Installation Instructions Specifications are subject to change without notice Page 3

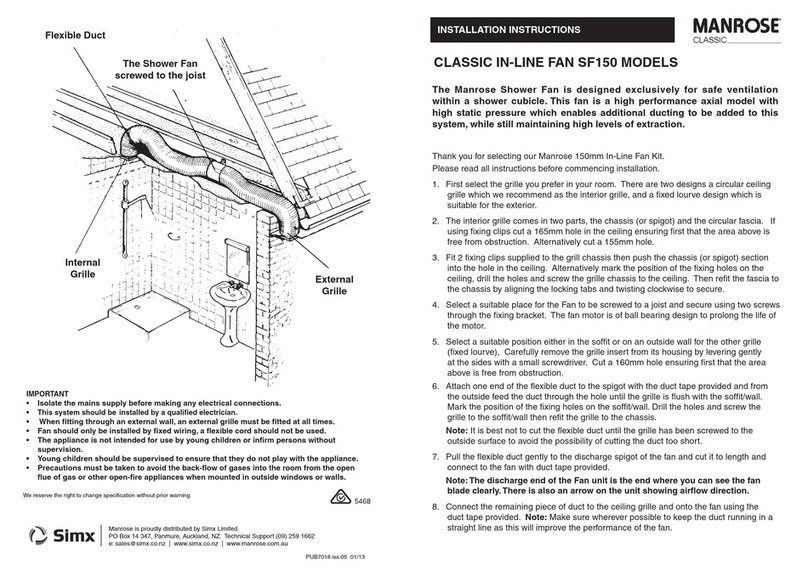

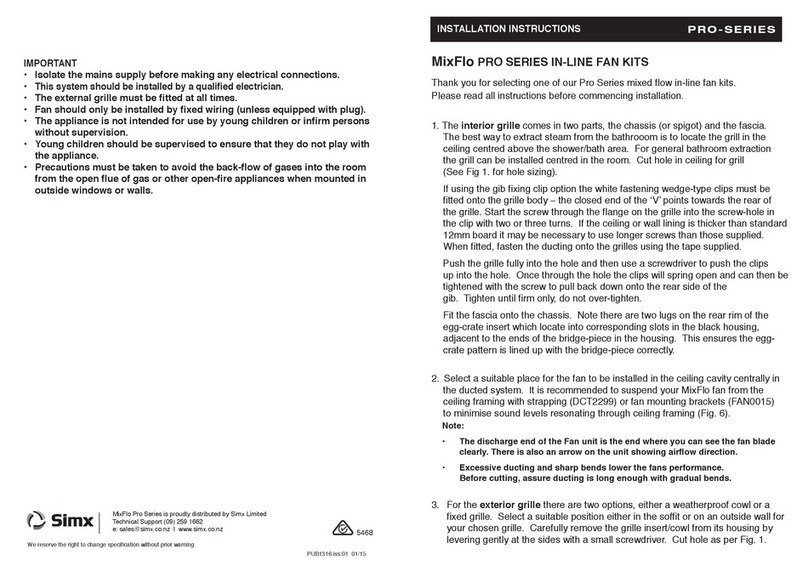

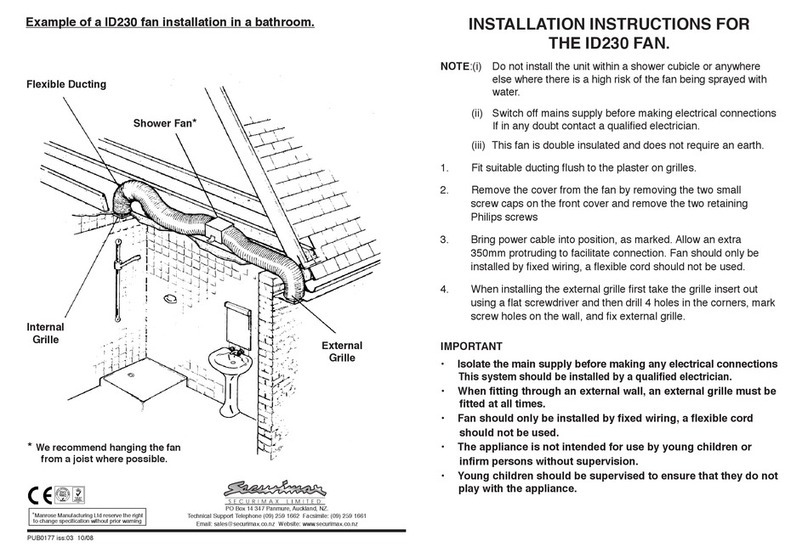

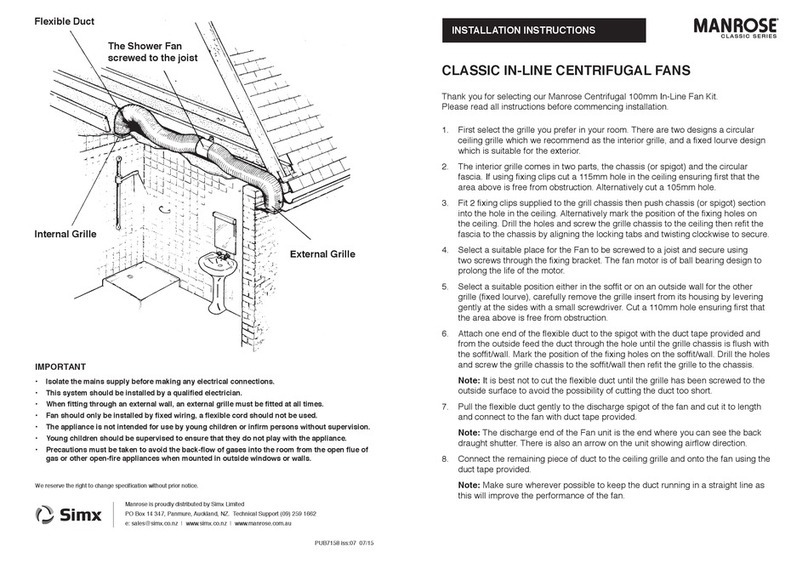

Inline Extraction Fan Kits - 150mm Std Profile

INLINE EXTRACTION FAN KIT INSTALLATION AND ELECTRICAL CONNECTION MUST

BE CARRIED OUT BY A REGISTERED ELECTRICIAN

BEFORE INSTALLING THE INLINE EXTRACTION FAN KIT, MAKE SURE YOU HAVE TURNED OFF THE MAIN

ELECTRICITY SUPPLY. DO NOT TURN IT BACK ON UNTIL THE INLINE EXTRACTION FAN KIT IS FULLY

INSTALLED AND READY TO USE.

ALL ELECTRICAL WORK MUST BE CARRIED OUT BY A REGISTERED ELECTRICIAN IN ACCORDANCE

WITH THE LATEST WIRING RULES AS/NZS3000.

CAUTION

• Before use, please check that the supply voltage and that of the appliance are the same (see product rating label).

• All wiring and wiring connections must comply with all current national wiring rules and regulations including AS/NZS3000:2017, or latest

edition thereof.

• Any changes or modifications made or attempted to this product, without the prior written approval of the manufacturer, will void any and all

stated warranties.

• When fitting through an external wall, and external grille must be fitted at all times.

• Fan kits should only be installed by fixed wiring. A flexible cord should not be used.

• This fan is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they are capable of, and have been given supervision or instruction concerning use of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure that they do not play with the fan.

• In case of damage to the supply cord, switch off the device and do not tamper with it. Damaged supply cords must only be repaired or

replaced exclusively by the manufacturer or by an appointed representative. Failure to comply with the above may endanger the safety of

people and cause possible damage to the whole system.

• The fan kit is to be installed so that the blades are more than 2.1m above the floor.

• Precautions must be taken to avoid the back-flow of gases into the room from the open flue of gas or other fuel-burning appliances when

mounted in outside windows or walls.

WARNING

• This inline extraction fan kit is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Keep combustible materials away

from the fan kit and keep them away from the sides and rear.

• Do not use near or in the immediate vicinity of a bath or swimming pool or any wet areas.

• To protect against electric shock, do not immerse cord or plug in water or any other liquids.

• Do not insert or allow foreign objects to enter any ventilation openings, as this may cause an electric shock, fire or damage to the fan kit.

• Do not put fingers or foreign objects into the grille while in operation.

• Any changes or modifications made or attempted to this product, without the prior written approval of the manufacturer, will void any and all

stated warranties.

• To prevent overheating of this fan kit, keep the air inlets and outlets clean and free of anything that may cause blockage. Check all inlets and

outlets from time to time to ensure it is clear of any dirt or dust accumulation. DO NOT COVER.

• Do not use it in areas where gasoline, paint, or flammable liquids are used or stored.

• This product contains recyclable materials. Do not dispose of this product as unsorted council waste. Please contact your local council for the

nearest collection point.