SKIL Europe BV - Konijnenberg 60 12/08 2610399062

4825 BD Breda - The Netherlands

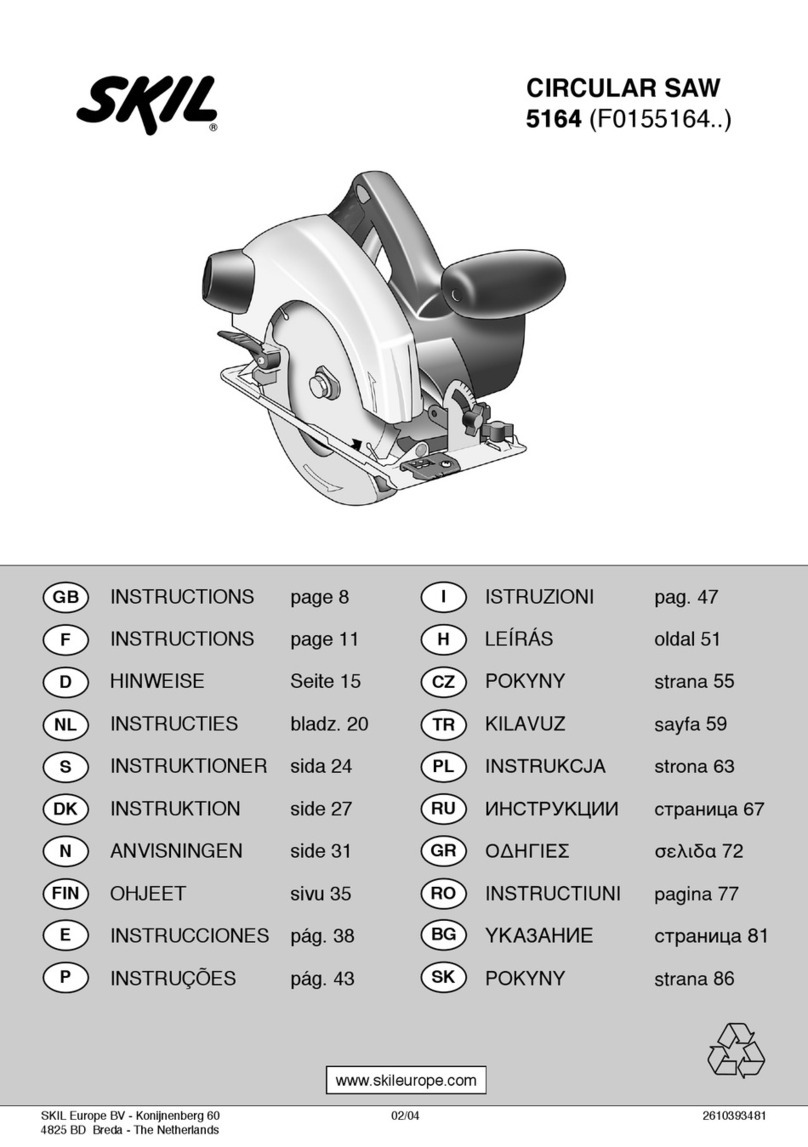

COMPOUND MITRE SAW

3100 (F0153100..)

www.skileurope.com

www.skilmasters.com

ORIGINAL INSTRUCTIONS. . . . . . . . . . . . 13

NOTICE ORIGINALE . . . . . . . . . . . . . . . . . 17

ORIGINALBETRIEBSANLEITUNG . . . . . . 22

ORIGINELE GEBRUIKSAANWIJZING. . . . 28

BRUKSANVISNING I ORIGINAL . . . . . . . . 33

ORIGINAL BRUGSANVISNING . . . . . . . . . 38

ORIGINAL DRIFTSINSTRUKS. . . . . . . . . . 42

ALKUPERÄISET OHJEET . . . . . . . . . . . . . 47

MANUAL ORIGINAL . . . . . . . . . . . . . . . . . 52

MANUAL ORIGINAL. . . . . . . . . . . . . . . . . . 57

ISTRUZIONI ORIGINALI . . . . . . . . . . . . . . 62

EREDETI HASZNÁLATI UTASÍTÁS. . . . . . 68

PÒVODNÍM NÁVODEM K POUÎÍVÁNÍ . . . 73

OR‹J‹NAL ‹fiLETME TAL‹MATI . . . . . . . . . 78

INSTRUKCJÑ ORYGINALNÑ. . . . . . . . . . . 82

ОРИГИНАЛНЬОЕ РУКОВОДСТВО

ПО ЭКСПЛУАТАЦИИ . . . . . . . . . . . . . . . . 88

ОРИГІНАЛЬНА ІНСТРУКЦІЯ

З ЕКСПЛУАТАЦІЇ . . . . . . . . . . . . . . . . . . . 94

ΠΡΩΤΟΤΥΠΟ Ο∆ΗΓΙΩΝ ΧΡΗΣΗΣ . . . . . . 99

INSTRUCØIUNI DE FOLOSIRE

ORIGINALE . . . . . . . . . . . . . . . . . . . . . . . 106

ОРИГИНАЛНО РЪКОВОДСТВО

ЗА ЕКСПЛОАТАЦИЯ . . . . . . . . . . . . . . . 111

PÔVODN¯ NÁVOD NA POUÎITIE . . . . . 117

ORIGINALNE UPUTE ZA RAD . . . . . . . . 122

ORIGINALNO UPUTSTVO ZA RAD . . . . 127

IZVIRNA NAVODILA . . . . . . . . . . . . . . . . 131

ALGUPÄRANE KASUTUSJUHEND . . . . 136

ORI˛INÅLÅ LIETO·ANAS PAMÅC±BA. . 141

ORIGINALI INSTRUKCIJA. . . . . . . . . . . . 146