SMAR TT302 Manual

Specifications and information are subject to change without notice.

May/99

BRAZIL

Smar Equipamentos Ind. Ltda.

Av. Dr. Antonio Furlan Jr., 1028

Sertãozinho SP 14160-000

Tel.: +55 16 645-6455

Fax: +55 16 645-6450

CHINA

Smar China Corp.

3 Baishiqiao Road, Suite 30233

Beijing 100873, P.R.C.

Tel.: +86 10 6849-8643

Fax: +86 10 6849-9549

FRANCE

Smar France S. A. R. L.

1, bld de l'Oise

Immeuble Les Maradas

95031 Cergy – Pontoise

Tel.: +33 1 30 38-3888

Fax: +33 1 30 38-4110

GERMANY

Smar GmbH

Robert-Koch-Strasse 35

D 55129 Mainz

Tel.: +49 6131 582037

Fax: +49 6131 582249

MEXICO

Smar Mexico

11, Poniente, No. 1314-1 PB

Col. Centro C. P. 72000

Ciudad de Puebla, Puebla

Tel.: +52 22 46-4386

Fax: +52 22 46-4386

NORWAY

Smar Norge A/S

Sandviksveien, 18

N-5035 Sandviken Bergen

Tel.: +47 55 13-3885

Fax: +47 55 13-3886

SINGAPORE

Smar Singapore Pte. Ltd.

315 Outram Road

#04-05, Tan Boon Liat Building

Singapore 169074

Tel.: +65 324-0182

Fax: +65 324-0183

USA

Smar International Corporation

Northwest Point Service Center

7240 Brittmoore, Suite 118

Houston, TX 77041

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

Smar Laboratories Corporation

10960 Millridge North, Suite 107

Houston, TX 77070

Tel.: +1 281 807-1501

Fax: +1 281 807-1506

Smar Research Corporation

4250 Veterans Memorial Hwy.

Unit 156

Holbrook , NY 11741

Tel.: +1 516 737-3111

Fax: +1 516 737-3892

Index

III

Table of Contents

TABLE OF CONTENTS.................................................................................III

INDEX OF FIGURES .................................................................................... IV

INDEX OF TABLES ...................................................................................... IV

INTRODUCTION ........................................................................................... V

INSTALLATION ...........................................................................................1.1

GENERAL.......................................................................................................................................1.1

MOUNTING ....................................................................................................................................1.1

NETWORK WIRING .......................................................................................................................1.2

BUS TOPOLOGY AND NETWORK CONFIGURATION ................................................................ 1.4

OPERATION................................................................................................2.1

FUNCTIONAL DESCRIPTION – HARDWARE...............................................................................2.1

TEMPERATURE SENSOR.............................................................................................................2.3

CONFIGURATION.......................................................................................3.1

TRANDUCER BLOCK ....................................................................................................................3.1

HOW CONFIGURE A TRANSDUCER BLOCK ..............................................................................3.1

SENSOR TRANSDUCER NUMBER ..............................................................................................3.1

SENSOR WIRING ..........................................................................................................................3.2

JUMPER ONFIGURATION.............................................................................................................3.2

SENSOR CONFIGURATION .........................................................................................................3.3

HOW TO CONNECT TWO SENSORS TO TT302 .........................................................................3.5

COMPENSATION OF LEAD RESISTANCE FOR RTD or Ohm.....................................................3.6

COMPENSATION OF LEAD RESISTANCE FOR RTD or Ohm Double Sensors ..........................3.6

CALIBRATION IN TT302 BY THE USER .......................................................................................3.6

CHANGING UNITS IN TEMPERATURE SENSORS......................................................................3.6

TRANSDUCER DISPLAY – CONFIGURATION.............................................................................3.7

DISPLAY TRANSDUCER BLOCK..................................................................................................3.7

DEFINITION OF PARAMETERS AND VALUES ............................................................................3.8

PROGRAMMING USING LOCAL ADJUSTMENT........................................................................3.11

LOCAL PROGRAMMING TREE...................................................................................................3.11

MAINTENCE PROCEDURES......................................................................4.1

TOUBLESANTING..........................................................................................................................4.1

DISASSEMBLY PROCEDURE.......................................................................................................4.2

REASSEMBLY PROCEDURE........................................................................................................4.2

INTERCHANGEABILITY ................................................................................................................4.3

RETURNING MATERIALS .............................................................................................................4.3

TECHNICAL CHARACTERISTICS..............................................................5.1

FUNCIONAL SPECIFICATIONS ....................................................................................................5.1

PERFORMANCE SPECIFICATIONS .............................................................................................5.2

PHYSICAL SPECIFICATIONS .......................................................................................................5.2

TT302 – Fieldbus Temperature Transmitter

IV

Index of Figures

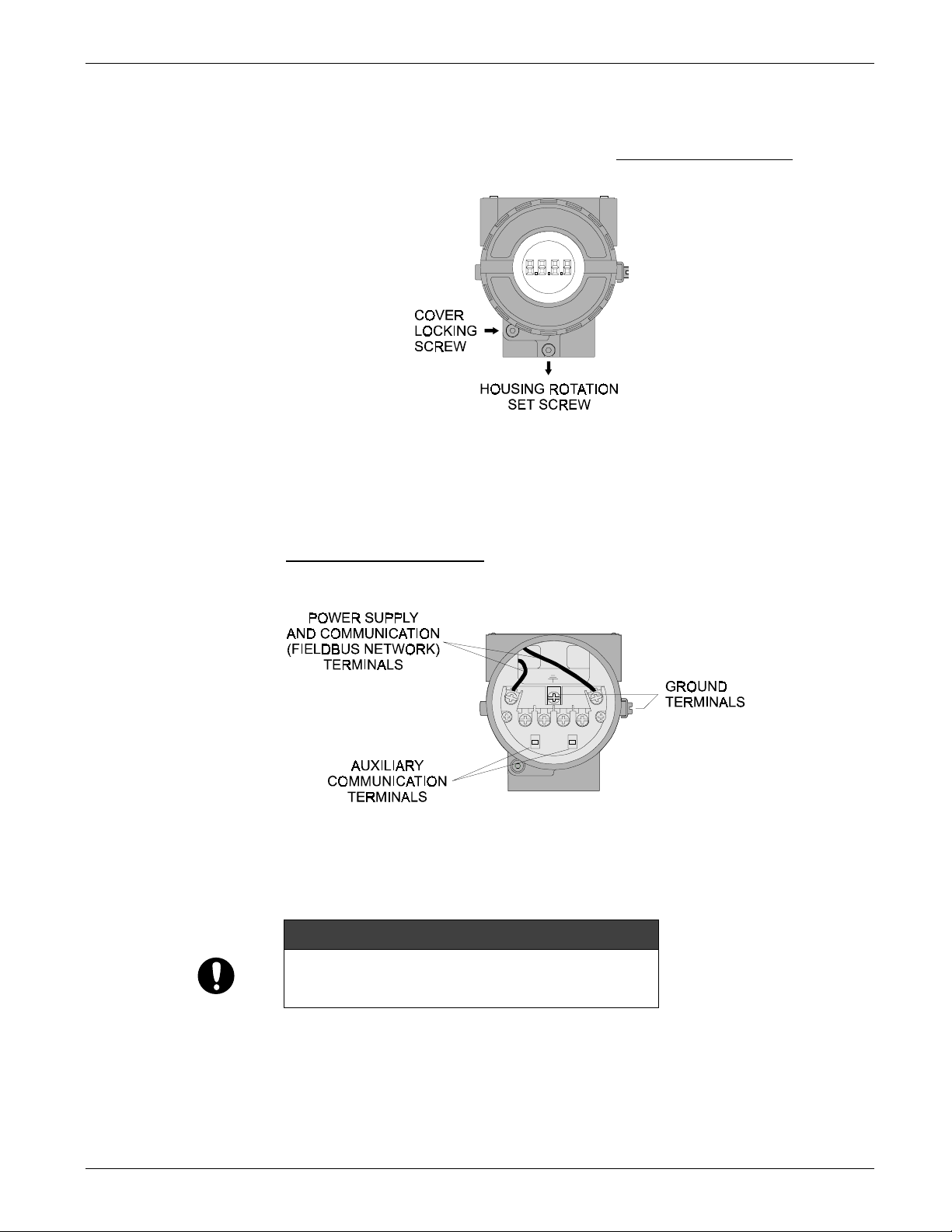

FIGURE 1.1 – COVER LOCKING ........................................................................................................1.2

FIGURE 1.2 – GROUND TERMINALS.................................................................................................1.2

FIGURE 1.3 – DIMENSIONAL DRAWING AND MOUNTING POSITIONS..........................................1.3

FIGURE 1.4 – BUS TOPOLOGY..........................................................................................................1.4

FIGURE 1.5 – TREE TOPOLOGY .......................................................................................................1.5

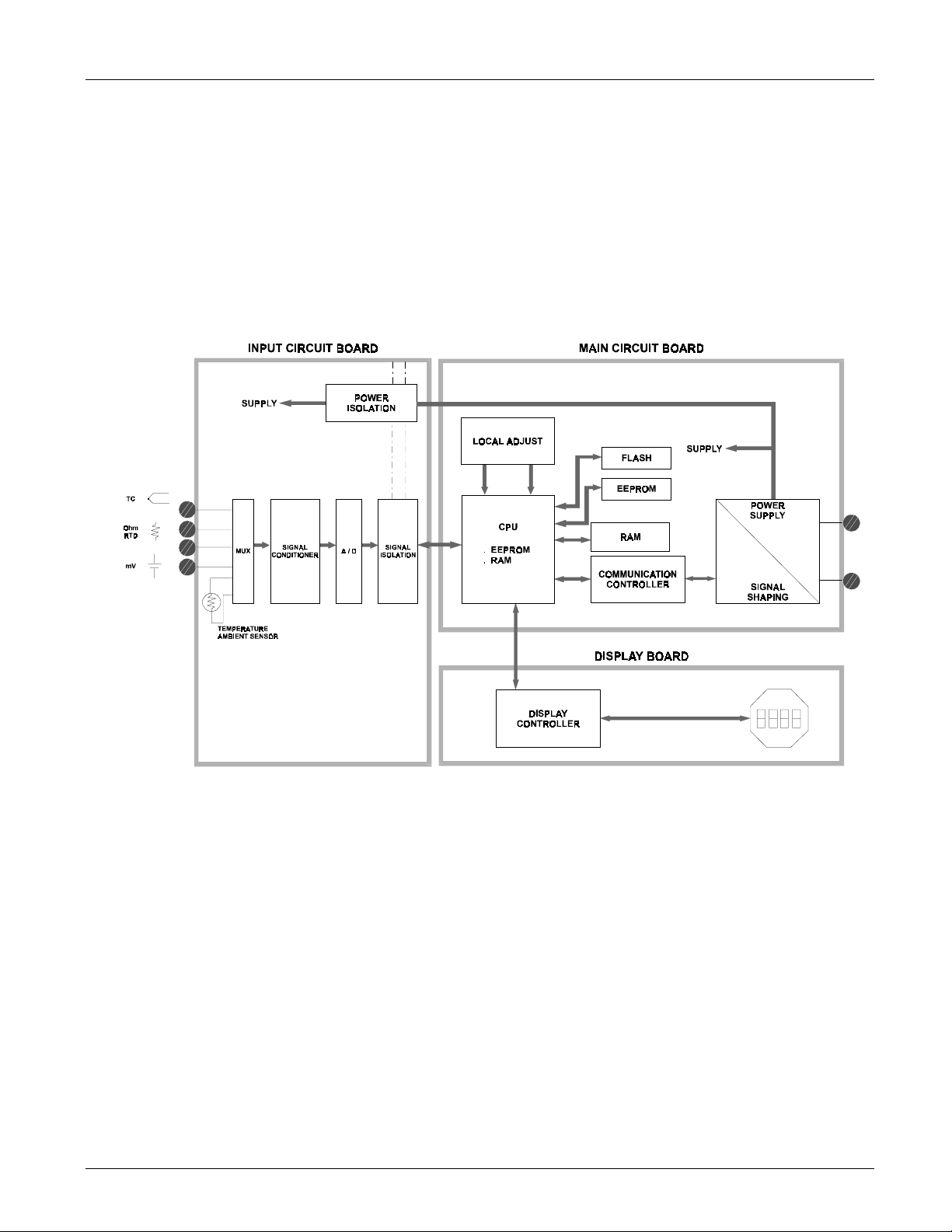

FIGURE 2.1 – TT302 BLOCK DIAGRAM.............................................................................................2.1

FIGURE 2.2 – LCD INDICATOR ..........................................................................................................2.2

FIGURE 2.3 – TWO-WIRE CONNECTION ..........................................................................................2.4

FIGURE 2.4 – TREE – WIRE CONNECTION ...................................................................................... 2.4

FIGURE 2.5 – FOUR WIRE CONNECTION ........................................................................................2.5

FIGURE 2.6 – DIFFERENTIAL OR DUAL CONNECTION...................................................................2.5

FIGURE 3.1 – SENSOR WIRING ........................................................................................................3.2

FIGURE 3.2 – TEMPERATURE CALIBRATION – TT302....................................................................3.3

FIGURE 3.3 – TEMPERATURE CALIBRATION – TT302....................................................................3.3

FIGURE 3.4 – TEMPERATURE CALIBRATION – TT302....................................................................3.4

FIGURE 3.5 – TEMPERATURE CALIBRATION – TT302....................................................................3.5

FIGURE 3.6 – CREATING TRANSDUCER AND FUNCTION BLOCKS ..............................................3.7

FIGURE 3.7 – PARAMETERS FOR LOCAL ADJUSTMENT CONFIGURATION ................................3.9

FIGURE 3.8 – PARAMETERS FOR LOCAL ADJUSTMENT CONFIGURATION ................................3.9

FIGURE 3.9 – PARAMETERS FOR LOCAL ADJUSTMENT CONFIGURATION ..............................3.10

FIGURE 3.10 – PARAMETERS FOR LOCAL ADJUSTMENT CONFIGURATION ............................3.10

FIGURE 3.11 – PARAMETERS FOR LOCAL ADJUSTMENT CONFIGURATION ............................3.11

FIGURE 3.12 – STEP 1 – TT302 .......................................................................................................3.11

FIGURE 3.13 – STEP 2 – TT302 .......................................................................................................3.12

FIGURE 3.14 – STEP 3 – TT302 .......................................................................................................3.12

FIGURE 3.15 – STEP 4 – TT302 .......................................................................................................3.12

FIGURE 3.16 – STEP 5 – TT302 .......................................................................................................3.13

FIGURE 3.17 – STEP 6 – TT302 .......................................................................................................3.13

FIGURE 3.18 – STEP 7 – TT302 .......................................................................................................3.13

FIGURE 4.1 – FOUR POSSIBLE POSITION OF THE DISPLAY.........................................................4.2

FIGURE 4.1 – EXPLODED VIEW ........................................................................................................4.3

Index of Tables

TABLE 3.1 – SENSOR TYPE TABLE ..................................................................................................3.4

TABLE 3.2 – TYPE OF CONNECTION TABLE ...................................................................................3.5

TABLE 3.3 – UNIT TABLE ...................................................................................................................3.6

TABLE 4.1 – MESSAGES OF ERRORS AND POTENTIAL CAUSE ...................................................4.1

Introduction

V

Introduction

The TT302 is from the first generation of FIELDBUS devices. It is a transmitter mainly

intended for measurement of temperature using RTDs or thermocouples, but can also

accept other sensors with resistance or mV output such as: pyrometers, load cells,

resistance position indicators, etc. The digital technology used in the TT302 enables a

single model to accept several types of sensors, an easy interface between the field and

the control room and several others features that considerably reduces the installation,

operation and maintenance costs.

FIELDBUS is not only a replacement for 4-20 mA or intelligent/smart transmitter

protocols. It contains much more. FIELDBUS is a complete system enabling distribution

of the control function to equipment in the field.

Some advantages of bi-directional digital communications are known from existing smart

transmitter protocols: higher accuracy, multivariable access, remote configuration and

diagnostics and multi-dropping of several devices on a single pair of wires. These

protocols were not intended to transfer control data, but maintain information. Therefore

they were slow and not efficient enough to be used.

The main requirements for Fieldbus were to overcome these problems. Closed loop

control with performance like a 4-20 mA system requires higher speed. Since higher

speed means higher power consumption, this clashes with the need for intrinsic safety.

Therefore a moderately high communication speed was selected, and the system was

designed to have minimum communication overhead. Using scheduling, the system

controls the variable sampling, the algorithm execution and the communication to

optimize the usage of the network, thus achieving high closed loop performance.

Using Fieldbus technology, with its capability to interconnect several devices, very large

control schemes can be constructed. In order to be user friendly, the function block

concept was introduced (users of SMAR CD600 should be familiar with this, since it was

implemented several years ago). The user may now easily build and overview complex

control strategies. Another advantage is adding flexibility, the control strategy may be

edited without having to rewire or change any hardware.

Now, thanks to Fieldbus, the transmitter accepts two channels, i.e., two measurements.

This reduces the cost per channel. Other function blocks are also available. They allow

flexibility in control strategy implementation.

The need for Fieldbus implementation in small as well as large systems was considered

when developing the entire 302 line of Fieldbus devices. They have the common features

of being able to act as a master on the network.

Get the best result of the TT302 by carefully reading these instructions.

TT302 – Fieldbus Temperature Transmitter

VI

WARNING

This Manual is compatible with version 3.XX, where 3 denote

software version and XX software release. The indication 3.XX

means that this manual is compatible with any release of

software version 3.

Section 1

1-1

Installation

General

The overall accuracy of temperature and other measurements depends on several

variables. Although the transmitter has an outstanding performance, proper installation is

essential in order to maximize its performance.

Among all factors which may affect transmitter accuracy, environmental conditions are

the most difficult to control. There are, however, ways of reducing the effects of

temperature, humidity and vibration.

Locating the transmitter in areas protected from extreme environmental changes can

minimize temperature fluctuation effects.

In warm environments, the transmitter should be installed in such a way as to avoid, as

much as possible, direct exposure to the sun. Installation close to lines and vessels

subjected to high temperatures should also be avoided. For temperature measurements,

sensors with cooling-neck can be used or the sensor can be mounted separately from the

transmitter housing.

Use of sunshades or heat shields to protect the transmitter from external heat sources

should be considered.

Humidity is fatal for electronic circuits. In areas subjected to high relative humidity, the O-

rings for the electronic housing covers must be correctly placed and the covers must be

completely closed by tightening them by hand until you feel the O-rings being

compressed. Do not use tools to close the covers. Removal of the electronics cover in the

field should be reduced to the minimum necessary, since each time it is removed, the

circuits are exposed to humidity. The electronic circuit is protected by a humidity proof

coating, but frequent exposure to humidity may affect the protection provided. It is also

important to keep the covers tightened in place. Every time they are removed, the threads

are exposed to corrosion, as painting cannot protect these parts. Code-approved sealing

methods should be employed on conduit entering the transmitter.

Connecting the sensor as close to the transmitter as possible and using proper wires

(See Section 2 - Operation), can decrease measurement error.

Mounting

The transmitter may be mounted in two basic ways:

Separated from the sensor, using optional mounting brackets.

Mounted on the sensor assembly.

It can be mounted in several different positions using the bracket, as shown in Figure 1.3

- Dimensional Drawing and Mounting Positions. As shown in Figure 1.3 - Dimensional

Drawing and Mounting Positions one of the conduit inlets for electrical connection is used

to mount the sensor integral to the temperature transmitter.

For better visibility, the digital display may be rotated in steps of 90°. (See Figure 4.1 -

Four Possible Positions of the Display).

TT302 – Fieldbus Temperature Transmitter

1-2

Network Wiring

Access the terminal block by removing the Electrical Connection Cover. This cover can

be locked closed by the cover locking screw (See Figure 1.1 - Cover Locking).To release

the cover, rotate the locking screw clockwise.

Figure 1.1 - Cover Locking

Cable access to wiring connections are obtained by one of the two conduit outlets.

Conduit threads should be sealed by means of code-approved sealing methods. The

unused outlet connection should be plugged accordingly.

The wiring block has screws on which fork or ring type terminals can be fastened. (See

Figure 1.2 - Ground Terminals).

Figure 1.2 - Ground Terminals

For convenience, there are three ground terminals: one inside the cover and two

externally, located close to the conduit entries.

WARNING

Do not connect the Fieldbus network wires to the sensor

terminals. (Terminals 1, 2, 3 and 4).

TT2EM102.CDR

TT2EM101.CDR

Installation

1-3

Figure 1.3 - Dimensional Drawing and Mounting Positions

The TT302 uses the 31.25-kbit/s, voltage mode option for the physical signaling. All other

devices on the same bus must use the same signaling. All devices are connected in

parallel along the same pair of wires.

Various types of Fieldbus devices may be connected on the same bus. The TT302 is

powered via the bus. The limit for such devices is 16 for one bus for non-intrinsically safe

requirement.

In hazardous areas, the number of devices may be limited to 6 devices by intrinsically

safe restrictions.

The TT302 is protected against reverse polarity, and can withstand ±35 VDC without

damage.

Use of twisted pair cables is recommended. It is also recommended to ground shield of

shielded cables at one end only. The non-grounded end must be carefully isolated.

NOTE

Please refer to the General Installation, Operation and Maintenance

Manual for more details.

TT2EM103.CDR

TT302 – Fieldbus Temperature Transmitter

1-4

Bus Topology and Network Configuration

WARNING

HAZARDOUS AREAS

In hazardous zones with explosion proof requirements the

covers must be tightened with at least 7 turns. In order to avoid

moisture or corrosive gases, hand tighten the covers until the O-

rings are compressed. Lock the covers closed with the locking

screw.

In hazardous zones with intrinsically safe or non incendive

requirements, the circuit entity parameters and applicable

installation procedures must be observed.

Cable access to wiring connections is obtained by the two

conduit outlets. Conduit threads should be sealed by means of

code-approved sealing methods. The unused outlet connection

should be plugged and sealed accordingly.

Should other certifications be necessary, refer to the certification

or specific standard for installation limitations.

The connection of couplers should be kept at less than 15 per 250 m.

Figure 1.4 - Bus Topology

TT2EM104.CDR

Installation

1-5

Figure 1.5 - Tree Topology

TT2EM105.CDR

TT302 – Fieldbus Temperature Transmitter

1-6

Section 2

2-1

Operation

The TT302 accepts signals from mV generators such as thermocouples or resistive

sensors such as RTDs. The criterion is that the signal is within the range of the input. For

mV, the range is -50 to 500 mV and for resistance, 0-2000 Ohm.

Functional Description - Hardware

The function of each block is described below.

Figure 2.1 - TT302 Block Diagram

MUX Multiplexer

The MUX multiplexes the sensor terminals to the signal conditioning section ensuring that

the voltages are measured between the correct terminals.

Signal Conditioner

Its function is to apply the correct gain to the input signals to make them suit the A/D -

converter.

A/D Converter

The A/D converts the input signal to a digital format for the CPU.

Signal Isolation

Its function is to isolate the control and data signal between the input and the CPU.

TT2EM201.CDR

TT302 – Fieldbus Temperature Transmitter

2-2

(CPU) Central Processing Unit, RAM, PROM and EEPROM

The CPU is the intelligent portion of the transmitter, being responsible for the

management and operation of measurement, block execution, self-diagnostics and

communication. The program is stored in a PROM. For temporary storage of data there is

a RAM. The data in the RAM is lost if the power is switched off. However there is a

nonvolatile EEPROM where data that must be retained is stored. Examples, of such data

are trim, calibration, block configuration and identification data.

Communication Controller

It monitors line activity, modulates and demodulates communication signals and inserts

and deletes start and end delimiters.

Power Supply

Takes power of the loop-line to power the transmitter circuitry.

Power Isolation

Just like the signals to and from the input section, the power to the input section must be

isolated. Isolation is achieved by converting the DC supply into a high frequency AC

supply and galvanically separating it using a transformer.

Display Controller

Receives data from the CPU informing which segments of the Liquid Crystal Display,

should be turned on.

Local Adjustment

There are two switches that are magnetically activated. They can be activated by the

magnetic tool without mechanical or electrical contact.

Figure 2.2 - LCD Indicator

TT2EM202.CDR

Operation

2-3

Temperature Sensors

The TT302, as previously explained, accepts several types of sensors. The TT302 is

specially designed for temperature measurement using thermocouples or Resistive

Temperature Detectors (RTDs).

Some basic concepts about these sensors are presented below.

Thermocouples

Thermocouples are constructed with two wires made from different metals or alloys

joined at one end, called measuring junction or "hot junction". The measuring junction

should be placed at the point of measurement. The other end of the thermocouple is

open and connected to the temperature transmitter. This point is called reference junction

or cold junction.

For most applications, the Seebeck effect is sufficient to explain thermocouple behavior

as following:

How the Thermocouple Works (Seebeck Effect)

When there is a temperature difference along a metal wire, a small electric potential,

unique to every alloy, will occur. This phenomenon is called Seebeck effect. When two

wires of dissimilar metals are joined at one end, and left open at the other, a temperature

difference between the two ends will result in a voltage since the potentials generated by

the dissimilar materials are different and do not cancel each other out. Now, two

important things must be noted. First: the voltage generated by the thermocouple is

proportional to the difference between the measuring-junction and the cold junction

temperatures. Therefore the temperature at the reference junction must be added to the

temperature derived from the thermocouple output, in order to find the temperature

measured. This is called cold junction compensation, and is done automatically by the

TT302, which has a temperature sensor at the sensor terminals for this purpose.

Secondly, if the thermocouple wires are not used, all the way to the terminals of the

transmitter (e.g., copper wire is used from sensor-head or marshaling box) will form new

junctions with additional Seebeck effects. It will be created and ruin the measurement in

most cases, since the cold-junction compensation will be done at the wrong point.

NOTE

Use thermocouple wires or appropriate extension wires all the way

from sensor to transmitter.

The relation between the measuring junction temperature and the generated mili-voltage

is tabulated in thermocouple calibration tables for standardized thermocouple types, the

reference temperature being 0°C.

Standardized thermocouples that are commercially used, whose tables are stored in the

memory of the TT302, are the following:

NBS (B, E, J, K, N, R, S & T)

DIN (L & U)

Resistive Temperature Detectors (RTDs)

Resistance Temperature Detectors, most commonly known as RTD’s, are based on the

principle that the resistance of metal increases as its temperature increases.

Standardized RTDs, whose tables are stored in the memory of the TT302, are the

following:

JIS [1604-81] (Pt50 & Pt100)

IEC, DIN, JIS [1604-89] (Pt50, Pt100 & Pt500)

GE (Cu10)

DIN (Ni120)

TT302 – Fieldbus Temperature Transmitter

2-4

For correct measurement of RTD temperature, it is necessary to eliminate the effect of

the resistance of the wires connecting the sensor to the measuring circuit. In some

industrial applications, these wires may be hundreds of meters long. This is particularly

important at locations where the ambient temperature changes constantly.

The TT302 permits a 2-wire connection that may cause measuring errors, depending on

the length of connection wires and on the temperature to which they are exposed. (See

Figure 2.3 - Two-Wire Connection).

In a 2-wire connection, the voltage V2 is proportional to the RTD resistance plus the

resistance of the wires.

V2 = [RTD + 2 x R] x I

Figure 2.3 - Two-Wire Connection

In order to avoid the resistance effect of the connection wires, it is recommended to use a

3-wire connection (See Figure 2.4 - Three – Wire Connection) or a 4-wire connection

(See Figure 2.5 - Four - Wire Connection).

In a 3-wire connection, terminal 3 is a high impedance input. Thus, no current flows

through that wire and no voltage drop is caused. The voltage V2-V1 is independent of the

wire resistances since they will be cancelled, and is directly proportional to the RTD

resistance alone.

V2-V1 = [RTD + R] x I - R x I = RTD x I

Figure 2.4 - Three – Wire Connection

TT2EM204.CDR

TT2EM203.CDR

Operation

2-5

In a 4-wire connection, terminals 2 and 3 are high impedance inputs. Thus, no current

flows through those wires and no voltage drop is caused. The resistance of the other two

wires is not of interest, since there is no measurement registered on them. Hence the

voltage V2 is directly proportional to the RTD resistance.

(V2 = RTD x I)

Figure 2.5 - Four - Wire Connection

A differential or dual channel connection is similar to the two-wire connection and gives

the same problem (See Figure 2.6 - Differential or Dual Connection). The resistance of

the wires will be measured and do not cancel each other out in a temperature

measurement, since linearization will affect them differently.

Figure 2.6 - Differential or Dual Connection

TT2EM206.CDR

TT2EM205.CDR

TT302 – Fieldbus Temperature Transmitter

2-6

Section 3

3-1

Configuration

One of the many advantages of Fieldbus is that device configuration is independent of

the configurator. The TT302 may be configured by a third party terminal or operator

console. Any particular configurator is therefore not addressed here.

The TT302 contains two input transducer blocks, one resource block, one display

transducer block and other function blocks.

For explanation and details of function blocks, see the “Function Blocks Manual”.

Transducer Block

Transducer block insulates function blocks from the specific I/O hardware, such as

sensors, actuators. Transducer block controls access to I/O through manufacturer

specific implementation. This permits the transducer block to execute as frequently as

necessary to obtain good data from sensors without burdening the function blocks that

uses the data. It also insulates the function block from the manufacturer specific

characteristics of certain hardware.

By accessing the hardware, the transducer block can get data from I/O or passing control

data to it. The connection between Transducer block and Function block is called

channel. These blocks can exchange data from its interface.

Normally, transducer blocks perform functions, such as linearization, characterization,

temperature compensation, control and exchange data to hardware.

How to Configure a Transducer Block

The transducer block has an algorithm, a set of contained parameters, it means, you are

not able to link these parameters to other blocks and publish the link via communication,

and a channel connecting it to a function block.

The algorithm describes the behavior of the transducer as a data transfer function

between the I/O hardware and other function block. The set of contained parameters

defines the user interface to the transducer block. They can be divided into Standard and

Manufacturer Specific.

The standard parameters will be present for such class of device, as pressure,

temperature, actuator, etc., whatever is the manufacturer. Oppositely, the manufacturers

specific ones are defined only for its manufacturer. As common manufacturer specific

parameters, we have calibration settings, material information, linearization curve, etc.

When you perform a standard routine such as calibration, you are conducted step by step

by a method. The method is generally defined as guideline to help the user to make

common tasks. The SYSCON identifies each method associated to the parameters and

enables the interface to it.

Sensor Transducer Number

The Sensor Transducer Number associates the sensor to the transducer. It can be set to

one up to two, in case of dual sensor.

TT302 – Fieldbus Temperature Transmitter

3-2

Sensor Wiring

The TT302 accepts up to two sensors and may operate in one of three modes:

Single channel single sensor measurement

Dual channel dual sensor measurement

Single channel dual sensor differential measurement.

Single channel dual sensor backup measurement.

NOTE

Avoid routing sensor wiring close to power cables or switching

equipment.

In accordance with connection and sensor types, the terminal blocks shall be wired as

shown on the figure below (See Figure 3.1 - Sensor Wiring).

Figure 3.1 - Sensor Wiring

Jumper Configuration

In order to work properly, the jumpers J1 and J3 located in the TT302 main board must

be correctly configured.

J1 is responsible to enable the AI block simulate mode.

W1 is responsable to enable the local adjustment.

TT2EM301.CDR

Other manuals for TT302

2

Table of contents

Other SMAR Transmitter manuals

Popular Transmitter manuals by other brands

DCI

DCI DigiTrak FALCON F5 Sub-k Rebar Supplement

NIVELCO

NIVELCO EchoTREK S-300 Installation and programming manual

Long Range Systems

Long Range Systems T9560 Multitouch user manual

Infinite

Infinite L-Com SRAQ-G213 manual

VARIZOOM

VARIZOOM VZ-WFF instruction manual

Stageline

Stageline TXS-862HSE instruction manual