SMAR Foundation 302 Series User manual

web: www.smar.com

smar

Specifications and information are subject to change without notice.

For the latest updates, please visit the SMAR website above.

BRAZIL

Smar Equipamentos Ind. Ltda.

Rua Dr. Antonio Furlan Jr., 1028

Sertãozinho SP 14170-480

Tel.: +55 16 3946-3510

Fax: +55 16 3946-3554

ARGENTINA

Smar Argentina

Soldado de La Independencia, 1259

(1429) Capital Federal – Argentina

Telefax: 00 (5411) 4776 -1300 / 3131

CHINA

Smar China Corp.

3 Baishiqiao Road, Suite 30233

Beijing 100873, P.R.C.

Tel.: +86 10 6849-8643

Fax: +86-10-6894-0898

FRANCE

Smar France S. A. R. L.

42, rue du Pavé des Gardes

F-92370 Chaville

Tel.: +33 1 41 15-0220

Fax: +33 1 41 15-0219

GERMANY

Smar GmbH

Rheingaustrasse 9

55545 Bad Kreuznach

Germany

Tel: + 49 671-794680

Fax: + 49 671-7946829

MEXICO

Smar México

Cerro de las Campanas #3 desp 119

Col. San Andrés Atenco

Tlalnepantla Edo. Del Méx - C.P. 54040

Tel.: +53 78 46 00 al 02

Fax: +53 78 46 03

SINGAPORE

Smar Singapore Pte. Ltd.

315 Outram Road

#06-07, Tan Boon Liat Building

Singapore 169074

Tel.: +65 6324-0182

Fax: +65 6324-0183

USA

Smar International Corporation

6001 Stonington Street, Suite 100

Houston, TX 77040

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

Smar Laboratories Corporation

10960 Millridge North, Suite 107

Houston, TX 77070

Tel.: +1 281 807-1501

Fax: +1 281 807-1506

Smar Research Corporation

4250 Veterans Memorial Hwy.

Suite 156

Holbrook , NY 11741

Tel: +1-631-737-3111

Fax: +1-631-737-3892

Index

III

Table of Contents

INDEX OF FIGURES................................................................................................... IV

INDEX OF TABLES .................................................................................................... IV

INTRODUCTION.......................................................................................................... V

INSTALLATION ........................................................................................................ 1.1

NETWORK WIRING .............................................................................................................................1.1

PHYSICAL SIGNALING........................................................................................................................1.2

TOPOLOGIES ......................................................................................................................................1.2

BUS TOPOLOGY .................................................................................................................................1.2

TREE TOPOLOGY ...............................................................................................................................1.2

DAISY CHAIN TOPOLOGY..................................................................................................................1.5

POINT-TO-POINT TOPOLOGY............................................................................................................1.6

FIELDBUS NETWORK COMPONENTS ..............................................................................................1.6

POWER SUPPLY .................................................................................................................................1.6

DEVICE QUANTITY .............................................................................................................................1.7

TERMINAL BLOCKS ............................................................................................................................1.7

TERMINATOR ......................................................................................................................................1.7

TERMINATOR PLACEMENT ...............................................................................................................1.8

PSI302 POWER SUPPLY IMPEDANCE ..............................................................................................1.8

REDUNDANT POWER.........................................................................................................................1.9

BT302 TERMINATOR...........................................................................................................................1.9

PS302 POWER SUPPLY .....................................................................................................................1.9

CABLING ..............................................................................................................................................1.9

CABLE OPTIONS...............................................................................................................................1.10

TOTAL CABLE LENGHT ....................................................................................................................1.10

SPUR LENGHT ..................................................................................................................................1.13

RECOMMENDED MAXIMUM SPUR LENGHT .................................................................................1.13

INTERFACE AND BRIDGE ................................................................................................................1.14

BRIDGE CONNECTION .....................................................................................................................1.14

INTRINSIC SAFETY CONNECTION ..................................................................................................1.15

INTRINSIC SAFETY...........................................................................................................................1.15

ATTACHING DEVICES TO THE FIELDBUS......................................................................................1.19

WIRING DOS AND DON’TS...............................................................................................................1.29

INTRINSIC SAFETY GALVANIC ISOLATOR.....................................................................................1.20

COMPUTER INSTALLATION.............................................................................................................1.21

INTERFACE CONNECTION ..............................................................................................................1.21

INTERFACE ADDRESING .................................................................................................................1.22

INTERFACE CONFIGURATION.........................................................................................................1.22

BASIC TROUBLESHOOTING ............................................................................................................1.23

OPERATION ............................................................................................................. 2.1

THE LCD DISPLAY .............................................................................................................................2.1

NORMAL DISPLAY OPERATION ........................................................................................................2.2

CONFIGURATION .................................................................................................... 3.1

FUNCTION BLOCKS............................................................................................................................3.1

DISPLAY TRANSDUCER BLOCK........................................................................................................3.1

LOCAL PROGRAMMING TREE...........................................................................................................3.3

DISPLAY CONFIGURATION USING SYSCON ...................................................................................3.3

PROGRAMMING USING LOCAL ADJUSTMENT ...............................................................................3.5

LOCAL ADJUSTMENT METHODOLOGY............................................................................................3.5

TRANSDUCER BLOCK........................................................................................................................3.7

HOW CONFIGURE A TRANDUCER BLOCK.......................................................................................3.7

CHANNEL.............................................................................................................................................3.8

CALIBRATION......................................................................................................................................3.8

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

IV

MAINTENANCE PROCEDURES .............................................................................. 4.1

GENERAL.............................................................................................................................................4.1

RETURNING SMAR PRODUCTS AND/OR MATERIALS ....................................................................4.1

Index of Figures

FIGURE 1.1 – HOUSING ROTATION.........................................................................................................1.1

FIGURE 1.2 – WIRING BLOCK ..................................................................................................................1.1

FIGURE 1.3 – WIRE MEDIA.......................................................................................................................1.2

FIGURE 1.4 – FIELDBUS NETWORK........................................................................................................1.3

FIGURE 1.5 – BUS TOPOLOGY ................................................................................................................1.4

FIGURE 1.6 – TREE TOPOLOGY ..............................................................................................................1.4

FIGURE 1.7 – DAISY – CHAIN TOPOLOGY..............................................................................................1.5

FIGURE 1.8 – DAISY – CHAIN WIRING ....................................................................................................1.5

FIGURE 1.9 – POINT-TO-POINT TOPOLOGY ..........................................................................................1.6

FIGURE 1.10 – TERMINAL BLOCKS .........................................................................................................1.7

FIGURE 1.11 – PSI302 CONNECTION......................................................................................................1.8

FIGURE 1.12 – REDUNDANT POWER......................................................................................................1.9

FIGURE 1.13 – TOTAL CABLE LENGHT.................................................................................................1.10

FIGURE 1.14 – CABLE ENTITY PARAMETERS......................................................................................1.11

FIGURE 1.15 – GROUNDING THE SHIELD ............................................................................................1.12

FIGURE 1.16 – SPUR LENGHT AND TERMINATOR PLACEMENT .......................................................1.13

FIGURE 1.17 – BRIDGE CONNECTION ..................................................................................................1.14

FIGURE 1.18 – I. S. CONNECTION .........................................................................................................1.15

FIGURE 1.19 – REPEATER CONNECTION ............................................................................................1.18

FIGURE 1.20 – IF302 CONNECTION.......................................................................................................1.18

FIGURE 1.21 – FI302 CONNECTION.......................................................................................................1.18

FIGURE 1.22 – CONNECTION.................................................................................................................1.20

FIGURE 1.23 – IF302 IN I. S. INSTALLATION .........................................................................................1.20

FIGURE 1.24 – FI302 IN I. S. INSTALLATION .........................................................................................1.21

FIGURE 1.25 – INTERFACE CONNECTION ...........................................................................................1.21

FIGURE 1.26 – INTERFACE ADDRESSING ...........................................................................................1.22

FIGURE 2.1 – TYPICAL NORMAL DISPLAY SHOWING PV, IN THIS CASE 50.0%.................................2.2

FIGURE 2.2 – LCD DISPLAY .....................................................................................................................2.2

FIGURE 3.1 – FUNCTION AND TRANDUCERS BLOCKS ........................................................................3.2

FIGURE 3.2 – TRANSDUCER DISPLAY – CONFIGURATION..................................................................3.2

FIGURE 3.3 – THE SETINGS OF TRANDUCER DISPLAY PARAMETERS..............................................3.3

FIGURE 3.4 – THE SETINGS OF TRANDUCER DISPLAY PARAMETERS II...........................................3.4

FIGURE 3.5 – THE SETINGS OF TRANDUCER DISPLAY PARAMETERS II...........................................3.4

FIGURE 3.6 – THE SETINGS OF TRANDUCER DISPLAY PARAMETERS II...........................................3.5

FIGURE 3.7 – LOCAL ADJUSTMENT SWITCHES ....................................................................................3.5

FIGURE 3.8 – BROWSING GENERIC PARAMETER ................................................................................3.6

FIGURE 3.9 – ACTING A GENERIC VALUE..............................................................................................3.6

Index of Tables

TABLE 1.1 – CABLE OPTIONS ................................................................................................................1.10

TABLE 1.2 – TOTAL CABLE LENGHT EXAMPLE ...................................................................................1.11

TABLE 1.3 – DEVICES PER SPUR VS. SPUR LENGHT.........................................................................1.13

TABLE 1.4 – TEMPERATURE CLASSIFICATIONS .................................................................................1.16

TABLE 2.1 – DISPLAY MESSAGES...........................................................................................................2.3

TABLE 3.1 – PARAMETER FUNCTION AND CLASS DEFAULT OF DEVICE ..........................................3.3

TABLE 3.2 – TRANSDUCER DISPLAY PARAMETERS ............................................................................3.4

TABLE 4.1 – DIAGNOSTIC OF THE FIELD DEVICES...............................................................................4.1

Introduction

V

Introduction

This manual introduces the series 302 of Fieldbus Foundation devices.

They are: LD302 – FOUNDATIONFieldbus Pressure Transmitter, TT302 – FOUNDATION

Fieldbus Temperature Transmitter, IF302 – FOUNDATIONFieldbus Triple Channel Current

to Fieldbus Converter, FI302 – FOUNDATIONFieldbus Triple Channel Fieldbus to Current

Converter, FP302 - FOUNDATIONFieldbus to Pressure Converter and FY302 -

FOUNDATIONFieldbus Positioner.

They are based on a field-proven technology that provides reliable operation and high

performance. The digital technology used in the Series 302 enables the choice of several

types of function blocks. An easy interface between the field and the control room and several

interesting features that considerably reduce the installation, operation and maintenance costs

and will develop new ways to improve plant performance, plant safety and plant availability.

Fieldbus is not only a replacement for 4-20 mA or intelligent device protocols, it contains much

more. Fieldbus is a complete network system enabling migration and distribution of the control

functions to field devices, and vastly expands the amount of process and non-process

information flowing both from and to field devices.

Some of the advantages of bi-directional digital communications are known from existing

smart field devices protocols: Higher accuracy, multi-variable access, remote configuration

and diagnostics, and multi-dropping of several devices on a single pair of wires. Those

protocols were not intended to transfer control data, but maintain information. Therefore, they

were slow, being not efficient enough to be used to digital control by communication and not

giving opportunity to come to control strategies totally reside in the field.

Fieldbus overcame these limitations. Closed loop control with performance like a 4-20 mA

system requires higher speed. Since higher speed requires higher power consumption, this

clashes with the need for intrinsic safety. Therefore a moderately high communication speed

was selected, and the system was designed to have minimum communication over-head.

Using scheduling, the system controls the variables poling, algorithm execution and the traffic

to optimize the network usage, thus achieving high and secure closed loop performance.

Using FoundationFieldbus technology, with its capability to interconnect several devices,

very large control schemes can be constructed. In order to be user friendly, the function blocks

concept was introduced1, it means, basic automation functions performed by an application.

Each function block processes input parameters according to a specified algorithm and an

internal set of contained parameters. They produce output parameters that are available for

use within the same device or by other one in the application process. Using them, the user

may easily build and overview complex control strategies. Another advantage can be seen as

extending flexibility, considering that the control strategy may be edited without having to re-

wire or change any hardware.

Each field device has a set of blocks likes Analog Input, PID, Control Selector, etc., eliminating

the need for a separate control devices. The communication requirement is considerably

reduced, and that means less dead-time and tighter control is achieved, not to mention the

reduction in cost. Other function blocks are also available2. They allow flexibility in control

strategy implementation and guarantee interoperability together of Device Description.

The need for implementation of fieldbus in small as well as large systems was considered

when developing the Series 302 of fieldbus devices. They have a common feature of being

able to act as a master on the network and be configured locally using a magnetic tool,

eliminating the need for a configurator or console in very basic applications.

Get the best results of the Foundation

Fieldbus Series 302 by carefully reading these

instructions.

1 Users of SMAR CD600 multi-loop digital controller should be familiar with this, since it was implemented several years ago.

2 For more details, Please look at Function Blocks Instruction Manual

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

VI

WARNING

This Manual is compatible with version 3.XX, where 3 denote

software version and XX software release. The indication 3.XX

means that this manual is compatible with any release of Series

302 field devices with software version 3.

Section 1

1-1

Installation

Network Wiring

Access the wiring block by removing the Electrical Connection Cover. This cover can be

locked closed by the cover locking screw to release the cover, rotate the locking screw

clockwise. (See Figure 1.1 - Housing Rotation).

Figure 1.1 - Housing Rotation

Cable access to wiring connections is obtained by one of the two outlets. Conduit threads

should be sealed by means of code-approved sealing methods. The unused outlet connection

should be plugged accordingly.

The wiring block has screws on which fork or ring-type terminals can be fastened. (See Figure

1.2 - Wiring Block).

For convenience there are two ground terminals: one inside the cover and one external,

located close to the conduit entries.

Avoid routing signal wiring close to power cables or switching equipment.

Figure 1.2 - Wiring Block

GEREM101.CDR

GEREM102.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-2

WARNING

HAZARDOUS AREAS

In hazardous zones with explosion proof requirements, the

covers must be tightened with at least 7 turns. In order to avoid

moisture or corrosive gases, hand tighten the covers until the O-

rings are compressed. Lock the covers closed with the locking

screw.

In hazardous zones with intrinsically safe or non-incendive

requirements, the circuit entity parameters and applicable

installation procedures must be observed.

Cable access to wiring connections is obtained by one of the two

conduit outlets. Conduit threads should be sealed by means of

code-approved sealing methods. The unused outlet connection

should be plugged accordingly.

Should other certifications be necessary, refer to the certification

or specific standard for installation limitations.

The Series 302 devices are protected against reverse polarity, and can withstand up to 35

VDC without damage.

Physical Signaling

The Foundation

Fieldbus Series 302 devices use the 31.25 kbit/s voltage mode wire

media option for the physical signaling. All devices on the same bus must use the same

signaling. All devices are connected in parallel along the same pair of wires.

Various types of fieldbus devices may be connected on the same bus. The Series 302 device

is powered via bus. The limit for such devices is 16 for one bus for non-intrinsically safe

requirements.

In hazardous areas, the number of devices may be limited to 4 devices per safety barrier by

intrinsically safe restrictions.

One fieldbus network may have many barriers.

Bus-Powered

(Field device takes power from the bus)

Non Bus-Powered

(Field devices gets power over separate wires)

Figure 1.3 - Wire Media

A Smar fieldbus System consists of several fieldbus networks. A fieldbus network may consist

of several segments. Several fieldbus devices may be connected to each segment

GEREM103.CDR

Installation

1-3

Figure 1.4 - Fieldbus Network

Topologies

Almost any topology is possible. It is mainly a matter of where the terminator is connected.

•Bus

•Tree (Chicken-foot)

•Daisy-chain

•Point-to-point

As far as fieldbus is concerned that are all alike, what matters is the placement of the

terminator.

Of course combinations of two or more topologies is possible.

NOTE

Ring topology is not possible. Because connecting the bus in a

ring damage the Termination scheme.

GEREM104.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-4

Bus Topology

Devices are distributed along the trunk connected through spurs. A spur may be up to 120 m

long.

Figure 1.5 - Bus Topology

Tree topology

A main trunk runs from the control room into the field where it branches out to the individual

devices.

For tree topology it is important to ensure that the spur length does not exceeds the maximum

allowed.

Figure 1.6 - Tree Topology

GEREM105.CDR

GEREM106.CDR

Installation

1-5

Daisy Chain Topology

Cable is chained from device to device.

It is important to ensure that a device may be disconnected without other devices also being

disconnected. Therefore make sure to use same conduit for ”in” and “out” wires in order to

enable removal of device without interrupting bus.

Figure 1.7 - Daisy-Chain Topology

Figure 1.8 - Daisy-Chain Wiring

GEREM108.CDR

GEREM107.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-6

Point-to-Point Topology

Only two devices connected to each other. This topology does not take advantage of the

multidrop capability of fieldbus. Typically used only on workbench with device and notebook

computer.

Figure 1.9 - Point-to-Point Topology

Fieldbus Network Components

•Cable (“Media”)

•Field devices

•Transmitters

•Valve positioners

•Converters

•Programmable controllers

•Interfaces

•Operator stations

•Hand-held terminals

•Terminator

•Power supply impedance and power supply

•Intrinsic safety barriers / Galvanic Isolators

•Bus analyzer

Power Supply

The power consumption varies from one device to another. There are no upper or lower limits.

The power consumption is indicated on device. The lower consumption a device has the

better, especially in intrinsic safety applications. It is important that the wire resistance is not

too high making the supply voltage at the device too low. Good connections and junctions

must be made to keep resistance low. It is possible to test the voltage (not signal) on the

installed network using a hand-held Digital voltmeter (DVM).

Power Supply Example

•PSI302 output voltage is 16 V (worst case)

•Cable resistance for 1.9 km is 84 ohm

•Device needs minimum 9 V

•Maximum voltage drop is 7 V

•Maximum total current draw is 83 mA

•Each device needs 15 mA

•Maximum 5 devices, or shorter cable

GEREM109.CDR

Installation

1-7

Device Quantity

Rules of thumb:

32 separately powered or 12 bus-powered plus an interface.

4 per safety barrier in hazardous area (one fieldbus network may have many barriers). More or

less devices may be possible depending on wire size and length, power consumption and

barrier rating.

Using repeaters more devices are theoretically possible (224), though there is a penalty on

control cycle time and display update.

Terminal Blocks

No special terminal blocks are required and no special couplers are required to join spurs to

trunk. Keep it inside a junction box.

Figure 1.10 - Terminal Blocks

Terminator

The terminator has two major functions:

•Signal current shunt: The communication signal is transmitted as a current but received as

a voltage, the terminator does the conversion.

•Prevent signal reflection: The communication signal bounces back when it reaches the end

of the wire, potentially distorting itself. The terminator prevents that. There are actually two

terminators in a fieldbus network, one in each end. However, one of them is typically built into

the power supply impedance or safety barrier.

Terminator - shunt

The low-speed wire media fieldbus signal is transmitted as an AC current with amplitude of 10-

20 mA.

Each of the two terminators has impedance of 100 ohm, and since they are connected in

parallel the network will have resulting impedance of 50 ohm.

The terminator will cause a voltage drop as the transmitted current passes through. A voltage

with amplitude of 250-500 mV will therefore be seen over the network. The receivers in all the

other fieldbus devices sense this voltage.

Terminator - end

When the fieldbus signal traveling down the wire reaches the end, it is faced with a change in

impedance from the characteristic impedance of the wire to the infinite impedance of open air.

This will cause a part of the signal power to be reflected back up through the wire. The

reflected signal interferes with the oncoming "real" signal. If the reflected signal is powerful

enough, it may distort the "real" signal such that the communication does not work. The

terminator has the same impedance as the cable such that when placed at the end the

fieldbus signal sees no change in impedance and hence there is no reflection. It is also clear

that the terminator must be at the end of the wire to really work.

GEREM110.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-8

Terminator Placement

The terminator should be placed at each end of the trunk. The power supply impedance

PSI302 has one of the terminators built in. In bus topology the end of the trunk is easy to see.

In tree topology the end of the trunk is where the spurs branch out. There may never be more

than two terminators, and the terminators must not be forgotten. The bus may function with

only one terminator, but performance may be degraded.

PSI302 Power Supply Impedance

•Allows use of standard power supplies.

•18 +/-2 V, 300 mA output.

•Built-in terminator

•DIN-rail or panel mount

•Fail indication

A power supply impedance module shall be connected between the fieldbus and the power

supply. Prevents short circuit of communication signal by the power supply. The power supply

impedance also regulates the power supply voltage. If a normal power supply is connected

directly to the fieldbus the communication will be short-circuited, the power supply impedance

prevents this. The power supply impedance has built functionality for automatic and bumpless

switch over from a main to a backup in redundant configuration should the main unit not

provide power

Connect maximum 4 channels per PSI302 per PS302.

Figure 1.11 - PSI302 Connection

NOTE

AC Short Circuit Prevention

A DC power supply acts as a short on a AC circuit. Therefore the

power supply impedance is introduced. The impedance acts as a

3kΩimpedance between field

GEREM111.CDR

Installation

1-9

Redundant Power

Automatic bumpless switchover between redundant power supplies. Only one PSI302 should

have the terminator connected, or a separate power supply-end terminator is used.

Figure 1.12 - Redundant Power

BT302 Terminator

Intrinsically safe, equivalent unprotected capacitance.

PS302 Power Supply

•Wide input range:

90-264 VAC (47-440 Hz)

127-367 VDC

•24 VDC, 1.5 A output; up to four PSI302.

•Galvanically isolated

•Failure indication and output

Cabling

Several types of cable may be used, though shielded twisted pair is recommended. Depending

on the size and other factors of the cable the maximum length can vary varies. Four cable

types have been identified, though there are many more options. No special cable is required.

Normal instrument wires may be used. However, "fieldbus cable" is available from several

vendors to make selection easier.

GEREM112.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-10

Cable Options

Type A is recommended for best possible performance.

Pair

Shield

Twist

Size

Max Length

Type

Single

Y

Y

0.75 mm2

1900 m

A

Multi

Y

Y

0.32 mm2

1200 m

B

Multi

N

Y

0.13 mm2

400 m

C

Multi

Y

N

1.25 mm2

200 m

D

Table 1.1 - Cable Options

For non-twisted cable the distance is very short even for thick and shielded wire.

NOTE

Detail characteristics for type “A”

Zo @ 31.25 kHz = 100 ohm +/- 20 %

Max attenuation @ 39 kHz = 3 dB/km

Max capacitive unbalance to shield = 2 nF/km

Max DC resistance per conductor = 22 ohm/km

Max propagation delay change 7.8-39 kHz = 1.7 us/km

Conductor cross-sectional area = 0.75 mm2

Total Cable Length

Maximum total cable length depends on the cable used. The total length includes the trunk

and all spurs.

Figure 1.13 - Total Cable Length

GEREM113.CDR

Installation

1-11

Segment

Length

Trunk

240 m

Spur 1

80 m

Spur 2

120 m

Spur 3

40 m

Total

480 m

Table 1.2 - Total Cable Length Example

Entity Parameter Example

It is good practice to make a table for each segment (barrier) listing the entity parameters for

each part for easy analysis

Cable Entity Parameters

Pay attention to capacitance and inductance of cables. Typically the L/R ratio of a cable is

used rather than just L since R cancels the effect of L. Typical cable values:

•L/R = 25 uH/ohm

•C = 200 nF/km

Figure 1.14 - Cable Entity Parameters

Normally the capacitance is the limiting factor for cable length in a fieldbus network. A 1.9-km

cable would contribute 380 nF, more than a barrier can handle.

GEREM114.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-12

NOTE

Mixing Cable Types

To check if a combination of cable types is within the

specification the below equation may be used:

L1/L1max + L2/L2max + … < 1

Where:

L1 is length of cable type 1

L2 is length of cable type 2

L1max is the maximum length for cable type 1

L2max is the maximum length for cable type 2

Example:

L1 = 1000 m of cable type A

L2 = 100 m of cable type B

1000/1900 + 100/1200 = 0.61

Which is acceptable since 0.61 < 1

Cable Shield

Shield is preferred to achieve best performance. Shield should cover minimum 90% of the

cable length. If there is no shielding the cable should be within a metal conduit, which act as a

shield.

Grounding

Only the shield should be grounded never the fieldbus wires. The shield should be grounded in

only one point. The shield of the spurs shall be connected to the shield of the trunk. In high

EMI/RFI environments several additional RF grounds of the shield may be done using

capacitors, though this is rare. Do not use the shield as a conductor. The shield should be

grounded at the negative terminal of the power supply.

Figure 1.15 - Grounding the Shield

GEREM115.CDR

Installation

1-13

Spur Length

Remember that in tree like topologies the branches are actually spurs. Spur length is basically

independent of cable type as long as the maximum total length is not exceeded, but depends

on the number of devices connected to the spur. There should never be more than four

devices per spur. No special connectors are required to connect the spur to the trunk. Spurs

should be used to connect devices to the trunk so that one device may be removed without

disturbing the other.

Figure 1.16 - Spur Length and Terminator Placement

Recommended Maximum Spur Length

Total

1 per spur

2 per spur

3 per spur

4 per spur

25-32

1 m

1 m

1 m

1 m

19-24

30 m

1 m

1 m

1 m

15-18

60 m

30 m

1 m

1 m

13-14

90 m

60 m

30 m

1 m

1-12

120 m

90 m

60 m

30 m

Table 1.3 - Devices per spur vs. spur length

These lengths are rules of thumb. Longer is very often possible.

Spur Precautions

It is important to pay attention to spur length when star topology is used since the spurs in this

case is often quite long in comparison with bus topology. If the distance between the PSI302

and the PCI is more than 120 m (maximum spur length) then the internal terminator in the

PSI302 cannot be used, and a separate BT302 should instead be used.

Polarity

Some devices have polarity, others don't. It is important to ensure correct polarity for devices

with polarity. In a fieldbus system all devices are connected in parallel, i.e. all negative

terminals together, and all positive terminals together. Use of color-coded wires is

recommended to distinguish positive from negative.

GEREM116.CDR

FoundationTM Fieldbus Series 302 – Installation, Operation and Maintenance Manual

1-14

Interface and Bridge

An interface is used to connect a computer to the fieldbus. There are two types:

•Permanent installation

•Temporary connection

A bridge is used to pass data between networks.

Bridge Connection

Data may be passed between devices on different channels on the same PCI card, or even

between different PCI cards.

Figure 1.17 - Bridge Connection

GEREM117.CDR

This manual suits for next models

6

Table of contents

Other SMAR Transmitter manuals

Popular Transmitter manuals by other brands

M-system

M-system Mini-M M2RTS instruction manual

IMI SENSORS

IMI SENSORS 682B03 Installation and operating manual

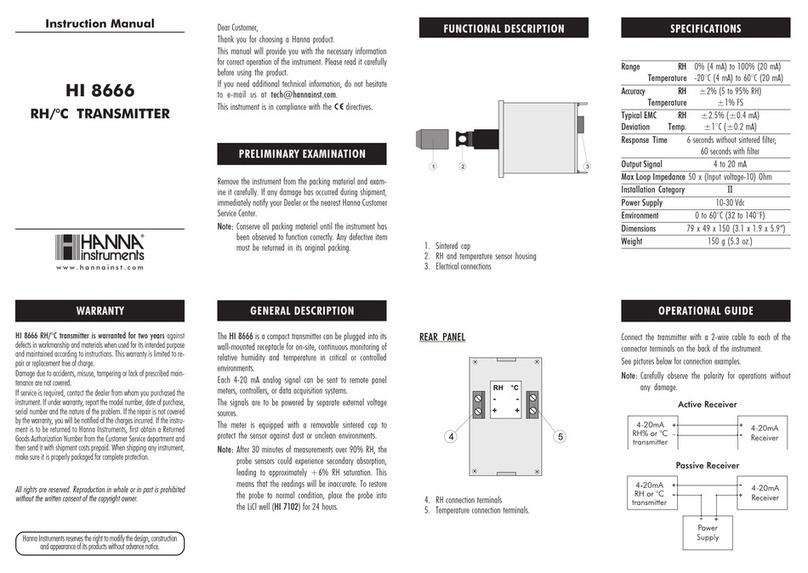

Hanna Instruments

Hanna Instruments HI 8666 instruction manual

Suntex

Suntex PC-3310 Operation manuals

Tele Radio

Tele Radio T60TX-0 STL installation instructions

SenseAir

SenseAir aSENSE installation manual

Q5X

Q5X QT-5100 manual

Endress+Hauser

Endress+Hauser HART Flowmeter Proline 400 Brief operating instructions

Ramsey Electronics

Ramsey Electronics CUBE 2000 instruction manual

steute

steute RF 10 ST SW868 Mounting and wiring instructions

Sennheiser

Sennheiser SK 5012 instruction manual

GF Signet

GF Signet 8750-2 manual