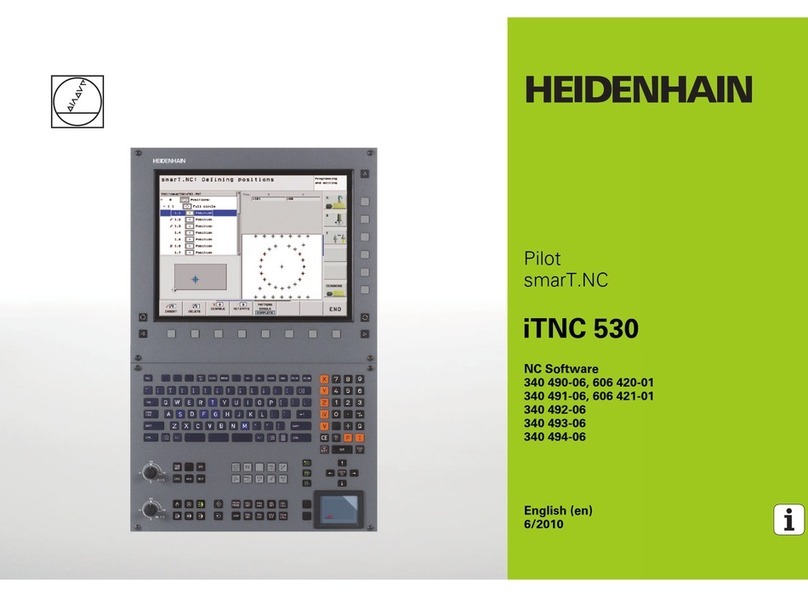

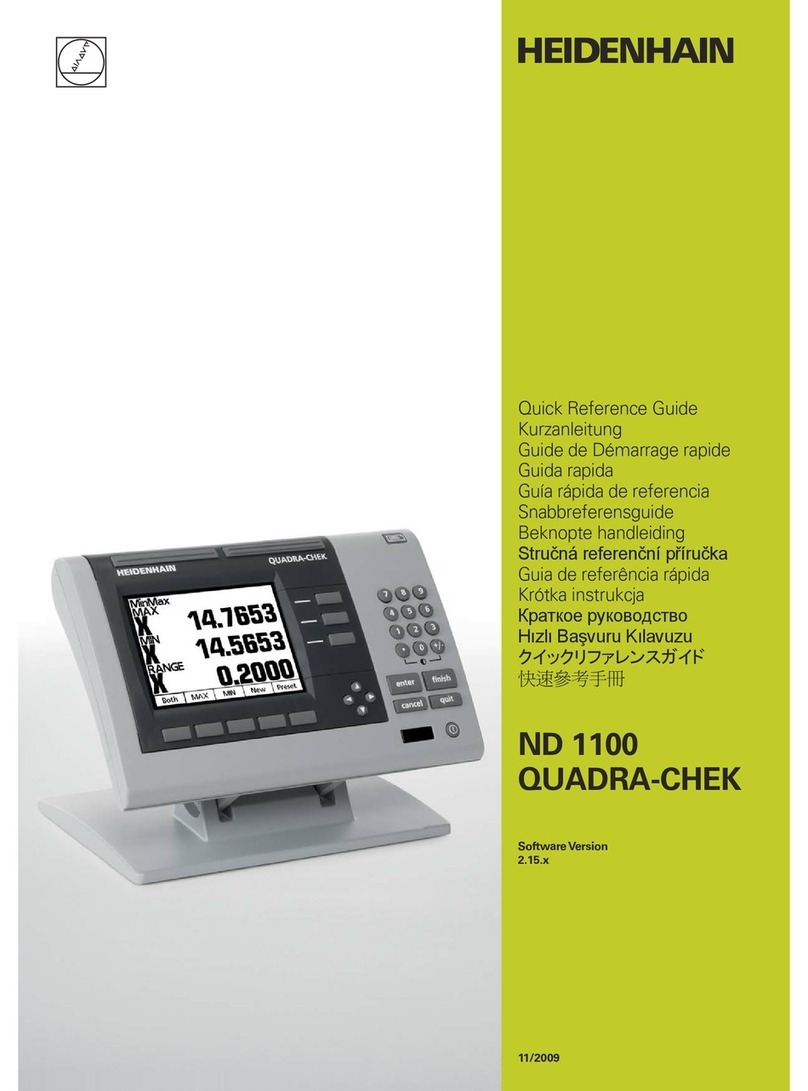

ND 1200 QUADRA-CHEK 9

1.1 ND 1200 Overview ..... 14

1.2 Basic Functions of the ND 1200 ..... 16

Switching on the ND 1200 ..... 16

Establishing a repeatable machine zero ..... 17

Switching off the ND 1200 ..... 17

Panel key descriptions ..... 18

LCD screen and soft key layout ..... 22

DRO mode screen and soft keys ..... 22

Feature evaluation mode screens and soft keys ..... 23

Feature measurement mode screen and soft keys ..... 24

ND 1200 Menus ..... 25

1.3 Preparing to Measure ..... 29

Power-up the ND 1200 ..... 29

Establish machine zero ..... 29

Adjust LCD screen contrast ..... 30

Select unit of measure ..... 30

Select a datum ..... 30

Select a coordinate system ..... 30

Select the desired annotation ..... 31

Toggle between forward and backward annotation ..... 31

Select a probe type ..... 32

Select crosshairs: ..... 32

Select an optical edge probe ..... 32

Calibrate the optical edge detector ..... 33

Perform a Teach ..... 33

Perform a D. Cal ..... 33

Perform an X Cal ..... 33

Align the part to a measurement axis ..... 34

Perform a part alignment (Skew) ..... 34

Establish a datum ..... 35

Probe skew and part edge lines for point construction ..... 35

Construct a datum point from line features ..... 36

Zeroing the datum ..... 36

Presetting the datum ..... 37

1.4 Measuring Part Features ..... 38

Part features ..... 38

Feature list ..... 38

Probing part features ..... 39

Probing with crosshairs ..... 39

Probing with optical edge detection ..... 39

Probing with Measure Magic ..... 40

Measuring features ..... 41

Auto repeat ..... 41

Measuring points ..... 42

Measuring lines ..... 43

Measuring circles ..... 44

Measuring distances ..... 45

Measuring angles ..... 46

1 Operation ..... 13