INSTALLATION & OPERATION

3

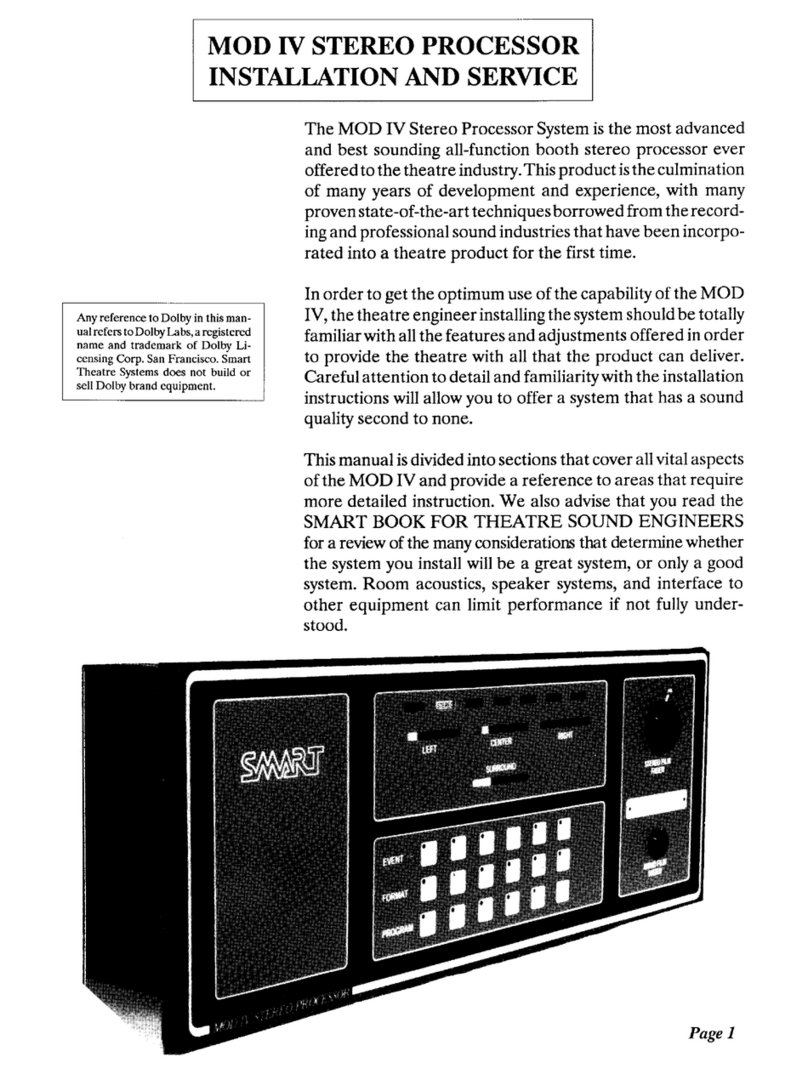

CircleSurroundDSP Matrix. The patented Circle Surround

produces 6 channels of audio from a standard optical stereo

soundtrack. It does this by sensing the slight phase bias on

the surround channel when digital masters are mixed down to

4-channel optical tracks. This means you can have split

surround optical sound presentations in auditoriums that are

equipped for split surround operation. SMART is the first

manufacturer to introduce this technology into professional

cinemaapplications. TheDSPmatrixintheMODVIpro-

duces highly accurate decoding of the optical stereo or SR

soundtrack.

SRS3-DSoundEnhancement. The patented SRS enhance-

ment is a standard feature of the new MOD VI. No longer an

expensive option, this process can be turned on or off from a

front panel operator switch or by automation. The MOD VI is

the first processor to be able to use SRS on optical stereo

tracks and digital soundtracks. This process is not active in

theaters using Front Surround Mode.

FaderControl/RemoteEqualizationSettings. TheMOD VI

has one master FADER that controls the overall playback

level for all six channels. This master fader is used as the

volume control for all formats. The individual left and right

master music level controls are located to the front right of

the main circuit board (MR and ML). The octave equalization

settings (7 bands plus bass and treble) are set with potenti-

ometers on the front PCB panel, so re-equalizing the MOD VI

will not be necessary in the event of a main circuit board

replacement.

FormatSwitching. The formats available on the MOD VI are

Mono, Stereo A, Stereo SR, SRS On/Off, Digital and Music.

All formats may be manually controlled by the gray

pushbuttons on the front panel. Red Light Emitting Diodes

mounted in the front pushbuttons indicate the selected

format. The indicator LED’s are visible from a distance so it is

not necessary to be near the processor to verify the status.

Format switching is also possible by connecting an automa-

tion or remote switch contacts to the AUTOMATION

terminals on the back of the MOD VI.

SolarCell/Reverse Scan Inputs. The MOD VI has stereo

solar cell inputs with electronic changeover for two projec-

tors. Each pair of stereo cell inputs is an electronically

balanced circuit that helps to reduce any interference pickup

on the solar cell leads. Separate “neutral” leads for right and

left channels allow for Reverse Scan wiring.

DigitalInputs. TheMODVIisfullycompatiblewithpopular

digitalformats(i.e.DTS,DolbyDigital,etc.). The MOD VI

will easily handle the stage, split surround, and subwoofer

channels from an external digital decoder.

Music Inputs. The MOD VI is designed to process both

stereo and mono music sources from tape, CD or cartridge

players. The music is processed through the Circle Surround

matrix to produce 6 channels of sound from a stereo music

source. In addition, these inputs may be used as an A/V

input for use with VCR’s or laserdisc players. The music

inputs are run through the Circle Surround matrix.

SurroundChannelTimeDelay. The MODVIhasadigital

time delay circuit for the surround channel while playing

optical stereo prints. Time delay of the surround channel in

optical stereo mode is necessary for two reasons: 1) to mask

any front to surround crosstalk and, 2) to synchronize the

stage and surround channels to eliminate echo caused by

different sound path lengths from the stage and surround

speakers.

MainOutputs. The MODVIhassixoutputchannels:LEFT,

CENTER,RIGHT,LEFTSURROUND,RIGHTSURROUND

and SUB(woofer). The SUB outputs are balanced with SUB+

and SUB- terminals available. This allows a standard dual

channel amplifier to be used in mono bridged mode to feed a

subwoofer speaker.

MainPowerSupply. A fully-regulated switching power

supply is furnished with the MOD VI processor. This supply

is heavily filtered and supplies ample current for both the

positive and negative 15 VDC supplies, as well as the logic

level 5 VDC supply. This external power supply minimizes the

chances of hum pickup when high gain electronic circuits are

placed in the same chassis as a power supply.

EmergencySoundBackupPowerSupply. A120V backup

power supply is included with the MOD VI to power the

backup preamp built into the MOD VI. This will ensure that

you will never lose a show when using the MOD VI proces-

sor. The 120V backup supply delivers about 12 VDC at

100mA. For installations where 120V is not available, the user

should supply their own power supply. The output should

be 12VDC @ 100mA and be relatively ripple free. The bypass

capability is a standard feature on the MOD VI and is not an

extra cost option as it is on other systems. MONO BYPASS

supplies sound to the Center Channel only.

DigitalSmartPort. TheDigitalSmartPortallowsforfuture

upgrades in the MOD VI, including digital 1/3 octave

equalization and Afterburner effects, as well as an alternative

port for monitor signals.

SECTION 2

FEATURES