1 Content

1 Content................................................................................................................................................. 2

2 Overview............................................................................................................................................... 4

2.1 Overview devices........................................................................................................................... 4

2.2 Usage & Areas of use..................................................................................................................... 4

2.3 Exemplary circuit diagram............................................................................................................. 5

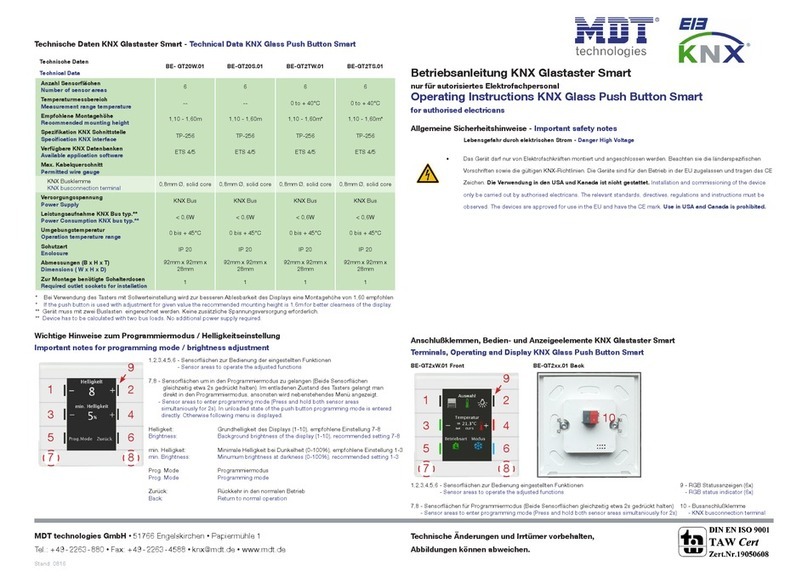

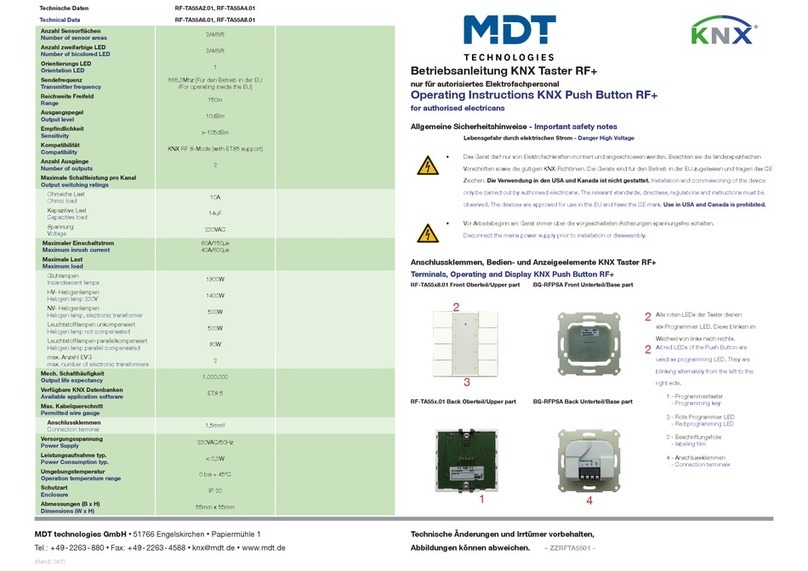

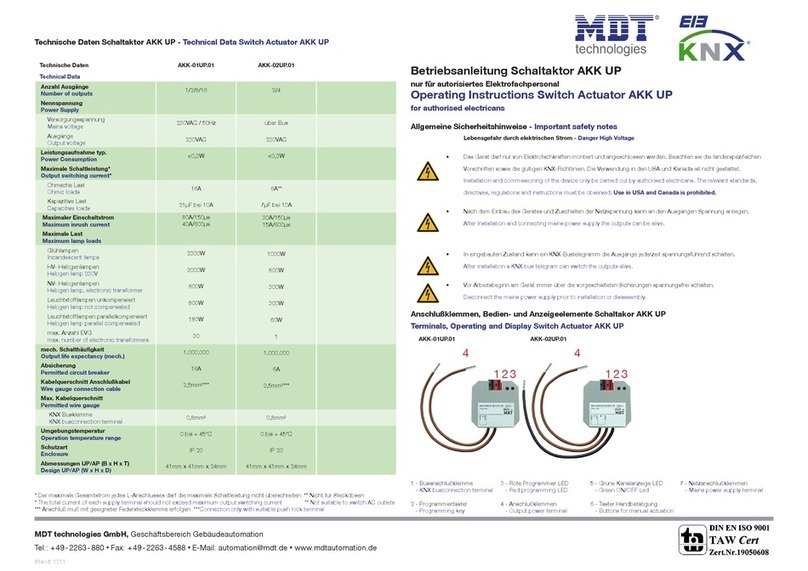

2.4 Structure & Handling..................................................................................................................... 6

2.5 Functions ....................................................................................................................................... 7

2.5.1 Overview Functions................................................................................................................ 8

2.6 Channel-LEDs................................................................................................................................. 9

2.7. Settings at the ETS-Software ........................................................................................................ 9

2.8. Starting up .................................................................................................................................... 9

3 Communication objects...................................................................................................................... 10

3.1 Overview...................................................................................................................................... 10

3.2 Global Communication objects ................................................................................................... 10

3.3.1 Communication objects –switching (1 Bit).......................................................................... 11

3.3.2 Communication objects –continuous (1 Byte) .................................................................... 11

3.3.3 Communication objects –integrated controller .................................................................. 12

3.4 Default settings of the communication objects .......................................................................... 14

4 Reference ETS-Parameter .................................................................................................................. 16

4.1 Setup general............................................................................................................................... 16

4.1.1 Device configuration ............................................................................................................ 16

4.1.2 Summer/Winter mode ......................................................................................................... 17

4.1.3 Heating/Cooling requirement & switchover ........................................................................ 18

4.1.4 Protection of forse fit ........................................................................................................... 19

4.1.5 Max. Control value ............................................................................................................... 20

4.1.6 Behavior after bus power reset............................................................................................ 21

4.2 Mode selection............................................................................................................................ 22

4.3 Channel Configuration –sithig Bit................................................................................ 23

4.3.1 General setting ..................................................................................................................... 23

4.3.2 Blocking function.................................................................................................................. 25

4.3.3 Emergency mode.................................................................................................................. 25

4.3.4 Forced position/Dew point alarm ........................................................................................ 26