21

EN

WARNING

TRANSLATION OFTHE ORIGINAL INSTRUCTIONS

Read and keep in mind that indicated in the INSTRUCTION

MANUAL - SAFETY WARNINGS.

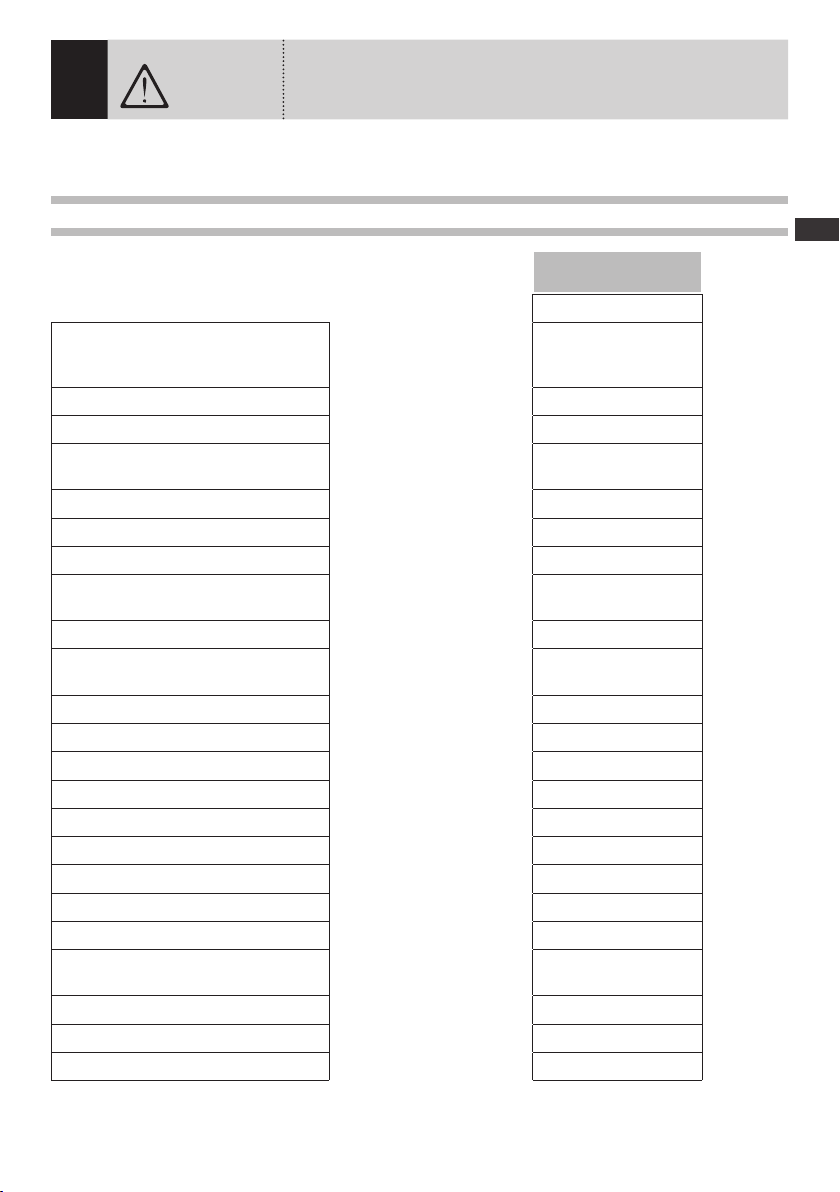

TECHNICAL CHARACTERISTICS AND SPECIFICATIONS

08958

ELECTRICAL CONNECTIONS

Power supply 230V

1~50 Hz

Input (kW - HP)

3.0 - 4.1

Fuse

13A

HYDRAULIC CIRCUIT

Maximum supply water temperature (°C - °F) 60 - 140

Minimum supply water temperature (°C - °F) 5 - 41

Minimum supply water ow rate (l/min - USgpm)

12 - 3,4

Maximum supply water pressure (bar - psi) 8 - 116

Maximum priming depth (m - ft)

Inlet water box

PERFORMANCE

Maximum ow rate (l/min - USgpm)

12 - 3.0

Nominal ow rate (l/min - USgpm)

9-2.2

Maximum pressure (bar - psi)

100- 1450

Nominal pressure (bar - psi)

90 - 1305

Maximum water outlet temperature (°C - °F) 110 - 230

Maximum reaction force on the spray gun (N) 21

Sound pressure level - Uncertainty (dB(A))

78.7 - 0.7

(1)

Sound power level (dB(A)) 93

(1)

Operator hand-arm vibration - Uncertainty (m/s

2

)

0.9 - 0.24

(1)

PUMP OIL ENI MULTITECHTHT

(2)

WEIGHT AND DIMENSIONS

Length x width x height (mm - in) 950 x 620 x 850 - 37,4 x 24,4 x 33,5

Weight (kg - lb) 115 - 254

Diesel tank (l - USgal) 18 - 4,8

Detergent tank (l - USgal)

3.5 - 0.9

(1)

Measurements in agreement with 60335-2-79.

(2)

Also see the corresponding oils table.

The characteristics and specications are guidelines only. The manufacturer reserves the right to make all modications to the equipment deemed necessary.

0 - 0 (with water softener)

YES

SIP Tempest

PH720/100