5

Table of contents

Masthead ...............................................................................................4

Table of contents..................................................................................5

Safety alerts, visual presentation, and layout.................................7

1. Safety instructions...........................................................................8

1.1 General safety instructions......................................................8

1.2 General electrical safety instructions.....................................8

1.3 General behaviour when handling the product ...................9

1.4 Intended use...............................................................................9

1.5 Persons authorized to use the product.................................9

1.6 Foreseeable misuse ..................................................................9

1.7 Referenced documents ......................................................... 10

1.8 Prohibition of certain activities ............................................ 10

1.9 Painting plastic components and seals .............................. 10

1.10 Safety markings on the product ....................................... 10

1.11 Note on the type plate ........................................................11

1.12 Notes on CE marking .......................................................... 11

1.13 Note on Low Voltage Directive.......................................... 11

1.14 Note on Pressure Equipment Directive........................... 11

1.15 Note on UKCA marking.......................................................11

1.16 Note on UL mark .................................................................11

1.17 Note on ECE mark ...............................................................11

1.18 Note on EAC marking.......................................................... 11

1.19 Note on China RoHS mark................................................. 11

1.20 Emergency shutdown ......................................................... 11

1.21 Assembly, maintenance, fault, repair............................... 12

1.22 First start-up, daily start-up.............................................. 12

1.23 Residual risks........................................................................ 13

2. Lubricants ...................................................................................... 14

2.1 General information............................................................... 14

2.2 Material compatibility ............................................................ 14

2.3 Temperature properties........................................................14

2.4 Aging of lubricants .................................................................14

2.5 Avoidance of faults and hazards.......................................... 14

2.6 Solid lubricants ....................................................................... 14

3. Overview, functional description................................................ 15

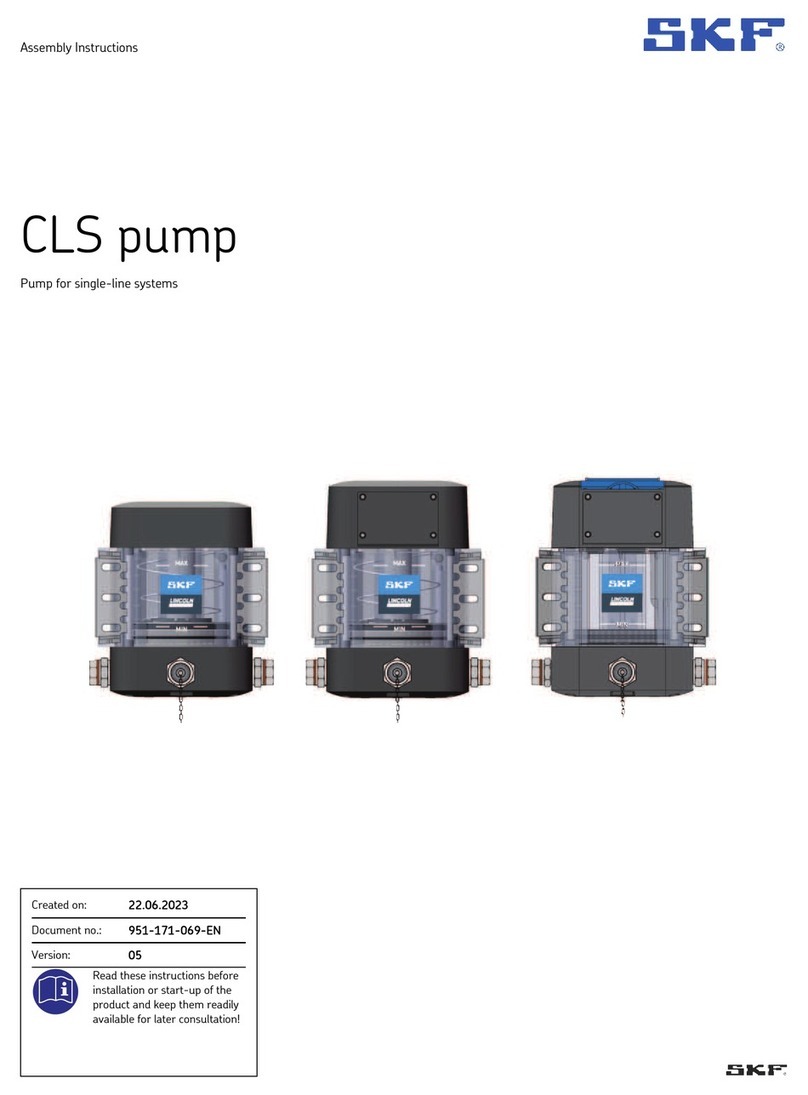

3.1 General..................................................................................... 15

3.2 Design.......................................................................................15

3.2.1 Pump housing............................................................. 15

3.2.2 Lubricant reservoir .................................................... 15

3.2.3 Fill level monitoring ................................................... 15

3.2.4 KFGS and KFGL control units .................................. 15

3.3 Overview ..................................................................................16

3.3.1 KFG pump units.......................................................... 16

3.3.2 KFGS pump units....................................................... 16

3.3.3 KFGL pump units ....................................................... 16

3.4 Functional description in progressive systems................. 17

3.4.1 KFG pump unit............................................................ 17

3.4.2 Progressive system with a KFGS or KFGL pump

unit ..........................................................................................19

3.5 Functional description in single-line systems................... 20

3.5.1 KFG-Pump unit with grease follower plate

technology.............................................................................. 20

3.5.2 Single-line system with a KFGL pump unit .......... 22

4. Accessories..................................................................................... 23

5. Technical data ............................................................................... 25

5.1 General technical data...........................................................25

5.2 Nominal delivery rates ..........................................................26

5.3 Pressure limiting valve..........................................................27

5.4 Pressure relief valve with integrated pressure limiting

valve .................................................................................................29

5.5 Lubricant level switch............................................................29

5.6 Type identification code for pump KFG..............................30

6. Delivery, returns, storage............................................................ 31

6.1 Delivery.....................................................................................31

6.2 Return shipment.....................................................................31

6.3 Storage..................................................................................... 31

6.4 Storage temperature range .................................................31

6.5 Storage conditions for products filled with lubricant....... 31

6.5.1 Storage period up to 6 months...............................31

6.5.2 Storage period between 6 and 18 months........... 31

6.5.3 Storage period more than 18 months................... 31

7. Assembly ........................................................................................ 32

7.1 General safety instructions................................................... 32

7.2 Mechanical connection ..........................................................32

7.2.1 Minimum mounting dimensions .............................32

7.2.2 Setup and attachment ..............................................33

7.2.3 Mounting diagram......................................................34

7.2.4 KFG dimensions.......................................................... 35

7.2.5 KFGL/KFGS dimensions ............................................35

7.3 Pump elements of the KFG series.......................................36

7.3.1 Pump element designs .............................................37

7.3.2 Installing a pump element with spring-return

piston ......................................................................................37

7.3.3 Assembly of a pump element with positively driven

pistons.....................................................................................38

7.3.4 Pressure limiting valve (DBV) ..................................39

7.4 Filling with lubricant...............................................................39

7.4.1 Filling via fill connection............................................39

7.4.2 Filler coupling..............................................................40

7.4.3 Filling cylinder.............................................................40

7.5 Power supply...........................................................................41

7.5.1 General conditions for electrical connections ....... 41

7.5.2 KFG power supply...................................................... 42

7.5.3 KFGS/KFGL power supply.........................................42

7.6 Control port assignments ..................................................... 43

7.6.1 KFG series (external control)....................................43

7.6.2 KFGS series (integrated control) .............................43

7.6.3 KFGL series .................................................................47

7.6.4 Pressure relief valve with integrated pressure

limiting valve.......................................................................... 49

7.6.5 Fill level monitoring ...................................................49

7.7 Pump unit fill level control.................................................... 51

7.8 Connection of the lubrication line........................................52

8. First start-up................................................................................. 53

8.1 Inspections before first start-up..........................................53

8.2 Inspections during first start-up..........................................53

8.3 Progressive system ventilation............................................ 54

8.4 Single-line system ventilation..............................................54

9. Operation........................................................................................ 55

9.1 KFGS control unit ................................................................... 55

9.1.1 Display and control elements of control screen... 55

9.1.2 KFGS display mode....................................................58

9.1.3 KFGS programming mode........................................60

9.1.4 KFGS operating modes .............................................65