons CH and the light L1 will start flashing (Fig 4.)

5) Release the transmitter button CH and the light L1 will

continue flashing (Fig5)

6) Release the button J1 and the light will go out (Fig 6) That

transmitter button CH now has its code programmed.

7) Repeat steps 3-4-5-6 for each of the buttons CH on the

transmitter.

8) If using a 12 channel transmitter (4 buttons CH and ABC

slide switch Y1), repeat steps 2-3-4-5-6-7 with the slide

switch Y1 in each position. (A-B-C)

IMPORTANT: It is recommended for the receiver memory

to be cleared before memorizing transmitter codes for

the first time. Press buttons P1 and P2 simultaneously for

5 seconds until led LD flashes rapidly.

Dipswitch SW1 functions (Fig. 9)

DIP1 ON / DIP2 ON

Memorized code control in sequencing function.

OPEN-STOP-CLOSE-STOP-OPEN.....

DIP1 OFF / DIP2 OFF

Run time programming

DIP1 ON / DIP2 OFF

Memorized code will give up command

DIP1 OFF / DIP2 ON

Memorized code will give down command

1) Using SW1 select the function to be associated with that

button on the transmitter. (ON/ON) Is standard for individual

control.

2) Press button P1 and the LED labeled LD will start to flash

3) While holding down button P1, bring the transmitter within 6

inches of the receiver and press the transmitter button CH

you wish the receiver to memorize. The LED LD will flash faster

4) Release the transmitter button CH and the receiver button

P1. The receiver has memorized the code for that button on

the transmitter.

5) Repeat steps 1-2-3-4 for all other transmitter buttons you

wish the receiver to memorize.

6) When finished programming the receiver move both

dipswitches on SW1 to the off position.

* If the receiver will not memorize a code it could be due to:

- The memory is full (24 codes memorized) and led LD

remains lit. If this is the case, a new code can be

memorized only after one is erased or the whole memory

is cleared. (See “ERASING RECEIVER MEMORY BELOW)

- The code is already in memory

- You have not generated a code for that transmitter button.

(See “SETTING CODES IN TRANSMITTERS” ABOVE)

To erase a single transmitter button code from receiver memory

1) Press and hold button P2 and the led LD will flash slowly

2) Press the button of the receiver you wish to erase and hold

for 3 seconds until led LD flashes faster. The code is erased.

3) Repeat steps 1 and 2 for each button on all receivers you

want to erase from the receiver’s memory.

To erase the entire memory of a receiver

1) press and hold buttons P1 and P2 for at least 5 seconds

until led LD flashes rapidly. The whole memory is cleared.

ERASING RECEIVER MEMORY

CH1

CH3

CH2

CH4

Run time programming (SW1)

- move the door/shutter to the completely closed position;

- press and hold down the MEMO button for 4 seconds:

release the button when the LED starts to flash;

- press the MEMO button once, within 10 s, to start the

opening manoeuvre; when the door/shutter has stopped in the

completely open position, wait for 2-3 seconds and then press

the button again to memorise the run time; this completes

the program function and the LED will switch off;

NOTE: during programming the photoelectric cells are ignored

and the LED will flash rapidly indicating that the run time is being

counted.

• The maximum programmable run time is 120 seconds.

F1 - 4.0 A

ZVL408.01-P2 Mod: 18-04-2008

PAGE: 2 of 2

AA

BB

CCDD

EEFF

CDR 863 with SMCCDR 863 with SMC

”1.5”1.5

.5 ”

3 4

.5 ”

3 4

1.96”

1.96”

1

3

2

A: Mounting Gasket

B: Base Plate

C: Cover Gasket

D: Adjustable Optic

E: Control Board

F: Cover with Optic Window

ASSEMBLY

Test Point

+

_

112233445566

24V

+

12V

+

0V

- NC NO COM

~ ~ ~

Receiver

11223344

24V

+

12V

+

0V

-

~ ~ ~0V

-

~

Emitter

112233445566

24V +

12V +

0V -

NC

NO

COM

~

~

~

C

NC

NO

C

NO

NC

180

+30

-30

Fig. 1

Fig. 2 Fig. 3 Fig. 4 Fig. 5

DIMENSIONS CONNECTIONS TEST POINT ALIGNMENT

Description

The CDR863 is an outdoor/indoor photoelectric beam and can be used with

the SMC to control a tubular motor covering passage way up to 30’ outdoors

and 45’ indoors.

Mounting (Fig. 1)

1) Using the template on the lid of the box, mark the position of the transmitter

and receiver and install gasket (A) and the mounting plate (B) in the desired

locations using the four #6 flat head wood screws. When mounting to other

than wood surfaces use the appropriate anchors.

2) Run the wires through the hole in the gasket and mounting plate and into

the unit.

Wiring and Calibration

WARNING: DO NOT APPLY POWER UNTIL ALL CONNECTIONS HAVE BEEN MADE!

1) Connect wires as shown on page one of this addendum.

2) Power the units. The red LED on the transmitter will light. The red LED on the

receiver will light only if the optic eyes are not aligned

3) Align the eyes using a DC voltage meter on the test point (Fig. 4). The meter

should read 0.9V or higher when aligned.

4) Seal the wire holes using the supplied rubber plugs. Install the cover and

secure with supplied screws (Fig. 1 a,b,c)

5) Test the function. Note: If the eye causes the door to lower instead of raise,

reverse the red and black motor leads.

Technical Specifications

Optical

Range: (outdoors) up to 30 ft.

(indoors) up to 45 ft.

Transmitter beam width: 6 degrees (typical)

Receiver field of view: 6 degrees (typical)

Adjustment Vertical: +/- 30 degrees

Horizontal: 180 degrees

Electrical

Voltage: 12 or 24 VAC/VDC _ 10%

Current consumption @ 12V: 23mA (rest) 65mA (active)

Current consumption @ 24V: 29mA (rest) 68mA (active)

Relay: Form C (Com, NO, NC)

Relay drop out with loss of power

Contacts rated 60VA @ 24VDC/VAC

Max 30VDC/VDC

Infrared source: Double Gallium Arsenide LEDs

Transmitter frequency: 4.7 kHz

IR wavelength: 950 nm

Environmental

Operating temperature: 14 to 131 degrees F (-10 to +55 degrees C)

+

APPENDIX 2

This manual suits for next models

6

Other Simu Controllers manuals

Popular Controllers manuals by other brands

Honeywell

Honeywell TRADELINE SV9501 installation guide

Vimar

Vimar ELVOX EG30/N instruction manual

NT Engineers

NT Engineers DigiCut PLASMA THC 1.4 Installation & operation manual

Planar

Planar DX/PCI user guide

Xvent

Xvent ELEMENTAIR B-MARK I Operation and installation instructions

GE

GE PAC8000 series user manual