SMAR LD290 User manual

Introduction

III

INTRODUCTION

The LD290 is a pressure transmitter for gauge and level measurement. It is based on a field-proven

capacitive sensor that provides reliable operation and high performance.

A liquid crystal display can be added to provide additional operation and local indication. Its

microprocessed electronic circuit permits a total interchangeability with Smar’s capacitive sensors. It

automatically corrects the sensors’ characteristic changes caused by temperature variations.

The LD290, besides the normal functions offered by other transmitters, offers the following

functions:

LOCAL ADJUSTMENT –Adjust through magnet tool the lower and upper value, input/output

function, and indication.

Writing protection via hardware.

Get the best results of the LD290 by carefully reading these instructions.

Smar’s pressure transmitters are protected by U.S. patents 6,433,791 and 6,621,443.

LD290 - Operation and Maintenance Instruction Manual

IV

NOTE

This manual is compatible with version 7.XX.YY, where 7 indicates the software version,

XX software release, and YY software emission. The indication 7.XX.YY means that this

manual is compatible with any release of software version 7.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or other

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since their

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

Table of Contents

V

TABLE OF CONTENTS

SECTION 1 - INSTALLATION .................................................................................................................. 1.1

GENERAL.....................................................................................................................................................................1.1

MOUNTING..................................................................................................................................................................1.1

ELECTRONIC HOUSING.............................................................................................................................................1.8

WIRING ........................................................................................................................................................................1.8

INSTALLATION IN HAZARDOUS AREAS ................................................................................................................1.11

EXPLOSION/FLAME PROOF....................................................................................................................................1.11

INTRINSICALLY SAFE ..............................................................................................................................................1.11

SECTION 2 - OPERATION....................................................................................................................... 2.1

FUNCTIONAL DESCRIPTION - SENSOR ..................................................................................................................2.1

FUNCTIONAL DESCRIPTION - HARDWARE.............................................................................................................2.2

THE DISPLAY ..............................................................................................................................................................2.4

SECTION 3 - PROGRAMMING USING LOCAL ADJUSTMENT.............................................................. 3.1

THE MAGNETIC TOOL................................................................................................................................................3.1

COMPLETE LOCAL ADJUSTMENT............................................................................................................................3.2

SIMPLE LOCAL ADJUSTMENT ..................................................................................................................................3.2

ZERO AND SPAN RERANGING .................................................................................................................................3.2

COMPLETE LOCAL ADJUSTMENT............................................................................................................................3.3

LOCAL PROGRAMMING TREE..................................................................................................................................3.3

CONFIGURATION [CONF]..........................................................................................................................................3.3

CONFIGURATION BRANCH (CONF) .........................................................................................................................3.4

RANGE (RANGE).........................................................................................................................................................3.5

RANGE BRANCH (RANGE) ........................................................................................................................................3.5

FUNCTION (FUNCT) ...................................................................................................................................................3.7

PRESSURE TRIM [TRIM]............................................................................................................................................3.8

ESCAPE LOCAL ADJUSTMENT [ESC] ......................................................................................................................3.9

SECTION 4 - MAINTENANCE PROCEDURES ........................................................................................ 4.1

GENERAL.....................................................................................................................................................................4.1

DIAGNOSTIC BY DISPLAY.........................................................................................................................................4.1

DISASSEMBLY PROCEDURE....................................................................................................................................4.2

SENSOR.................................................................................................................................................................................. 4.2

ELECTRONIC CIRCUIT........................................................................................................................................................... 4.3

REASSEMBLY PROCEDURE.....................................................................................................................................4.3

SENSOR.................................................................................................................................................................................. 4.3

ELECTRONIC CIRCUIT........................................................................................................................................................... 4.3

INTERCHANGEABILITY..............................................................................................................................................4.4

RETURNING MATERIALS...........................................................................................................................................4.4

ORDERING CODE FOR HOUSING ............................................................................................................................4.7

ORDERING CODE FOR SENSOR..............................................................................................................................4.7

SECTION 5 - TECHNICAL CHARACTERISTICS..................................................................................... 5.1

ORDERING CODE.......................................................................................................................................................5.5

APPENDIX A - CERTIFICATIONS INFORMATIONS ...............................................................................A.1

EUROPEAN DIRECTIVE INFORMATION.................................................................................................................. A.1

HAZARDOUS LOCATIONS GENERAL INFORMATION ........................................................................................... A.1

HAZARDOUS LOCATIONS APPROVALS................................................................................................................. A.2

IDENTIFICATION PLATES AND CONTROL DRAWING ........................................................................................... A.6

APPENDIX B –SRF –SERVICE REQUEST FORM.................................................................................B.1

LD290 - Operation and Maintenance Instruction Manual

VI

Section 1

1.1

INSTALLATION

General

NOTE

The installation carried out in hazardous areas should follow the recommendations of the

IEC60079-14 standard.

The overall accuracy ofa flow, level, or pressure measurementdepends on severalvariables.Although

the transmitter has an outstanding performance, proper installation is essential to maximize its

performance.

Among all factors, whichmay affect transmitter accuracy, environmentalconditionsarethemostdifficult

to control. There are, however, ways of reducing the effects of temperature, humidity and vibration.

The LD290 has a built-in temperature sensor to compensate for temperature variations. At the factory,

each transmitter is submitted to a temperature cycle, and the characteristics under different

temperatures are recorded in the transmitter memory. At the field, this feature minimizes the

temperature variation effect.

Locating the transmitter in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should also

be avoided. Use longer sections of impulse piping between tap and transmitter whenever the process

fluid is at high temperatures. Use of sunshades or heat shields to protect the transmitter from external

heat sources should be considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronic housing coversmust be correctlyplaced and the coversmustbecompletelyclosedbytighten

them by hand until you feel the O-rings being compressed. Do not use tools to close the covers.

Removal of the electronics cover in the field should be reduced to the minimum necessary, since each

time it is removed; the circuits are exposed to the humidity.

The electronic circuit is protected by a humidity proof coating, but frequent exposures to humidity may

affect the protection provided. It is also important to keep the covers tightenedin place. Everytime they

are removed, the threads are exposed to corrosion, since painting cannot protect these parts. Code-

approved sealing methods should be employed on conduit entering the transmitter. The unused outlet

connection should be plugged accordingly.

Although the transmitter isvirtually insensitive tovibration, installation close to pumps, turbinesorother

vibrating equipment should be avoided.

Proper winterization (freeze protection) should be employed to prevent freezing within the measuring

chamber, since this will result in an inoperative transmitter and could even damage the cell.

NOTE

When installing or storing the level transmitter, the diaphragm must be protected avoid scratching-

denting or perforation of its surface.

Mounting

The transmitter has been designed to be both rugged and lightweight at the same time. This make its

mounting easier mounting positions are shown in Figure 1.1.

Should the process fluid contain solids in suspension, install valves orrod-outfittingsat regularintervals

to clean out the pipes.

The pipes should be internally cleaned by using steam or compressed air, or by draining the line with

the process fluid, before such lines are connected to the transmitter (blow-down).

LD290 –Operation and Maintenance Instruction Manual

1.2

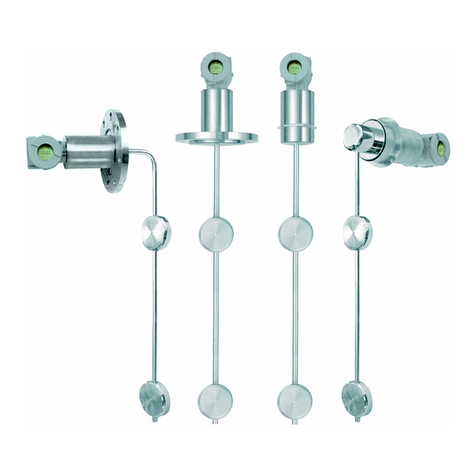

Figure 1.1 (a) –Dimensional Drawing and Mounting Position for LD290

Installation

1.3

Figure 1.1 (b) –Dimensional Drawing and Mounting Position for LD290 - Sanitary

LD290 –Operation and Maintenance Instruction Manual

1.4

Figure 1.1 (c) –Dimensional Drawing and Mounting Position for LD290 –Sanitary

Installation

1.5

Figure 1.1 (d) –Dimensional Drawing and Mounting Position for LD290 –Level

LD290 –Operation and Maintenance Instruction Manual

1.6

ELECTRIC

CONNECTION

FIXED

Sanitary

ADJUSTABLE

Diaphragm protection VIEW BY ‘’A’’

MOUNTING

BRACKET IN ‘ L’’‘

ADJUSTABLE

(OPTIONAL) O’RING

Mobile adjusting flange

VIEW BY ‘’BB’’

Mobile fixing flange

Flange process tank

FIXED

VIEW BY ‘’D’’

MACHINING DETAIL

OF FLANGE

4 M8 Screws

VIEW BY ‘’C’’ - DIMENSIONS ARE IN mm (in)

PROBE

LENGTH

Diaphragm protection with screen

Figure 1.1 (e) –Dimensional Drawing and Mounting Position for LD290 –Level (Insertion)

Installation

1.7

Observe operating safety rules during wiring, draining or blow-down.

Some examples of installation, illustrating the position of the transmitter in relation to the taps, are

shown in Figure 1.3.

Figure 1.2 –Fixing of the Transmitter in the Tap

GAS LIQUID STEAM

Figure 1.3–Position of the Transmitter and Taps

The location of pressure taps and the relative position of the transmitter are indicated in Table 1.1.

Process Fluid

Location of Taps

LOCATION OF LD290 IN RELATION TO THE TAPS

Gas

Top or Side

Above the Taps

Liquid

Side

Below the Taps or at the Piping Centerline

Steam

Side

Below the Taps using Sealing (Condensate) Pots

Table 1.1 - Location of Pressure Taps

NOTE

Except for dry gases, all impulse lines should slope at the ratio 1:10, in order to avoid trapping

bubbles in the case of liquids, or condensate for steam or wet gases.

LD290 –Operation and Maintenance Instruction Manual

1.8

Electronic Housing

The electronic housing can be rotated in order to better position the digital display. To rotate it use the

Housing Rotation Set Screw, see Figure 1.4.

The digital display itself can also be rotated. See Section 4, Figure 4.3.

Wiring

Reach the wiring block by removing the Electrical Connection Cover. This cover can be locked closed

by the cover locking screw (Figure 1.4). To release the cover, rotate the locking screw clockwise.

HOUSING

ROTATION

SCREW

COVER

LOCK

SCREW

Figure 1.4 –Housing Rotating Set Screw

The wiring block has screws on which fork or ring-type terminals can be fastened. See Figure 1.5.

Test terminals allow measuring the current in the 4 - 20 mA loop, without opening it. To measure it,

connect a multimeter in the mA scale in the "" and "" terminals.

The wiring block has screws on which fork or ring-type terminals can be fastened. See Figure 1.6.

GROUND

TERMINALS

NOT USED TEST TERMINALS

Figure 1.5 –Wiring Block

For convenience there aretwo ground terminals: one inside the coverandoneexternal,located closeto

the conduit entries.

Use of twisted pair (22 AWG or greater than) cables is recommended.

Avoid routing signal wiring close to power cables or switching equipment.

The unused outlet connection should be plugged and sealed accordingly. The LD290 is protected

against reverse polarity. However, it will not work in this situation.

The Figure 1.6 shows the correct installation of the conduit, in order to avoid penetration of water, or

other substance, which may cause malfunctioning of the equipment.

Installation

1.9

CORRECT

WIRES INCORRECT

Figure 1.6 - Conduit Installation Diagram

NOTE

The transmitters are calibratedin the vertical position and a differentmountingposition displaces the

zero point. Consequently, the indicator will indicate a different value from the applied pressure. In

these conditions, it isrecommended to do the zero pressuretrim. The zero trim isto compensate the

final assembly position and its performance, when the transmitter is in its final position. When the

zero trim is executed, make sure the equalization valve is open and the wet leg levels are correct.

In the factory, the transmitter is rangedin the vertical position, and in this position the capacitive sensor

is in the horizontal position. If it is mounted in the field in another position, it should be ranged again to

avoid readout error. See Figure 1.8.

DIAPHRAGM SENSOR

SENSOR IN THE VERTICAL POSITION SENSOR IN THE HORIZONTAL POSITION

HEAD OF THE FLUID

DIAPHRAGM SENSOR

Figure 1.7 - Sensor Positions

It is also recommended to ground the shield of shielded cables at only one end. The ungrounded end

must be carefully isolated.

Connection of the LD290 should be done as in Figure 1.8.

POWER

SUPPLY

SIGNAL LOOP BE GROUNDED

ATANY POINT OR LEFT UNGROUND

Figure 1.8 - Wiring Diagram for the LD290

LD290 –Operation and Maintenance Instruction Manual

1.10

NOTE

Make sure that the transmitter is operating within the operating area as shown on the load curve

(Figure 1.10).

12

Operating area

Power Supply (Volt)

Load(Ohm)

0

250

500

1000

1500

1650

20 30 12 40 45

Figure 1.9 - Load Curve

Installation

1.11

Installation in Hazardous Areas

WARNING

Explosions could result in death or serious injury, besides financial damage. Installation of this

transmitter in explosive areas must be carried out in accordance with the local standards and the

protection type adopted .Before continuing theinstallation make sure the certificate parametersareI

n accordance with the classified area where the equipment will be installed.

The instrument modificationor parts replacementsupplied by otherthanauthorizedrepresentative of

Smar is prohibited and will void the certification.

The transmitters are marked with options of the protection type. The certification is valid only when

the protection type is indicated by theuser. Once a particular type ofprotection is selected,anyother

type of protection can not be used.

The electronic housing and the sensor installed in hazardous areas must have a minimum of 6 fully

engaged threads. Lock the housing using the locking screw (Figure 1.4).

The cover must be tightened with at least 8 turns to avoid the penetration of humidity or corrosive

gases. The cover mustbe tightened until it touches the housing. Then,tightenmore 1/3turn (120)to

guarantee the sealing. Lock the covers using the locking screw (Figure 1.4).

Consult the Appendix A for further information about certification.

Explosion/Flame Proof

WARNING

Only use Explosion Proof/Flameproof certified Plugs, Adapters and Cable glands.

In Explosion-Proof installations the cable entries must be connected or closed using metal cable

gland and metal blanking plug, both with at least IP66 and Ex-d certification.

The standard plugs provided by Smar are certified according to CEPEL certificate. If the plug needs

to be replaced, a certified plug must be used.

The electrical connection withNPT thread must use waterproofingsealant. Anon-hardening silicone

sealant is recommended.

For NEMKO ATEX certificate please to follow the installation guidelines in hazardous locations

below: Group II Category 2G, Ex d, Group IIC, Temperature Class T6, EPL Gb U = 28VDC

Ambient Temperature: -20 to 60ºC for T6

Environmental Protection: IP66/687 or IP66W/687W

The electrical connection available are ½ - 14NPT and M20x1,5.

Cable entries must be connected or closed using metal cable gland and metal blanking plug, both

with at least IP66 and Ex-d certification or any appropriate ATEX approved metal cable gland and

metal blanking plug. Do not remove the transmitter covers when power is ON.

Intrinsically Safe

WARNING

In hazardous zones with intrinsically safe or non-incendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

To protect the application the transmitter must be connected to a barrier. Match the parameters

between barrier and theequipment (Consider the cable parameters). Associatedapparatusground

bus shall be insulated from panels and mounting enclosures. Shield is optional. If used, be sure to

insulate the end not grounded. Cable capacitance and inductance plus Ciand Limust be smaller

than Co and Lo of the associated Apparatus.

It is not recommended to remove the transmitter cover when the power is ON.

LD290 –Operation and Maintenance Instruction Manual

1.12

Section 2

2.1

OPERATION

Functional Description - Sensor

The LD290 Series Pressure Transmitters use capacitive sensors (capacitivecells) as pressure

sensing elements, as shown in Figure 2.1.

Figure 2.1 –Capacitive Cell

Where,

P1and P2are the pressures in chambers H and L

CH = capacitance between the fixed plate on P1side and the sensing diaphragm.

CL = capacitance between the fixed plate on the P2side and the sensing diaphragm.

d = distance between CH and CL fixed plates.

d = sensing diaphragm's deflection due to the differential pressure P = P1- P2.

Knowing that the capacitance of a capacitor with flat, parallel plates may be expressed as a

function of plate area (A) and distance (d) between the plates as:

Where,

=dielectric constant of the medium between the capacitor's plates.

Should CH and CLbe considered as capacitances of flatand parallelplateswithidenticalareas,

then:

However, should the differential pressure (P) applied to the capacitive cell not deflect the

sensing diaphragm beyond d/4; it is possible to assume P as proportional to d.

By developing the expression (CL - CH)/ (CL + CH), it follows that:

as the distance (d) between the fixed plates CH and CL is constant, it is possible to conclude

that the expression (CL - CH)/(CL + CH) is proportional to d and, therefore, to the differential

pressure to be measured.

Thus it is possible to conclude that the capacitive cell is a pressure sensor formed by two

capacitors whose capacitances vary according to the applied differential pressure.

dA

C

=

dd

CHCL CHCL

P

=

+

−

= 2

and

dd A

CL −

=)2/( .

dd A

CH +

=)2/( .

LD290- Operation and Maintenance Instruction Manual

2.2

Functional Description - Hardware

Refer to the block diagram Figure 2.2. The function of each block is described below.

Oscillator

This oscillator generates a frequency as a function of sensor capacitance.

Signal Isolator

The Control signals from the CPU are transferred through optical couplers, and the signal from

the oscillator is transferred through a transformer.

(CPU) Central Processing Unit and PROM

The CPU is the portion of the transmitter,being responsible for the management and operation

of all other blocks..

The program is stored in an external PROM. For temporary storage of data the CPU has an

internal RAM. The data in the RAM is lost, if the power is switched off, however the CPU also

has an internal nonvolatile EEPROM where data that must be retained is stored. Examples of

such data are: calibration, configuration and identification data.

EEPROM

Another EEPROM is located within the sensor assembly. It contains data pertaining to the

sensor's characteristics at different pressures and temperatures. This characterization is done

for each sensor at the factory.

D/A Converter

Converts the digital data from the CPU to an analog signal with 15-bits resolution.

Output

Controls the current in the line feeding the transmitters.

It acts as a variable resistive load whose value depends on the voltage from the D/A converter.

Power Supply

P

H

P

L

PRESSURE

SENSOR

ELECTRONIC

CONVERTER

CONVERTER

TEMPERATURE

DIGITAL

DISPLAY

4-20 mA

PROCESSING UNIT

RANGES

SPECIAL FUNCTIONS

OUTPUT CONTROL

D/A

CONVERTER

MATH

COPROCESSOR

DISPLAY

CONTROLLER

LOCAL ADJUSTMENTS

ZERO / SPAN

HT3012

POWER

SUPPLY

SENSOR MAIN BOARD

OUTPUT

ELECTRONIC

CONVERTER

Figure 2.2 –LD290 Block Diagram Hardware

Power shall be supplied to the transmitter circuit using the signal line (2-wire system). The

transmitter quiescent consumption is 3.6mA; during operation, consumption may be ashighas

21 mA, depending on the measurement and sensor status.

Power Supply Isolation

The sensor power supply is isolated from the main circuit by this module.

Display Controller

It receives the data from the CPU and actives the LCD segments. Also it actives the back plane

and the control signals for each segment.

Local Adjustment

Twoswitchesthataremagneticallyactivated.Themagnetictoolwithoutmechanicalorelectricalcontact

can activatethem.

Table of contents

Other SMAR Transmitter manuals

Popular Transmitter manuals by other brands

SIMOLIO

SIMOLIO SM-264D manual

ULFA TECHNOLOGY

ULFA TECHNOLOGY JANITOR PLT Series instruction manual

KROHNE

KROHNE OPTISOUND 3030 C Quick setup guide

Greystone

Greystone RH200A installation instructions

CAMDEN

CAMDEN Lazerpoint CM-TX-99 installation instructions

Xantech

Xantech HDTXSG01 installation instructions