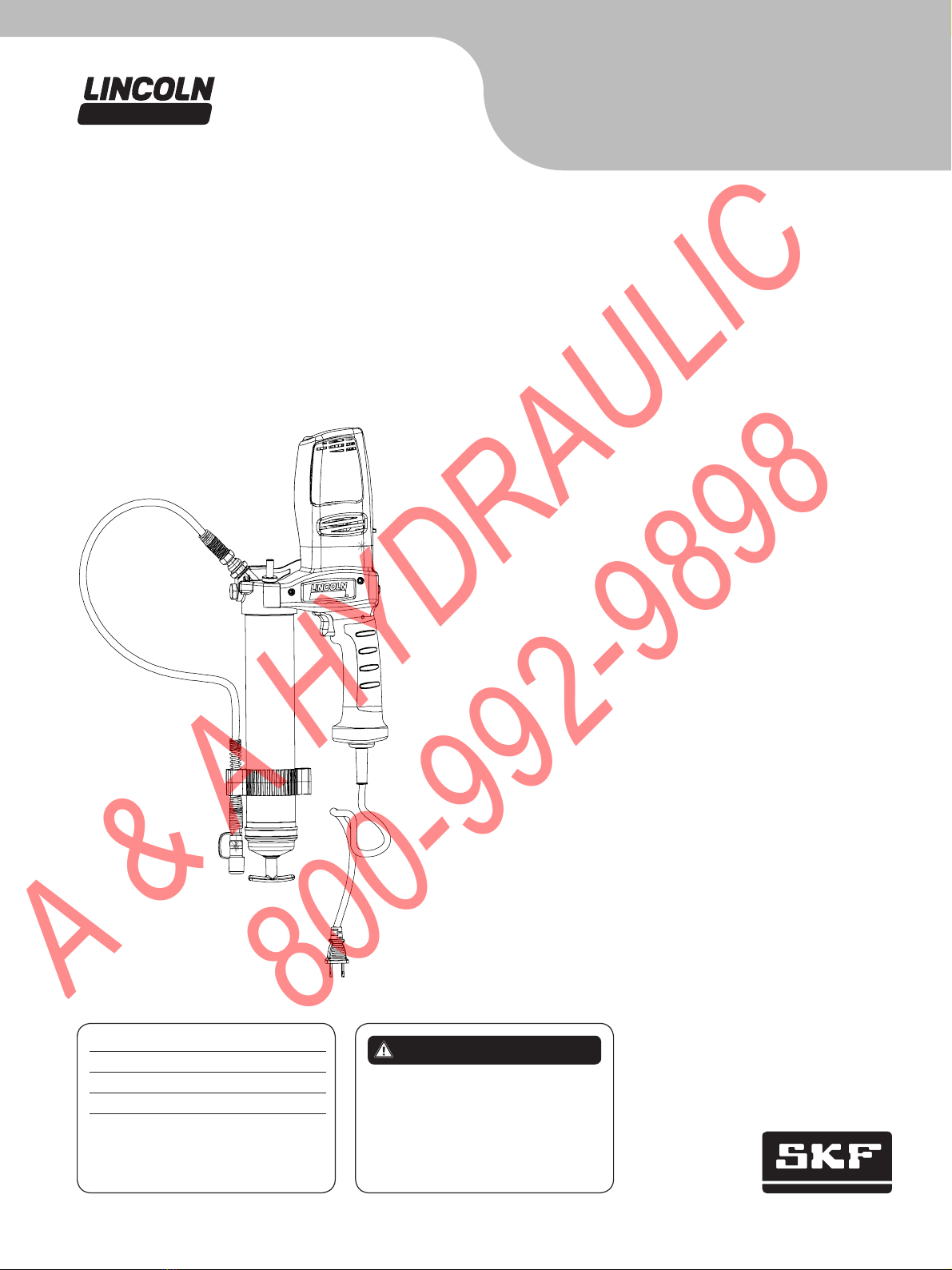

Variable output switch

The variable speed switch permits motor

speed control, the more the trigger is

depressed the higher speed of the motor

and therefore the higher the grease output

of the gun.

Double insulation

The electric PowerLuber utilizes a double

insulated motor design for safety. The dou-

ble insulation eliminates the need for a three

wire grounded cord. All exposed metal parts

are isolated from the internal metal motor

components with a double layer of protec-

tion insulation. Double insulated tools do not

need to be grounded.

Inspection

1 Visually inspect for damaged, loose or

missing parts.

2 If tool is worn or damaged, remove from

service. Contact an authorized service

center for damage assessment or repair.

Operation

Changing “L” or “H” mode

To change the mode of operation:

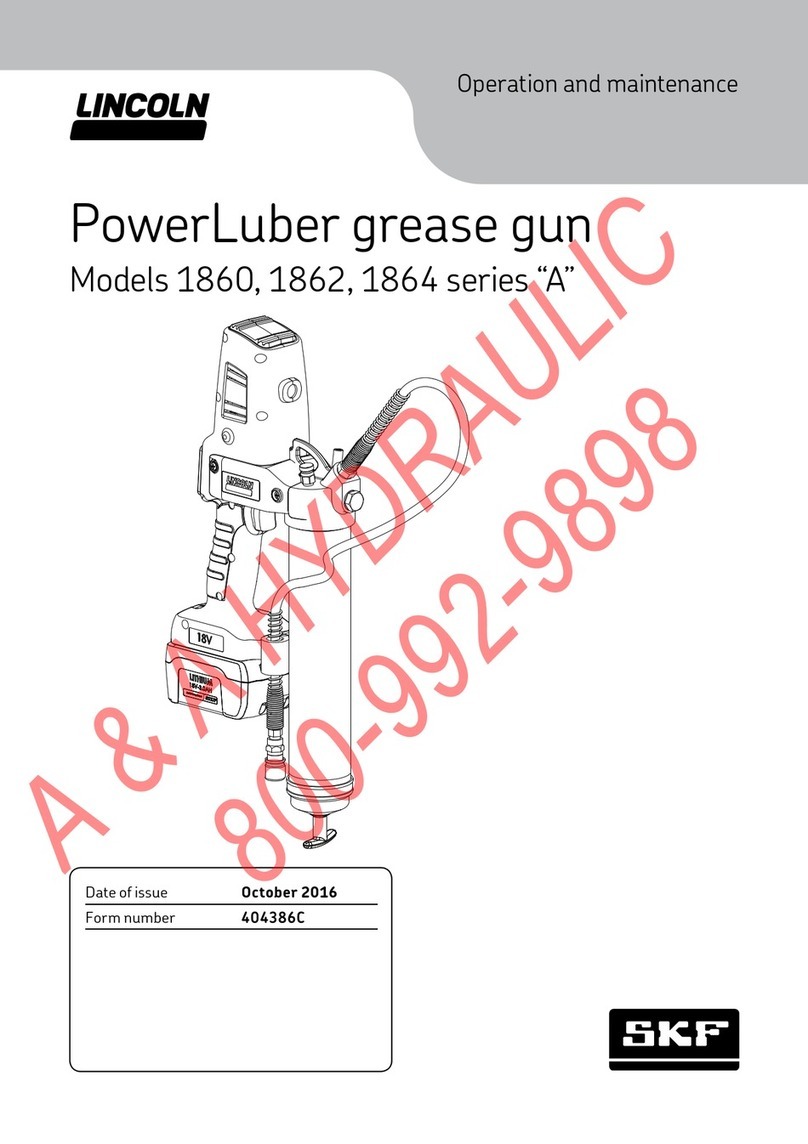

General description

Appropriate use

The Lincoln PowerLuber was developed for

manual lubrication of grease points and

includes a safety valve, stroke counter, out-

put lever, whip hose with coupler and 6 ft.

(1,8 m) power cord.

The PowerLuber is driven by a small

electric motor connected to a three-stage

planetary gear reducer. The rotary motion

of the motor is converted into a reciprocat-

ing motion of the plunger through an eccen-

tric and yoke mechanism. The PowerLuber

is a positive displacement single acting

pump.

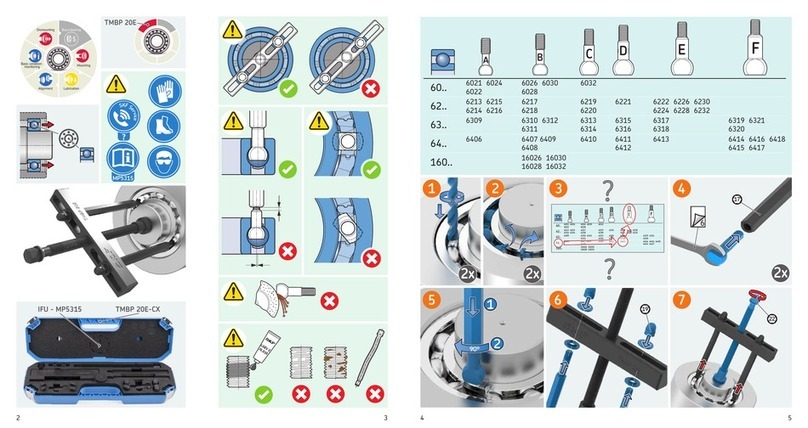

Safety valve

The safety valve († fig. 1) is factory set to

relieve pressure above 7,000 psi (482 bar).

The valve also is an indicator of the bearing

and lubrication line conditions. If grease

comes out of the safety valve, it indicates a

clogged or tight bearing or fitting or line.

Correct this before continuing lubrication

with the PowerLuber.

Stroke counter

The tool is equipped with capability for cali-

bration. This is accomplished by measuring

(weighing) grease flow output and dividing

the weight of grease by number of strokes.

Simply put your thumb on the stroke coun-

ter button († fig. 1) during operation of the

tool and count.

Some Original Equipment Manufacturers

(OEM’s) recommend the exact amount of

grease to lubricate critical bearings. By

counting the strokes you will know how

much grease has been dispensed to

lubricate the bearing. Table 2 details the

grease output verse number of strokes.

Output

Stroke count Output per stroke

10 0.20 oz (5,7 g)

15 0.30 oz (8,5 g)

20 0.40 oz (11,4 g)

Note: Lincoln recommends this feature only on low output/

high pressure mode.

Do not operate tool if outer casing is

cracked, chipped or damaged

Double insulated system is intended

to protect user from shock resulting

from a break in the tool’s internal

insulation.

Observe all normal safety precautions

to avoid electrical shock.

WARNING

• “L” (low output/high pressure)

• “H” (high output/low pressure)

When motor is not running, push the red

lever († fig. 1) until letter “L” or “H” will be

completely visible in the window. In case the

red lever is not completely shifted/

engaged, hold this lever and bump the

switch to engage gears.

High output is recommended if the tool is

used to lubricate large bearings not requir-

ing high pressure, beyond 3,000 psi

(206 bar). Also, high output is recommend-

ed if tool is used to refill small reservoirs of

automatic lubrication systems.

Low output is recommended if the tool is

used in construction, agricultural and min-

ing applications and general lubrication.

Low output will provide the maximum pres-

sure of up to 7,000 psi (482 bar) the tool is

capable of producing.

Prime the PowerLuber after each refill or

grease cartridge change. Prime the gun

before using it to lubricate grease points.

To prime, operate the gun until grease

flows from the hose. Use vent valve

(† fig. 1) to expel air pockets.

!Notice

To prevent damage to the gears in

the transmission, the motor must be

completely stopped before changing the

lever to the “L” or “H” (low or high) mode

of operation.

5

A & A HYDRAULIC

800-992-9898