SMAR ld301 Manual

INTELLIGENT PRESSURE TRANSMITTER

WITH CONTROL CAPABILITY

OPERATION AND MAINTENANCE

INSTRUCTION / MANUAL

LD301

VERSION 6

LD301ME

JAN / 03

web: www.smar.com

smar Specifications and information are subject to change without notice.

For the latest updates, please visit the SMAR website above.

BRAZIL

Smar Equipamentos Ind. Ltda.

Rua Dr. Antonio Furlan Jr., 1028

Sertãozinho SP 14170-480

Tel.: +55 16 645-3599

Fax: +55 16 645-6454

e-mail: dncom@smar.com.br

ARGENTINA

Smar Argentina

Soldado de La Independencia, 1259

(1429) Capital Federal – Argentina

Telefax: 00 (5411) 4776 -1300 / 3131

e-mail: smarinfo@smarperifericos.com

CHINA

Smar China Corp.

3 Baishiqiao Road, Suite 30233

Beijing 100873, P.R.C.

Tel.: +86 10 6849-8643

Fax: +86-10-6894-0898

e-mail: [email protected]

FRANCE

Smar France S. A. R. L.

42, rue du Pavé des Gardes

F-92370 Chaville

Tel.: +33 1 41 15-0220

Fax: +33 1 41 15-0219

e-mail: sm[email protected]r

GERMANY

Smar GmbH

Rheingaustrasse 9

55545 Bad Kreuznach

Germany

Tel: + 49 671-794680

Fax: + 49 671-7946829

e-mail: [email protected]

MEXICO

Smar México

Cerro de las Campanas #3 desp 119

Col. San Andrés Atenco

Tlalnepantla Edo. Del Méx - C.P. 54040

Tel.: +53 78 46 00 al 02

Fax: +53 78 46 03

e-mail: vent[email protected]

SINGAPORE

Smar Singapore Pte. Ltd.

315 Outram Road

#06-07, Tan Boon Liat Building

Singapore 169074

Tel.: +65 6324-0182

Fax: +65 6324-0183

e-mail: [email protected]

MIDDLE EAST

Smar Middle East

Al Sadaka Tower, Suite 204

P.O. Box 268

Abu Dhabi

Tel: 9712-6763163 / 6760500

Fax: 9712-6762923

e-mail: sm[email protected].ae

USA

Smar International Corporation

6001 Stonington Street, Suite 100

Houston, TX 77040

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

e-mail: [email protected]om

Smar Laboratories Corporation

10960 Millridge North, Suite 107

Houston, TX 77070

Tel.: +1 281 807-1501

Fax: +1 281 807-1506

e-mail: sm[email protected]

Smar Research Corporation

4250 Veterans Memorial Hwy.

Suite 156

Holbrook , NY 11741

Tel: +1-631-737-3111

Fax: +1-631-737-3892

e-mail: sales@smarresearch.com

Introduction

III

INTRODUCTION

The LD301 is a smart pressure transmitter for differential, absolute, gauge, level and flow measurements.

It is based on a field-proven capacitive sensor that provides reliable operation and high performance. The

digital technology used in the LD301 enables the choice of several types of transfer functions, an easy

interface between the field and the control room and several interesting features that considerably reduce

the installation, operation and maintenance costs.

The LD301, besides the normal functions offered by other smart transmitters, offers the following

functions:

√

√√

√(∆

∆∆

∆P)3- used for trapezoidal weirs in open channel flow metering.

√

√√

√(

((

(∆

∆∆

∆P)5- used for V-notch weirs in open channel flow metering.

TABLE - the pressure signal is custom linearized according to a 16-point table, enabling, e.g.,

conversion of level to volume of a horizontal cylindrical tank.

CONTROLLER - the Process Variable is compared to a Setpoint. The deviation acts on the

output signal according to a PID algorithm (optional).

LOCAL ADJUSTMENT - not Only for Lower and Upper value, but input/output function,

operation mode, indication, setpoint, PID parameters (optional) as well.

PASSWORD - three levels for different functions.

OPERATION COUNTER - shows the number of changes in each function.

TOTALIZATION - flow totalization into volume or mass.

USER-UNIT - indication in engineering unit of the property actually measured, e.g., level, flow or

volume.

Get the best results of the LD301 by carefully reading these instructions.

Smar’s pressure transmitters are protected by U.S. patents 643379.

LD301 - Operation and Maintenance Instruction Manual

IV

NOTE

This manual is compatible with version 6.XX, where 6 denotes software

version and XX software release. The indication 6.XX means that this

manual is compatible with any release of software version 6.

Index

V

Table of Contents

1 INSTALLATION

GENERAL.............................................................................................................................................................. 1.1

MOUNTING ........................................................................................................................................................... 1.1

ELECTRONIC HOUSING ROTATION ................................................................................................................... 1.3

ELECTRIC WIRING............................................................................................................................................... 1.4

2 OPERATION

FUNCTIONAL DESCRIPTION - SENSOR ............................................................................................................. 2.1

FUNCTIONAL DESCRIPTION - HARDWARE ....................................................................................................... 2.2

FUNCTIONAL DESCRIPTION - SOFTWARE ........................................................................................................ 2.3

THE DISPLAY........................................................................................................................................................ 2.5

3 CONFIGURATION

CONFIGURATION FEATURES ............................................................................................................................. 3.2

MANUFACTURING DATA AND IDENTIFICATION ................................................................................................ 3.2

PRIMARY VARIABLE TRIM - PRESSURE ............................................................................................................ 3.3

PRIMARY VARIABLE CURRENT - TRIM .............................................................................................................. 3.4

ENGINEERING UNIT SELECTION........................................................................................................................ 3.6

TRANSMITTER ADJUSTMENT TO THE WORKING RANG................................................................................. 3.5

TRANSFER FUNCTION FOR FLOW MEASUREMENT......................................................................................... 3.7

TABLE POINTS ..................................................................................................................................................... 3.8

TOTALIZATION CONFIGURATION....................................................................................................................... 3.9

PID CONTROLLER CONFIGURATION ............................................................................................................... 3.10

EQUIPMENT CONFIGURATION ........................................................................................................................ 3.11

EQUIPMENT MAINTENANCE ............................................................................................................................ 3.12

4 PROGRAMMING USING LOCAL ADJUSTMENT

THE MAGNETIC TOOL ......................................................................................................................................... 4.1

SIMPLE LOCAL ADJUST ...................................................................................................................................... 4.2

ZERO AND SPAN RERANGING ........................................................................................................................... 4.2

COMPLETE LOCAL ADJUSTMENT ...................................................................................................................... 4.3

LOCAL PROGRAMMING TREE ............................................................................................................................ 4.3

OPERATION [OPER]............................................................................................................................................. 4.4

TUNING [TUNE] .................................................................................................................................................... 4.5

CONFIGURATION [CONF] .................................................................................................................................... 4.7

RANGE (RANGE) .................................................................................................................................................. 4.8

OPERATION MODE (MODE) .............................................................................................................................. 4.12

TOTALIZATION [TOTAL] ..................................................................................................................................... 4.12

PRESSURE TRIM [TRIM] .................................................................................................................................... 4.13

ESCAPE LOCAL ADJUSTMENT [ESC] ............................................................................................................... 4.15

5 MAINTENANCE PROCEDURES

GENERAL.............................................................................................................................................................. 5.1

DIAGNOSTIC WITH THE CONFIGURATOR ......................................................................................................... 5.1

ERRO MESSAGES............................................................................................................................................... 5.1

DIAGNOSTIC WITH THE TRANSMITTER............................................................................................................. 5.2

DISASSEMBLY PROCEDURE .............................................................................................................................. 5.4

SENSOR................................................................................................................................................................ 5.4

REASSEMBLY PROCEDURE ............................................................................................................................... 5.6

ELECTRONIC CIRCUIT ........................................................................................................................................ 5.7

INTERCHANGEABILITY........................................................................................................................................ 5.8

ACCESSORIES ..................................................................................................................................................... 5.8

SPARE PARTS LIST FOR TRANSMITTER ........................................................................................................... 5.8

LD301 - Operation and Maintenance Instruction Manual

VI

6 TECHNICAL CHARACTERISTICS

FUNCTIONAL SPECIFICATIONS.......................................................................................................................... 6.1

CONFIGURATOR.................................................................................................................................................. 6.3

PERFORMANCE SPECIFICATIONS..................................................................................................................... 6.3

PHYSICAL SPECIFICATIONS............................................................................................................................... 6.4

ORDERING CODE FOR DIFFERENTIAL, MANOMETRIC AND ABSOLUTE TRANSMITTER .............................. 6.6

ORDERING CODE FOR LEVEL TRANSMITTER .................................................................................................. 6.7

APPENDIX

A: CONTROL DRAWING....................................................................................................................................... 6.8

Section 1

1.1

INSTALLATION

GENERAL

The overall accuracy of a flow, level, or pressure measurement depends on several variables. Although

the transmitter has an outstanding performance, proper installation is essential to maximize its

performance.

Among all factors, which may affect transmitter accuracy, environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

The LD301 has a built-in temperature sensor to compensate for temperature variations. At the factory,

each transmitter is submitted to a temperature cycle, and the characteristics under different

temperatures are recorded in the transmitter memory. At the field, this feature minimizes the

temperature variation effect.

Locating the transmitter in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should also

be avoided. Use longer sections of impulse piping between tap and transmitter whenever the process

fluid is at high temperatures. Use of sunshades or heat shields to protect the transmitter from external

heat sources should be considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronic housing covers must be correctly placed and the covers must be completely closed by

tighten them by hand until you feel the O-rings being compressed. Do not use tools to close the covers.

Removal of the electronics cover in the field should be reduced to the minimum necessary, since each

time it is removed; the circuits are exposed to the humidity.

The electronic circuit is protected by a humidity proof coating, but frequent exposures to humidity may

affect the protection provided. It is also important to keep the covers tightened in place. Every time they

are removed, the threads are exposed to corrosion, since painting cannot protect these parts. Code-

approved sealing methods should be employed on conduit entering the transmitter. The unused outlet

connection should be plugged accordingly.

Although the transmitter is virtually insensitive to vibration, installation close to pumps, turbines or other

vibrating equipment should be avoided.

Proper winterization (freeze protection) should be employed to prevent freezing within the measuring

chamber, since this will result in an inoperative transmitter and could even damage the cell.

NOTE:

When installing or storing the level transmitter, the diaphragm must be protected to avoid

scratching-denting or perforation of its surface.

MOUNTING

The transmitter has been designed to be both rugged and lightweight at the same time. This make its

mounting easier mounting positions are shown in Figure 1.1.

Existing standards for the manifolds have also been taken into account, and standard designs fit

perfectly to the transmitter flanges.

Should the process fluid contain solids in suspension, install valves or rod-out fittings at regular

intervals to clean out the pipes.

The pipes should be internally cleaned by using steam or compressed air, or by draining the line with

the process fluid, before such lines are connected to the transmitter (blow-down).

LD301 – Operation and Maintenance Instruction Manual

1.2

ANSI-B 16.5 - DIMENSIONS

pclassA B C D E F G X

150 152.4 120.7 22 1.6 19.1 91.9 48 4

300 165.1 127 22.8 1.6 19.1 91.9 48 82”

600 165.1 127 32.3 6.4 19.1 91.9 48 8

150 190.5 152.4 24.4 1.6 19.1 127 73 4

300 209.5 168.1 29 1.6 22.2 127 73 83”

600 209.5 168.1 38.7 6.4 22.2 127 73 8

150 228.6 190.5 24.4 1.6 19.1 158 96 8

300 254 200 32.2 1.6 22.3 158 96 84”

600 273 215.9 45 6.4 25.4 158 96 8

DIN 2501 / 2526 form D - DIMENSIONS

DN PN A B C D E F G X

50 10/40 165 125 20 3 18 102 48 4

80 10/40 200 160 24 3 18 138 73 8

10/16 220 180 20 3 18 158 96 8

100 25/40 235 190 24 3 22 162 96 8

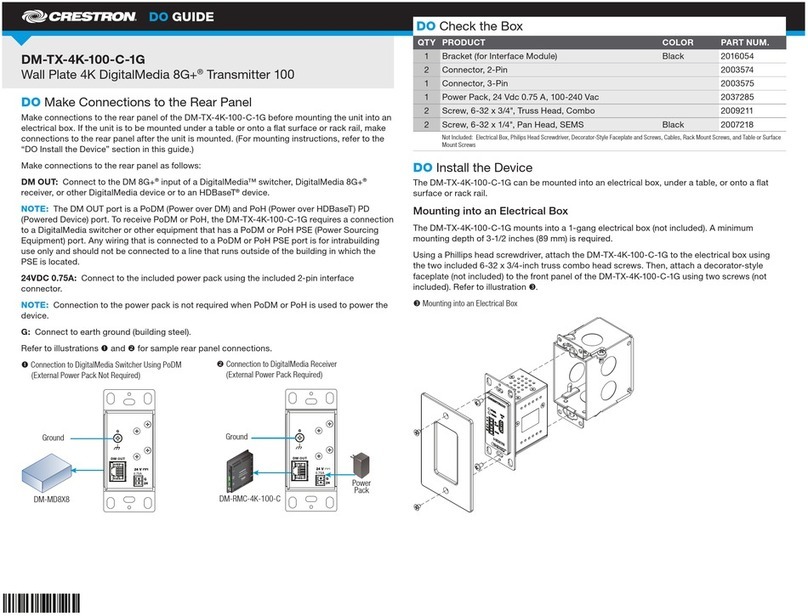

Fig. 1.1 – Dimensional Drawing and Mounting Position for LD301

Electrical

Connection

Mounting Bracket

Adapter

Allow 150mm minimum for local

zero and span adjustment with

magnetic tool

Level Diaphragm

Screws

Label

Level Diaphragm

with extension

Drain for Vent

1/4 - 18 NPT

Without Adapters

1/2 - 14 NPT

With Adapters

DIMENSIONS

RANGE

F1 - F2 - F3

F4

F6

F5

X

mm

1.71 2.13 2.68

1.77 2.25 2.78

1.75 2.20 2.76

1.79 2.27 2.82

43.5 54.0 68.0

45.0 57.2 70.6

44.5 56.0 70.0

45.5 57.6 71.6

mmin ininmm

YZ

Allow 150mm minimum for local

zero and span adjustment with

magnetic tool

Terminal

Connections

1/4 - 18 NPT

Without Adapters

1/2 - 14 NPT

With Adapters

113

(4,44)

186,5

(7,34)

94

(3,70)

41.3

(1,62)

179

(7,04)

DN-50X

Y

Z

83

( 3,26)

181

(7,12)

97

(3,81)

47,5

(1,87)

72,5

(2,85)

100,5

(3,95)

Electrical

Connection

Terminal

Connections

11 3

(4,44)

182

(7,16)

72,5

(2,85)

100,5

(3,95)

83

( 3,26)

96

(3,78)

83

(3,26)

97

(3,81)

45 máx

(1,77)

D

C

E

B

G

F

A

Drain for Vent

Installation

1.3

Fig. 1.2 – Drawing Mounting of LD301 on the Panel

Observe operating safety rules during wiring, draining or blow-down.

Some examples of installation, illustrating the position of the transmitter in relation to the taps, are

shown in Figure 1.3. The location of pressure taps and the relative position of the transmitter are

indicated in Table 1.1.

Process

Fluid

Location

of Taps

Location of LD301 in

Relation to the Taps

Gas Top or Side Above the Taps

Liquid Side Below the Taps or at the Piping Centerline

Steam Side Below the Taps using Sealing (Condensate) Pots

Table 1.1 - Location of Pressure Taps

NOTE:

Except for dry gases, all impulse lines should slope at the ratio 1:10, in order to avoid trapping

bubbles in the case of liquids, or condensate for steam or wet gases.

ELECTRONIC HOUSING ROTATION

The electronic housing can be rotated in order to better position the digital display. To rotate it, use the

Housing Rotation Set Screw, see Figure 1.4

WARNING: EXPLOSION PROOF INSTALLATIONS

The electronic housing and the sensor assembly in potentially explosive atmospheres must have a

minimum of 6 threads fully engaged. The provided joint allows 1 turn extra. Try to adjust the display

window position by rotating the housing clockwise. If the thread reaches the end before the desired

position, then rotate the housing counterclockwise, but not by more than one turn of the thread end.

Transmitters have a stopper that restricts housing rotation to one turn. See Section 5, Figure 5.1.

The digital display itself can also be rotated. See Section 5, Figure 5.4.

NOTE

The process flange of the level transmitters can be rotated ±45º. To do this just loosens the two screws

(Fig. 1.1) and rotate the flange. Do not take the screws out. There is a label (Fig. 1.1) on the

transmitter with these instructions

PANEL MOUNTING

(See section 5 - spare parts list

for mounting backets available)

LD301 – Operation and Maintenance Instruction Manual

1.4

Fig 1.3 – Position of the Transmitter and Taps

ELECTRIC WIRING

Reach the wiring block by removing the Electrical Connection Cover. This cover can be locked closed

by the cover locking screw (Figure 1.4). To release the cover, rotate the locking screw clockwise.

Fig. 1.4 – Housing Rotating Set Screw

The wiring block has screws on which fork or ring-type terminals can be fastened. See Figure 1.5.

HAZARDOUS AREAS

In hazardous areas with explosion proof requirements, the covers must be tightened with

at least 8 turns. In order to avoid the penetration moisture or corrosive gases, tighten the

O’ring until feeling the O'ring touching the housing. Then, tighten more 1/3 turn (120°) to

guarantee the sealing. Lock the covers using the locking screw.

In hazardous zones with intrinsically safe or nonincendive requirements, the circuit entity

parameters and applicable installation procedures must be observed.

Cable access to wiring connections is obtained by one of the two conduit outlets. Conduit

threads should be sealed by means of code-approved sealing methods. The unused outlet

connection should be plugged and sealed accordingly.

Explosion proof, nonincendive and intrinsic safety Factory Mutual certification are standards

for LD301 (see control drawing in Appendix A).

Should other certifications be necessary, refer to the certification or specific standard for

installation limitations.

Installation

1.5

Fig. 1.5 – Wiring Block

For convenience there are two ground terminals: one inside the cover and one external, located close

to the conduit entries.

Use of twisted pair (22 AWG or greater than) cables is recommended.

Avoid routing signal wiring close to power cables or switching equipment.

The unused outlet connection should be plugged and sealed accordingly.

The LD301 is protected against reverse polarity.

The Figure 1.6 - Conduit Installation Diagram, shows the correct installation of the conduit, in order to

avoid penetration of water, or other substance, which may cause malfunctioning of the equipment.

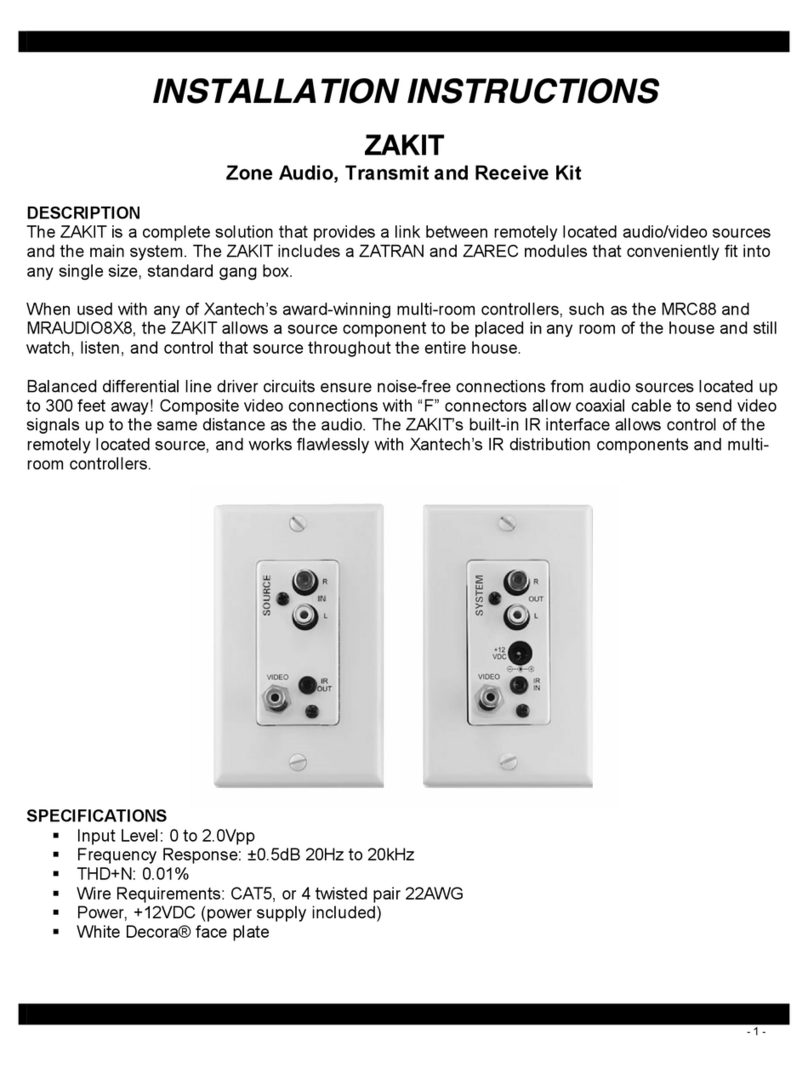

Figure 1.6 - Conduit Installation Diagram.

CO

RRE

C

T

WIRES

IN

CO

RRE

C

T

LD301 – Operation and Maintenance Instruction Manual

1.6

NOTE

The transmitters are calibrated in the vertical position and a different mounting position displaces

the zero point. Consequently, the indicator will indicate a different value from the applied pressure.

In these conditions, it is recommended to do the zero pressure trim. The zero trim is to compensate

the final assembly position and its performance, when the transmitter is in its final position. When

the zero trim is executed, make sure the equalization valve is open and the wet leg levels are

correct.

For the absolute pressure transmitter, the assembly effects correction should be done using the

Lower trim, due to the fact that the absolute zero is the reference for these transmitters, so there

is no need for a zero value for the Lower trim.

When the sensor is in the horizontal position, the weight of the fluid pushes the diaphragm down,

making it necessary a Lower Pressure Trim.

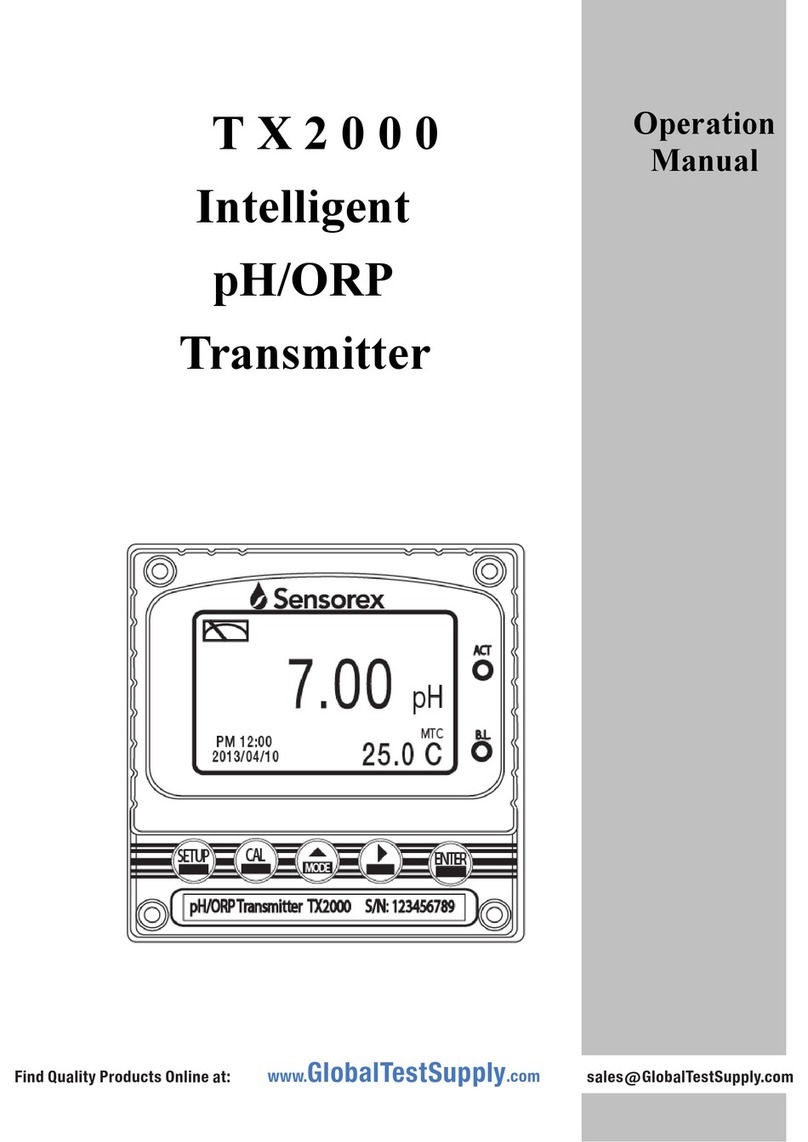

Fig.1.7 - Sensor Positions

Connection of the LD301 working as transmitter should be done as in Figure 1.8.

Connection of the LD301 working as a controller should be as indicated in Figure 1.9.

Connection of the LD301 in multidrop configuration should be done as in Figure 1.10. Note that a

maximum of 15 transmitters can be connected on the same line and that they should be connected in

parallel.

Take care to the power supply as well, when many transmitters are connected on the same line.

The current through the 250 Ohm resistor will be high causing a high voltage drop. Therefore make

sure that the power supply voltage is sufficient.

The Hand-Held Terminal can be connected to the communication terminals of the transmitter or at any

point of the signal line by using the alligator clips. It is also recommended to ground the shield of

shielded cables at only one end. The ungrounded end must be carefully isolated.

NOTE:

Make sure that the transmitter is operating within the operating area as shown on the load curve (Figure 1.11).

Communication requires a minimum load of 250 Ohm.

DIAPHRA

G

M

S

EN

SO

R

SENSOR IN THE VERTICAL POSITION SENSOR IN THE HORIZONTAL POSITION

HEAD OF THE FLUID

DIAPHRAGM SENSO

R

Installation

1.7

Fig. 1.8 – Wiring Diagram for the LD301 Working as a Transmitter

Fig. 1.9 – Wiring Diagram for the LD301 Working as a Controller (Optional)

Fig. 1.10 – Wiring Diagram for the LD301 in Multidrop Configuration

Fig. 1.11 – Load Curve

LD301 – Operation and Maintenance Instruction Manual

1.8

Section 2

2.1

OPERATION

FUNCTIONAL DESCRIPTION – SENSOR

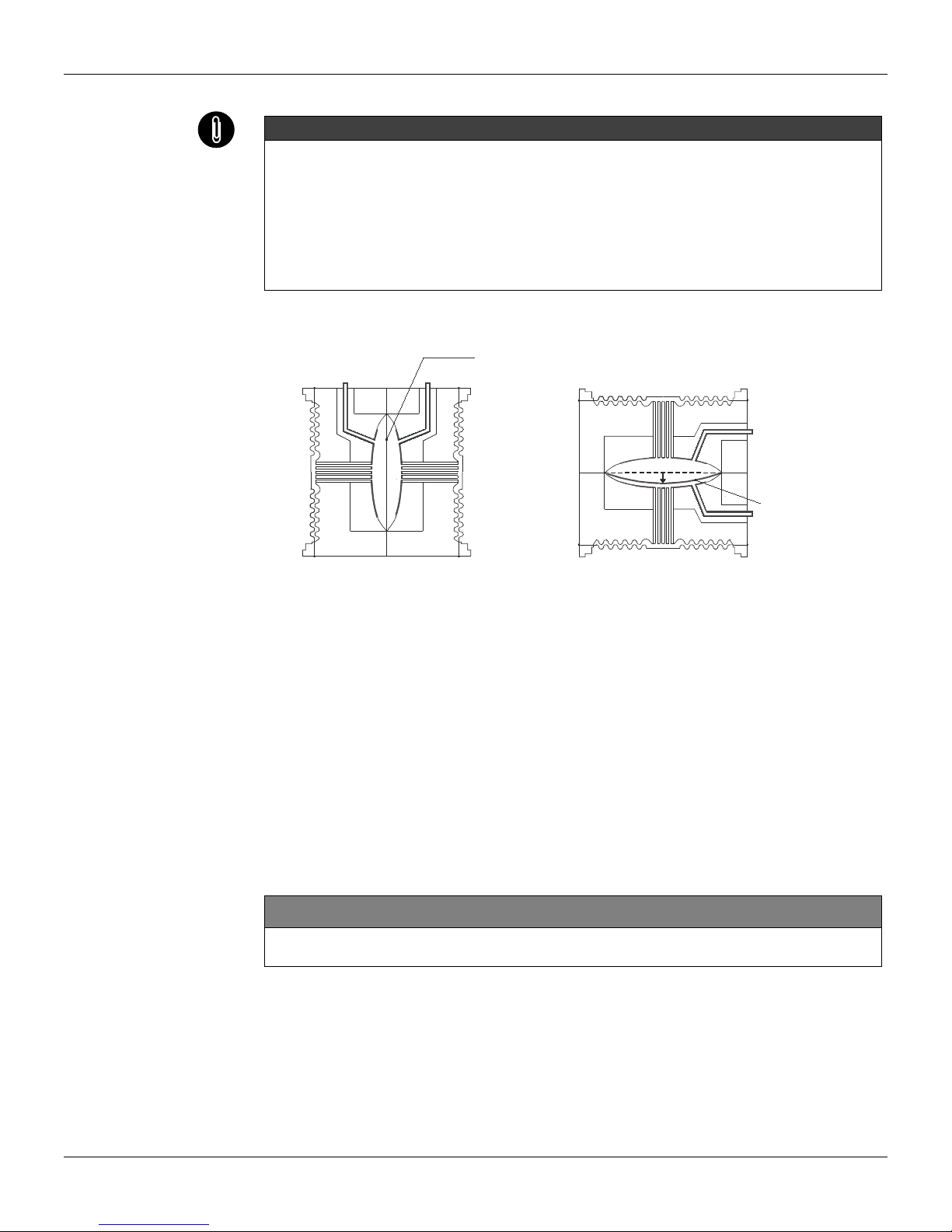

The LD301 Series Intelligent Pressure Transmitters use capacitive sensors (capacitive cells)

as pressure sensing elements, as shown in Figure 2.1.

Fig. 2.1 – Capacitive Cell

Where,

P1and P2are the pressures in chambers H and L

CH= capacitance between the fixed plate on P1side and the sensing diaphragm.

CL= capacitance between the fixed plate on the P2side and the sensing diaphragm.

d = distance between CH and CL fixed plates.

∆

∆∆

∆d= sensing diaphragm's deflection due to the differential pressure ∆P = P1- P2.

Knowing that the capacitance of a capacitor with flat, parallel plates may be expressed as a

function of plate area (A) and distance (d) between the plates as:

Where,

ε

εε

ε

=dielectric constant of the medium between the capacitor's plates.

Should CH and CL be considered as capacitances of flat and parallel plates with identical

areas, then:

However, should the differential pressure (∆P) applied to the capacitive cell not deflect the

sensing diaphragm beyond d/4, it is possible to assume ∆P as proportional to ∆d, that is:

By developing the expression (CL - CH)/(CL + CH), it follows that:

as the distance (d) between the fixed plates CH and CL is constant, it is possible to conclude

that the expression (CL - CH)/(CL + CH) is proportional to ∆d and, therefore, to the differential

pressure to be measured.

Thus it is possible to conclude that the capacitive cell is a pressure sensor formed by two

capacitors whose capacitances vary according to the applied differential pressure.

d

A

C∈

=

dP ∆∆

α

d

d

CHCL

CHCL

P∆

=

+

−

=∆ 2

and dd

A

CL

∆−

∈

=

)2/(

.

dd

A

CH

∆+

∈

=

)2/(

.

LD301- manual de Instruções, Operação e manutenção

2.2

FUNCTIONAL DESCRIPTION - HARDWARE

Refer to the block diagram Figure 2.2. The function of each block is described below.

Oscillator

This oscillator generates a frequency as a function of sensor capacitance.

Signal Isolator

The Control signals from the CPU are transferred through optical couplers, and the signal from

the oscillator is transferred through a transformer.

(CPU) Central Processing Unit and PROM

The CPU is the intelligent portion of the transmitter, being responsible for the management and

operation of all other blocks, linearization and communication.

The program is stored in an external PROM. For temporary storage of data the CPU has an

internal RAM. The data in the RAM is lost, if the power is switched off, however the CPU also

has an internal nonvolatile EEPROM where data that must be retained is stored. Examples of

such data are: calibration, configuration and identification data.

EEPROM

Another EEPROM is located within the sensor assembly. It contains data pertaining to the

sensor's characteristics at different pressures and temperatures. This characterization is done

for each sensor at the factory.

D/A Converter

Converts the digital data from the CPU to an analog signal with 14-bits resolution.

Output

Controls the current in the line feeding the transmitters.

It acts as a variable resistive load whose value depends on the voltage from the D/A

converter.

Modem

This system providers the data exchange between the se serve-master digital communication

. The transmitter demodulates information from the current line, then modulates the relies

sending then over the line. A "1" is represented by 1200 Hz and "0" by 2200 Hz. The frequency

signal is symmetrical and does not affect the DC-level of the 4-20 mA signal.

Power Supply

Power shall be supplied to the transmitter circuit using the signal line (2-wire system). The

transmitter quiescent consumption is 3.6 mA; during operation, consumption may be as high

as 21 mA, depending on the measurement and sensor status.

The ld301, in the transmitter mode, shows failure indication at 3.6 mA if configured for low

signal failure; at 21 mA, if configured for high signal failure; 3.8 mA in the case of low saturation;

20.5 mA in the case of high saturation and measurements proportional to the applied pressure

in the range between 3.8 mA and 20,5 mA. 4 mA corresponds to 0% of the working range and

20 mA to100 % of the working range.

Fig. 2.2 – LD301 Block Diagram Hardware

Operation

2.3

Power Supply Isolation

The sensor power supply is isolated from the main circuit by this module.

Display Controller

It receives the data from the CPU and actives the LCD segments. Also it actives the back plane

and the control signals for each segment.

Local Adjustment

Two switches that are magnetically activated. The magnetic tool without mechanical or electrical contact

can activate them.

FUNCTIONAL DESCRIPTION - SOFTWARE

Factory Characterization

Calculates the actual pressure from the capacitances and temperature readings obtained from the

sensor using the factory characterization data stored in the sensor EEPROM.

Digital Filter

The digital filter is a low pass filter with an adjustable time constant. It is used to smooth noisy signals.

The Damping value is the time required for the output reaching 63.2% for a step input of 100%.

Customer Characterization

The characterization TRIM points P1-P5 can be used to complement the transmitter's original

characterization.

Pressure Trim

Here the values obtained by Zero Pressure TRIM and Upper Pressure TRIM corrects the transmitter for

long term drift or the shift in zero or upper pressure reading due to installation or over pressure.

Ranging

Used to set the pressure values corresponding to the output 4 and 20 mA. In transmitter mode the

LOWER-VALUE is the point corresponding to 4 mA, and UPPER-VALUE is the point corresponding to

20 mA. In PID mode the LOWER-VALUE corresponds to MV = 0% and UPPER-VALUE corresponds

to MV = 100%.

Function

Depending on the application, the transmitter output or controller PV may have the following

characteristics according to the applied pressure: Linear (for pressure, differential pressure and level

measurement); Square-root (for flow measurement with differential pressure producers) and Square-root

of the Third and Fifth power (for flow measurements in open channels). The function is selected with

FUNCTION.

Customer Linearization

This block relates the output (4-20 mA or Process Variable) to the input (applied pressure) according to

a look-up table from 2 to 16 points. The output is calculated by the interpolation of these points. The

points are given in the function "TABLE POINTS" in percent of the range (Xi) and in percent of the output

(Yi). It may be used to linearize, e.g., a level measurement to volume or mass. In flow measurement it

can be used to correct for varying Reynolds number.

Setpoint

Is the desired value in the process variable when the controller is activated. The operator in the

\CONTR\INDIC option adjusts it.

PID

First the error is calculated as SP-PV or PV-SP depending on which action (direct or reverse) it is

configured. Then the manipulated variable MV is calculated according to the type of PID algorythm.

Auto/Manual

The Auto/Manual mode is configured in CONTR/INDIC. With the PID in Manual, the MV can be adjusted

by the user in the range LOW LIMIT to HIGH LIMIT (adjustable by the user) in the CONTR/LIM-SEG

option. The POWER-ON option is used here to determine in which mode the controller should be upon

powering it on.

Limits

This block makes sure that the MV does not go beyond its minimum and maximum limits as established

by the HIGH-LIMIT and LOW-LIMIT. It also makes sure that the Rate-of-Change does not exceed the

value set in OUT-CHG/S.

LD301- manual de Instruções, Operação e manutenção

2.4

Fig.2.3 – LD301 – Software Block Diagram

Operation

2.5

Output

Calculates the current proportional to the process variable or manipulated variable to be

transmitted on the 4-20 mA output depending on the configuration in OP-MODE. This block also

contains the constant current function configured in OUTPUT. The output is physically limited

to 3.6 to 21 mA.

Current Trim

The 4 mA TRIM and 20 mA TRIM adjustment is used to make the transmitter current comply

with a current standard, should a deviation arise.

User Unit

Converts 0 and 100% of the process variable to a desired engineering unit read out available

for the display and communication. It is used, e.g., to get a volume or flow indication from a

level or differential pressure measurement, respectively. A unit for the variable can also be

selected.

Totalization

Used for flow to application totalize the accumulated total since the last reset, getting the

volume or the transferred.

The totalized value is persistent; the totalization may proceed even after a power failure. Only

the totalization residue value is discarded.

Display

Can alternate between two indications as configured in DISPLAY.

THE DISPLAY

The integral indicator is able to display one or two variables, which are user selectable. When

two variables are chosen, the display will alternate between the two with an interval of 3

seconds.

The liquid crystal display includes a field with 4 ½ numeric digits, a field with 5 alphanumeric

digits and an information field, as shown on Figure 2.4.

When the total is displayed, the significant most part appears in the unit and function field

(upper) and the least significant part in the variable field (lower). See Totalization in Section 3.

DISPLAY V6.00

The display controller, from release V6.00 on, is integral to the main board. Please

observe the new spare parts codes.

Monitoring

During normal operation, the LD301 is in the monitoring mode. In this mode, indication

alternates between the primary and secondary variable as configured by the user. See Figure.

2.5. The display indicates engineering units, values and parameters simultaneously with most

status indicators.

The monitoring mode is interrupted when the user does complete local adjustment.

The display is also capable of displaying an error and other messages (See table 2.1).

NEW

NEW

LD301- manual de Instruções, Operação e manutenção

2.6

Fig. 2.4 - Display

Fig. 2.5 – Typical Monitoring Mode Display Showing PV, in this case 25.00 mmH20

DISPLAY DESCRIPTION

INIT The LD301 is in initializing after power on.

CHAR The LD301 is characterization mode. See Section 3 – Trim.

FAIL SENS Sensor failure. Refer to Section 5 - Maintenance.

SAT Current output saturated in 3.6 or 21 mA. See Section 5 – Maintenance.

Table 2.1 - Display Messages

NEW

Other manuals for ld301

1

Table of contents

Other SMAR Transmitter manuals

Popular Transmitter manuals by other brands

DLO

DLO TuneStik quick start guide

MSA

MSA ICM Tx installation instructions

Cobalt Digital Inc

Cobalt Digital Inc BlueBox BBG-OE-MK2 Fiber-To-Coax quick start guide

Canon

Canon Wireless File Transmitter WFT-E2 II A instruction manual

WIKA

WIKA S-11 operating instructions

Nautel

Nautel NV30 Operation and maintenance manual