Siruba 700KST User manual

Other Siruba Sewing Machine manuals

Siruba

Siruba DL7200B User manual

Siruba

Siruba C007KD User manual

Siruba

Siruba NC008 User manual

Siruba

Siruba DL720 User manual

Siruba

Siruba LZ457A Datasheet

Siruba

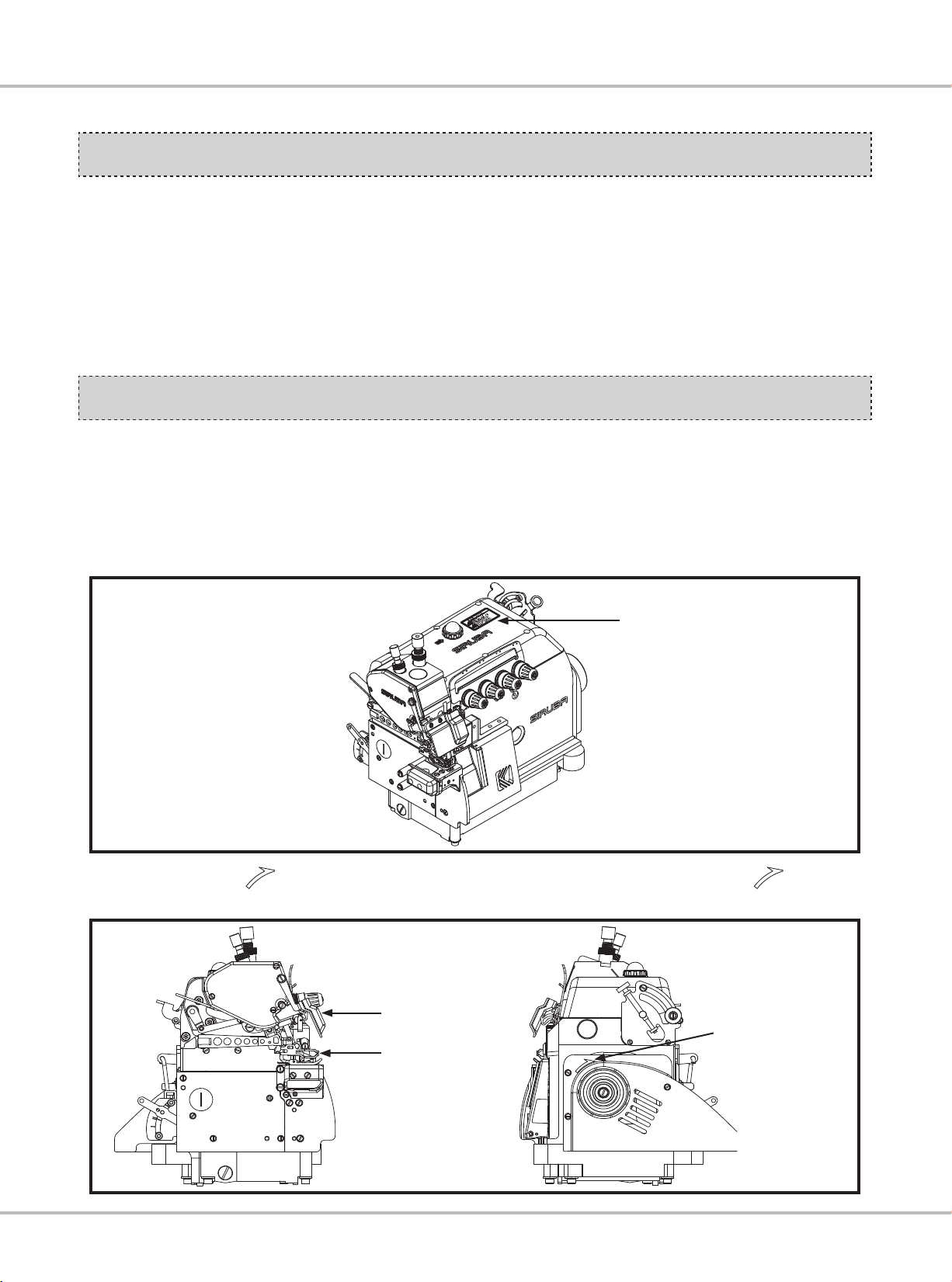

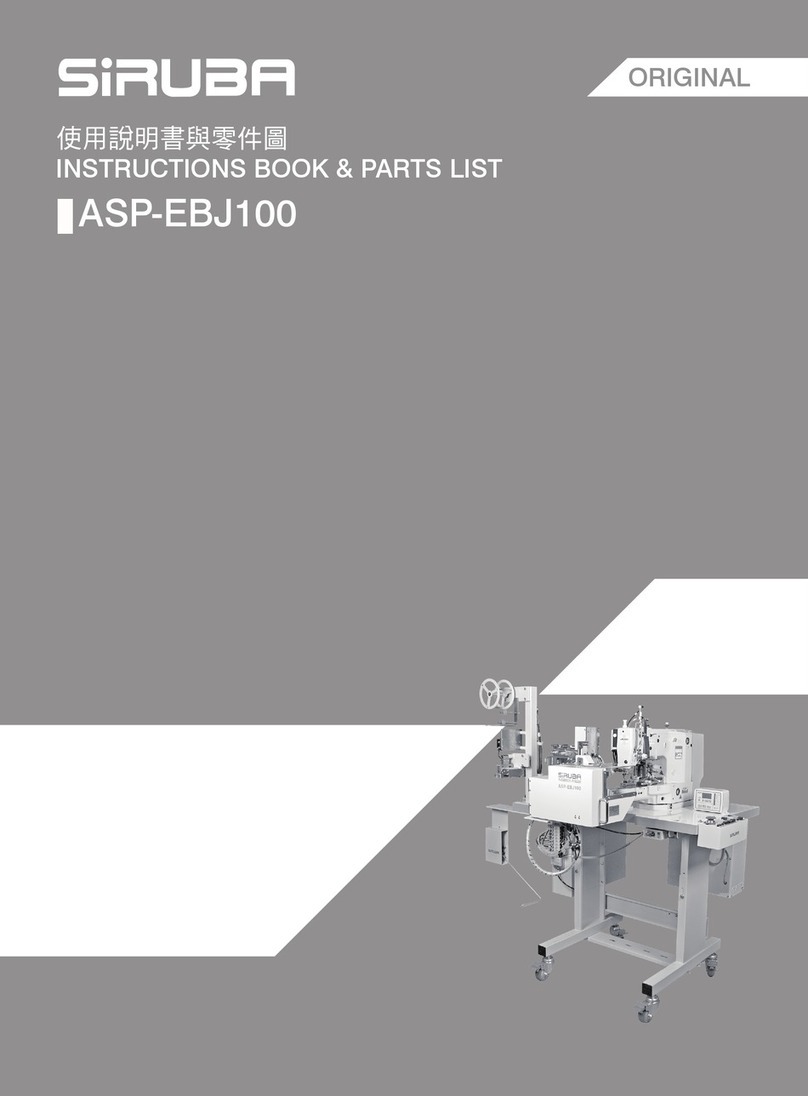

Siruba ASP-EBJ100 User manual

Siruba

Siruba VC008 VSQ User manual

Siruba

Siruba 700K User manual

Siruba

Siruba HF008A User manual

Siruba

Siruba DT828L User manual

Siruba

Siruba VC008B User manual

Siruba

Siruba 700Q User manual

Siruba

Siruba 700L-BKF1 User manual

Siruba

Siruba 700QD User manual

Siruba

Siruba PK511 User manual

Siruba

Siruba HSM-2517 User manual

Siruba

Siruba ASL-JBH200C User manual

Siruba

Siruba F007D User manual

Siruba

Siruba LBHS-1790S User manual

Siruba

Siruba DL3880 Series User manual