2

Table of Contents

Introduction ................................................................................................... 3

Product Quality.............................................................................................. 3

Safety ............................................................................................................ 4

Features......................................................................................................... 4

Included......................................................................................................... 4

Specications................................................................................................ 5

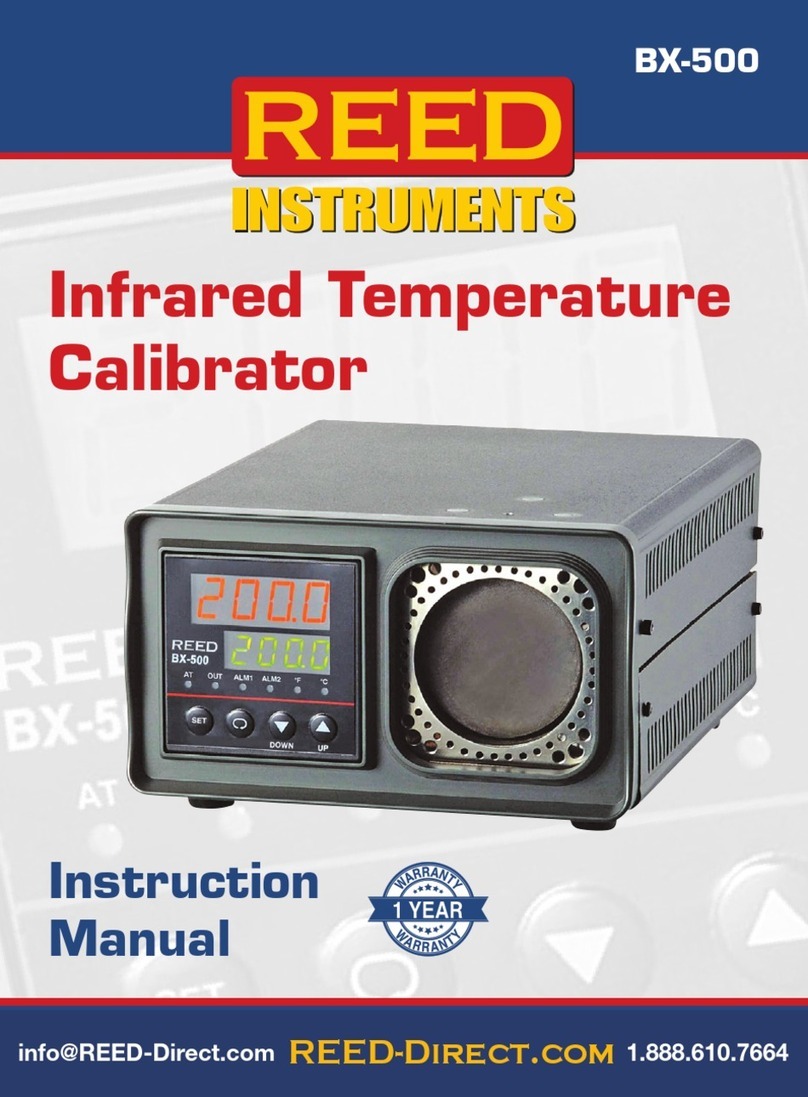

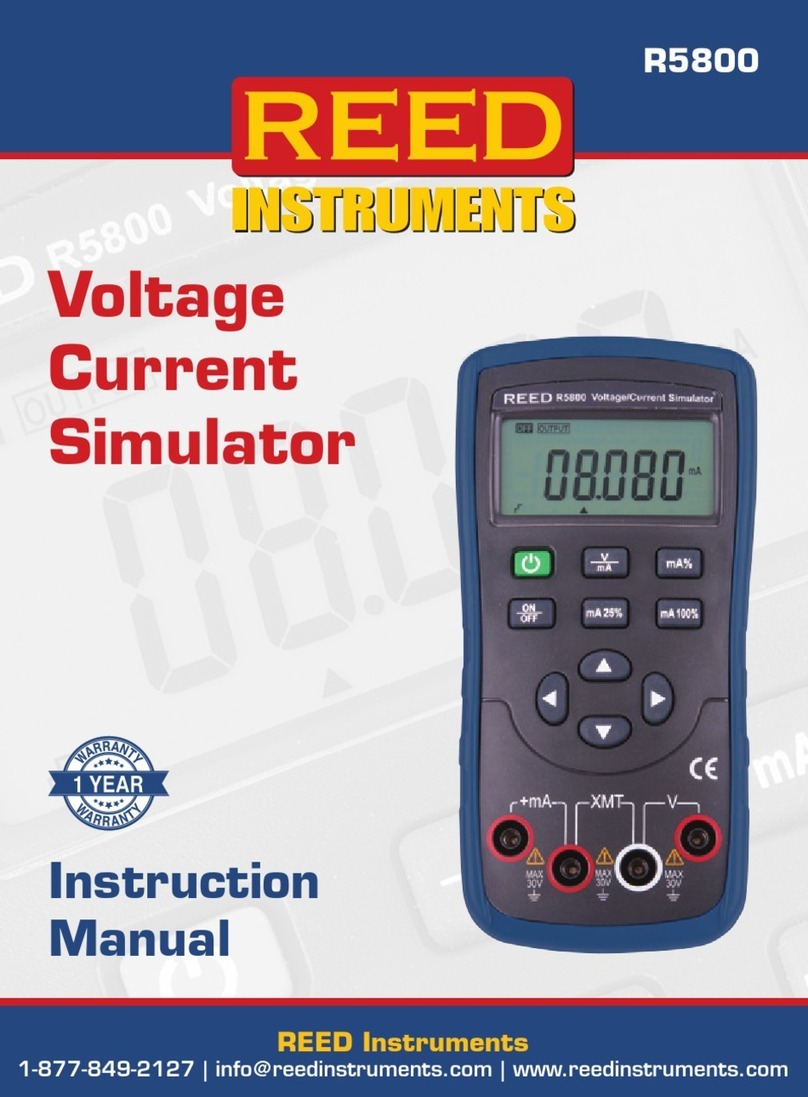

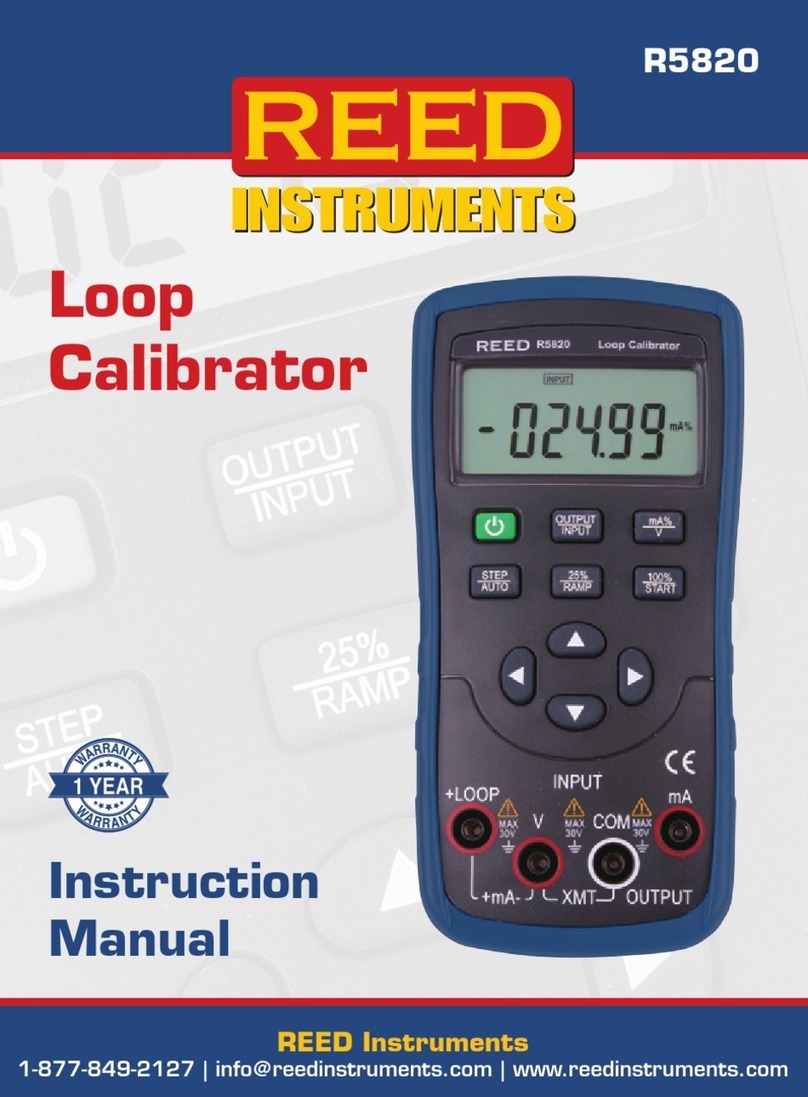

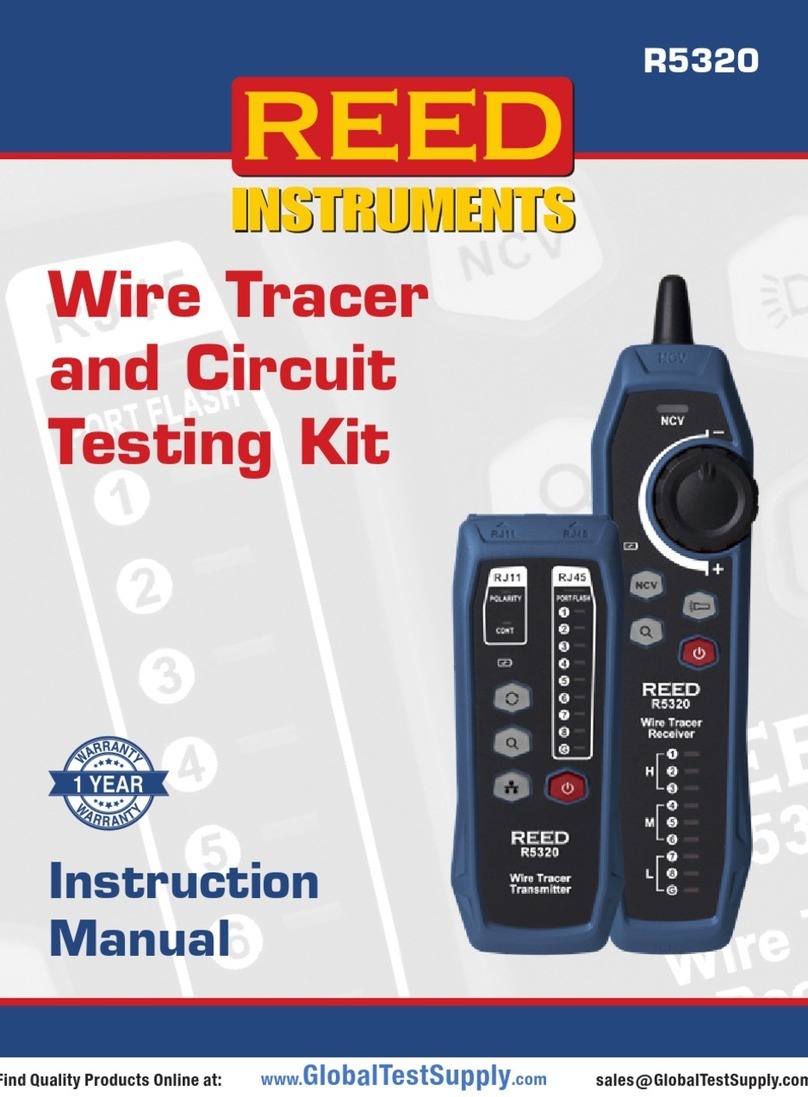

Instrument Description.................................................................................. 6

Display Description ....................................................................................... 6

Operating Instructions................................................................................... 7

Power ON/OFF......................................................................................... 7

Measuring Procedure............................................................................... 7

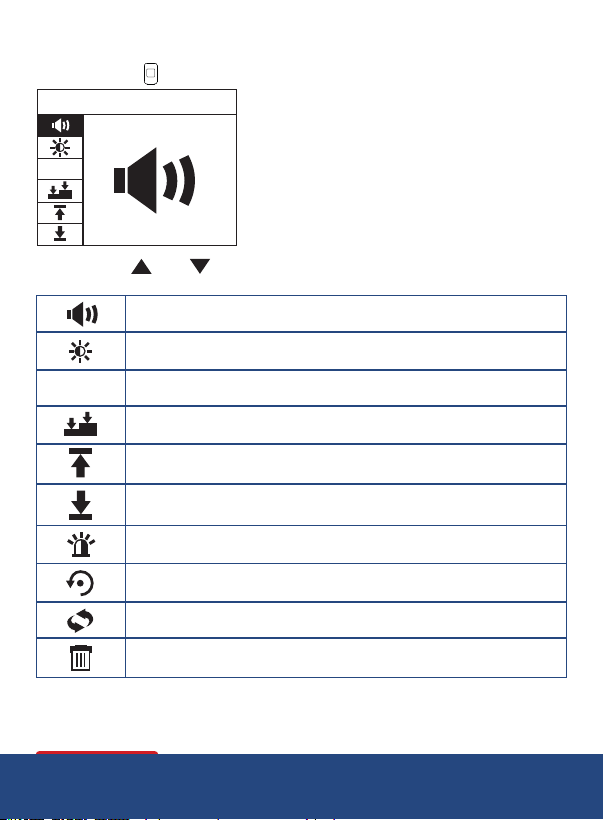

Setup Mode..............................................................................................8-12

Enabling/Disabling Audible Beep............................................................. 9

Setting the LCD Brightness...................................................................... 9

Selecting the Thickness Unit of Measure ................................................. 9

Selecting Calibration Mode...................................................................... 9

Setting Higher Limit Value ...................................................................... 10

Setting Lower Limit Value....................................................................... 10

Enabling/Disabling LED Indicators ......................................................... 11

Factory Reset ......................................................................................... 11

Selecting Continuous Measurement Mode............................................ 11

Delete Recorded Data............................................................................ 12

Minimum, Maximum, and Average Values .................................................. 12

Quick Decision Mode .............................................................................12-13

Single-Point Decision Configuration ...................................................... 13

Multi-Point Decision Configuration ........................................................ 13

continued...

REED Instruments