damaging the pump.

•10WARNING:

Appliances equipped with T.S –

Automatic Stop System: these appliances

should not be left in standby for more than

5 minutes.

•11WARNING: Switch the appliance o

completely (master switch on (0)OFF)

whenever it is left unattended.

•12WARNING: Every machine is tested in its

operating conditions, so it is normal for a few

drops of water to be left inside it.

•13WARNING: Take care not damage the

electric cable. If the supply cord is damaged,

it must be replaced by the manufacturer, its

service agent or similarly qualied persons in

order to avoid a hazard

•14WARNING: Appliance with uid under

pressure. Keep a rm hold on the gun and be

prepared to take the kickback pressure. Only

use the high pressure nozzle provided with

the appliance.

•16WARNING: This appliance is not intended

for use by persons (including children)

with reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use

of the appliance by a person responsible for

their safety.

•17WARNING: Children should be

supervised to ensure that they do not play

with the appliance.

•18WARNING: Never start the high-pressure

cleaner without rst completely unwinding

the high-pressure hose.

•19WARNING: When winding and

unwinding the pipe take care not to cause

the high-pressure cleaner to overturn.

•20WARNING: Before unwinding or winding

the hose, switch the machine o and release

the pressure in the hose itself (switching o).

•21WARNING: Risk of explosion — Do not

spray ammable liquids.

•22WARNING: To ensure machine

safety, use only original spare parts from

the manufacturer or approved by the

manufacturer.

•23WARNING: Do not direct the jet against

yourself or others in order to clean clothes or

foot-wear.

• 24WARNING: High pressure cleaners

shall not be used by children or untrained

personnel.

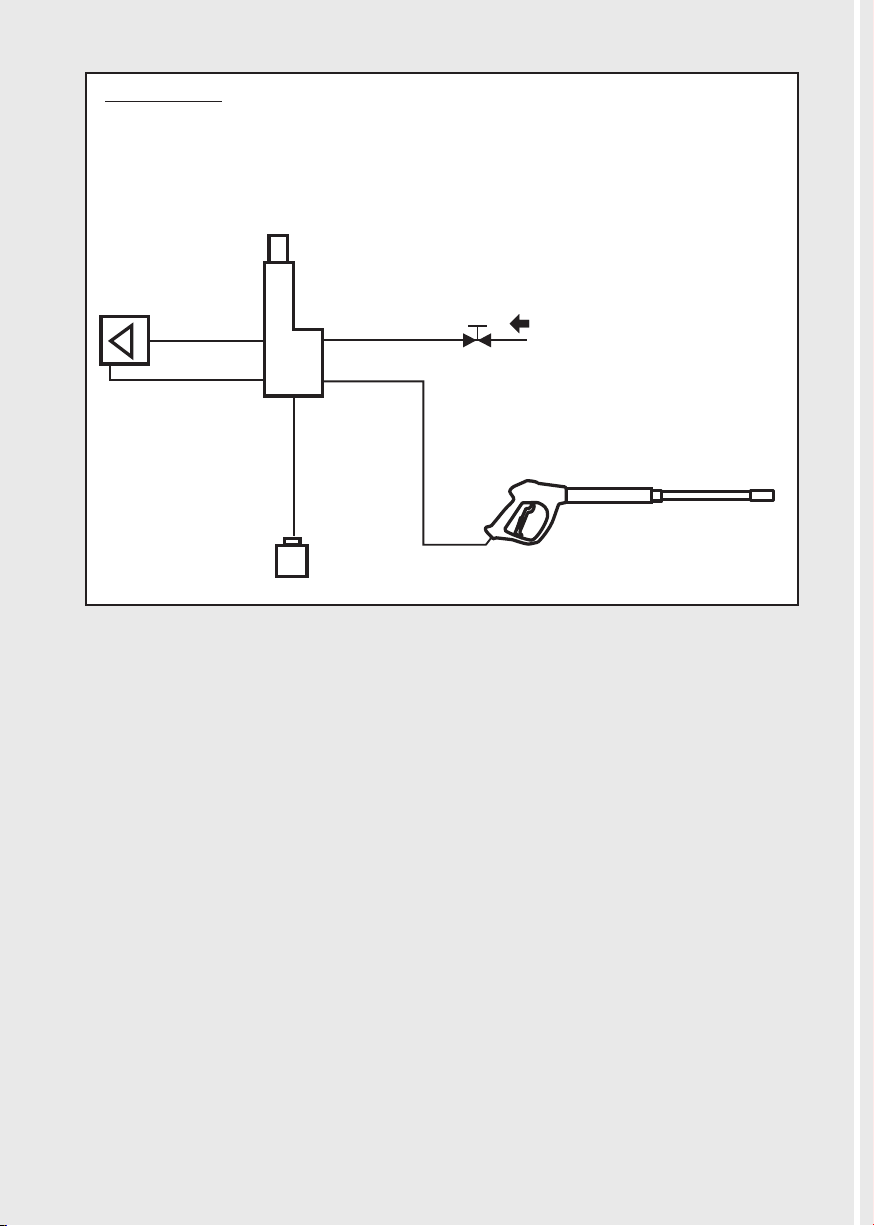

•WARNING:Water that has own through

backow preventers is considered to be

non-potable.

• XX WARNING: the machine shall be

disconnected from its power source, by

removing the plug from the socket-outlet,

during cleaning or maintenance and when

replacing spare parts

• XJ WARNING: If an extension cord is used,

the plug and socket must be of watertight

construction.

• XY WARNING: Inadequate extension cords

can be dangerous.

•WARNING: It is absolutely forbidden to

use the machine in potentially explosive

environments or areas.

•

WARNING:

- NEVER EVER TOUCH THE MACHINE WITH WET

HANDS OR BARE FEET.

- NEVER PULL THE POWER SUPPLY CABLE OR

MACHINE IN ORDER TO DISCONNECT THE PLUG

FROM THE SOCKET.

- IF DURING FUNCTIONING THE POWER SUPPLY

RUNS OUT, FOR SAFETY REASONS, TURN THE

MACHINE OFF.

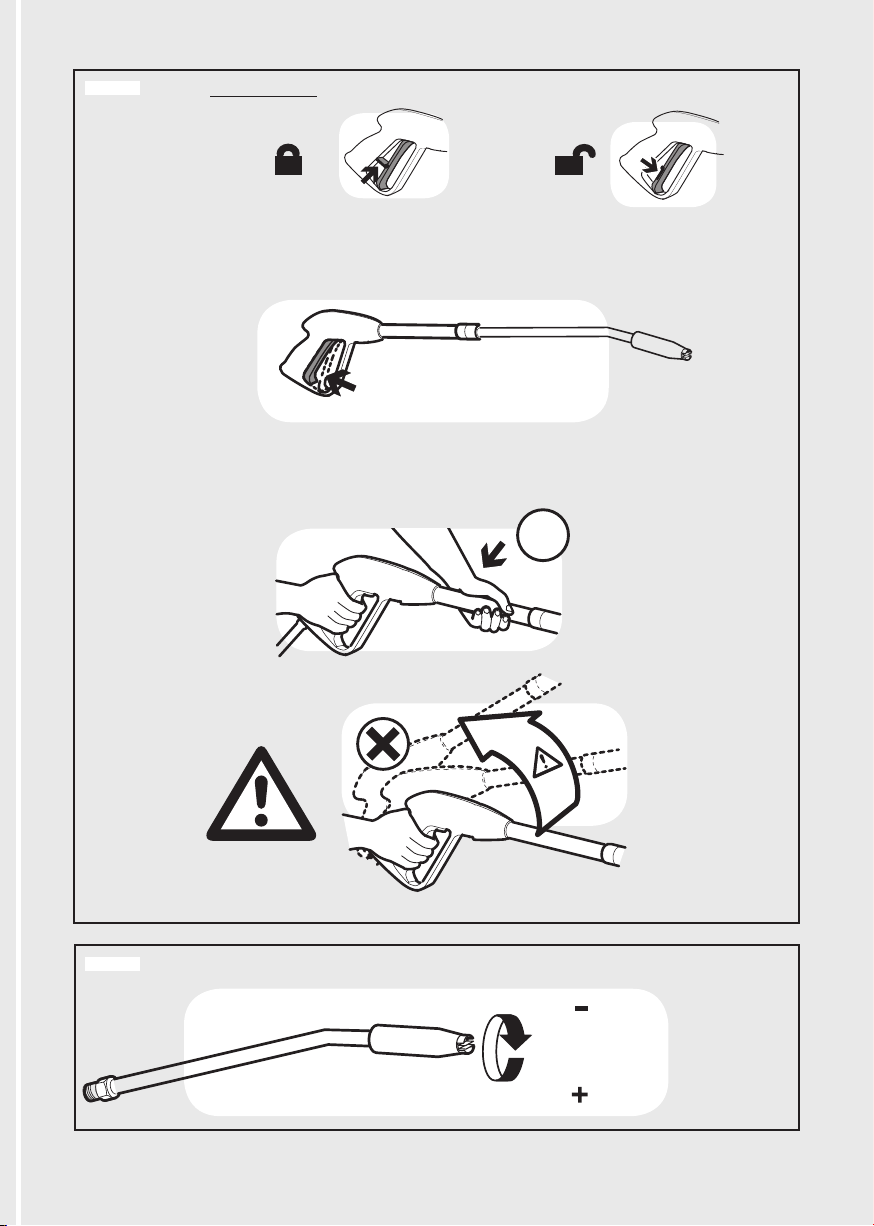

> SAFETY DEVICE

•WARNING: the gun is tted with a safety

catch. Whenever use of the machine is

interrupted it is important to operate the

safety catch to prevent accidental activation

of the jet.

- Safety features: gun equipped with safety

locking device, appliance equipped with

(Class I) overload cutout, pump equipped

with by-pass valve or shutdown device.

- The safety button on the gun is not there

to lock the lever during operation, but to

prevent its accidental operation.

•WARNING: The appliance is equipped

with a motor protection device: in case of

device intervention, wait some minutes or,

in alternative, disconnect and re-connect

the product to the electric system. In case

this problem repeats again or if the product

does not start again, take the product to the

nearest After Sales Service Point

EN

9