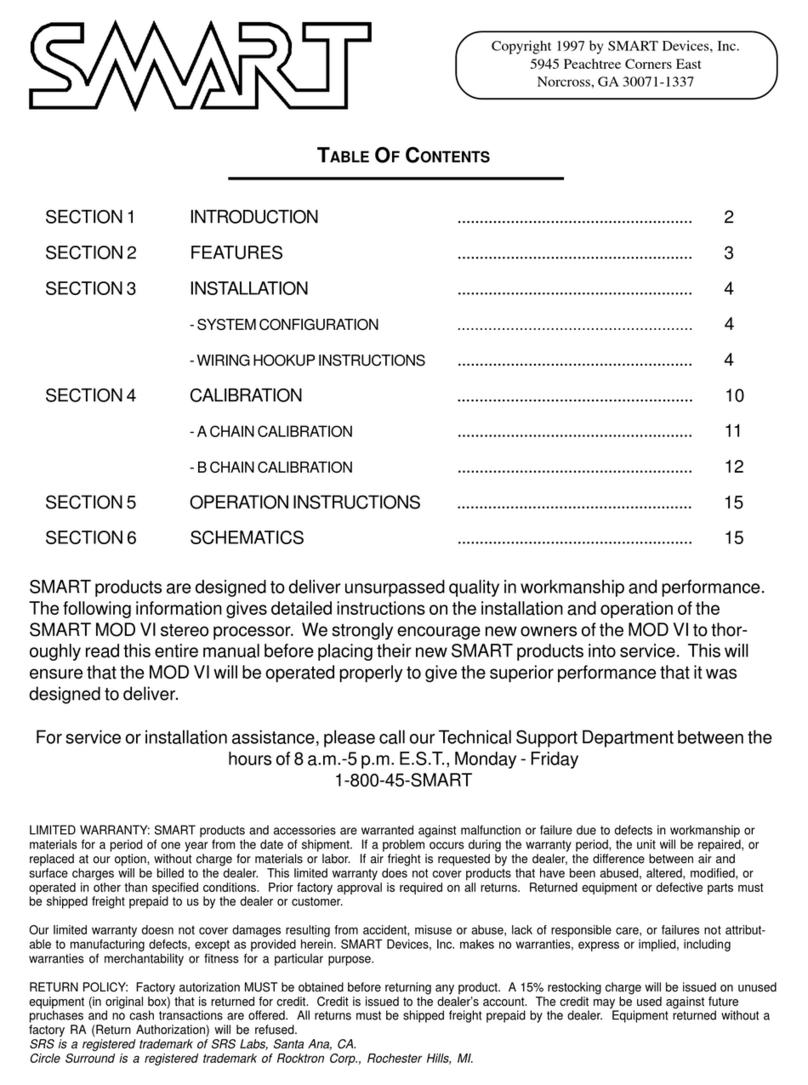

8

DOUBLE CHECK your work to see that the solar cell leads

arrive at the proper terminals. A reversal of leads will cause

very strange results. You may hear the center channel infor-

mation through the surround speakers, the surround through

the stage, and the left channel out of phase with the right.

This is a common error, so verify correct wiring before pro-

ceeding.

AUTOMATION TERMINALS:

A momentary ground contact to one of the format terminals

on the automation inputs of the MOD V will switch the

processor to any desired format, including music. When the

MOD V is in music mode and any one of the film formats

are pulsed, the film sound will appear at the main outputs,

and the music will slowly fade out. While the processor is in

one of the film formats and the music terminal is pulsed, the

MOD V will fade from the film mode to music.

OUTPUTS:

The 8 channel outputs are labeled LEFT, LEFT EXTRA,

CENTER, RIGHT, RIGHT EXTRA LEFT SURROUND,

RIGHT SURROUND, SUB+ and SUB-. Shielded cable

should be run between these terminals and the next piece of

equipment in the sound system (equalizer, amplifier, etc.).

Convenient GROUND terminals are provided near the out-

puts. A balanced subwoofer output is available on the MOD

V. The balanced output provides an easy means to mono

bridge the sub amplifier.

CHANGEOVER WIRING OF DUAL PROJECTOR PRE-

AMPS:

Changeover between projectors is done electronically in the

MOD V. This necessitates that BOTH exciter lamps be lit at

the same time. No exciter light changeover is provided in

the unit. An exciter light changeover has at least 3 dB more

circuit noise than an electronic changeover and is NOT rec-

ommended in high quality systems.

Projector changeover is accomplished by using only a single

pair of wires and either a manual switch or relay contacts in

the automation system. A relay closure in the automation

equipment will execute a changeover by grounding the

CHANGEOVER terminal. Run a pair of twisted unshielded

wires to the “dry” contacts of the automation projector

changeover relay. Connect one wire from the other end of

the pair to the CHANGEOVER terminal of the MOD V

only. Ground the other wire of the pair to the nearest ground

terminal on the MOD V. When the automation relay closes,

projector TWO of the MOD V will be “enabled,” and the

first pair of stereo preamplifiers (PROJ 1) will be “dis-

abled.” Releasing the relay will cause the reverse action to

occur. In other words, PROJ 1 is always ON until the

CHANGEOVER terminal is grounded. The

CHANGEOVER terminal must be held low to activate

PROJ 2. It is not a pulse input.

DIGITAL INPUTS:

The MOD V system has 8 inputs on the rear barrier strip

labeled for each channel of a digital decoder. There is also a

DB25 input connector that can be used for digital inputs

(see the REAR CHASSIS DB25 SECTION for specific

pinout designation). The Digital inputs accept any high

level multi-channel source and route the signals through the

MOD V, which includes the Master Fader and EQs.

Another application of the Digital Input terminals is for

external sync sources. Sound-Interlock from a 35mm repro-

ducer or a single 16mm projector may be fed into the

Digital inputs and selected with the front panel DIGITAL

program switch on the MOD V front panel.

MUSIC INPUT:

The non-sync music inputs for the MOD V feature a special

music matrix decoder that separates in-phase and out-of-

phase signals on a standard two channel recording (CD

player or tape) and creates four channels of auditorium

music. Connect your stereo music source to the LEFT and

RIGHT MUSIC inputs on the MOD V.

Occasionally, a theatre may use a monaural sound player

such as a background music cartridge player that does not

have stereo capabilities. A jumper on the OUTPUT CARD

in the MOD V is moved to the MONO position for this use.

The music source should then be connected to both LEFT

and RIGHT MUSIC inputs. Music will appear on all stage

channel and surround speakers when mono material is feed-

ing the sound system.

REAR CHASSIS DB25 CONNECTORS:

The computer type DB25 connectors on the back of the

processor are for special inputs and outputs. On the far left

(as you view the rear of the chassis) there is a DB25 con-

nector that provides monitor outputs of all channels for a

THX booth monitor/crossover package. Output pinout of

the DB25 connector is compatible with a THX monitor.

You may use a shielded SERIAL computer cable to make