INSTRUCTION

MANUAL

FOR

POST

-BED

INDUSTRIAL

SEWING

MACHINE

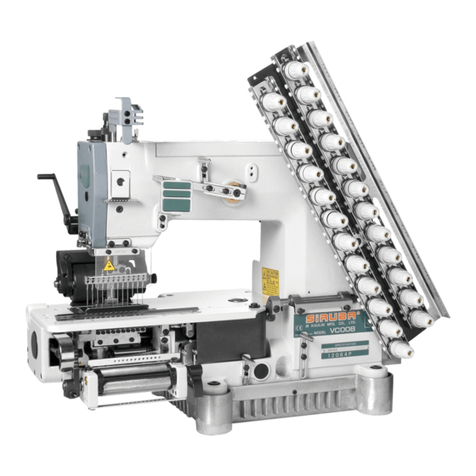

This manual is prepared to permit the sewing machine to be used efficiently and for highest performance.

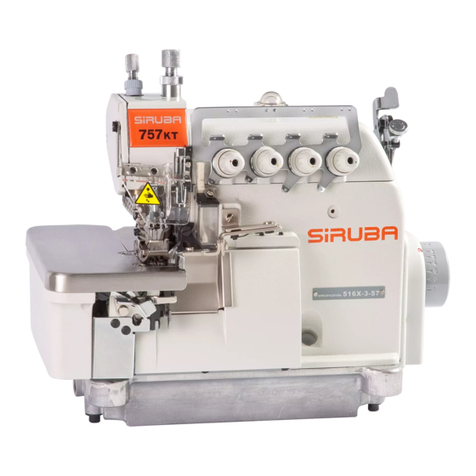

This machine is post-bed industrial

sewing

machine suitable for sewing shoes, bags, caps and general

leather

works.

You

can either select !-needle

or

2-needle machine according to your type

of

works.

Being equipped with spring return reverse lever type feed mechanism opener type vertical hook, and slide

type thread take-up provides perfect uniformed stitching.

-INDEX-

Specification···...·········...·········...······...·········...·········...······...·········...·········...······...·..······...···2

Mainparts name

of

machine head···...···...···...···...···...···...···...···...···...···...···...···...···...···...···...3

I .Preparation for installation of machine

...........................................................................

4

1). Place of installation of machine

....................................................................................

4

2).

How to mount the machine head ·················································································4

3).

How to mount the

motor"···························

.......

····················

............

···············

··--······4

4).

How to connect the motor lever and foot pedaJ

............................................................

4

5).

How

to mount the bobbin winder assembly..

·························································

..........

4

6).

How to mount and adjust the knee lifter mechanism

...................................................

5

7).

How to mount the oil

pan···························································································

..6

8). How to mount the vibration preventing rubber············.......

··········································

··6

!!.

Preparation for

operation····························································································

·7

1). Selection of

thread································································································7

2). How to attach the

needle·······················································································7

3).

How to lead the upper thread..···············································································8

4).

How to wind the lower thread on the bobbin..

··•·······•····•····•·······•···

..

························9

5). How to adjust the bobbin winder assembly..

···························································

··10

6). How to place the bobbin into the book..

··································································

·11

ill.

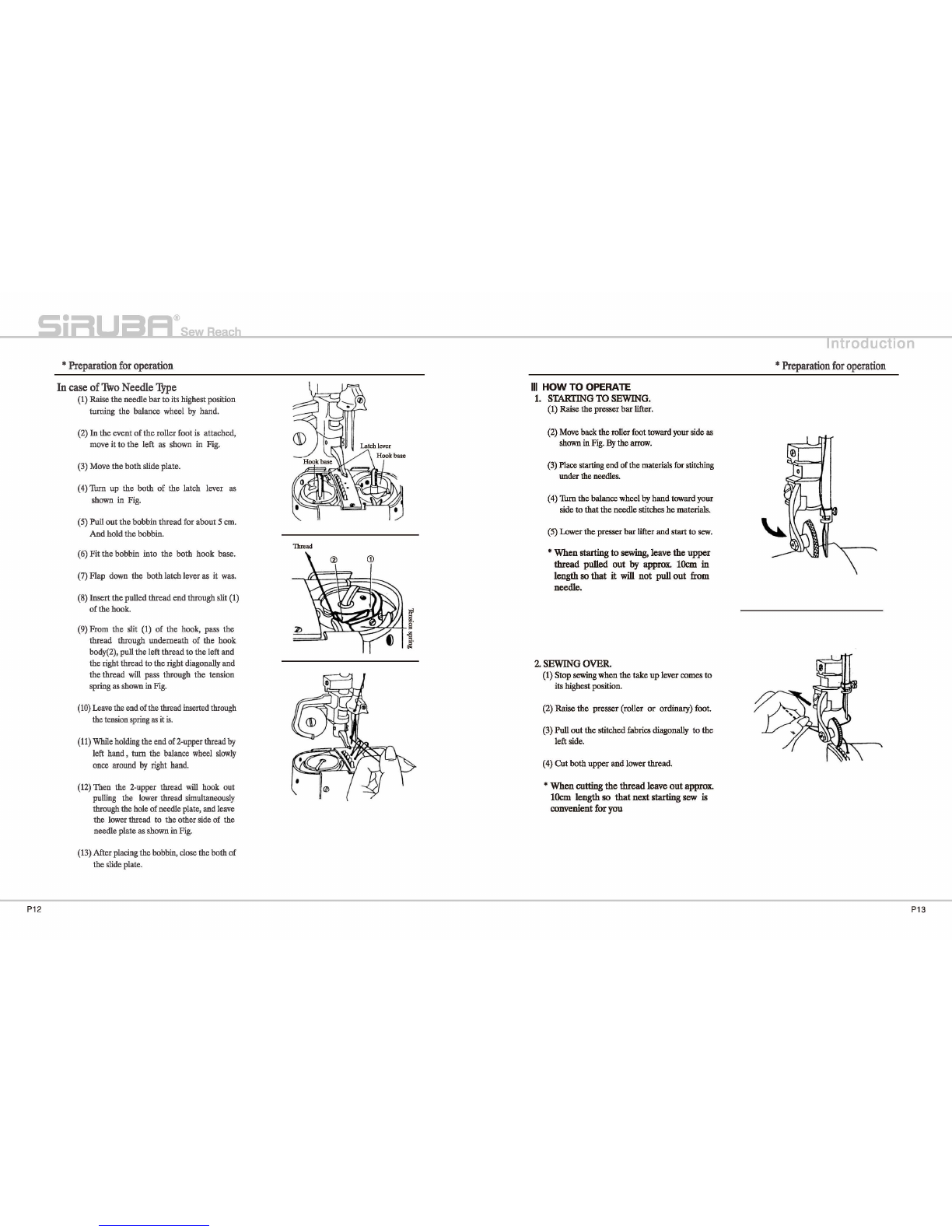

How

to

operate······································································································13

1

).

Starting to

sewing·······························································································

·13

2). Sewing

over·····································································································

····13

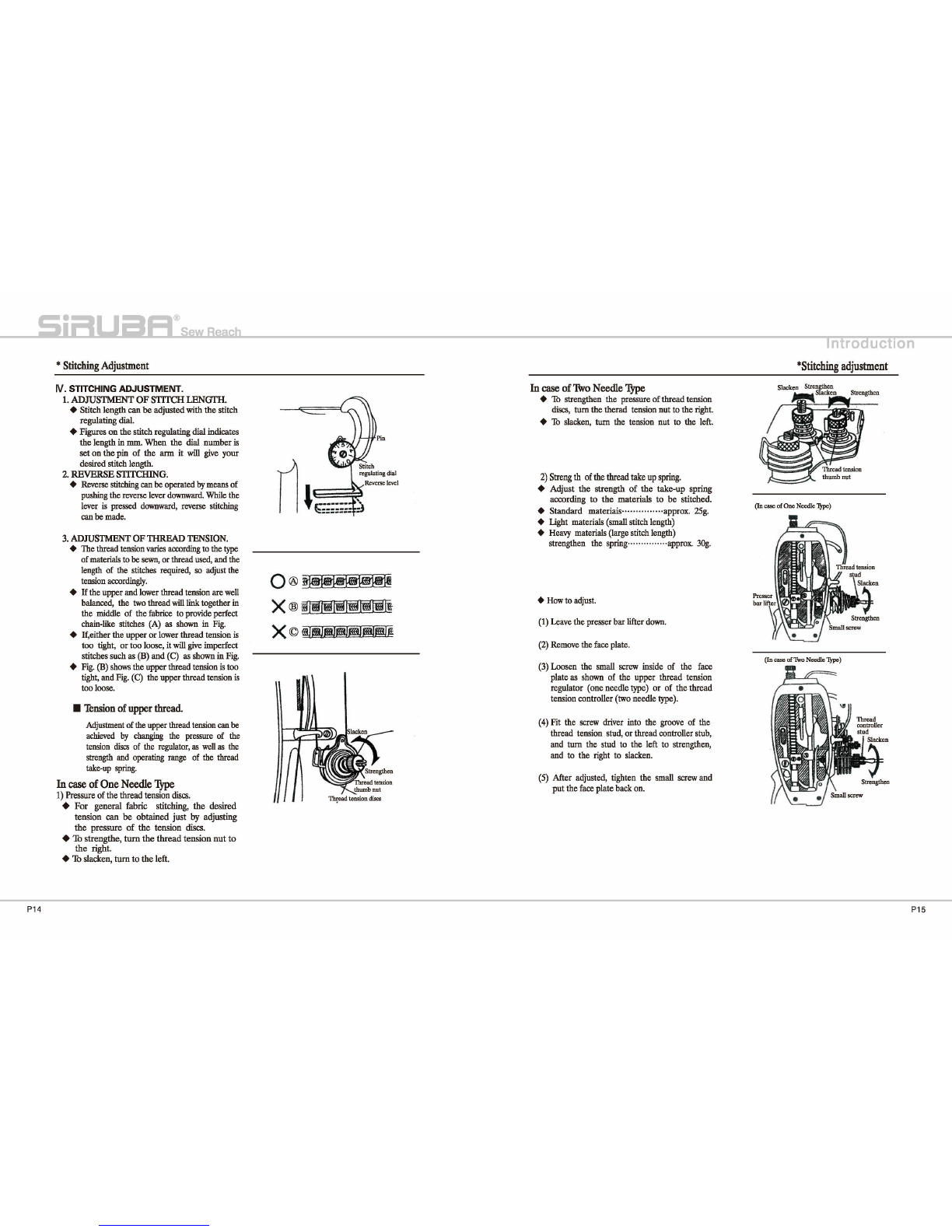

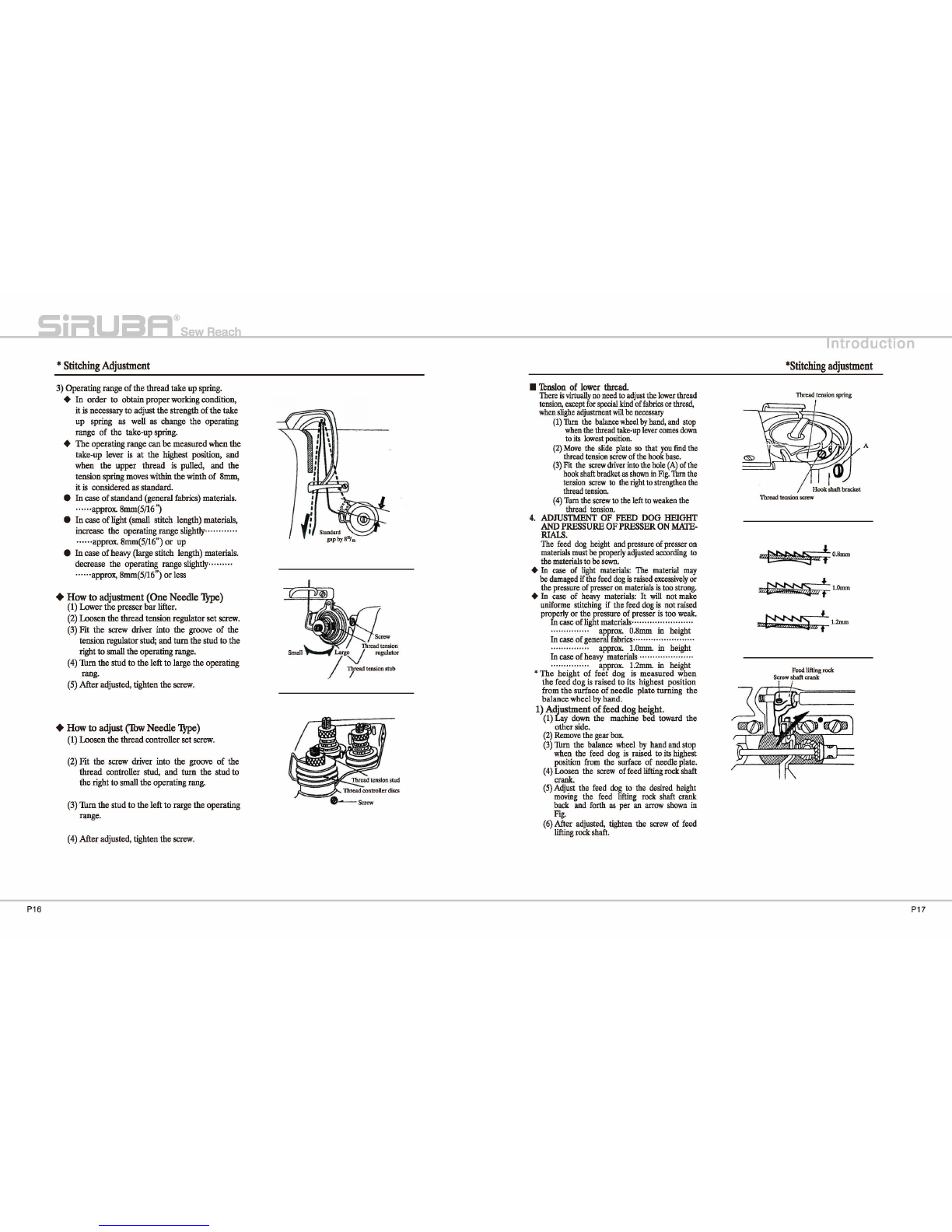

IV. Stitching

adjustment··············································

..

···..

··········································

·14

1). Adjustment

of

stitch

length·················································································14

2). Forward and Reverse stitching······..

··························

..

··········································14

3).

Adjustment

of

thread tension ··············································································14

4). Adjustment

of

feed dog height and pressure

of

presser

on

matcrials

........................

17

5). Proper timing between the hook and needle...

··················································

....

18

6). Proper timing between the hook and opener..····•··•···•··••··•······•······•··••······•··•···•····21

7). Proper timing between the feed dog and needle..···••···••····•·········••··

.....

··•·····•····•·

·22

V.

Cleaning and Lubrication··

........................................................................................

23

1).

Cleaning············································································································23

2). Lubrication··..

···········································

..

···········································

..

···········23

3).

Grease··················································

......

······•·•·•·······•·•·•······••···•····

......

·····

·····24

P1