------------------------

----------

----

-

---

-

------

-------

-

-

-- --

-

----

-----

-----

---

-

---------------

-

- -

-----------

---

-- --

-

--

-

-----

--

-

-

-

--~

I

:le~

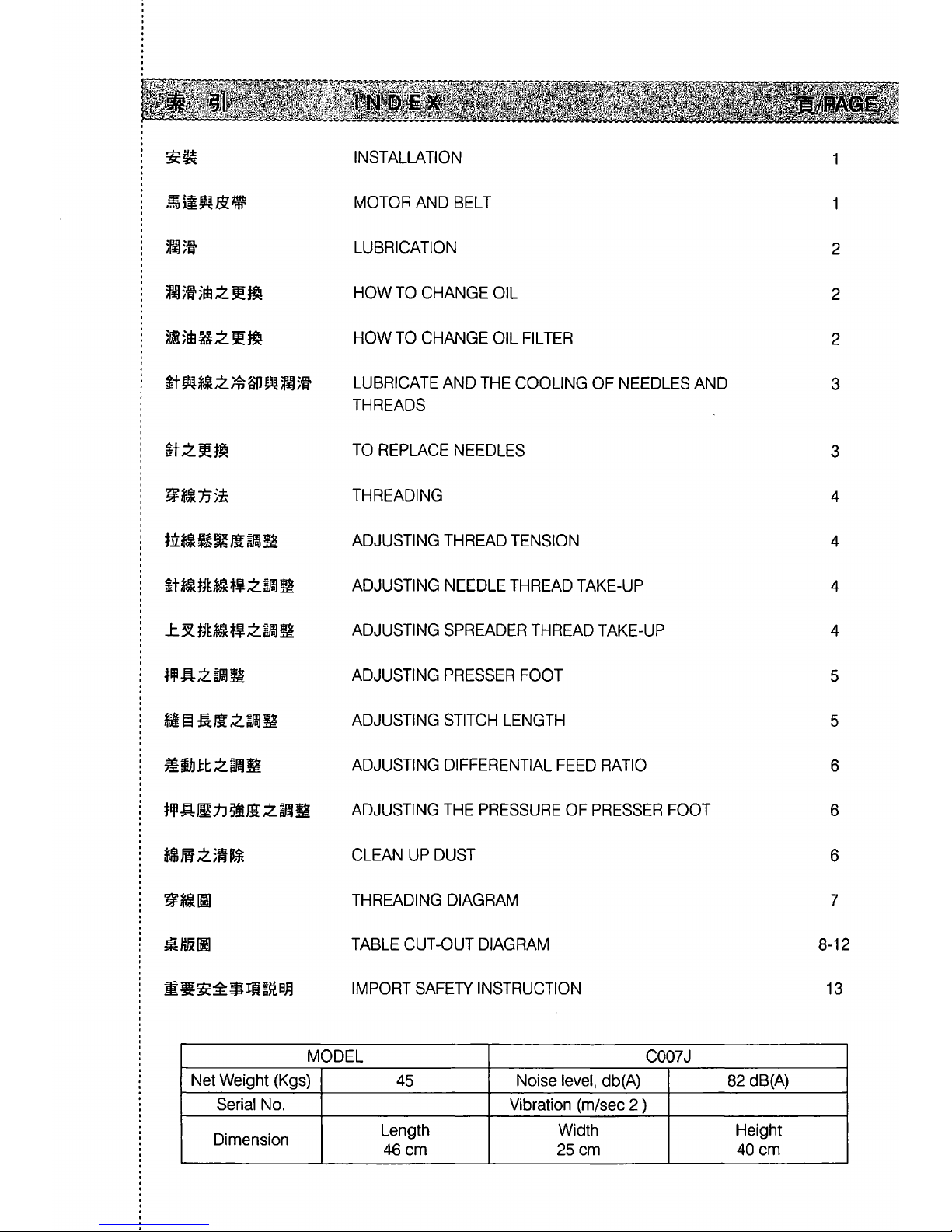

INSTALLATION

l

----

-----

-

---

--

----

---

-

--------- -~-------

--

--------

-

-

-------

--------

-------

---

----------

-----------

-

--

---

-

-

-

-

--

-

--

-

--

----

-

--

-

-

-

--

-

-

--

·

1.

ftvt:::f~H.PITI!f1~1&~~1l11:&~1!f*Jlg~J51T91J

1.

Before installing mach

in

e, please refer

totable·

z~cf!f.f~ff;~~~1.i!H~mt.~~.

cut-out drawing, and the necessary

attachment as enclosed, according to the

sequence of installation, to fix cushion base,

thread stand.

2.

.~

ll

Z

~~

~

~

lllfi

B~

~

1J

~

,$.

~

Z

f~

~

Ji

1-;.1.

ffl

=F:t~~pg~T

2cm

~:§:.~a~ml"~~Jm~.

~~

fll.

t;lf

~&H~t~J:..

(~

.1

&

2)

;!~:

1.~ffl~~H~W-O~~Q~/i~~~~U

~.:28~.~~~~

~-~~llt;ff~R~

(~Ul

~

1).

2.

Be

sure that the motor turning direction

is

clockwise, and the motor belt tension can

be pressed wi

th

finger

in

ward about 2cm.

For safety reason, please fasten the belt

cover.

(F

ig. 1 &

2)

3. Regarding machine speed and motor pulley

diameter, please refer to Table

1.

Remarks:

1.

During the first month

of

using the machine,

the maximum speed shouldn't exceed 80%

of the speed listed in Table

1.

Make sure to

choose the correct size of motor pulley.

2.

The standard thickness ofTable

is

about

50mm.

tl·fll.t;tfR~~~~ffl~~~~rt·M~~~~

Note: Belt size depend on motor type.

~P.IT~W.

Table 1

(~

1)

MO

TOR

BELT

S.

P.M

PUL

L

EY

SIZE

~~~.

fll.t;ff~R-t

$.~

60HZ 50HZ

R~

J5ifl!l

(BELT)

60

00 105 125 36"

55

00

95

115 i

5000

85

105 35"

45

00

80

95

-1-

4000

70

85

34"

·----------------------------------------------------------------------------------------------------------- -

--

--------------------

--

-!

.~ii~Bltm

MOTOR

AND

BELT

!

.

----

--------------------

--

-------

·- -------------------------------------------

--

--

----------------------

-----------

____

_

____

__ j

1.

iWfrH.~ii

1/2

.~1J

(~

400

li

),

3

ffi

2

t~

M *V

~fll.t;/f.

2.~llffi2.:Z~~~~~-Hfll.t;ff~~

~~&

t;lf

~a~

t:f:l

,G

*~

&:,

~~

-

®:

*'~.

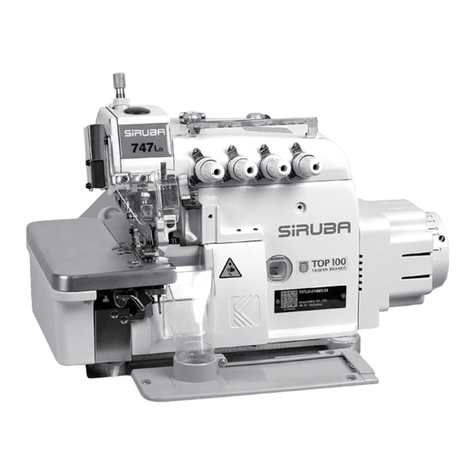

1.

Clutch Motor, 1/2 HP (400W), 3 phase, 2

po

le M type Vbelt.

2.

The centre line of

bo

th motor's and

machine's pulley must be aligned each

other, when installing the motor.

1