4 Commissioning

4.1 General

Before starting the lubrication unit, check that all outer connec-

tions (reservoir, air supply, electric connections, etc.) have been well

mounted and tightened.

!You must observe the machinery manufacturer's infor-

mation on the lubricants to be used in the machinery.

!CAUTION!

Only use a clean lubricant. Soiled lubricants can cause

major defects in the system.

!CAUTION!

Different lubricants must not be mixed together. Doing so

can cause damage and require extensive cleaning of the lubrica-

tion unit/centralized lubrication system. To prevent any risk of

error, it is recommended to clearly identify the lubricant used on

the reservoir.

4.2 First commissioning - pump priming

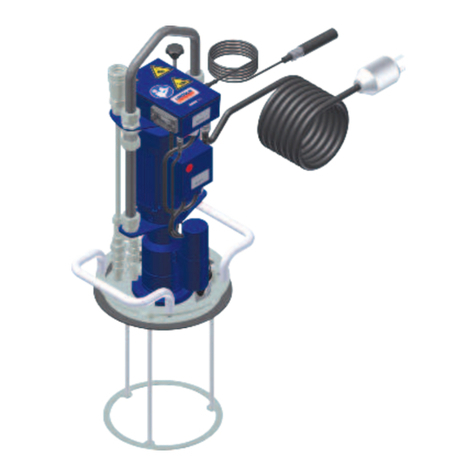

• Put a container under the bleed opening († 3 fig. 1) to collect

the lubricant flowing out

• Remove the bleed plug

• Open the bleed valve († 4 fig. 1)

• Actuate the forced operation button of the solenoid valve

(† 12 fig. 1)

• The pump starts

• Let the pump run until it is primed. Grease only must flow out of

the bleed opening without air.

• Release the forced operation button of the solenoid valve

• Close the bleed valve

• Put back the bleed plug

• The pump is ready for operation

4.3 Semi-automatic filling

• Check the filling control cabinet is switched on (white signal light

on). if it is not the case switch on the control cabinet with the dis-

connector († 7 fig. 2)

• Check the PTL filling pump is correctly connected to the PVP

pump supply line

• Check the PTL filling pump is correctly connected to the air supply

network (minimal pressure 2,7 , maximal pressure 4 bar)

• Turn the button Semi-automatic filling to position 1 († 4 fig. 2).

The PTL pump starts and delivers lubricant to the PVP pumps

• When the maximal level of the PVP pump has been reached, the

level switch of the PVP pump sends a signal and the green signal

light Reservoir full lights on

• The control cabinet stops automatically the filling

• The button Semi-automatic filling switches back to position 0

• The green signal light lights off when the lubricant drops under

the maximal level in the reservoir of the PVP pump

4.4 Replacing the drum

• Disconnect the air supply line from the PTL pump

• Put a container under the bleed opening († 3 fig. 1) to collect

the lubricant flowing out

• Remove the bleed plug

• Open the bleed valve († 4 fig. 1)

• Wait until the grease pressure falls to 0 bar on the manometer

(† 15 fig. 1)

• Close the bleed valve

• Disconnect the air inlet quick-release coupling († 11 fig. 1)

• Disconnect the lubricant outlet quick-release coupling

(† 16 fig. 1)

• Unscrew the butterfly screws from the cover

• Unscrew the bung adaptor of the pump († 8 fig. 1)

• Separate the pump from the follower plate and the cover and take

it out of the drum

• Lay down provisionally the pump on a clean surface to avoid any

contamination

• Remove the cover. The magnet, which holds the cable of the level

switch († 5 fig. 1) in contact with the follower plate, comes away

from the follower plate making the cable free.

• Pull with the handle the follower plate out of the drum

• Lay down provisionally the follower plate on a clean surface to

avoid any contamination

• Remove the empty drum

• Put the new drum in place and open it

• Put the follower plate on the grease (press it again the surface of

the grease)

• Put back the cover on the drum

!When putting back the cover put the magnet of the level

switch on the follower plate in the vertical axis of the level

switch.

• Insert the pump through the cover and the follower plate until the

bottom of the drum

• Tighten the pump bung adaptor

• Screw in the butterfly screws on the cover

• Connect the lubricant outlet quick-release coupling

• Connect the air inlet quick-release coupling

• Open the air supply

• Start the pump († § 4.2)

10