Smart Sensor AR936 User manual

SZ936-2009.10.16

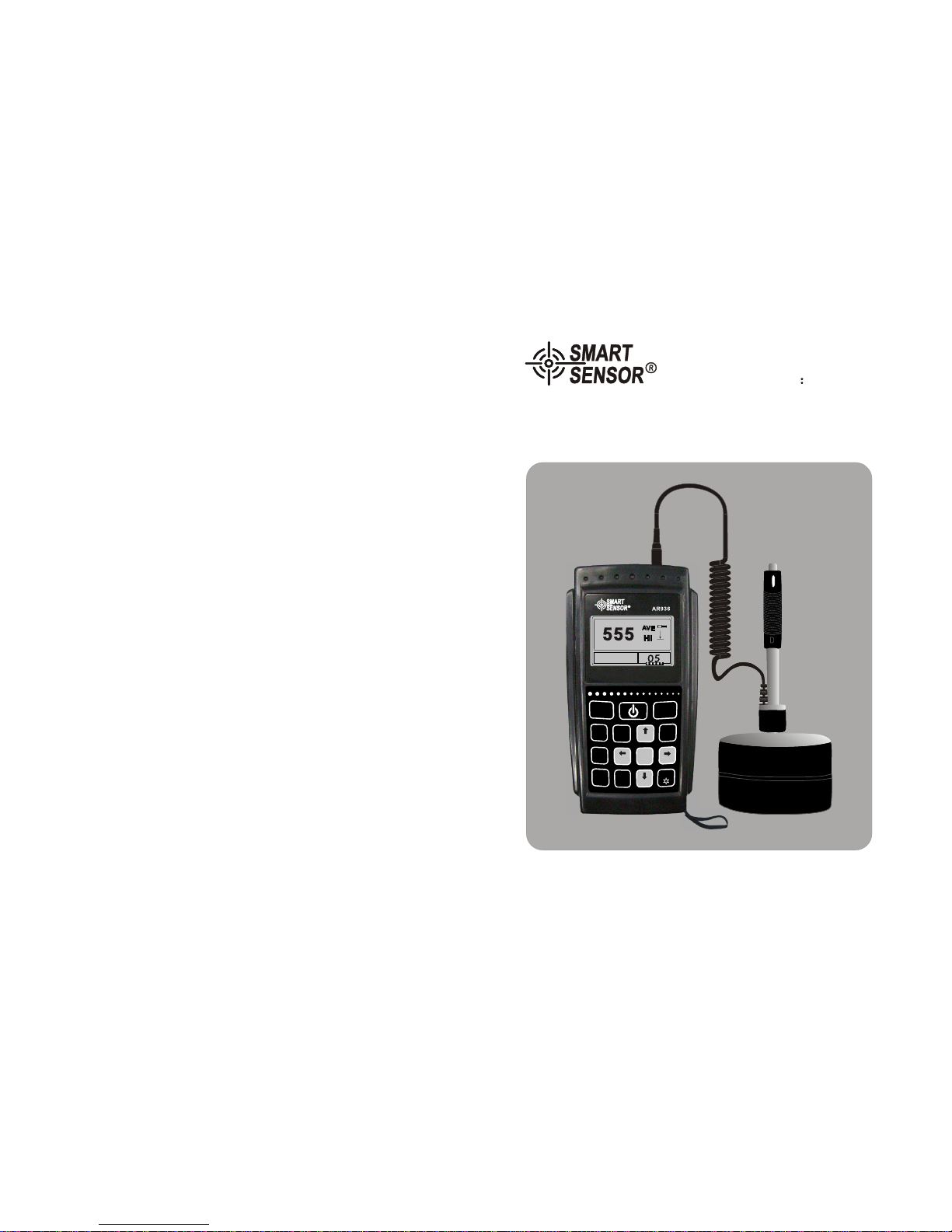

Operation Manual of

Leeb Hardness Tester

Model AR936

555555 VV

AAEE

HlHl

Portable Hardness Tester

Steel and cast steelSteel and cast steel

9

3

0

7

8

2

1

4

6

5

STORE

ENTER

9

3

DEL

0

DIR

7

AVE

8

HARD-

NESS

2

ESC

MAT’L

1

TIMES

4

MENU

6

5

special notice

Turn off the unit before replacement

of battery impact device!

Content

rief

-----------------------------------------------( 9)before operation

requirements on the measured-------------------------------( 9 )

system setting ------------------------------------------------(10)

measuring condition setting ------ ---------------------------(10)

measuring method --------------------------------------------(10)

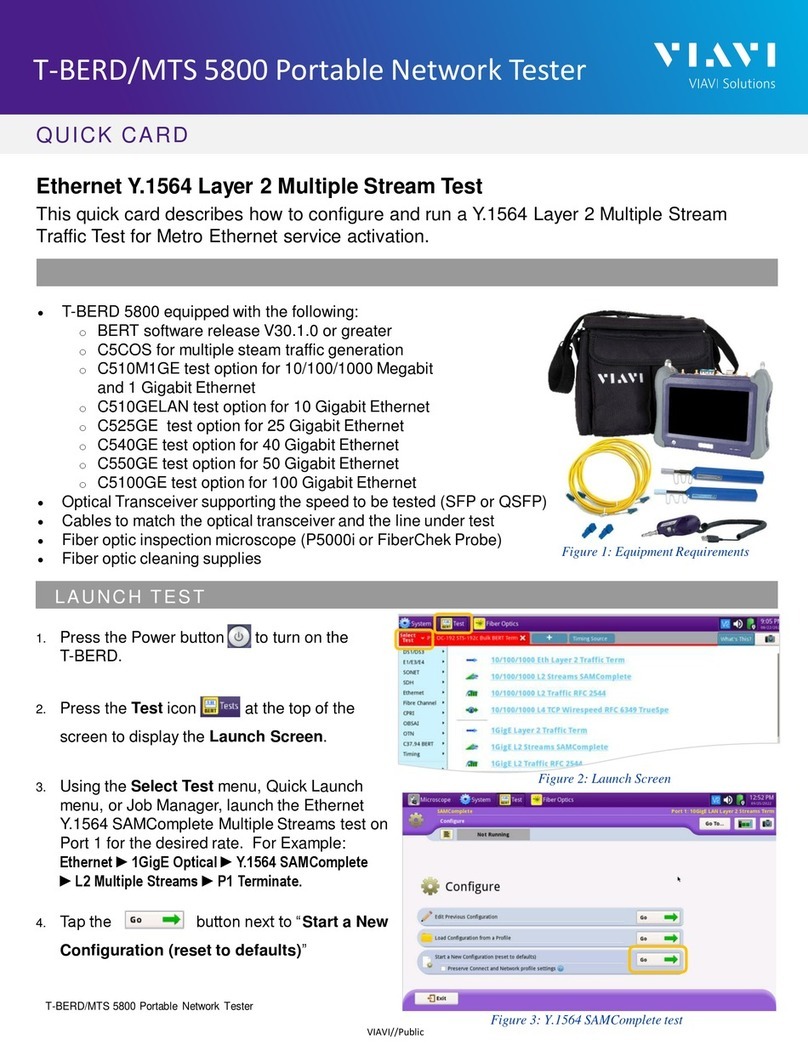

Working principle and Diagramof the instrument

4.O

peration

Working principle --------------------------------------------(05)

Diagram of the instrument------------------------------------(06)

hardness tester -----------------------------------------------(06)

Main unit------------------------------------------------------(07)

d type impact device---------------------------------------- (07)

irregular type impact device-------------------------------- (08)

3.Technical features

--------------------------------------------------------(04)features

application and its range -------------------------------------(04)

application----------------------------------------------------(04)

application range -------------------------------------------- (04)

model specifications -----------------------------------------(05)

operation condition------------------------------------------(05)

Starting ------------------------------------------- ------ -(10)-----

Load ---------------- ------ ------------------------------ -------(10)

Placement------------------------------ ------------ (10)---------- -

Measuring - ------------ ----------------------------------------(10)

-01-

Maintenance and warranty

1D

Maintenance

put

Warranty warranty

. o not the instrument under the following environment:

a. In risk of splash by water or highly intense dusy environment

b. Air of high content of salt or sulfurate

c. Air of othere chemical substance

d. High humidity and temperature(above 60 90%RH) or in sunlight

2. Don't disassemble the instrument or change the inner struction

3. Alcohol and diluent is erosive to the LCD, clean the housing with cloth

of slight water.

1. Refer to the terms in the card

2. Any damage resulting from unauthorized dismantle of the unit,

improper transport or storage in breach of the manual instruction

as well as unauthorized amendment of guarantee card or lack of

proof will lead to refusal of guarantee service.

D

a.

eclaration:

The battery used must be dealt with according to the local laws,

rules and regulatoins.

b. Our company reserve the right to upgrade and amend the

specifications and design of the instrument and instructions,

they are subject to change without further notification if any.

-28-

Other Items

-02-

-------------------------------------------(15)impact direction setting

average times setting-----------------------------------------------(15)

----------------------------------------- -- (15)material setting ---------

hardness setting ---------------------------------------------------- -(16)

tolorence setting ------------------------------------------------ --- (16)

hardness/intensity setting- ----------------------------------------- (16)

storage management --------------------------------------------- --(16)

review from first group to the last ------------- (17)-------------- ------

reviewing the selected ------- (17)-------------------------------- -------

data transmission ---------------------------------------------- -----(17)

deleting the selected ----------------------------------------- -------(17)

delete all --------------------------------------------------------- ----(17)

confirm of deletion -------------------------------------- ----------- (18)

data review ------------- ------------------------------------------ -- -(18)

system review ---------- ------------------------------------------- -- (19)

LCD brightness setting --------------------------------------- ------(19)

6.D

etails on operation

-------------------------------------------------------------- (12)turn on

turn off --------------------------------------------------------------(12)

measurement -------------------------------------------------------(12)

main menu-----------------------------------------------------------(13)

measuring operation------------------------------------------------(13)

buttons --------------------------------------------------------------(13)

menu tree------------------------------------------------------------(14)

measuring condition setting ---------------------------------------(14)

pick up value --------------------------------------------------------(11)

turn off ----------- -------------------------------------------------- -- (11)

5.Special instruction

User notice

1 After purchase ofthis unit, theuser is expectedto fill inthe guarantee

card withunit stamp,then deliverits copyalong withthe invoicecopy

to ourcustomer servicecenter, orask thedistributor todo so.

Incomplete proof willlead to maintenancewithout guarantee.

2 The instrument enjoysone year guaranteeservice since thepurchase

of theunit, inthis periodif thereis anymalfunction, againstthe

guarantee cardor invoice,contact ourservice centerfor freecharge

service. Incase noguarantee cardor invoicebe presentedour

company willcalculate theguarantee periodsince thedate offfactory.

3 Beyond theguarantee period,the maintenancewill becharged byour

service department.

4 The components like(irregular type , enlonged

cable, specialized softwareetc.) will becharged accordingly.

optional impact device

5 Any damage resultingfrom unauthorized dismantleof the unit,

improper transport orstorage in breachof the manualinstruction as

well asunauthorized amendmentof guaranteecard orlack ofproof

will lead torefusal of guaranteeservice.

6 Please followthe manualinstruction tooperate, ifthere isany

malfunction, contact ourcompany immediately.

-27-

----------------------------------- (22)maintenance impact device -

instrument maitenance -- (22)--------------------------------------- -

instrument check-------------------------------------------------(22)

notice of storage and transport--------- ------------------- ----- (22)

system calibration -- (20)-------------------------------------------- -

program infomation - (20)----------------------------------- ---------

Backlight ----- (21)--------------------------------------------------- -

automatical turn off (21)---------------------------------------------

battery replacement (21)---------------------------------------------

connection of data cable (21)----------------------------------------

7.Trouble shooting

8.U

pkeep and maintenance

A

ppendix

apeendixtwo - ---(24)-------------------------------------- ----------

appendixone -- - - (23)----------------------------------------- --- -- --

apeendix three - -- (25)---------------------------------------------- - -

apeendix four- - - -- (26)----------------------------------------- - -- ---

notice for user - ------------- --------------------------------- ---(27)

-03-

maintenance andwarranty-- --------------------------------- ---(28)

Appendix 4

-26-

time/date setting---------------------------------------------------(20)

No Model Sketch of supportring Remarks

for testing cylindricaloutside

surface

inner cylindrical surface

for testing cylindricaloutside

surface, radius adjustableR10-8

out cylindrical surface

out cylindrical surface

inner cylindrical surface

inner cylindrical surface

out cylindrical surface

or testing sphericaloutside

surface

for testing sphericalinside

surface

inner cylindrical surface

inner cylindrical surface

-04-

1Brief

1.1Features

l Adopting Leeb hardnessmeasuring principle, thisunit can testthe hardness of

most metals.

l 160*80 lattice LCDdisplay allows completeinformation and clearreading.Large

l All display with menuindication makes theoperation easy andconvenient.English

l Alternative white backlightdisplay and USBplug facilitate theopeation in darkness

and communication withPC for dataexchange and configuration.

l The is matchable with7 striking fittings,capable of identifyingthe striking

type automatically,and requires nofurther calibration afterreplacement.

main unit

l The unit canstore up to500 groups ofdate( times 32~1), inwhich each group

contains information ofsingle value, averagevalue, measuring date,

direction, times, material andhardness unit.

impact impact

impact

l With presettingof up andlow limits, theunit alarm automaticallyif reading is

beyond the limits,which facilitates massivemeasurement.

l Battery volume iconon LCD indicatesthe and calibratable with

software. battery power

l When using D/DCtype for steel materialhardness testing,

the reading canbe displayed directlywithout consultation ofthe table.

impact device

l Equipped with PCprogram, this softwaresupports transmission ofthe measuring

results, storage management,statistical analyzing, print and massive parameters

setting to ensurehigher quality andmanagement.

l Professional and niceoutline, smart, portableand reliable performacemakes the unit

operatable in roughenvironment, and immunefrom vibration, strikingand

elecmagnetic interference.

l 4 AAalkaline batteries supportcontinuous operation formore than 50hrs.

and automatical turnoff function.

l 150*80*38mmProduct Dimension

1.2 Application andrange

1.2.1 Application

l Toolingcavity

l Bearing and otherworkpiece.

l Pressure vessel, steamgenerator and itsfailure analysis.

l Heavy workpiece.

l Amounted machanism andpermanent assembly.

l Workpiecewith small testingspace.

l Original record oftesting results required.

l Division of metalmaterial warehouse.

l Quick test formany locations onlarge workpiece.

1.2.2 Measuring range

see appendix oneand two.

Appendix 3

impact device DC(D)/DL D+15 CGE

impacting energy

and mass of

impact body

11mJ

5.5g/7.2g 11mJ

7.8g 2.7mJ

3.0g 90mJ

20.0g 11MJ

5.5g

ball hardness

ball diameter

ball material

1600HV

3mm

carbonized

tungsten

1600HV

3mm 1600HV

3mm 1600HV

5mm

5000HV

3mm

Diameter of

length of

weitht

of

impact

device

impact device

impact device

20mm

86(147)/

75mm

50g

20mm

162mm

80g

20mm

141mm

75g

30mm

254mm

250g

20mm

155mm

80g

max hardness

of workpiece 940HV 940HV 1000HV 650HB 1200HV

Ra average

roughness of

workpiece 1.6 m 1.6 m 0.4 m 6.3 m 1.6 m

min weight of workpiec

direct measure requires

solid support

and intense coupling

>5kg

2~5kg

0.05

2kg

>5kg

2~5kg

0.05~2kg

>1.5kg

0.5~1.5kg

0.02~0.5kg

>15kg

5~15kg

0.5~5kg

>5kg

2~5kg

0.05~2kg

min thickness of

workpiece

intense coupling

min depth of

rigidified layer

5mm

0.8mm 5mm

0.8mm 1mm

0.2mm 10mm

1.2mm 5mm

0.8mm

hardness

300

hv hour

indentation

diameter

indentation

depth

0.54mm

24 m 0.54mm

24 m 0.38mm

12 m 1.03mm

53 m 0.54mm

24 m

hardness

600

hv hour

0.54mm

17 m 0.54mm

17 m 0.32mm

8m 0.90mm

41 m 0.54mm

17 m

hardness

800

hv hour

0.35mm

10 m 0.35mm

10 m 0.35mm

7m --

-- 0.35mm

10 m

application range

of impact device

DC type for

hole or cylinder.

DL type for long

and narrow

channel or hole

D type for

general peices

test

D+15 type for

measuring in

grooves or

recessed

surfaces

C type for

measuring

light and small

piece and

surface

hardened layer

G type forfor

measuring he

avy and rough

cast and forged

pieces

E type for

high

hardness

material

size of ballimpress

-25-

impress

diameter

impress

depth

impress

diameter

impress

depth

Operation

Explanations

-05-

1.4 Operating condition

environment temp operating temp-20~+60 storage temp -30 ~+60

relative humidity 90%

Do not usethe instrument instrong vibration, magneticfield, erosive substanceand

high density powderand dust codictions.

2Workingprinciple andDiagram ofthe instrument

2.1 Workingprinciple

An impact bodywith a sphericaltest tip madeof

tungsten carbide ispropelled against thesample

surface by aspring force andthen rebounds back.

At adistance of 1mmfrom the samplesurface, the

impact and rebound velocity ofthe impact body,

when passing through the coilin its coilerholder,

induces in thecoil and electricvoltage proportional

to the velocities fo themagnet. Leeb hardness as the

follo wing formula:

1.3 Specifications:

appendix two

No Material Leeb hardness

HLD Intension 0b (MPa)

1C350~522 374~780

2

C500~710 737~1670

3Cr 500~730 707~1829

4CrV 500~750 704~1980

5CrNi 500~750 763~2007

6CrMo 500~738 721~1875

7CrNiMo 540~738 844~1933

8CrMnSi 500~750 755~1993

9SSST 630~800 1180~2652

10 SST 500~710 703~1676

-24-

Name Number Remark

1main unit PCS

2D typeimpact device

3Standard leeb hardness block PCS

4A Nylonbrush A PCS

5Support ring PCS

6AA alkalinebattery PCS

7Manual PCS

8Alluminum box PCS

9software CD PCS

10 USB cable PCS

11 B Nylon brushB For G typeimpact

device

12 Irregular type

and support ring

impact device See appendix 3and 4

Standard

packing

No

13 Leeb hardness testing

method for metals. GB/717394-1998

PCS

PCS

Operation

Explanations

optional

accessory

HL=1000×VB/VA

Hl leed hardness

Vb rebound velocity

ofthe impact body

VA impact velocity

ofthe impact body

Table1

-06-

Voltage characteristic ofoutput signal:

2.2

2.2.1 Hardness tester

Diagram ofthe instrument

HV

HRC 127~

364

HV 32~168

23.8~

85.5

40~173

13.5~

95.3

60~290

45~315

material hardness

unit impact device

D/DC D+15 CGEDL

steel and

cast steel

HRC 17.9~

68.5 19.3~

67.9 20.0~

69.5 22.4~

70.7 20.6~

68.2

HRB 59.6~

99.6 47.7~

99.9 37.0~

99.9

HRA 59.1~

85.8 61.7~

88.0

HB 127~

651 80~638 80~683 90~646 83~663 81~646

HV 83~976 80~937 80~996 84~1042 80~950

HS 32.2~

99.5 33.3~

99.3 31.8~

102.1 35.8~

102.6 30.6~

96.8

steel

HB 143~

650

CWT ST HRC 20.4~

67.1 19.8~

68.2 20.7~

68.2 22.6~

70.2

HV 80~898 80~935 100~941 82~1009

Stainless

steel

HRB 46.5~

101.7

HB 85~655

HV 85~802

GC. IRON

HRC

HB 93~334 92~326

Nc

IRON HB 131~

387

c. alum HB 19~164 23~210

HRB 23.8~

84.6 22.7~

85.0

brass

HB

HRB

bronze HB

copper

HB

Appendix

Appendix one

-23-

Main unit

Impact device

Impact phase

time

Rebound

Phase

Operation

Explanations

555555 VV

AAEE

HlHl

Steel and cast steelSteel and cast steel

9

3

0

7

8

2

1

4

6

5

STORE

ENTER

9

3

DEL

0

DIR

7

AVE

8

HARD-

NESS

2

ESC

MAT’L

1

TIMES

4

MENU

6

5

-07-

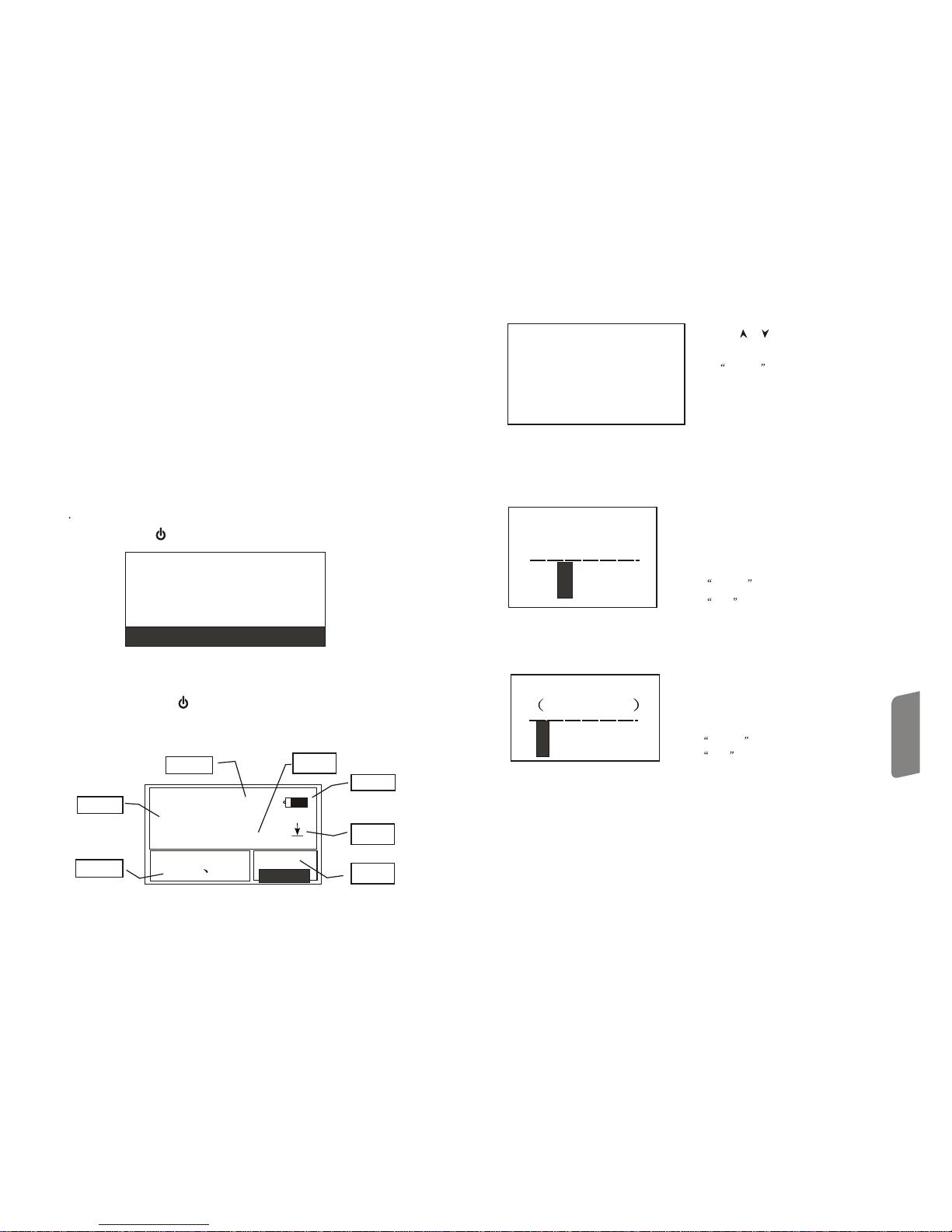

2.2.2 Main unit

2.2.3 D typeimpact device

release button load

supporting ring

tube guide tube coil holder

connecting cable impact head

-22-

8.1 Impact device

l After operation for1000~2000 times, clean pipe and

with nylon brush.For cleaning thepipe, take outthe body by

unscrewing the supportring, screw thenylon brush anticlockwiseinto the pipeuntil

the bottom thenpull out, repeatthis five times,then re-install the

and support ring.

impact device impact device tube

impact device tube

impact device tube

l After operation releasethe impact device tube.

l Forbid to useany lubricant for .impact device tube.

8.2 Instrument maintenance

l When checking withRockwell hardness blockand finding theerror over 2HRC,it is

recommendable to replacethe head or resulting from ballwearing.impact device

l In case thatthere is anymalfunction of theinstrument, the usershall not dismantleor

replace any componentof the instrument,please fill inthe guarantee cardand return

the unit toour maitance department.

9. Instrument checkup

The checkupperiod shall notbe more thanone year,the users candecide its regular

checkup period attheir convenience.

10. Storage andtransport

l Keep the unit from the vibration,high magnetic fieldand erosive substance,humid

zone and dustyroom in normaltemperature.

away

l Keep the originalpackage, the instrumentcan be transportedon 3 levelroad.

µç³ØÃÅ

µç³ØÃÅ

LCD display

Keypad

Impact device socket

rear cabinet

battery door

Vibration-proof suit

USB socket

Battery

back sidefront side

µç³ØÃŵç³ØÃÅ

8. Maintenance and warracnty

Operation

Explanations

-08-

2.2.4 Irregular impact device

3.Technicalfeatures

lSee table2 for and reading repeatibilitytolorence

No impact device hardness of theblock tolorence of the

reading reading

repeatibility

1D760 30HLD

530 40HLD 6 HLD

10 HLD

6 HLD

10 HLD

2DC 760 30HLDC

530 40HLDC 6 HLDC

10 HLDC 6 HLD

10 HLD

3DL 878 30HLDL

736 40HLDL 12 HLDL 12 HLDL

4D+15 766 30HLD+15

544 40HLD+15 12 HLD+15 12 HLD+15

5G590 40HLG

500 40HLG 12 HLG 12 HLG

6E725 30HLE

508 40HLE 12 HLE 12 HLE

7C822 30HLC

590 40HLC 12 HLC 12 HLC

l Measuring range HLD 170~960 HLD

l Measuring direction: verticaldown, side down,horizontal, side upand vertical down

-21-

6.11 Backlight

The white backlightfacilitates operation indarkness, pressing buttonto turn on/off

the light inmain menu interface.

6.12 Auto turnoff

lThe function isto save theenergy

lIf no furtheroperation within 5min the instrumentwill turn off automatically

lThe battery iconwill be blankif there islow battery

6.13 Battery replacement

After long timeoperation, the battery icon becomesfaded, the moreblack part the

more battery volume;after exhaustion ofthe battery,the batter iconshows ,this

means to replacethe battery immediately.

Refer the followingfigure to installthe battery:

6.14 Data transmissioncable connection

Plug one endof the cableinto the USBsocket at theleft of thehost while theother

end into PC'sUSB socket.

7. Trouble shooting

Problem Analysis Action

Fail to turnon Exhaustion of battery Replace battery

Wrong polarityconnection Connect the battery

in proper polarity

Blur reading Low battery Replace battery

Replace the batteriesas follow steps:

the unitlturn off

lTakeoff thevibration-proof glove on

the instrument, andopen the battery

door and takeout the oldbatteries.

lInsert the 4fresh batteries with

correct polarity, then closethe battery

door and takeon the glove.

lTurn onthe instrument tocheck if it

works properly.

lPay attention tothe polarity ofthe

batteries, otherwise itmay damage

the instrument.

battery door

Battery µç³ØÃÅ

µç³ØÃÅ

--

++

--

++

--

++

--

++

positivepolarity

negativepolarity

l Material: steel &cast-steel, alloy toolsteel, stainless steel,gray cast iron,nodular cast

iron, cast alluminumalloy, copper-zinc alloy,copper-tin alloy,pure copper,and forged

steel.

Operation

Explanations

Table2

l Hardness unit ( HL) HB HRB HRC HRA

HV HS

l Display 160*80 lattice LCDdisplay

l storage up to 500groups ( times:32~1)Data impact

l Operating voltage 6V

l Continuous operating time 50hrs without backlight.

4Instrument operation:

4.1 Before operation

4.1.1 Requirements ofthe measured.

The surface ofthe measured mustmeet the requirementscontained in table3.

l The surface ofthe measured mustbe no morethan 120 .

l The roughness cannot be toohigh, otherwise errorsmay be occurred.The measured

surface must bepolished and blareas smooth andflat as possiblewithout oil smear.

l Weightof the measured:for the measuredof more than5kg, there isno need to

support; for thatof 2~5kg orof thin wallsconstruction, a supportmust be applied

while operating toavoid distortion, warpageand movement; formiddle scale

workpiece, it mustbe placed inbalance on aflat and concretesurface without any

vibration or moving.

l Curve surface workpiece:the testing surfaceshould be The smallsupporting

ring or irrregulartype supporting ringshall be usedfor testing theworkpiece which

has its curvatureradius less than30mm(forD,DC, D+15, C,E and DLtype

) and biggerthan 50mm(G type ).

as flat.

impact

device impact device

-09-

-20-

6.8.2 Time /date setting

Current time/date displayson the LCDin format of

month/date/year hr/min.

Press number buttonsto input thenumber, thecursor

will move fromleft to rightrepeatedly.

Press ENTER button to completethe setting.

Press ESC button to cancelthe change.

6.9 System calibration

First operation, oruse after along time, theinstrument and the must be

calibrated with theprovided leeb hardnessblock. Whenseveral are

provided with , every only need onecalibration, and noneed

to re-calibrate whenreplacing .

Press menu toenter into systemcalibration submenu.

impact device

impact devices

main unit impact device

impact device

11 0/05/2005 11:02

time / date setting

After testing,averages display.

Press [ ][ ]to inputreal value.

Press ENTER button to completethe calibration.

Press ESC button to exitthe operation.

Calibraton range: 15hl.

system calibration

times

testing 5 times

Software Calibration

Average =780

Real Value=

778800

6.10 software info

press menu toenter into mainmenu

This interface showsthe info aboutthe instrument and

the plug-in software

The software versionno and plug-insoftware indentifier

is subject tochange without furthernotification.

Storage Manager

system calibrationsystem calibration

version No:AR936 B01

indentifierAR963BETA01

SN: 93600000

Setting the direction asimpact

With leebhardness block, test5 locatons indirection

of vertical downward.

System Configuration l The workpiece mustbe of enoughthickness, for the thickness please see

the appendix table3. minimum

l For the workpieceof rigid surface,the surface mustcomply with therequirements

prescribed in theappendix table 3.

l Coupling: for thelight workpiece, itmust be coupledwith the solidsupporting

body,the two couplingsurface must beflat and smoothwithout too muchcoupling

agent applied.The testing directionmust be verticalto the couplingsurface. For

the workpiece oflarge area,long stem shape,or crook shape,even its weightand

thichness are enough,it is stillpossible to findthe distortion andunbalance which

Press [ ][ ] tomove the cursorto software Info.

Press ENTER button to enterinto software info.

Operation

Explanations

-10-

4.1.2 Instrument system setting: see6.8 for details.

4.1.3 Measuring condition setting:see 6.5 fordetails.

4.2 Measuring method:

l Calibrate the unitwith the providedhardness block beforeoperation,and its

and repeatibility shallbe in linewith the table2. tolorance

4.2.1 Starting

l Plug the head in thesocket at themiddle of theunit.impact

l Press [ ]button to turnon the unie.

4.2.2 Loading( figure1)

l Push down theload to lock the body; for DCtype

the load stemon the surfaceof the workpiece;for DC

insert the stemuntil stop forloading process.

tube impact impact device,

adsourb impactdevice,

4.2.3 Placement (figure2)

Clamp the strikingsupport ring againstthe the surfaceof the workpiecein the

selected direction vertically.

-19-

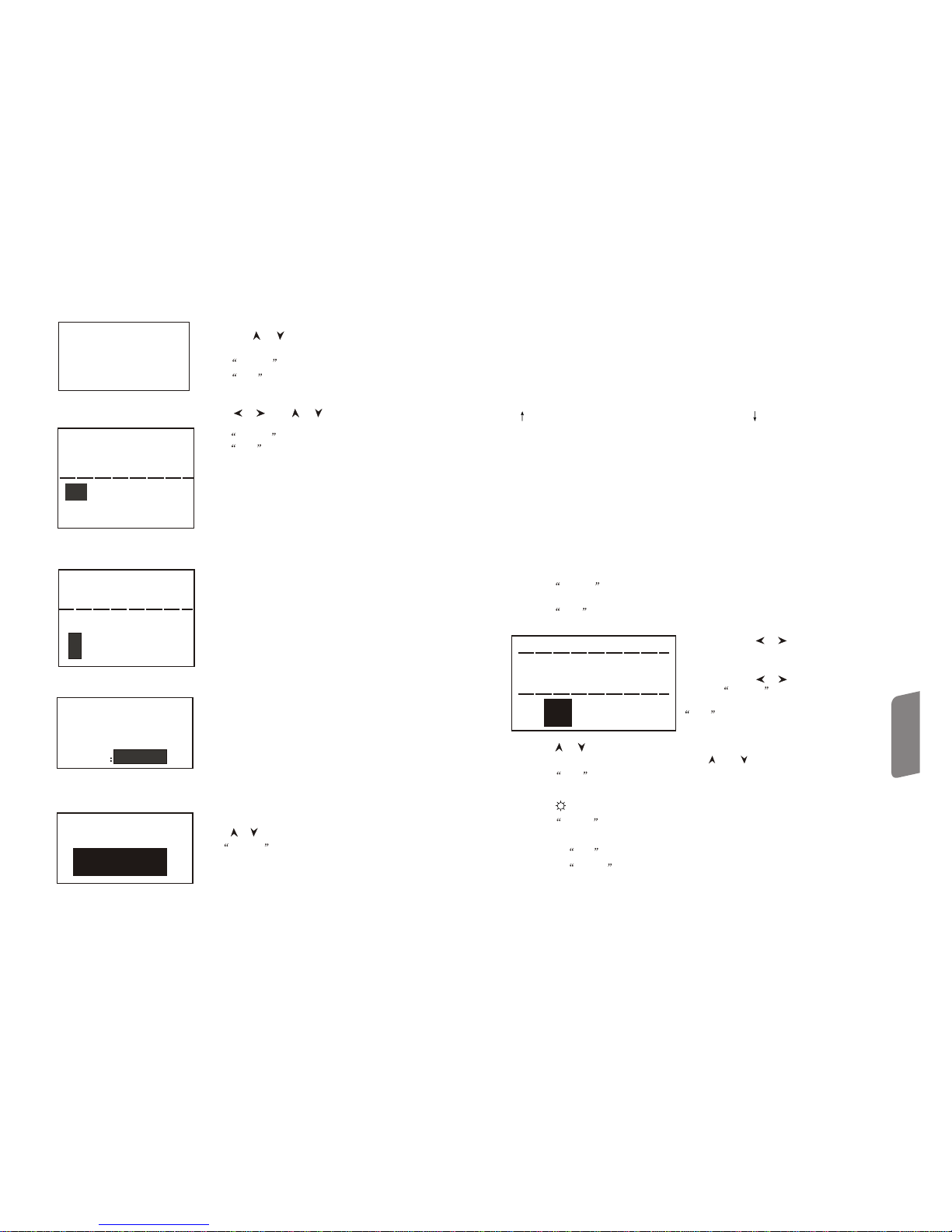

6.8 System configuration

Press menu toenter into mainmenu

Press [ ][ ] topoint the cursorto the System

configuration

Press ENTER button to enterinto the menu.

Auto storage Eliminate the bigerror

Auto data transmission]

[Button sound][Alarming sound]canbe turned

on/off bypressing the confirmbutton

l Auto storage: settingon will autostore the currentgroup data aftergiving average

reading.

l Eliminate the bigerror: setting onwill auto eliminatethe big errorbounding the 3

regulations after theadvance ending ofcomplete measurement bypressing average

button. If adata is eliminated,new data shallbe supplemented toreach the times

preset.

l Auto data transmission:setting on willoutput the currentdata through USB

interface in textformat after averagereading is given.

l Button sound: settingon makes thebuzzer beeps onceat every buttonoperation.

l Alarm sound: settingon makes thebuzzer beeps oncefor a longtime when the

measurement is beyondthe allowance limits.

storage manager

system configurtionsystem configurtion

measuring

condition setting

auto storage off

eliminate the big error off

auto data transmission off

button sound on

alarming sound on

LCD brightness setting

time/date setting

6.8.1 LCD brightnesssetting

LCD brightness setting

press [ ] toincreasethe brightness

press [ ] todecrease the brightness

Press [ ]to increase thebrightness

Press [ ]to decrease thebrightness

Press ENTER button to completethe setting.

Press ESC button to cancelthe change

figure 1 2figure 3figure

4.2.4 Measurement( figure3)

l Press the releasebutton at thetop of the device to measurewhile the

workpiece, device and operatormust stand steadilyand the force

should be inline with theaxis of device.

impact

impact impact

impact

l Normally test 5times for eachlocation of theworkpiece. Themax difference

between these resultsshould not be 15HLwithin

Note:

test the blockin direction ofvertical down for5 times withthe demarcated Leeb

tester, andtake the arithmeticaverage as thehardness value ofthe block. Ifthe

value is beyondthe limit, usesystem calibration functionto calibrate theunit.

lead to incorrectmeasuring, so reinforcingor supporting atthe back ofthe workpiece

is necessary.

Press [ ][ ] tomove the cursorto the desired.

Press ENTER button to changeor enter intothe

change interface.

Press ESC button to exit

Operation

Explanations

-11-

impact device

distance between

center of the 2 impress the distance between the

center and edge of workpiece

DDC 35

DL 35

D+15 35

G48

E35

C24

table 3

4.2.5 Read thevalue

l Takethe average ofreadings from manyvalid testing locationsas a Leebhardness

data.

l Before the Leebhardness signal HLis the hardnessreading. Afterthat is thetype

of striking fittingtype. For example,780HLD means thetested hardness is780 with

type D impactdevice.

l For conversion fromLeeb reading, acorresponding hardness singalshall be

placed after thereading, for example,420HVHLD means theVickerreading is 420

with the typeD impact device.

Note: The differentimpact device wiillhave the different hl valuereading, for

example:

4.2.6Turn off

-18-

are you sure to delelte?

YesYes NoNo

6.6.6 Confirm delete

6.7 Data review

No. 001 12/03 652HL

No. 002 12/03 587HL

No. 003 12/03 820HL

No. 004 12/03 693HL

No. 005 12/03 783HL

No. 006 12/03 782HL

No. 007 12/03 579HL

No. 008 12/03 687HL

No. 001 12/03 514HL

No. 002 12/03 785HL

No. 003 12/03 516HL

No. 004 12/03 789HL

No. 005 12/03 570HL

No. 006 12/03 852HL

No. 007 12/03 523HL

No. 008 12/03 796HL

Every LCD pagedisplays up to8 groups of

numbers, date andaverages

Press [ ][ ] topage up/down

Press ESC button to exitreview

Press ENTER button to callcursor for furtherreview.

A confirminterface appears whendelete the datastored.

Press [ ][ ] tomove the cursorto Yes and press

ENTER button to deletethe data.

Press [ ][ ] movethe cursor toNo and press

ENTER button to cancelthe delete. Regardlessthe

cursor position.

Press ESC button also leadto delete cancellation.

Press [ ][ ] toselect the groupdisplayed.

Press ESC button to exitreview

Press ENTER button to callcursor for furtherreview

511 513 516

514 515

Max: 516 Min: 511

Number 001 12/03/02

average= 514HL

D 05 times

steel and cast steel

press ““ button to turnoff.

5Special instruction:

l Replacement of battery must be performedafter turn off the

unit, otherwise,the can not beidentified and damage the unit.

impact device

impact device might

l Any distance betweenimpresses and thedistance between thecenter and theedge of

the workpiece shallbe in linewith the regulationof table 3.

l For specific material,a comparison testmust be performedto get aconversion map if

you want tochange the Leebreading into otherhardness value.This method isthat

using properly calibratedLeeb tester andthe desired testerto test onthe same

workpiece at 3locations nearby thetarget locationand get 5groups of theLeeb

readings. Thentake the averageof these readingsand these fromanother tester to

make a conversioncurve which atleast must involve3 pairs ofsampling readings.

l The magnetism ofthe workpiece shallnot be morethan 15 gauss.

6.6.5 Delete all

Delete Allwill delete allthe data storedin memory.

Press [ ][ ] topage up/down andreview the

averages, measuring conditionsand single readings.

Operation

Explanations

-12-

Leeb hardnesstester

impact device

DD

The instrumentwill check the and show onthe LCD, checkif the display

is right ornot, then theunit enters intothe main menudisplay.

impact device

6.3 Measurement

After turn on,the unit entersinto the mainmenu as shownbelow:

-17-

6.6.1 Review fromthe firstgroup/review fromthe lastgroup

The formerdisplays the datastored from thefirst goup

The later displaysthe data storedfromt the lastgroup

6.6.2 Review fromthe selectedgroup

lReview From theSelected Group will

display the startgroup interface

lPress number buttonsto input thenumber

lPress ENTER button to confirm thechoice

lPress ESC button to cancelthe change

6.6.3 Data transmission

Data Transmissionwill transmit thedata in textfrom USB interface.

Select thestart groupfrom

001 to 010

00 01

6.6.4 Delete theselected group

lDelete Selected Groupwill show thethe

interface of theselected group tobe deleted

lPress the numberbutton to inputthe number

lPress ENTER button to confirmthe choice

lPress ESC button to cancelthe change

Note:

1. If thegroup number isbeyond the existed,all the existedgroups will bedeleted

2. There isno differnceto input thefirst group numberor final groupnumber, ex,

delete 1 to5 equals delete5 to 1

3. After deletion, thenumber of thestored group willbe re-numbered

4. In deleting,especially for singlegroup delete, forre-number the existingstored data,

more 30 seconds is required,the instrument shallnot be turnedoff toavoid messing

up the data.

selectable group from

001 to 017

0001

To

001

Press the [ ] [ ] to move thecursor to the

desired function

Press ENTER button to confirmthe choice.

review fromthe firstgroup

review formthe lastgroup

review fromthe selectedgroup

data transmission

delete theselected group

delete all

AVE

784

HL

CWT ST 04

COUNTCOUNT

material

reading

average hardness

unit

battery

impact

direction

impact

times

lNormally, thereading cannot bestored if the times is lessthan the presetvalue.

If you wantto store thecurrent reading, pressthe Average button toend the

measurement and storethe value.

impact

lThis performance ofadvance end ofmeasurement by pressingAverage button disable

the functions ofautomatical storage andautomatical transmission inthe system munu.

lOnly D typeand DC type enable the intensiontesting function, ifother

are used thehardness/intension settings cannotbe changed. Incase that

if chage thesetting as Intensionwith D/DC , then changethe

with others, theHardness/Intension setting willbe changed intoHardness

automatically.

impact device

impact devices impact devices impact

devices

lIf the settingis Intension, thehardness unit resetcannot be performed.

lNot all thematerial hardness canbe converted intoothers, if thematerial is changedthe

tester will berestored into Leebhardness unit automatically. So materialsetting msut

be done beforethe hardness unitsetting in processof condition setting.

6Details ofinstrument operation

6.1 turn on:press[ ]to turnon asshown below:

6.2 In any case,press [ ] to turn off the unit.again

Operation

Explanations

-13-

6.3.1 Main menuinstruction

Battery: shows the residualbattery volume.

direction:current direction

Average: when the preset times is reached,the average valueshows.

Hardness unit:current unit

Reading: current single testingreading(without average alert),current average(with

average alert).

denotes value aboveconvertable or measurerange, denotes value belowthe

convertable or measurerange.

Material: current material seting.

times: shows the times done withpreset viaTimes button.

Times givesthe info ofthe times and Singlereview gives thesingle readings

with is timesof a singlereading.

6.3.2 Measuringoperation

At thisinterface, each testingwill be displayed,and the times added with1, if

the reading isbeyond the , the buzzergives a longbeep; when presettimes

is reached thebuzzer 2 shortbeeps, then theaverage shows after2 seconds withthe

buzzer gives ashort beep.

6.3.3 Button operation

l Press STORE button to storethe current groupreading, after theaverage is given.

The datacan only bestore once.

l Press DEL button to deletethe last singlereading, before theconfirmation of the

following dialogue:

Impact impact

Impact impact

impact

impact

tolerance

are you sure to delete?

yesyes nono

l Press AVE button to endthe measurement advancelybefore the preset

times and showsthe average. impact

l Press[ ]to turnon / off the backlight(thisfunctions only inthe main menuinterface)

l Press MENU button to enterinto main menu

l Quick set button

l Press the DIR button to setthe direction.

l Press the TIMES button to changethe times set, firstpress will displaythe

current the timesset, each pressadd 1 until32, then goback to the1.

impact

l Press[ ] [ ] button toreview the singlereadings, and pressthe Esc torestore the

average or lastreading display,press the [ ] or [ ] can reviewthe info inorder.

-16-

6.5.4 Hardness unit setting

mild steel

high carbonsteel

chrome steel

current material

hardness unit

HV HB HRC

HS HRB HRA

HLHL

6.5.5 limit settingTolerance

6.5.6 Hardness/intension setting

Press the [ ] [ ]to move thecursor to thedesired

material

Press ENTER button to confirmthe choice

Press ESC button to cancelthe change

Press [ ][ ] or[ ] [ ] to movethe cursor tothe

desired unit

Press ENTER button to confirmthe choice

Press ESC button to cancelthe change

Note:

1. Only thehardness unit availablefor convert with

suitable and material, forothers this

cannot be displayed.

impact device

2. Select materialbefore hardness unitsetting

3. Aftermaterial setting, thehardness unit will

be restored toHL automatically.

Press the Numberbutton to inputthe number andthe

cursor will moverepeatedly from leftto right.

Press confirm toconfirm the choice

Press Esc tocancel the change

Note:

1. If thesetting is beyondthe range, theinstrument will

alert you toreset.

2. If thelow limit isbigger than thetop limit, the

instrument will reversethe setting.

Press Confirm toselect hardness/intension, the

cursor shifts betweenthe hardness andintension

Note: 1. only D/DC are capable of

intension measurement, forthe others thischocie is

Hardness only.

impact device

tolerance limit

low limit top limit

00 200 0890

material

hardness unit

tolerance limit

hardness/

intension hardnesshardness

Press [ ][ ] to movethe cursor toStorage manage

Press ENTER button to enterinto storage managemenu.

If there isno data stored,“ NO DATA”shows.

measuring

condition setting

storage managestorage manage

By pressing the[ ] [ ] button tomove the

cursor toYesand click theConfirm button to

confirm the deleteof last singlereading.

By pressing the[ ] [ ] button toNo and

click the ENTER button to cancelthe delete.

Regardless the cursorposition, pressing the

ESC button can alsocancel the delete

operation.

6.6 Storage manage

Press the Menuto enter intomain menu

Operation

Explanations

-14-

l Press MAT L button will changethe material seting,each press willcycle the materials

preset in theinstrument, and putthe hardness asLeeb unit. Soit is necessaryto set

material before hardnessset.

Note: The so calledconversion means thatbased on themassive tests forLeeb

hardness and otherhardness, a correspondingmap is setup, and adoptingthis map the

tester calculates andconverts the Leebhardness into otherunits.

6.4 Menu tree

All the instrumentparameters's configuration andadded functions canbe performed

with menu opertion,press the Menubutton to enterinto the mainmenu interface.

main menu interface

measuring condition setting

storage manager

system setting

system calibration

program info

impact

tolerance

direction

average times

material

hardness unit

hardness/intension:hardness

review from firstgroup

review from thelast group

review from theselected group

data transmission(preserved)

delete the selectedgroup

delete all

automatic storage: off

eliminate the maxerror:off

auto data transmission:off

button sound: on

alarm sound: on

LCD brightness setting

time/date setting

6.5 measuring conditionsetting

Press Menu buttonto enter intomain menu interface.

measuring condition settingmeasuring condition setting

storage manager

system configuration

l Press ENTER button to enterinto

measuring condition settingmenu.

l Press [ ]to review upward.

l Press [ ]to review downward.

Press [ ][ ] buttonto move thecursor to thedesired

condition and press ENTER button to confirmchoice.

Note: 1. Ifthe hardness/intension isset as intension,

hardness cannot beselected, the cursorjump over the

Hardness unit choice.

Only D/DC are available to

intension measuring, whenusing other ,

the cursor isnot able tobe moved tothe Hardness/

Intension choice.

impact device impact device

6.5.1 direction settingimpact

6.5.2 Averagetimes setting Availableto select from1 to 32.

Press the Numberbutton to inputthe number

and the cursorwill move repeatedlyfrom left

to right.

Press ENTER button to completethe change.

Press ESC button to cancel the change.

Impact

tolerance

direction

average times

material

hardness unit

hardness / intension: hardness

impact direction Press [ ][ ] tomove the cursorto the

desired direction setting.impact

Press the ENTER button to confirmthe choice.

Press the ESC button to cancel the change.

average times

00 3

6.5.3 Material setting

If the Hardness/Intensionis set ashardness, the followingmaterials will showon LCD

steel & cast-steel,alloy tool steel,stainless steel, graycast iron, nodularcast iron, cast

aluminium alloy,copper-zinc alloy, copper-tinalloy, purecopper, forgedsteel

Press the ENTER button to confirmthe choice

Press the ESC button to cancelthe change

Note: After materialreset, the hardnessunit will

automatically restore itselfto HL

2. Before selectinghardness unit, setthe material.

copper/zinc alloycopper/zinc alloy

copper-tin alloy

pure copper

forged steel

If the Hardness/Intensionis set asIntension, the followingselectable material shows:

Mild steel, highcarbon steel, chromesteel, chrome/vanadium steel,chrome/nickle steel,

chrome/molybdenum steel, chrome/nickle/molybdenumsteel, chromansil,super high

intension steel andstainless steel.

Press the [ ] [ ]to move thecursor to the

desired material.

-15-

l Press the HARDNESS button to setthe hardness unit,each press changethe unit of

the hardness, ifthe current setis intension itwill go asLeeb hardness.

Operation

Explanations

Table of contents

Other Smart Sensor Test Equipment manuals

Popular Test Equipment manuals by other brands

Agilent Technologies

Agilent Technologies InfiniiVision 5000 Series Service guide

BEVS

BEVS 1605 user manual

Keysight Technologies

Keysight Technologies U3020AD01 User's and service guide

Credence

Credence CTE701A user guide

Reed Instruments

Reed Instruments R7800 instruction manual

Rebel TOOLS

Rebel TOOLS MIE-RB-168 quick start guide