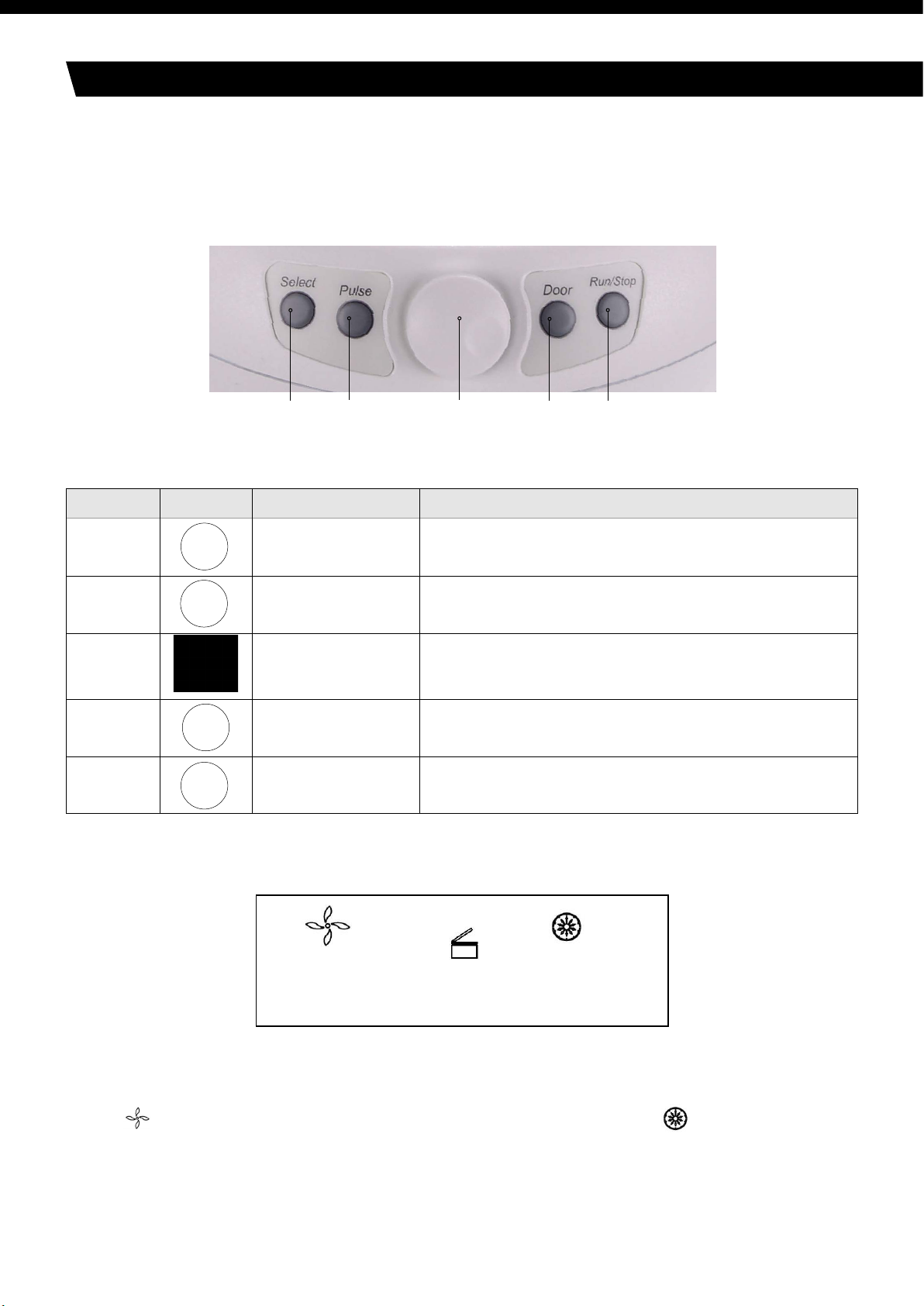

6. Operation panel

7

Figure 6.1 Operation Panel

12 3 4 5

Item Symbol Name Function

1 Select button Press the button to choose the program which you want

to modify

2 Pulse button The speed can be accelerated and held at the speed

when pressing Pulse on

3 Parameter button Clockwise rotate to increase program values. Rotate

anti-clockwise to decrease parameter values.

Press the button, shift between speed and RCF display

4 Open/Lock button Press the button to open the door. The button is not

available when the centrifuge is running

5 Run/Stop button Press the button to start running. The centrifuge will

brake to stop running if pressed during centrifugation

Select

Pulse

Door

Run/Stop

High Speed Mini Micro-Centrifuge

6. Operation panel

Figure 6-1 Operation Panel

Press the button to choose the program which you want to

modify.

The speed can be accelerated and held at the speed when

pressing Pulse on.

Clockwise rotate to increase program values. Rotate

anti-clockwise to decrease parameter values.

Press the button, shift between speed and RCF display.

Press the button to open the door The button is not available

when the centrifuge is running.

Press the button to start running. The centrifuge will brake to

stop running if pressed during centrifugation.

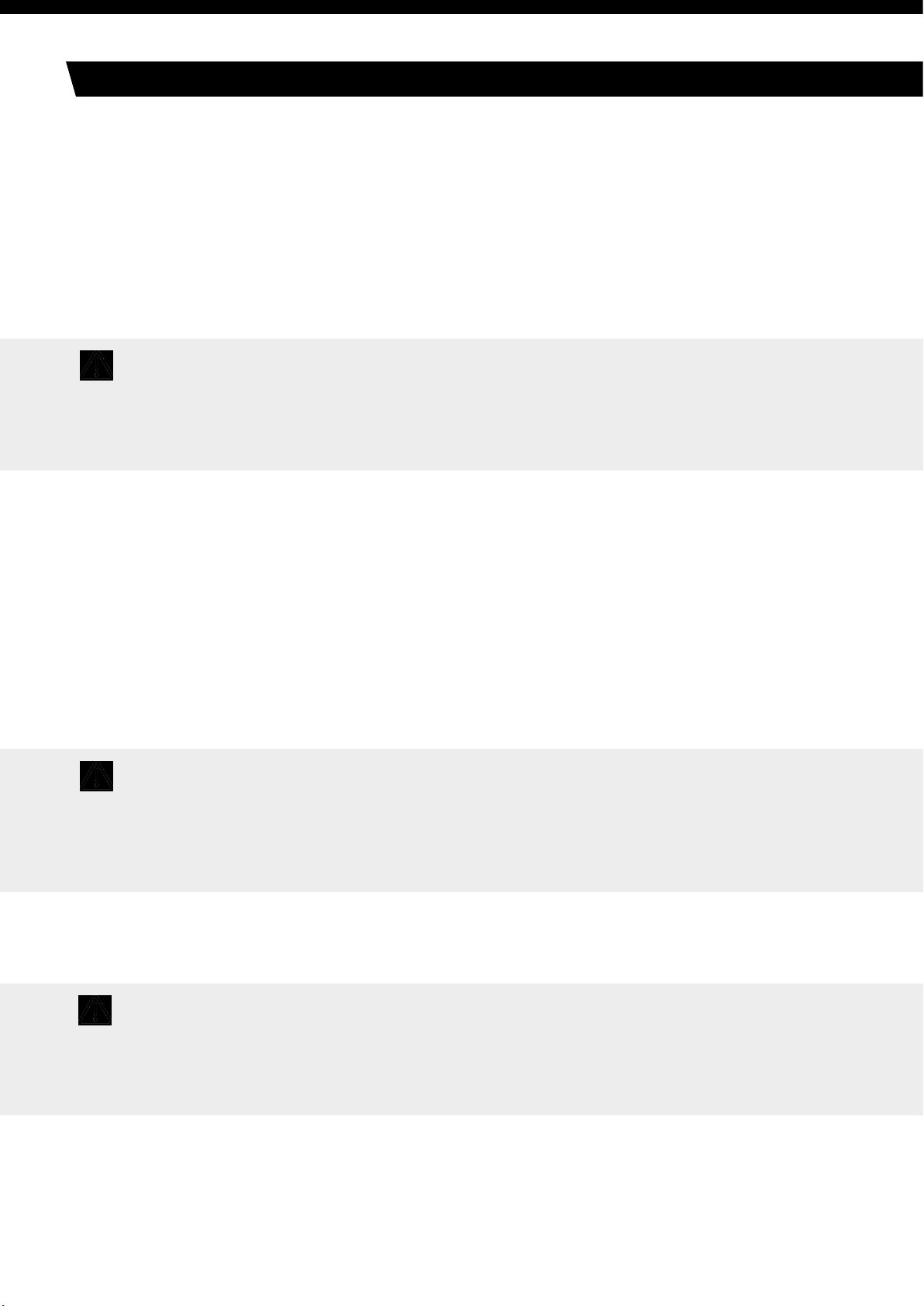

Figure 6-2 the main interface

Main interface is as figure 6-2. The speed is set to be 15000 rpm, running time is 12 minutes. When speed

symbol is rotating, indicating the centrifuge is running. Time display symbol display the ratio of

working to time setting. The total time setting is divided into 10 sections.

Speed area Lock status Time area

150 12 min

×

100rpm

Speed area Lock status Time area

Figure 6.2 The main interface

Main interface is as figure 6.2. The speed is set to be 15000 rpm, running time is 12 minutes. When speed

symbol is rotating, indicating the centrifuge is running. Time display symbol displays the ratio of

working to time setting. The total time setting is divided into 10 sections.

High Speed Mini Micro-Centrifuge

6. Operation panel

Figure 6-1 Operation Panel

Press the button to choose the program which you want to

modify.

The speed can be accelerated and held at the speed when

pressing Pulse on.

Clockwise rotate to increase program values. Rotate

anti-clockwise to decrease parameter values.

Press the button, shift between speed and RCF display.

Press the button to open the door The button is not available

when the centrifuge is running.

Press the button to start running. The centrifuge will brake to

stop running if pressed during centrifugation.

Figure 6-2 the main interface

Main interface is as figure 6-2. The speed is set to be 15000 rpm, running time is 12 minutes. When speed

symbol is rotating, indicating the centrifuge is running. Time display symbol display the ratio of

working to time setting. The total time setting is divided into 10 sections.

Speed area Lock status Time area

High Speed Mini Micro-Centrifuge

6. Operation panel

Figure 6-1 Operation Panel

Press the button to choose the program which you want to

modify.

The speed can be accelerated and held at the speed when

pressing Pulse on.

Clockwise rotate to increase program values. Rotate

anti-clockwise to decrease parameter values.

Press the button, shift between speed and RCF display.

Press the button to open the door The button is not available

when the centrifuge is running.

Press the button to start running. The centrifuge will brake to

stop running if pressed during centrifugation.

Figure 6-2 the main interface

Main interface is as figure 6-2. The speed is set to be 15000 rpm, running time is 12 minutes. When speed

symbol is rotating, indicating the centrifuge is running. Time display symbol display the ratio of

working to time setting. The total time setting is divided into 10 sections.

Speed area Lock status Time area

SLS Lab Basics 12 Place Microcentrifuge User Manual