5

Table of contents

Masthead ...............................................................................................4

Table of contents..................................................................................5

Safety alerts, visual presentation, and layout.................................7

1. Safety instructions...........................................................................8

1.1 General safety instructions......................................................8

1.2 General electrical safety instructions.....................................8

1.3 General behaviour when handling the product ...................8

1.4 Intended use...............................................................................8

1.5 Persons authorized to use the product.................................8

1.6 Foreseeable misuse ..................................................................9

1.7 Referenced documents ............................................................9

1.8 Prohibition of certain activities ...............................................9

1.9 Painting plastic components and seals .................................9

1.10 Possible safety markings on the product ...........................9

1.11 Note on the type plate ........................................................10

1.12 Notes on CE marking .......................................................... 10

1.13 Note on Low Voltage Directive.......................................... 10

1.14 Note on Pressure Equipment Directive........................... 10

1.15 Note on ECE mark ...............................................................10

1.16 Note on UKCA marking....................................................... 10

1.17 Note on EAC marking..........................................................10

1.18 Note on China RoHS mark................................................. 10

1.19 Note on the wireless module............................................. 10

1.20 Emergency shutdown .........................................................10

1.21 Assembly, maintenance, fault, repair............................... 11

1.22 First start-up, daily start-up.............................................. 11

1.23 Residual risks........................................................................ 12

2. Lubricants ...................................................................................... 13

2.1 General information............................................................... 13

2.2 Material compatibility ............................................................ 13

2.3 Temperature properties........................................................13

2.4 Aging of lubricants .................................................................13

2.5 Avoidance of faults and hazards.......................................... 13

2.6 Solid lubricants ....................................................................... 13

2.7 Chisel pastes............................................................................13

3. Overview, functional description................................................ 14

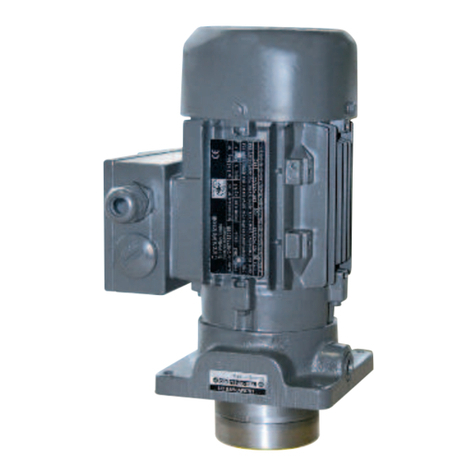

3.1.1 Pumps without a follower plate .............................. 14

4. Technical data ............................................................................... 16

4.1 General technical data........................................................... 16

4.2 Nominal delivery rates ..........................................................17

4.2.1 Influencing factors on the delivery rate ................. 17

4.2.2 Delivery rate charts for typical NLGI 2 lubricants 18

4.3 Principle of operation of the intermittent low-level signal

.......................................................................................................... 19

4.4 Operational limits of the intermittent empty signal......... 20

4.5 Hydraulic connection diagrams ........................................... 21

4.6 Usable reservoir volume....................................................... 22

4.6.1 Usable reservoir volume for reservoirs without a

follower plate.........................................................................22

4.6.2 Usable reservoir volume for reservoirs with a

follower plate.........................................................................22

4.6.3 Usable reservoir volume for reservoirs with

double-lip follower plate ..................................................... 22

4.7 Lubricant volume when an empty pump is filled for the

first time.......................................................................................... 23

4.8 Tightening torques................................................................. 23

4.9 Type identification code.........................................................24

4.9.1 Basic parameters and reservoir design................. 24

4.9.2 Pump elements ..........................................................26

4.9.3 Voltage supply and electrical connections............. 27

4.9.4 Control and lubricant.................................................28

5. Delivery, returns, storage............................................................ 30

5.1 Delivery.....................................................................................30

5.2 Return shipment.....................................................................30

5.3 Storage.....................................................................................30

5.4 Storage temperature range .................................................30

5.5 Storage conditions for products filled with lubricant....... 30

5.5.1 Storage period up to 6 months............................... 30

5.5.2 Storage period between 6 and 18 months........... 30

5.5.3 Storage period more than 18 months...................30

5.6 Declaration of decontamination ..........................................30

6. Assembly ........................................................................................ 31

6.1 General safety instructions................................................... 31

6.2 Transporting the pumps .......................................................31

6.3 Mechanical connection ..........................................................32

6.3.1 Minimum mounting dimensions .............................32

6.3.2 Assembly holes........................................................... 34

6.3.3 Assembly holes for 15 l, 20 l, and 25 l reservoirs34

6.4 Electrical connection.............................................................. 36

6.5 Setting the delivery rate on pump element R or KR ....... 37

6.6 Installing the pressure limiting valve..................................38

6.7 Connection of the lubrication line........................................ 39

6.8 Filling with lubricant...............................................................39

6.8.1 Filling via the reservoir cover................................... 39

6.8.2 Filling via filler nipple................................................. 40

6.9 Initial filling of an empty pump with follower plate.......... 40

6.9.1 Initial filling with double-lip follower plate ............ 41

7. First start-up................................................................................. 42

7.1 Inspections before first start-up.......................................... 42

7.2 Inspections during first start-up..........................................42

8. Operation........................................................................................ 43

8.1 Top up lubricant .....................................................................43

8.2 Triggering additional lubrication ......................................... 43

9. Maintenance .................................................................................. 44

10. Cleaning ....................................................................................... 45

10.1 Basics .....................................................................................45

10.2 Interior cleaning ...................................................................45

10.3 Exterior cleaning ..................................................................45

11. Faults, causes, and remedies................................................... 46

12. Repairs ......................................................................................... 47

12.1 Replacing pump element and pressure limiting valve.. 47

13. Shutdown, disposal.................................................................... 48

13.1 Temporary shutdown..........................................................48

13.2 Permanent shutdown, disassembly .................................48

13.3 Disposal..................................................................................48

14. Spare parts.................................................................................. 49

14.1 Housing cover, complete ....................................................49

14.2 Pump elements................................................................... 49

14.3 Pressure limiting valves and adapters............................. 49

14.4 Adapter D6 AX 1/8NPT I C................................................. 50

14.5 Motor 12 / 24 V DC............................................................. 50

14.6 Adapter with filler nipple .................................................... 50