4

Table of contents

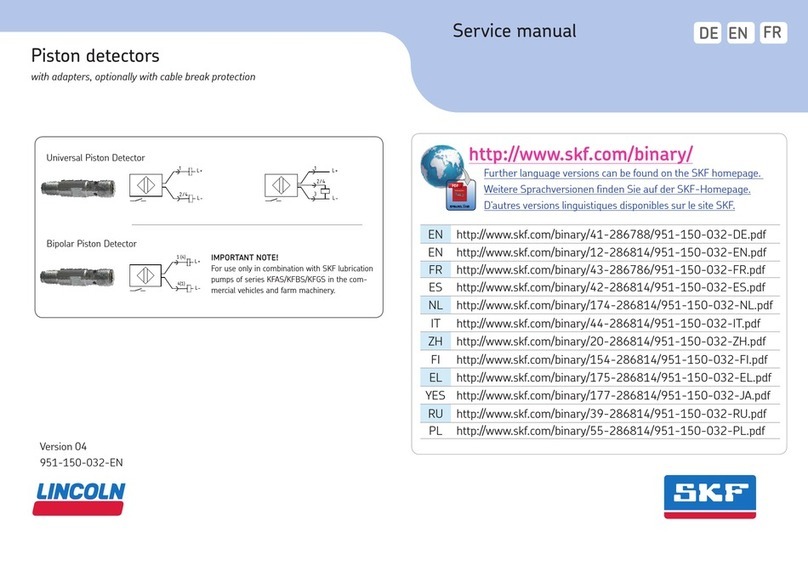

EU Declaration of Conformity in accordance with

Directive 2014/30/EU, Annex IV..........................................2

UK Declaration of Conformity pursuant to the Electromagnetic

Compatibility Regulations 2016 No. 1091, Annex IV ......2

Masthead................................................................................................3

Table of contents ..................................................................................4

Safety alerts, visual presentation, and layout .................................5

1. Safety instructions...........................................................................6

1.1 General safety instructions ..................................................... 6

1.2 General behaviour when handling the product................... 6

1.3 Intended use.............................................................................. 6

1.4 Persons authorized to use the product ................................ 6

1.5 Foreseeable misuse.................................................................. 6

1.6 Referenced documents............................................................ 7

1.7 Prohibition of certain activities............................................... 7

1.8 Painting plastic components and seals................................. 7

1.9 Safety markings on the product ............................................ 7

1.10 Note on the type plate........................................................... 7

1.11 Notes on CE marking............................................................. 7

1.12 Note on UKCA marking ......................................................... 7

1.13 Note on ECE mark.................................................................. 7

1.14 Note on EAC marking ............................................................ 7

1.15 Note on China RoHS mark ................................................... 7

1.16 Emergency shutdown............................................................ 7

1.17 Assembly, maintenance, fault, repair ................................. 7

1.18 First start- up, daily start- up................................................ 8

1.19 Residual risks .......................................................................... 9

2. Lubricants.......................................................................................10

2.1 General information ...............................................................10

2.2 Material compatibility.............................................................10

2.3 Temperature properties........................................................10

2.4 Aging of lubricants..................................................................10

2.5 Avoidance of fault s and hazards ..........................................10

2.6 Solid lubricants........................................................................10

3. Overview, functional description ................................................11

3.1 Field of application..................................................................11

3.2 How it works............................................................................11

3.3 Control units and pumps.......................................................11

3.4 Overview of the compatible lubricant metering devices

with mounting dimension.............................................................11

3.4.1 Metering device VPK / PSG1 Piston

detector 2340- 00000093 ..................................................11

3.4.2 Metering device VPB Piston

detector 2340- 00000094 ..................................................12

3.4.3 Metering device SSV / SSVD / SSVC / SSV- E /

SSVD- E / SLC / VSG (NP / NPI) / VSL (NP / NPI) Piston

detector 2340- 00000095 ..................................................12

3.4.4 Metering device VP / PSG2 Piston

detector 2340- 00000096 ..................................................13

4. Technical data................................................................................14

4.1 General technical data ...........................................................14

4.2 Dimensioned drawings ..........................................................15

4.2.1 Inductive piston detector 2340- 00000093 ..........15

4.2.2 Inductive piston detector 2340- 00000094 ..........15

4.2.3 Inductive piston detector 2340- 00000095 ..........15

4.2.4 Inductive piston detector 2340- 00000096 ..........15

4.3 Electrical connection...............................................................16

4.3.1 Connection options / connector pin assignment...16

4.3.2 Example of a connection between an inductive

piston detector with M12- plug and socket ......................16

4.3.3 Example of a connection between two inductive

piston detectors with M12- plug and socket ....................17

5. Delivery, returns, storage............................................................18

5.1 Delivery .....................................................................................18

5.2 Return shipment .....................................................................18

5.3 Storage .....................................................................................18

5.4 Storage temperature range..................................................18

5.5 Declaration of decontamination ...........................................18

6. Assembly.........................................................................................19

6.1 General information ...............................................................19

6.2 Installation or replacement of the inductive piston

detector ............................................................................................19

7. First start- up..................................................................................21

7.1 Checking the signal .................................................................21

8. Operation ........................................................................................22

9. Maintenance and repair ...............................................................22

9.1 Maintenance ............................................................................22

9.2 Repair ........................................................................................22

10. Cleaning........................................................................................23

10.1 Basics......................................................................................23

10.2 Exterior cleaning...................................................................23

11. Faults, causes, and remedies ...................................................24

12. Shutdown, disposal ....................................................................26

12.1 Temporary shutdown ..........................................................26

12.2 Permanent shutdown, disassembly..................................26

12.3 Disposal ..................................................................................26

12.3.1 Countries within the European Union ..................26

12.3.2 Countries outside the European Union ................26

13. Spare parts ..................................................................................27

13.1 Spare parts............................................................................27

13.2 Accessories ............................................................................27

14. Appendix.......................................................................................29

14.1 China RoHS Table ................................................................29