SKF TKBA 10 User manual

Other SKF Tools manuals

SKF

SKF 729101 User manual

SKF

SKF LINCOLN 1440CLR User manual

SKF

SKF TMBR User manual

SKF

SKF LINCOLN 1154 Instruction Manual

SKF

SKF TMHP 15 Series User manual

SKF

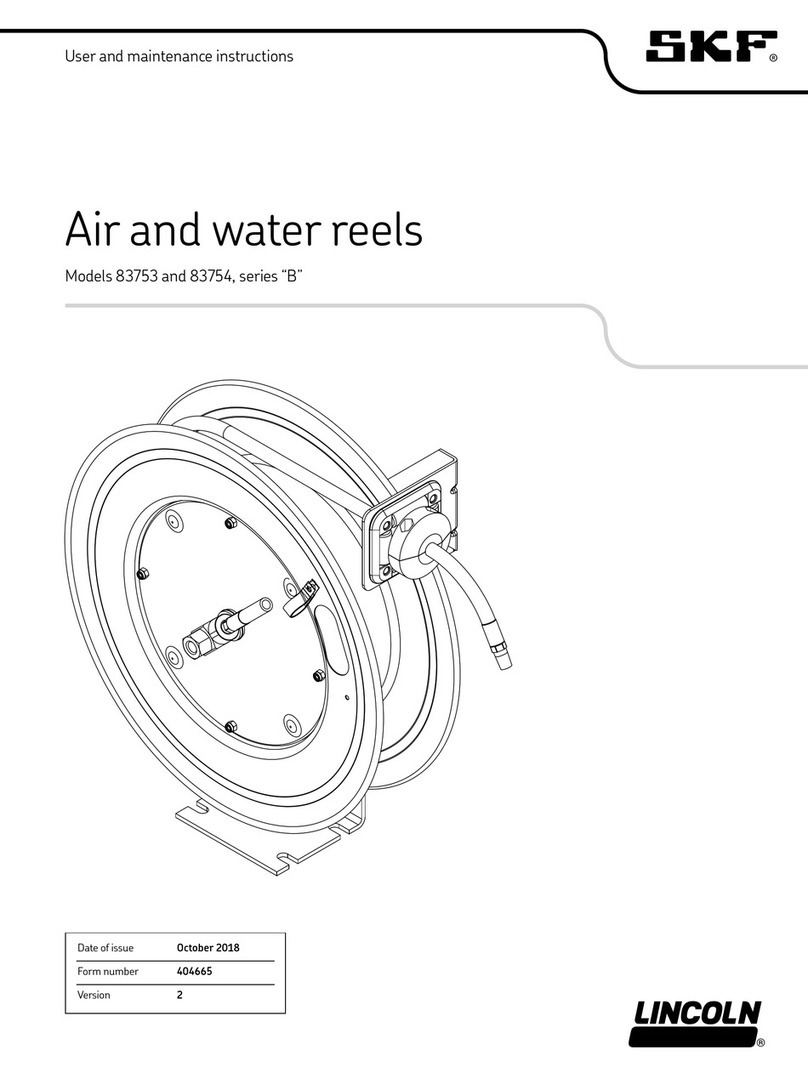

SKF 83753 Instruction Manual

SKF

SKF LINCOLN 1134 Product manual

SKF

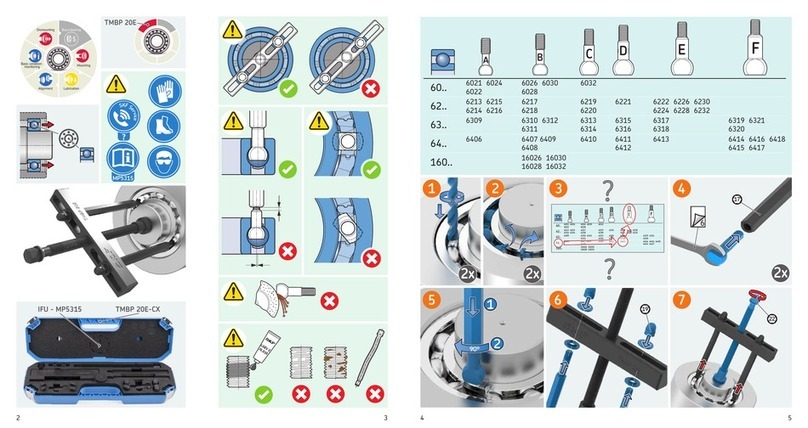

SKF TMBP 20E User manual

SKF

SKF TMBS 100E User manual

SKF

SKF TMHP 10E User manual

SKF

SKF Lincoln 91024 Product manual

SKF

SKF TMHC 110E User manual

SKF

SKF LINKOLN 1262E Product manual

SKF

SKF Lincoln PowerLuber B Series Product manual

SKF

SKF TMMA 75H User manual

SKF

SKF ALEMITE 597 Series User manual

SKF

SKF TLGB 20 User manual

SKF

SKF 1077600 User manual

SKF

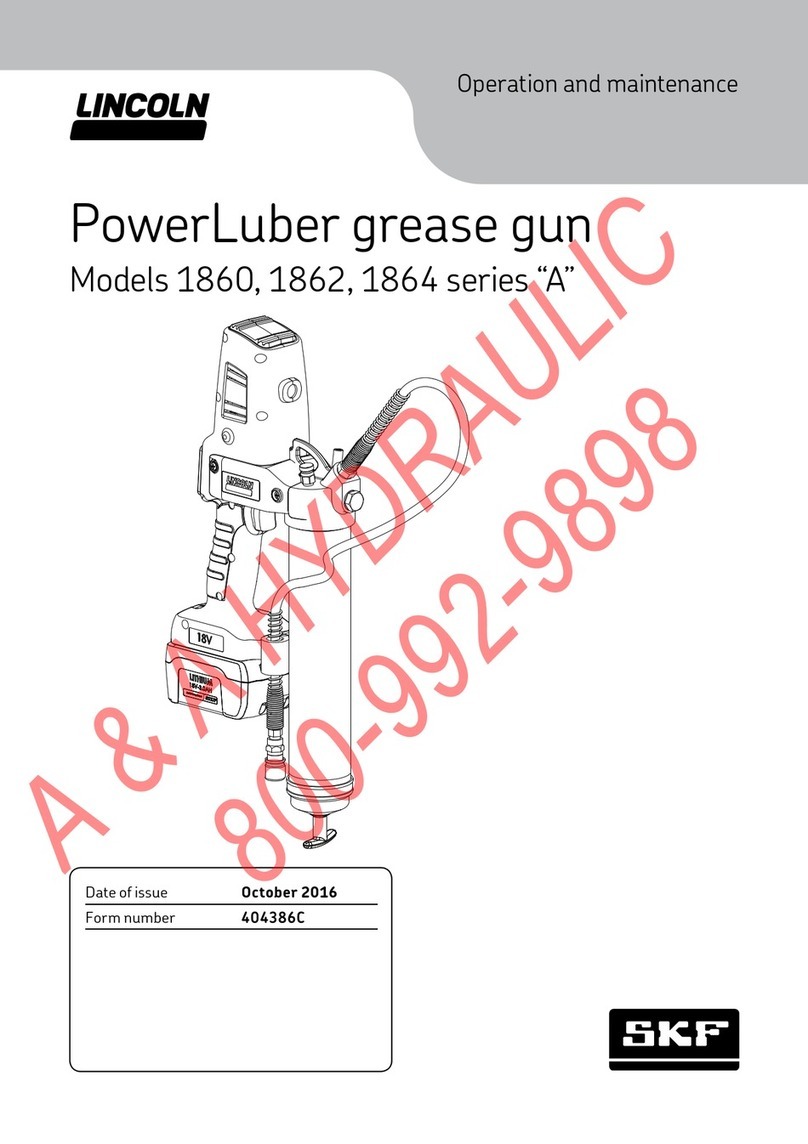

SKF Lincoln PowerLuber A Series Installation guide

SKF

SKF TMHC 110E User manual