SMART-SCAN 8K3 Series User manual

8K3 SERIES

CROSS-BEAM MUTING

ACCESSORIES

INSTALLATION GUIDE

MACHINERY SAFETY SYSTEMS

Smartscan Ltd

Pywell Road

Willowbrook Industrial Estate

Corby

Northamptonshire

NN17 5XJ - England

Tel. +44 (0)1536 –401 313

www.smartscan.co.uk

Important!

Failure to read and follow the instructions provided on the Installation Sheet

and Installation Guide can lead to the incorrect application or use of the 8K3

series mute accessories. This could lead to personal injury and damage to

equipment. The 8K3 series safety light curtain Installation Sheet and

Installation Guide must be used in conjunction with the 8K3 series mute

accessories Installation Sheet and Installation Guide. All applicable machine

safety standards and regulations should be taken into account when installing

the 8K3 series mute accessories or any machine safety product.

The Installation Sheet and Installation Guide can be downloaded from our web

site at www.smartscan.co.uk

The 8K3 series mute accessories Installation Guide (CD693) is subject to

change without notice. Smartscan Ltd shall not be held responsible for

technical errors, editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

© 2019 Smartscan Ltd. All Rights Reserved. Unless explicitly stated

otherwise, all rights including those in copyright in the content of this document

are owned by or controlled for these purposes by Smartscan Ltd.

Except as otherwise expressly permitted under copyright law or Smartscan

Ltd, reproduction of the document or alteration of this document may not be

carried out in any way without first obtaining Smartscan Ltd's written

permission.

CONTENTS

FIGURE A - UNPACKING ..........................................................................................................1

FIGURE B –DIMENSIONAL INFORMATION ........................................................................... 2

FIGURE C –MUTING MODULE MECHANICAL CONNECTION..............................................3

FIGURE D –RETRO-REFLECTIVE PHOTOCELL CONNECTION .......................................... 4

FIGURE E –MUTE MODULES SHOWING MUTE BEAM ARRANGEMENTS ........................ 5

MUTE ENABLE INPUT.................................................................................................................6

FIGURE F –PALLET LOAD POSITIONING..............................................................................7

FIGURE G –OPERATING REQUIREMENTS ........................................................................... 8

ACTIVATE SWITCH ELECTRICAL CONNECTION ............................................................................9

FIGURE H –MUTING TIMER SEQUENCE .............................................................................10

CROSS-BEAM CONTROL TIMERS..............................................................................................10

FIGURE I –IDENTIFICATION LABELS ..................................................................................11

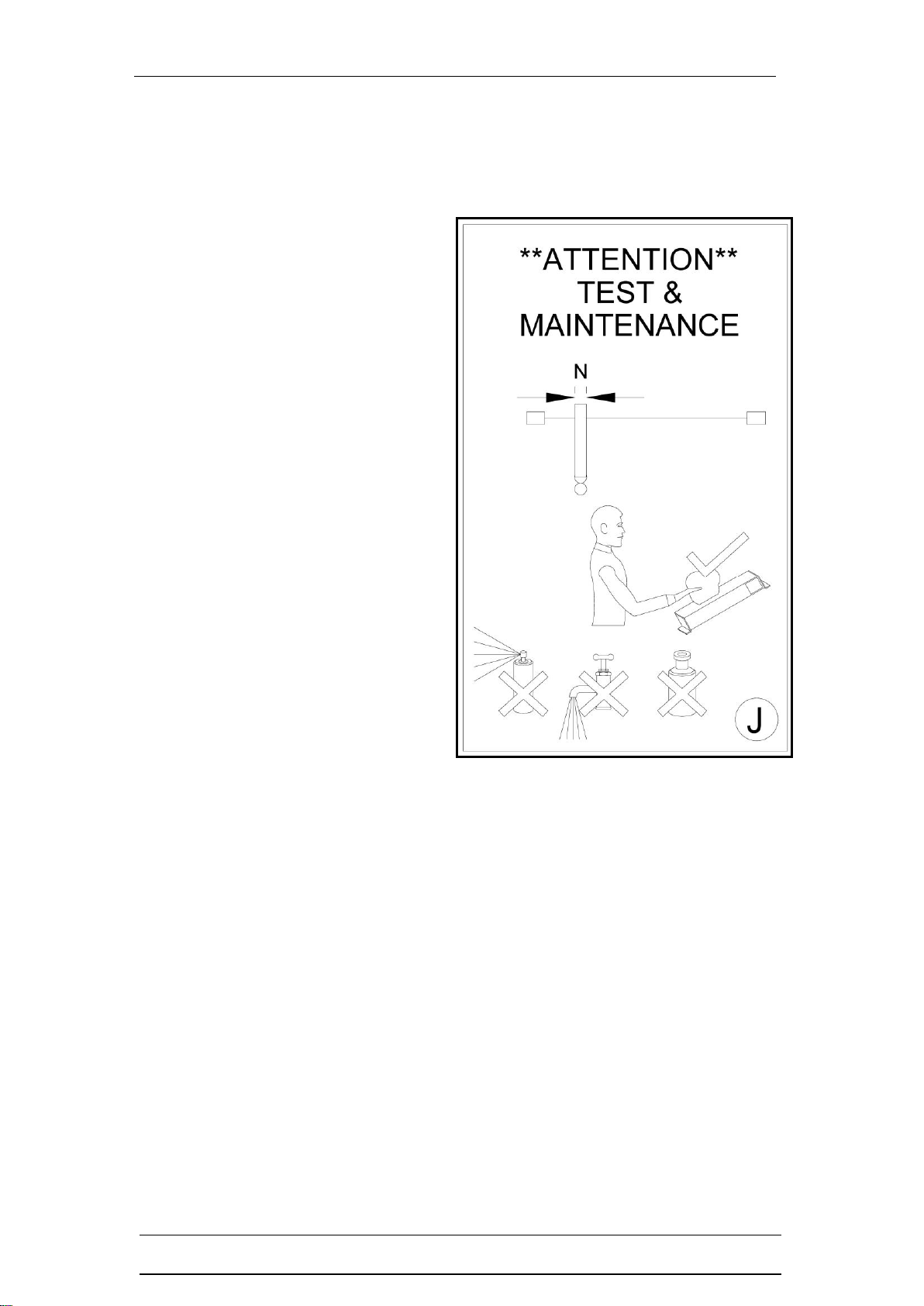

FIGURE J –TEST AND MAINTENANCE................................................................................12

TESTING THE MUTE ACCESSORIES WITH A TEST PIECE...............................................................12

MAINTENANCE ........................................................................................................................13

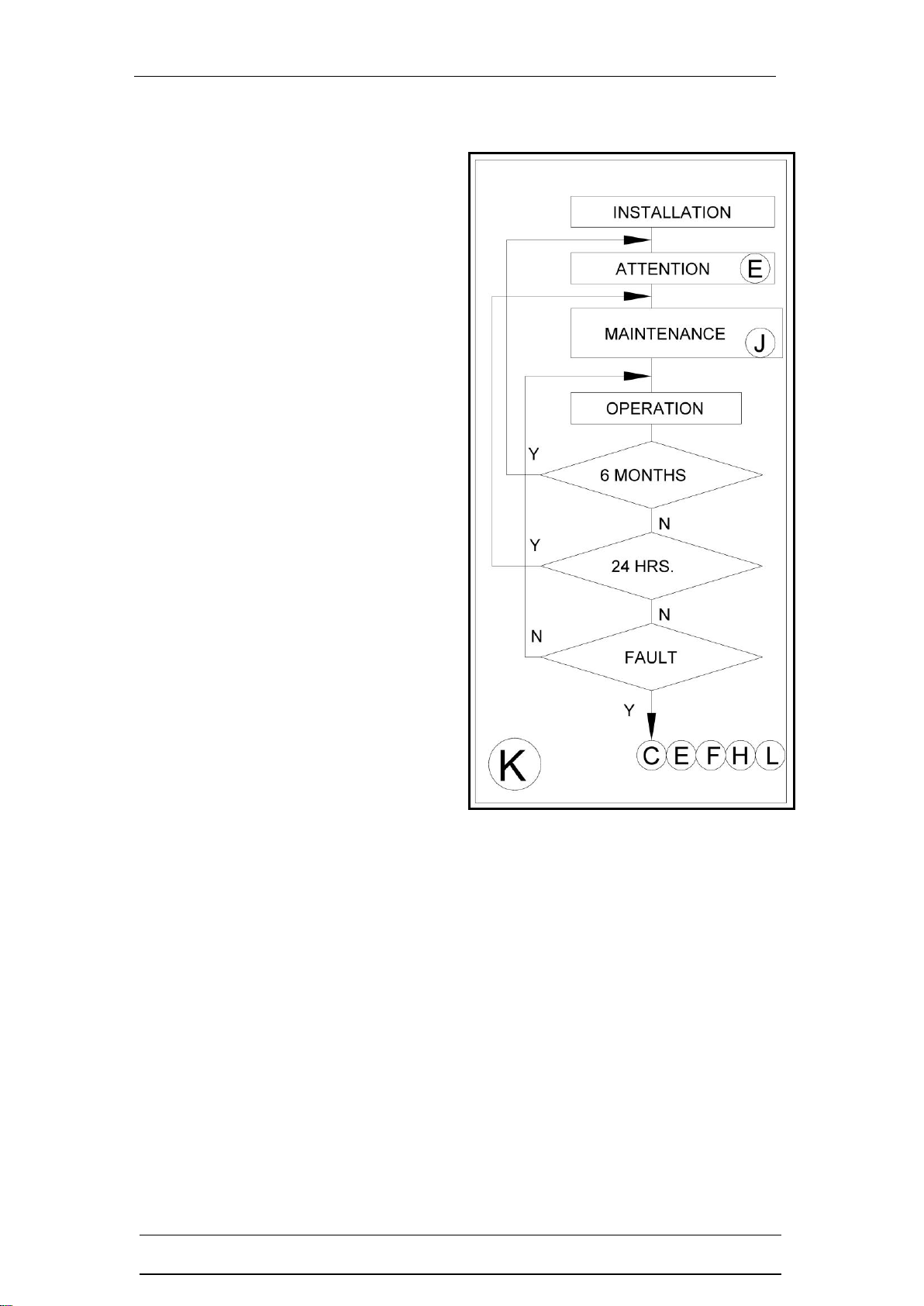

FIGURE K –OPERATION CYCLE...........................................................................................14

FIGURE L –PRODUCT RETURN PROCEDURE....................................................................15

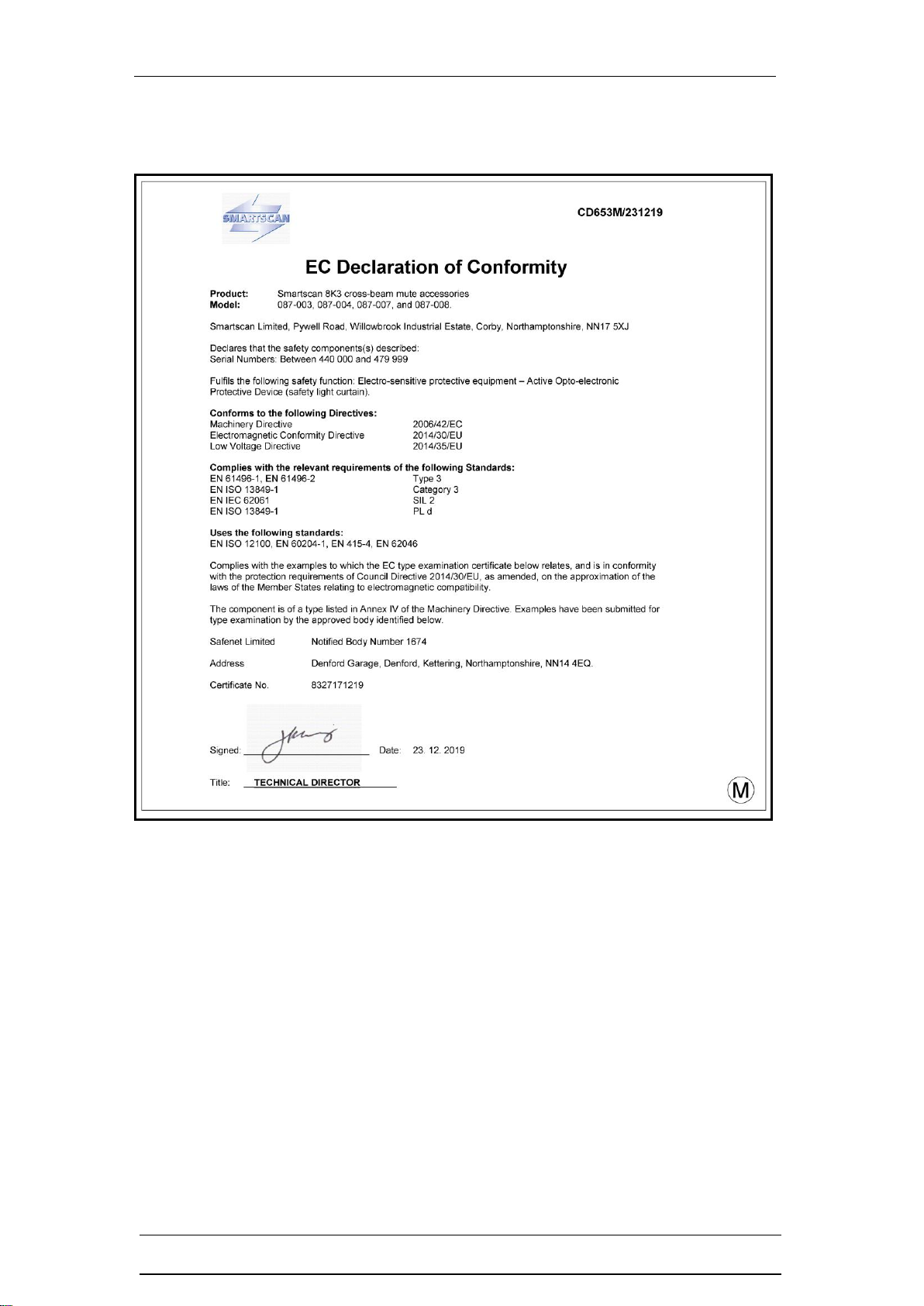

FIGURE M –DECLARATION OF CONFORMITY ...................................................................16

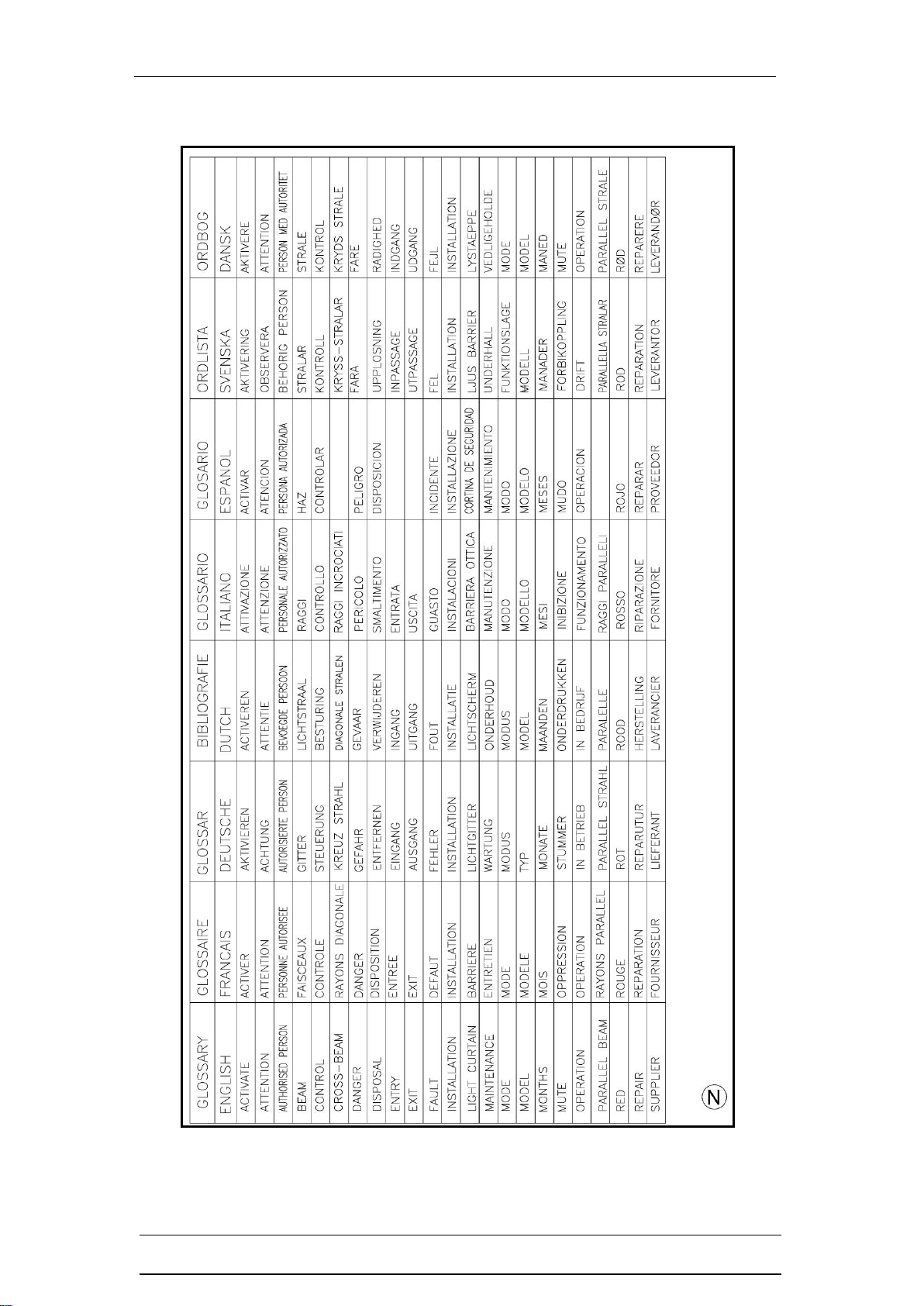

FIGURE N –GLOSSARY OF WORDS AND LANGUAGE TRANSLATION...........................17

APPENDIX 1 –IMPORTANT SAFETY WARNING INFORMATION.......................................18

APPENDIX 2 - CERTIFICATIONS............................................................................................19

NOTES ......................................................................................................................................20

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

1

8K3 Series (Model No. 087-xxxxx) Mute Accessories

Installation Sheet (CD692/150120)

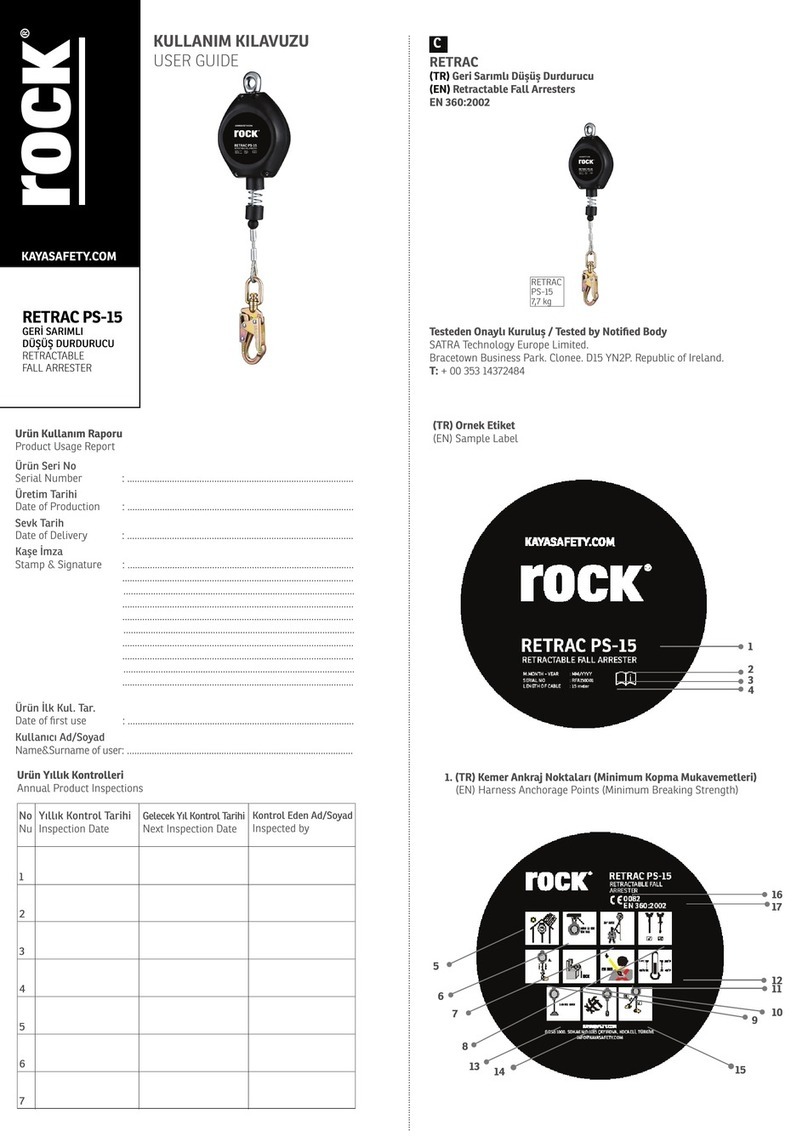

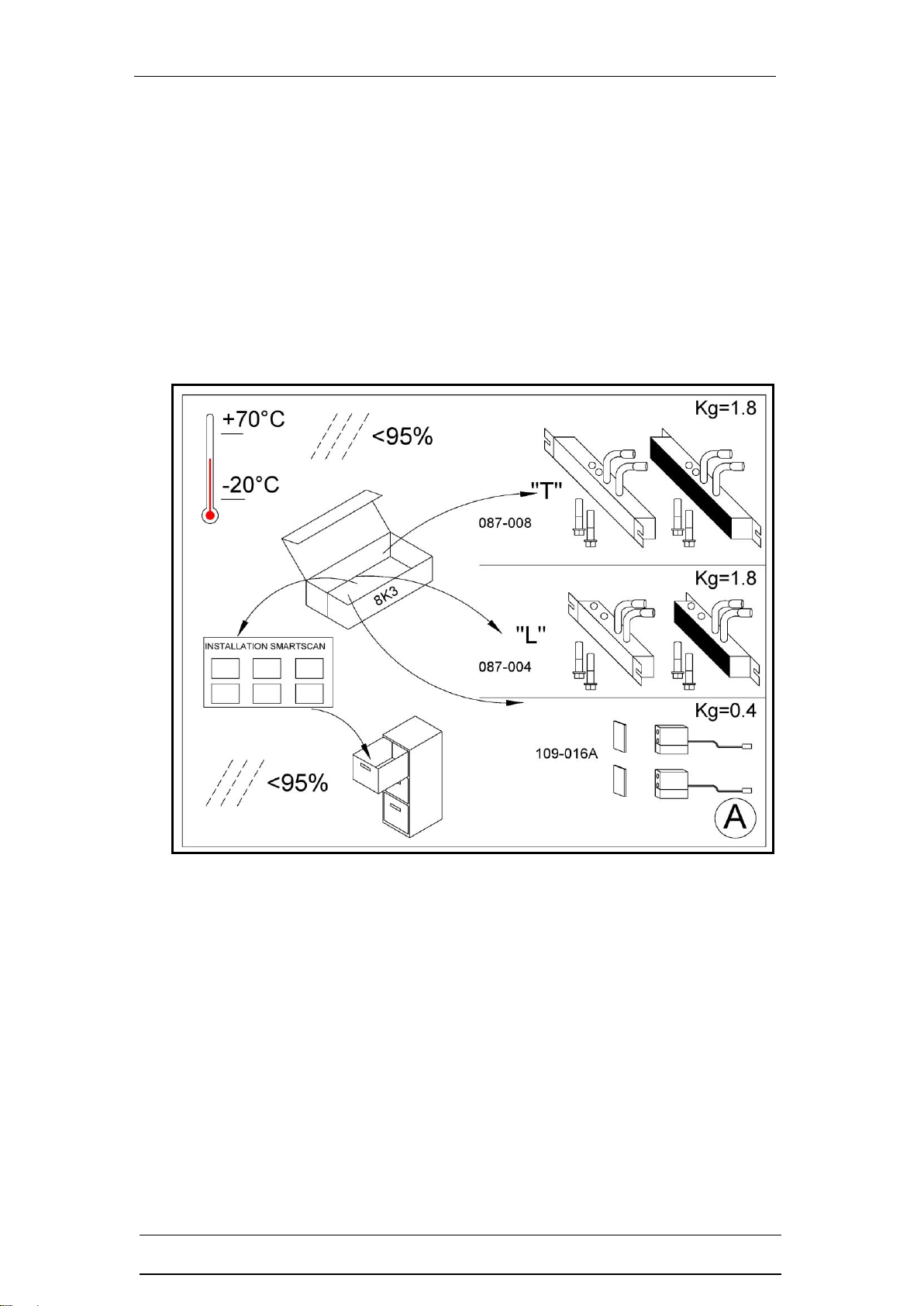

Figure A - Unpacking

❑Remove all packaging material and retain it

❑Locate and keep the delivery note

❑Inspect all items for transit damage

❑Match goods supplied to those specified on the delivery note

❑Keep the Installation Sheet in a safe place

Each 8K3 series mute accessory kit supplied would normally include:

❑Pair of ‘L’ or ‘T’ muting modules with fixing bolts or polarised retro-reflective

sensors with cables and connectors affixed, together with mounting brackets.

❑Installation sheet

❑Service questionnaire form

Storage requirements:

❑Humidity - <95%

❑Temperature range between –20°C and +70°C

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

2

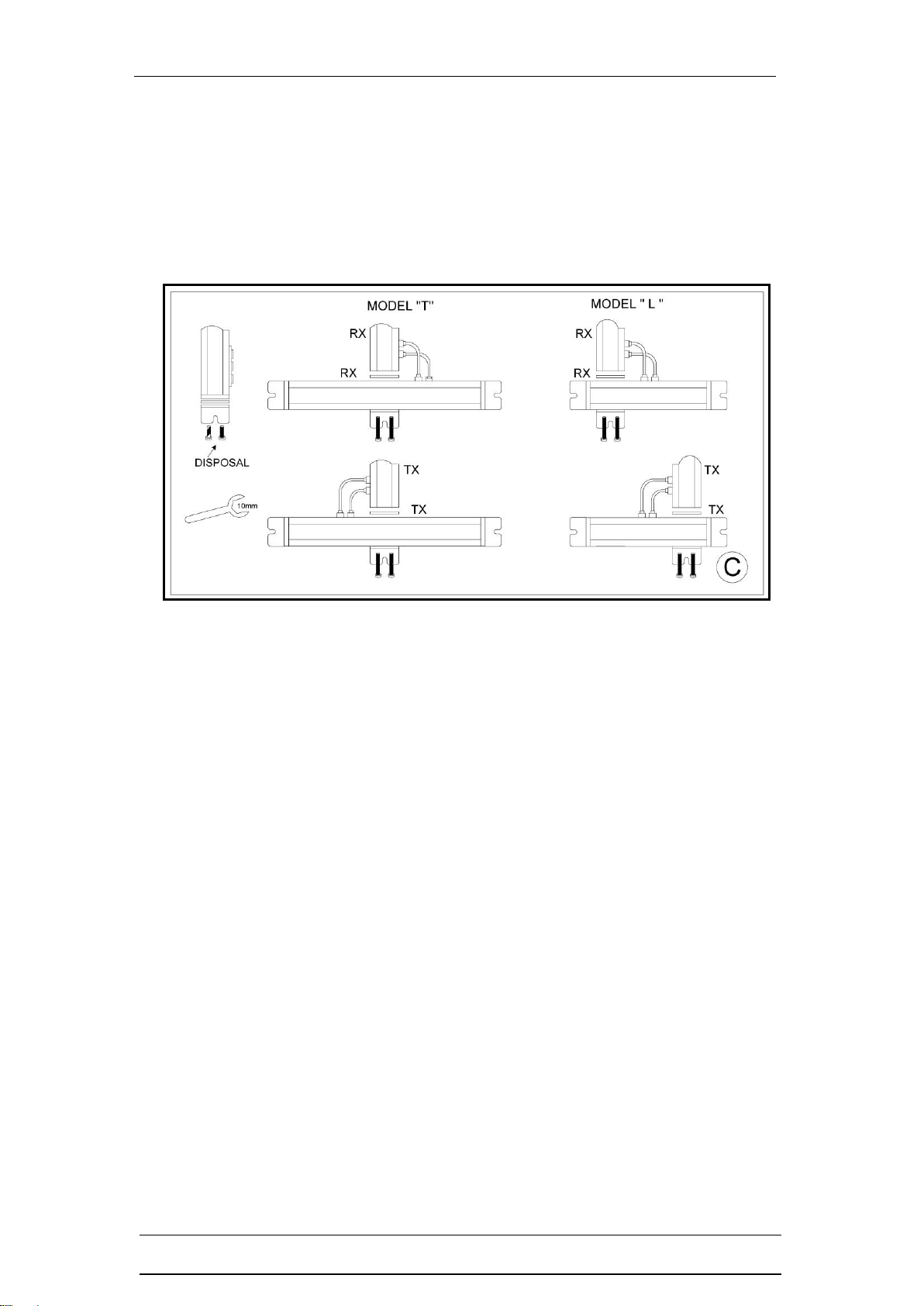

Figure B –Dimensional Information

The 8K3 Series T and L cross-beam muting modules have the same cross section

as the light curtain, 50 x 50mm.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

3

Figure C –Muting Module Mechanical Connection

Fixing ‘L’ or ‘T’ cross-beam mute modules to the safety light curtain columns is

very easy. Undo the fixing bolts and remove the end-cap fixing bracket and

rubber seal from both the transmitter (Tx) and receiver (Rx) columns.

Fit the appropriate ‘L’ or ‘T’ module to the base of each column using the longer

bolts that are supplied with the units. Tighten the bolts enough to ensure

waterproof sealing between the aluminium housings. If an additional guard

mounting point is required the bottom end cap bracket can be re-fitted underneath

the mute module housing.

Red LED’s in the receiver Rx mute module are illuminated to show the mute

beams are active.

On the Receiver (Rx) the two mute inputs are situated below the B (User) cable

connection and the A (interconnect) cable connection. On the Transmitter (Tx)

head the mute inputs are situated below the A (interconnect) cable connection.

Plug in the two cables from the Mute modules to the light curtain column as

shown above. Note the Rx Mute module cables must be crossed when using the

inverted ‘T’shape cross-beam muting or the ‘L’shape cross-beam muting. The

cables are connected so they are parallel when using the parallel beam muting

(timing control).

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

4

Figure D –Retro-Reflective Photocell Connection

The picture shows options for configuring the 8K3 series safety light curtain in

applications using non-integrated mute sensors.

There are particular applications where the standard mute modules are not

suitable for example, where there is a limitation in the space available for

mounting the modules. In such cases external sensors that allow more flexibility

are often used.

Polarised retro-reflective sensor - Type 109-016A, Maximum range = 4m

The sensor transceiver comes complete with polarised reflector, a 1.5m cable,

mounting brackets and a 4 pin bayonet locking connector for direct connection to

the mute input sockets, M1 and M2, on the Receiver (Rx) head of the 8K3 series

safety light curtain.

The sensors can be used in the cross-beam configuration.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

5

Figure E –Mute Modules Showing Mute Beam Arrangements

Figure E shows the cross-beam muting for entry/exit and exit only applications.

The Receiver head which has the status indication LEDs and the B (User) cable

connection back to the machine control panel/local junction box is located to the

left side of the conveyor when looking towards the danger area. The Receiver

head has the status LED indicators which are useful during installation, for status

checking during normal operation and diagnostics for fault finding.

Entry and Entry/Exit ‘T’

087- 008 (Type 2)

Inverted ‘T’ shape cross-beam muting at in-feed zones or in situations where a

pallet load may need to pass along the conveyor in both directions through the

safety light curtain.

This system is normally used at the infeed to a machine. The horizontal mute

modules house the muting beams transmitting diagonally across to the receiver

side forming a cross-beam muting arrangement.

The system works by the pallet load moving into the two mute beams and

interrupting them. The two mute beams are monitored with a disparity timer of 2.5

seconds.

The cross-beam entry system has a no time delay-off as default. Therefore, if one

of the mute beams is remade or the load is out of the cross-beam mutes the

safety light curtain will unmute at once.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

6

The entry/exit inverted ‘T’ mute beams have a scanning range of 1.25m to 3.5m.

Position the unit to ensure a pallet load does not stop in the safety light curtain

beams after clearing the mute beams.

Exit only ‘L’

087- 004 (Type 2)

The ‘L’ shape cross-beam muting is only for use at outfeed zones. You will note

that the mute beams are arranged on one side of the 8K3 safety light curtain. The

pallet load is always travelling in one direction, out from the danger area and

through the safety light curtain to the safe area.

The system works by the pallet load moving into the two mute beams and

interrupting them within the monitored mute disparity time of 2.5 seconds.

There is a short period of time when the trailing edge of a pallet load ‘clears’ the

detection field of both mute sensors but is still interrupting the light curtain beams.

A timer is incorporated within the safety control system that allows a period of 2.5

seconds between the pallet load ‘clearing’ the mute sensors and ‘clearing’ the

light curtain beams. If the 2.5 second period is exceeded the safety system will

trip.

Note for this exit system the MODE wire (Black/White) needs to be linked to +24V

DC in order for the 2.5 second mute delay-off timer to be active.

The exit only ‘L’ mute beams have a scanning range of 1m to 3.5m

Position the unit to ensure a pallet load does not stop in the safety light curtain

beams after clearing the mute beams.

Mute Enable Input

The ‘mute enable’ signal is a control system requirement for both entry/exit and

exit only cross-beam muting applications. This third signal is typically taken from

the conveyor transport system (conveyor run). This signal acts as a permissive

signal to the mute beam logic.

Inclusion of the signal indicates to the safety control that the conveyor is

transferring products towards the detection field of the safety light curtain, thus

instructing the controller to initiate the MUTE logic condition during a pallet

transfer through the safety light curtain.

Warning: The ‘L’ shape mute module must NOT be used at in-feed zones, (out-

feed only).

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

7

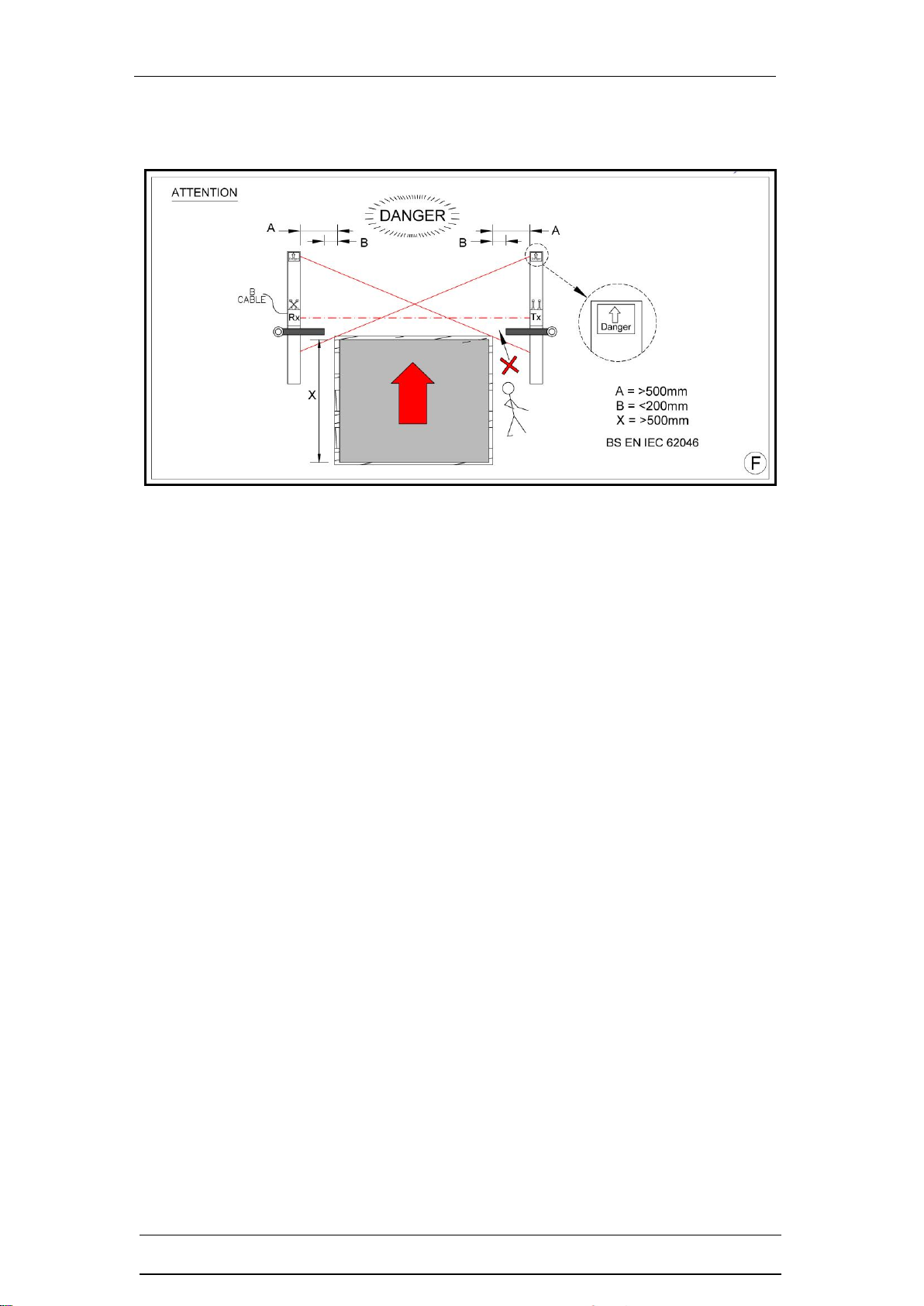

Figure F –Pallet Load Positioning

Figure F shows pallet load positioning on the conveyor relative to the transmitter

and receiver heads (note distances for A and B)

Ensure that the pallet when entering and exiting the self-muting safety light curtain

system is central on the conveyor. The distance for A and B to avoid ‘trapping’or

‘crushing’hazards and preventing entry during the muted condition should all be

considered in-line with the guidance within BS EN IEC 62046:2018.

X shows the minimum pallet load size, 500mm in length.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

8

Figure G –Operating requirements

❑Humidity <95%

❑Temperature range between 0°C and +50°C or -30°C and +30°C

❑Vibration: Frequency <55Hz Max. Movement <0.35mm

❑Do not use equipment in explosive atmospheres (contact the manufacturer for

further advice).

❑Noise generated by the equipment will never exceed 70 dB

Environmental factors can affect the operation of a safety light curtain and proper

consideration should be taken into account for mounting a system where fog, rain,

smoke, dust, large temperature fluctuations etc. is a consideration.

Safety light curtains do not protect personnel from chemicals, heat, gases,

radiation, flying parts etc. as they are not a physical barrier.

The owner/provider must carry out a Risk Assessment and provide machine

operators instruction for the use of the safety light curtain on the machinery.

The 8K3 series safety light curtain can be configured with either the ‘L’ type (exit

only or a ‘T’ type (entry / exit) system.

The ‘L’ muting module configuration shown above is for out-feed zones ONLY. It

operates in a cross-beam muting beam configuration, the distance between the

Transmitter (TX) and Receiver (RX) should not exceed 3.5 metres.

The inverted ‘T’ shape muting module configuration shown above is for infeed and

infeed/outfeed positions. It operates in a cross-beam muting beam configuration,

the distance between the Transmitter (TX) and Receiver (RX) should not exceed

3.5 metres.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

9

Heater options are available for application environments like cold stores.

Reset devices must be located such that the danger area can be seen to be clear

of persons before the system is activated. The reset device should also be

positioned so as not to be accessible from inside the danger area.

Activate Switch Electrical Connection

Activate switch - (F7). Connect the red/white wire in cable B to a normally open

switch contact. Connect the other side of the switch contact to +24V DC. The

switch could either be a spring return to off key switch or push button.

Mode - (F8) Connect the black/white wire in cable B to 0V DC, or for exit only

system where the mute delay-off timer is required to +24V DC.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

10

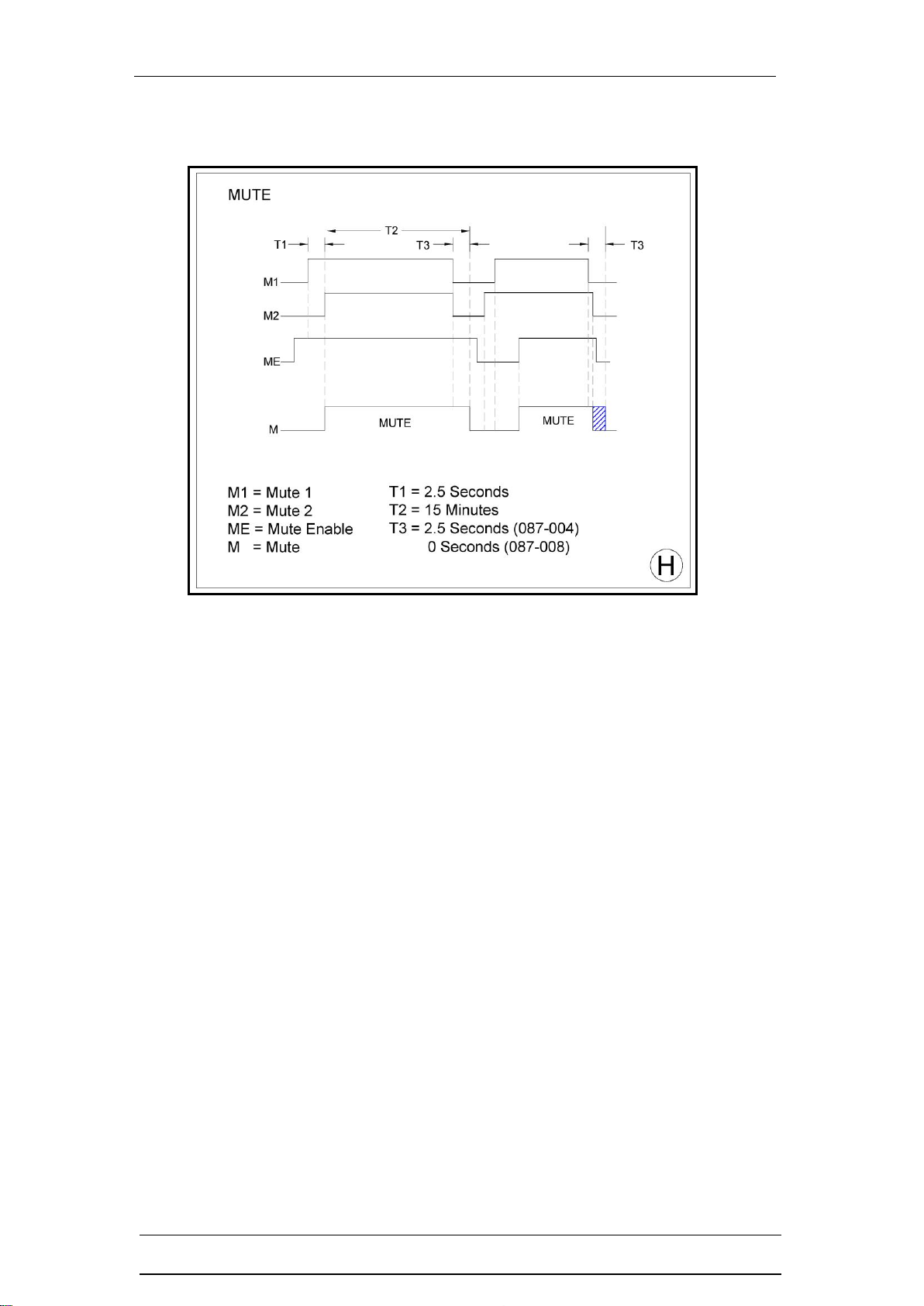

Figure H –Muting Timer Sequence

The timer diagram above shows the mute timer sequence for the ‘L’shape Exit

only cross-beam muting system, with and without the mute off delay time and the

inverted ‘T’shape Entry/Exit (bi-directional) cross-beam muting system.

Cross-beam Control Timers

T1 (Mute 1 and Mute 2 Disparity Time) = Maximum time allowed between

activation of signals mute 1 (M1) and mute 2 (M2) prior to the pallet load entering

the safety light curtain.

T2 (Mute Time Out Period) = A maximum pre-determined time the safety light

curtain will remain in a muted condition. Following this timed period, if the pallet

load is still interrupting the mute beams or the safety light curtain beams the

OSSDs will de-energise thus initiating a stop condition. Providing the pallet clears

the safety light curtain before the maximum time T2 is exceeded then the

automatic transfer of the pallet will continue.

T3 (Mute Off Delay Time) = This function can be used for the ‘L’shape Exit

system only and MUST NOT be used for the inverted ‘T’Entry/Exit system. A

predetermined time that the safety light curtain will remain in a muted condition

following de-activation of one or both of the mute signals.

Software version example

The standard 8K3 Series is supplied with ‘E’ version software, for example

087E903. This provides the following functions for cross-beam muting timers,

T1 = 2.5 Sec T2 = 15 min T3 = 2.5 Sec.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

11

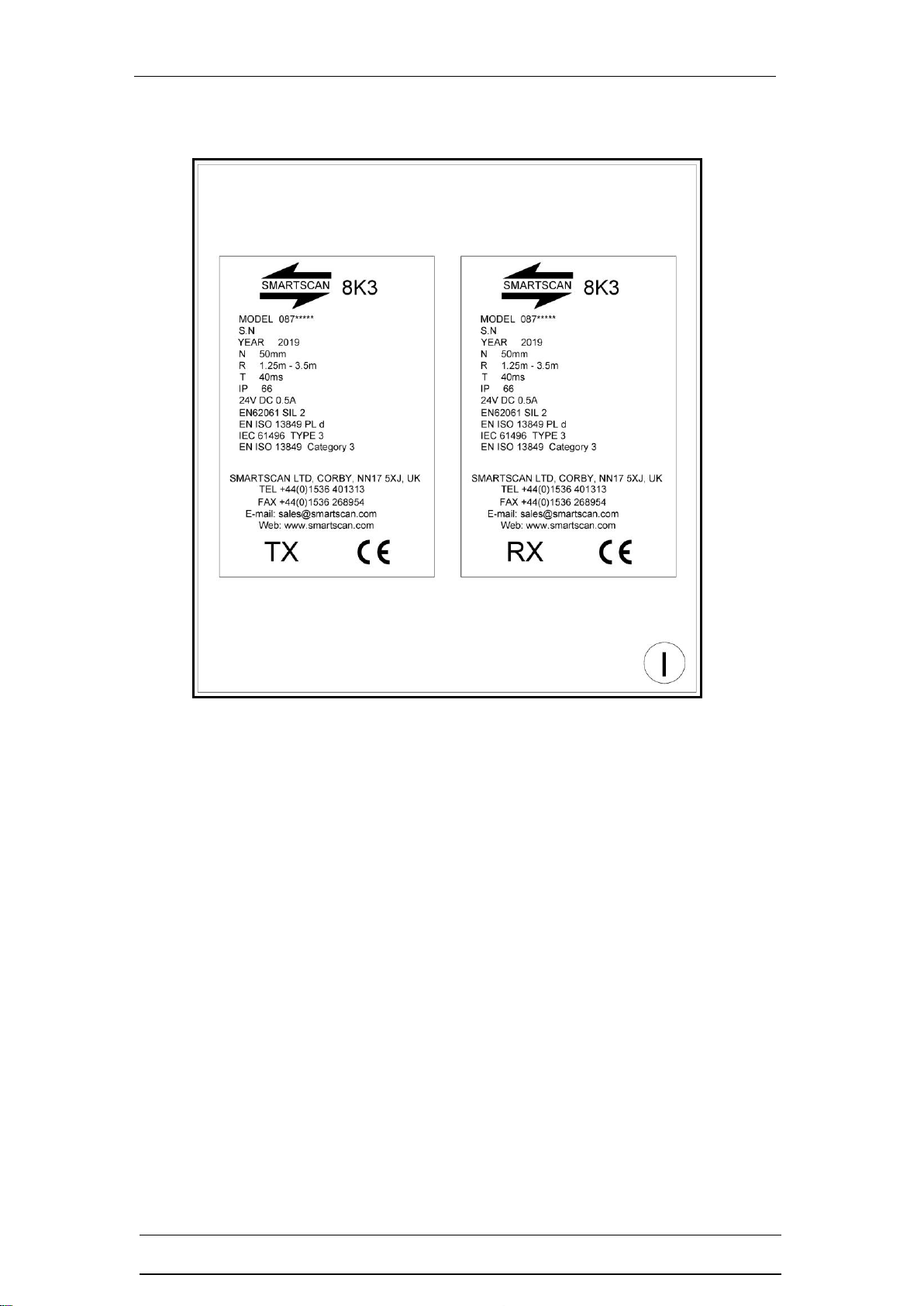

Figure I –Identification Labels

Examples are shown below of the identification labels that are affixed to the

bottom of the transmitter (TX) and receiver (RX) columns.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

12

Figure J –Test and Maintenance

Testing the mute accessories with a test piece

The test procedure should be carried

out frequently as indicated by the

risk assessment for the particular

installation.

A test must be carried out at the

initial installation and prior to the

machine start-up.

Smartscan Ltd recommends the test

should be carried out daily prior to

normal operation of the machine.

Any changes to the configuration of

the safety light curtain must be

followed by testing to check the

system is still working correctly.

Regular function checking of the

safety light curtain as well as at initial

installation is required as part of the

test and maintenance process.

The operating instructions for the

safety light curtain and machine

must be made available for the

operator and those responsible for installation, maintenance and safety control at

all times.

Power-up the 8K3 series safety light curtain and activate the output switching

circuits to an ON condition.

Cross-Beam

Insert a test piece of appropriate size into the detection zone of one of the mute

sensors. After 2.5 seconds the safety outputs will turn OFF. Repeat this

operation for the second mute sensor, again the outputs should turn OFF within

2.5 seconds.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

13

Maintenance

The Transmitter (TX) and Receiver (Rx) windows should be cleaned regularly as

indicated on the Installation Sheet, Figure K.

Dirt build-up or scratching on the windows may lead to

intermittent tripping or a totally blocked condition of the light

curtain. Clear adhesive tape may be applied to the windows

of curtains in dirty or abrasive conditions. Renew the clear

adhesive tape periodically.

Dust particles can be attracted to the Perspex window due to

static charges. This can be prevented by the use of an antistatic plastic cleaner

and antistatic cloth.

Clean the windows with a clean damp cloth using a mild

detergent. Never use abrasive, corrosive cleaners or

spray detergents.

During the maintenance inspection of the safety device and the danger area

checks include, damage and general wear, connection cables and the electrical

connections.

Check the mountings and physical extrusion, Perspex.

Access to the danger point should be through the infrared field of the safety light

curtain only.

See also the Operation Cycle checks within this document.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

14

Figure K –Operation Cycle

❑Before installation read and

understand the Installation Sheet

provided paying particular attention

to the information provided in

Figures C, E and I

❑Refer to Fig. J for test and

maintenance procedures

❑Every 24 hours carry out tests as

indicated in Fig. J

❑Every 6 months check the entire

installation including those on the

installation sheet for the safety

light curtain.

❑If the equipment fails to operate as

intended check through the entire

installation sheet.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

15

Figure L –Product Return Procedure

If a fault occurs that cannot be resolved or the equipment is damaged return the

equipment to the nearest Smartscan distributor or Smartscan Ltd. Indicate the

nature of the fault and the symptoms displayed on the form provided.

Note Please ensure that returned guards (Transmitter and Receiver heads)

are matching serial number pairs.

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

16

Figure M –Declaration of Conformity

8K3 Series Cross-Beam Mute Accessories Installation Guide

CD693/150120 Smartscan Ltd

17

Figure N –Glossary of Words and Language Translation

Table of contents

Other SMART-SCAN Safety Equipment manuals