Siruba FA007 Datasheet

Other Siruba Sewing Machine manuals

Siruba

Siruba 700QD User manual

Siruba

Siruba DL3880 Series User manual

Siruba

Siruba ASP-EBJ100 User manual

Siruba

Siruba 700L User manual

Siruba

Siruba PK511 User manual

Siruba

Siruba DL7200D-NM1 User manual

Siruba

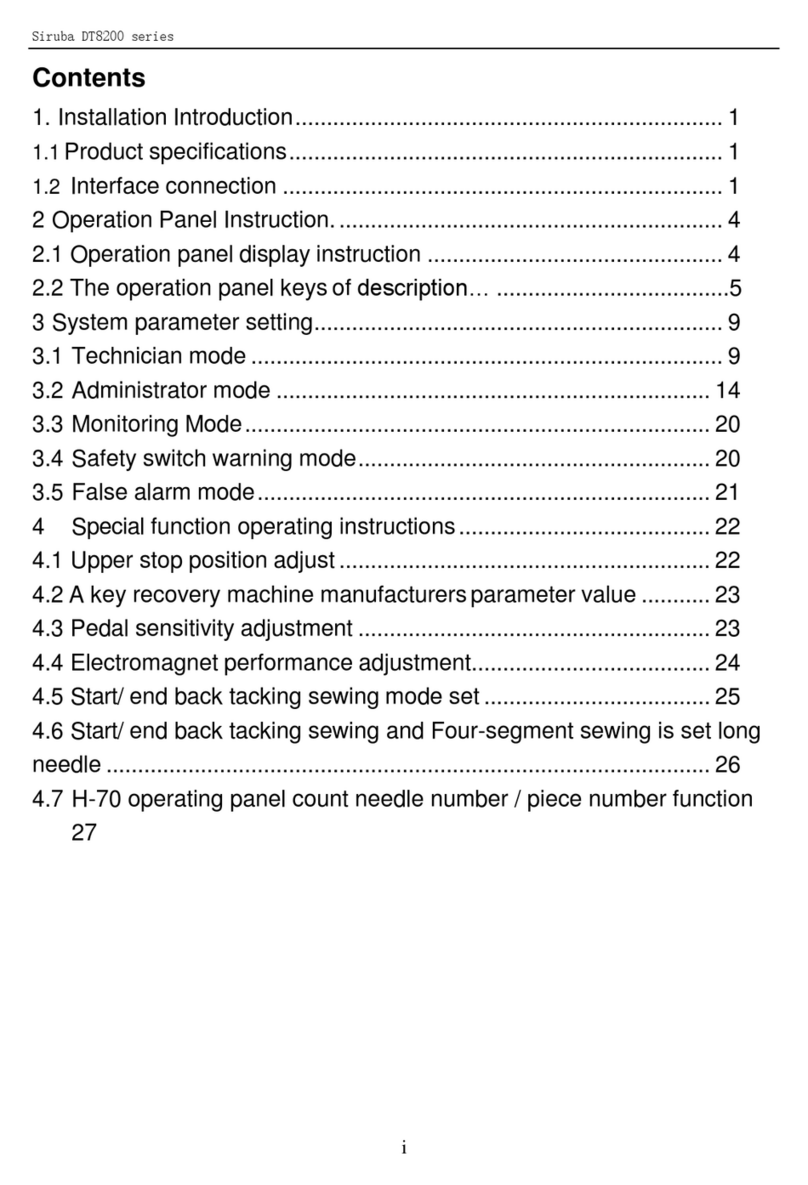

Siruba DT8200 Series User manual

Siruba

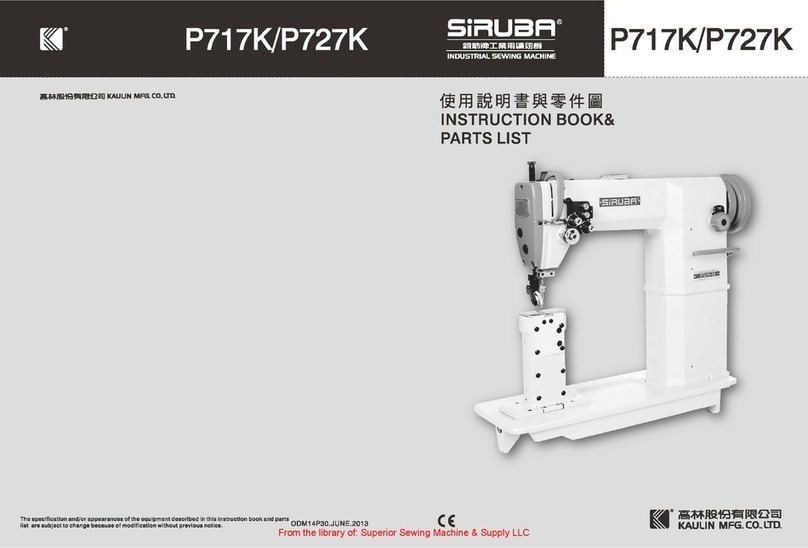

Siruba P717K User manual

Siruba

Siruba PK522 Datasheet

Siruba

Siruba DL918 User manual

Siruba

Siruba HSM-2517 User manual

Siruba

Siruba L818F User manual

Siruba

Siruba L818F-DM1 User manual

Siruba

Siruba Sew Reach ABF Series User manual

Siruba

Siruba DL720 User manual

Siruba

Siruba C007KD User manual

Siruba

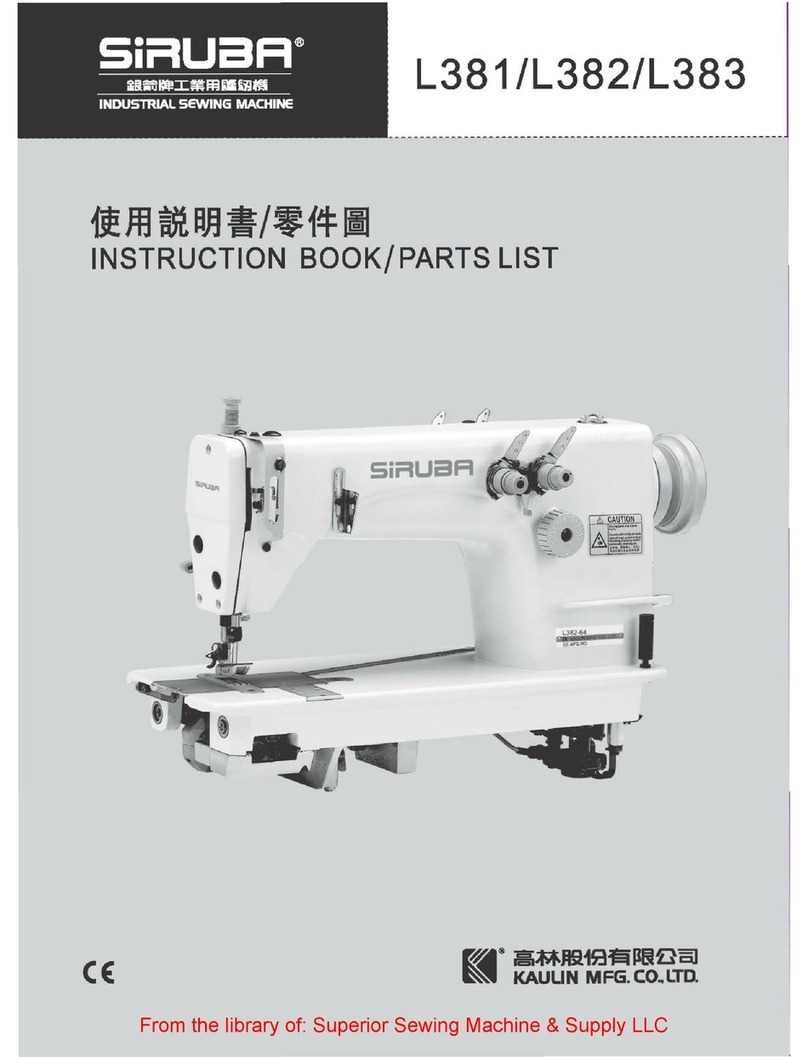

Siruba L381 User manual

Siruba

Siruba 700K/988 User manual

Siruba

Siruba Siruba HSO-747 User manual

Siruba

Siruba LKS-1900AN User manual