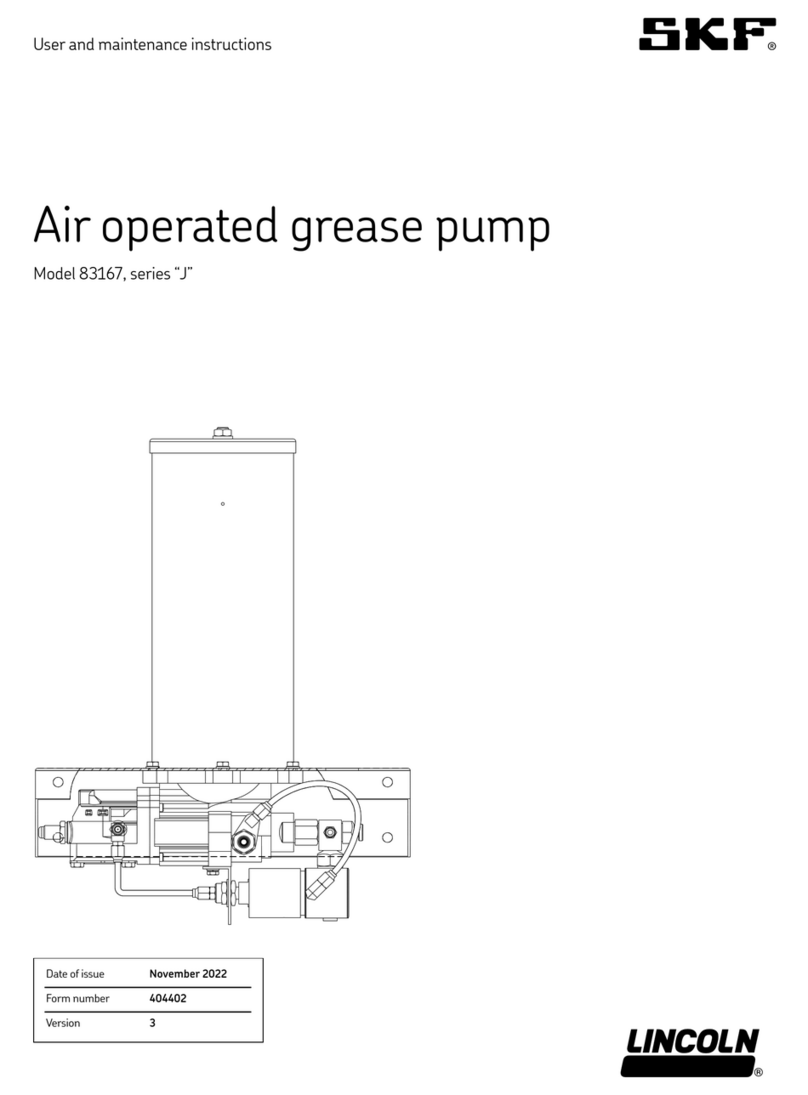

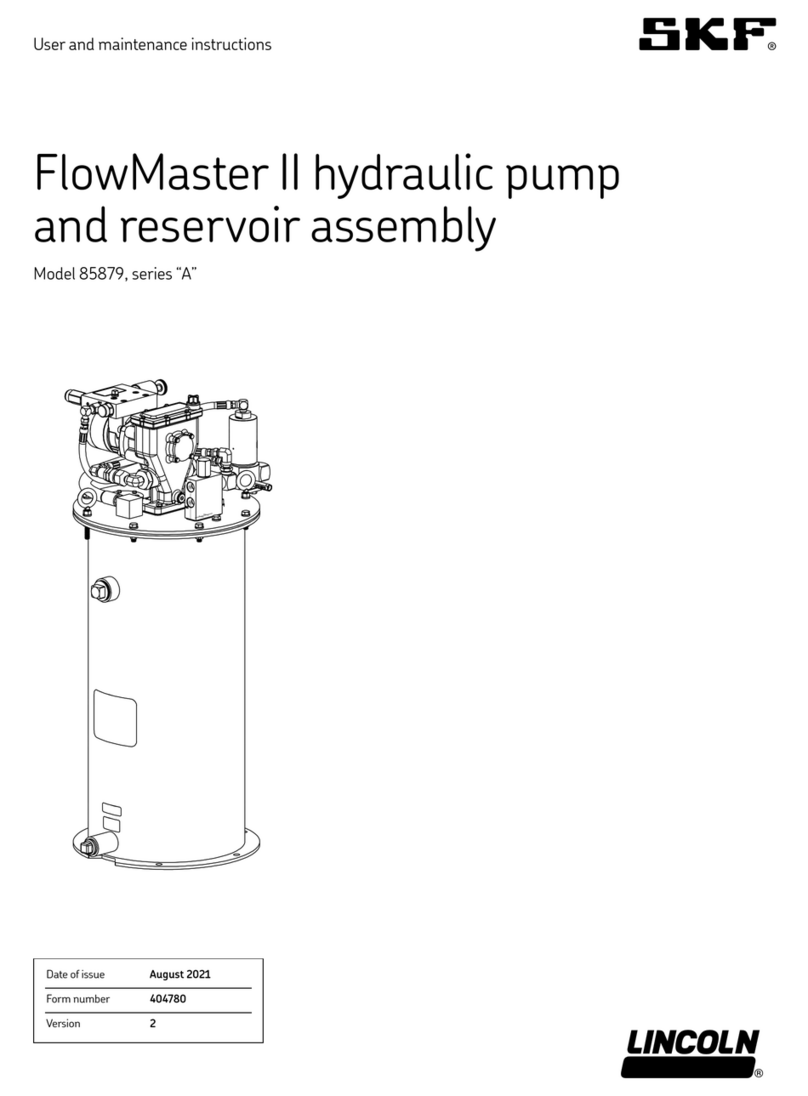

System specifications

Supply voltage 24 V

Ambient operating temperature –40 to +150 °F (–40 to +66 °C)

Container capacity 90 lb (41 kg)

Mechanical shut-off valve specifications

Maximum operating pressure 6 000 psi (413,6 bar)

Operating temperature –40 to +150 °F (–40 to +65 °C)

Port shut-off body 1/2NPTF

Contents

Explanation of safety signals . . . . . . . .

Safety . . . . . . . . . . . . . . . . . . . . . . . . .

System specifications . . . . . . . . . . . . . . . . . 2

Mechanical shut-off valve

specifications. . . . . . . . . . . . . . . . . . . . . . . . 2

Overview. . . . . . . . . . . . . . . . . . . . . . .

Install pump . . . . . . . . . . . . . . . . . . . .

Bare pump assembly . . . . . . . . . . . . . . . . . 3

Fill reservoir . . . . . . . . . . . . . . . . . . . .

Maintenance and repair . . . . . . . . . . . .

General maintenance . . . . . . . . . . . . . . . . . 3

System malfunction . . . . . . . . . . . . . . . . . . 3

Outlet check service . . . . . . . . . . . . . . . . . . 4

Safety unloader valve . . . . . . . . . . . . . . . . . 4

Follower. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Low level indicator . . . . . . . . . . . . . . . . . . . 5

Fill reservoir with optional 278552

bypass manifold assembly . . . . . . . . . . . . . 6

Float switch . . . . . . . . . . . . . . . . . . . . . . . . 7

Mechanical shut-off valve . . . . . . . . . .

Individual parts breakdown . . . . . . . . . . . . 9

Service parts. . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . .

Warranty. . . . . . . . . . . . . . . . . . . . . .

Safety

Read and carefully observe installation

instructions before installing, operating or

troubleshooting referenced equipment.

Equipment must be installed, maintained

and repaired exclusively by

persons familiar with instructions.

• Adequate personal protection must be

used to prevent splashing of material on

skin or in eyes.

• Always disconnect power source (electric,

air or hydraulic) from equipment, if

applicable, when not being used.

• If any fluid appears to penetrate skin, seek

medical treatment immediately.

• Any other use not in accordance with

instructions will result in loss of claim for

warranty or liability.

• Do not misuse, modify parts, or use worn

and/or damaged parts.

• Never exceed maximum specification

ratings of the equipment.

• Always read and follow manufacturer’s

recommendations regarding use of

protective clothing and equipment.

CAUTION

Do not treat injury as simple cut. Tell

attending physician exactly what fluid was

injected into skin.

Failure to comply may result in personal

injury and/or damage to equipment.

Explanation of

safety signals

DANGER

Indicates a dangerous situation that will lead

to death or severe personal injury if

precautionary measures are ignored.

WARNING

Indicates a dangerous situation that can lead

to death or severe personal injury if

precautionary measures are ignored.

CAUTION

Indicates a dangerous situation that can lead

to light personal injury or property damage if

precautionary measures are ignored.

NOTE

Emphasizes useful hints and

recommendations as well as information for

efficient and trouble-free operation.

2