Piano Duet Assembly Instructions

Duet Series

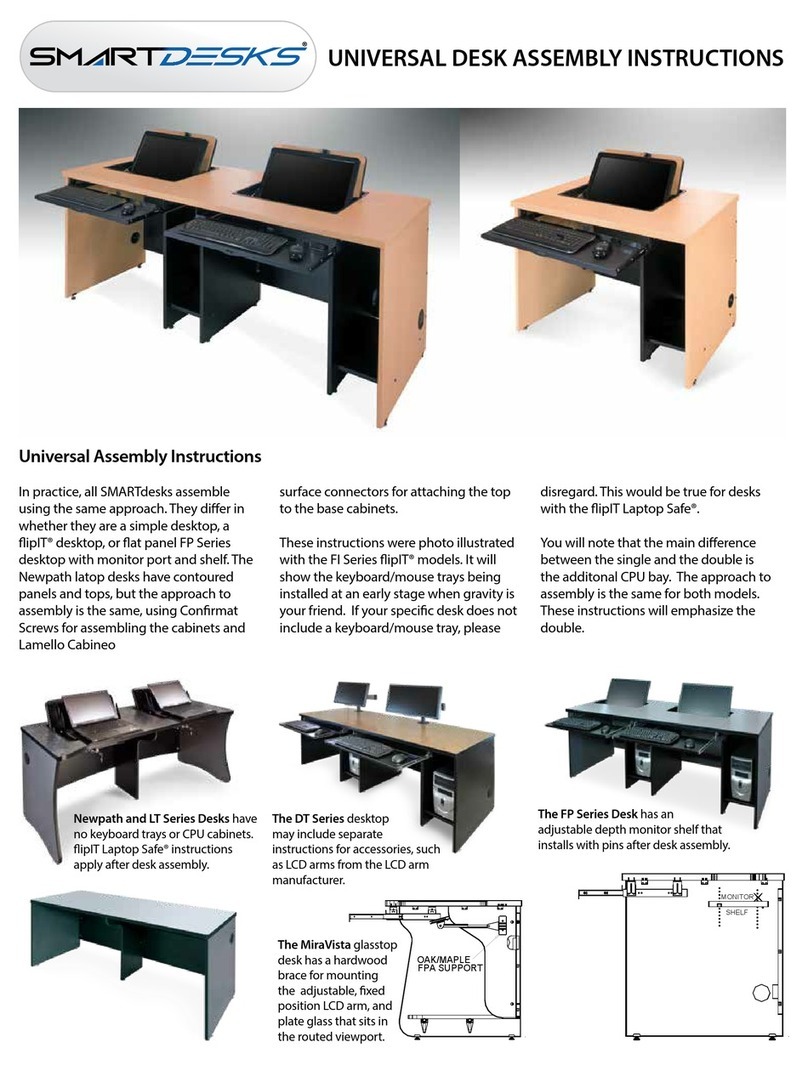

Piano Assembly Approach

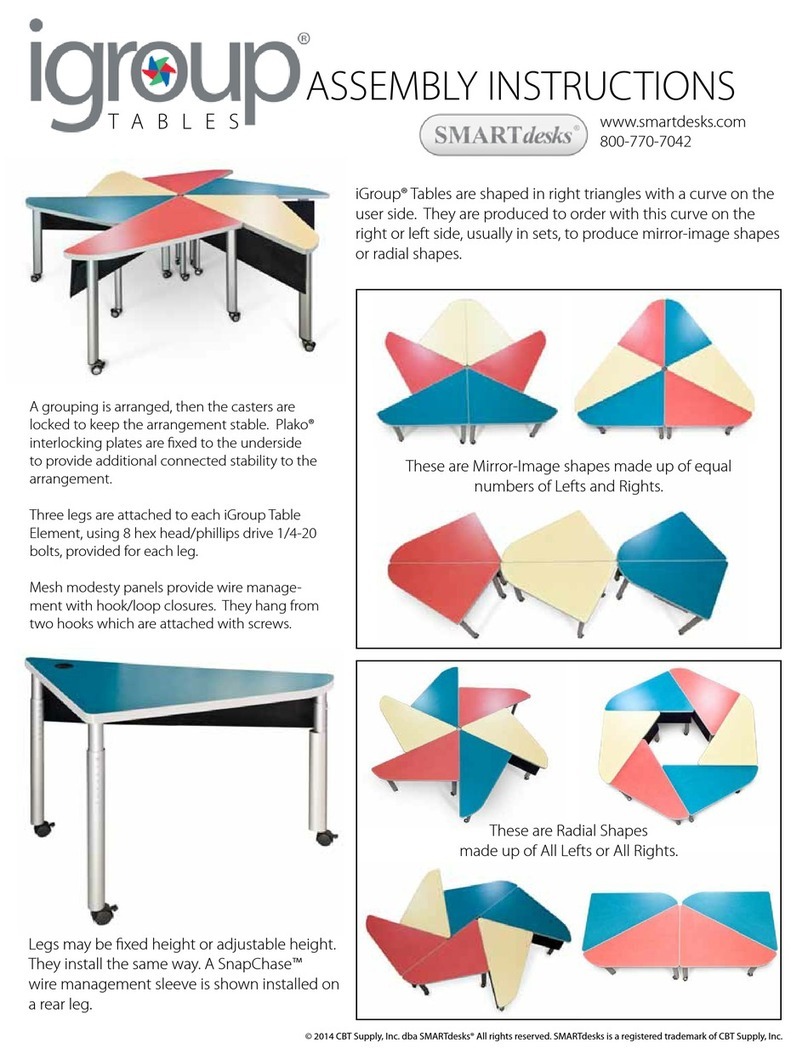

These instructions are illustrated for a Piano 10

Duet Computer ConferenceTable. Piano Duet is

available in other configurations, but the same

principles apply. Observe that there are curved

end sections, straight sections, and side transition

sections, plus hinged lids and Doric column legs.

If you are assembling a different model, you might

have…

• more straight sections, or

• the straight sections might have 3 ipIT®

stations instead of 2, or

• the side transition sections might be a slightly

different shape, or

• the side transition sections might be expanded

to include a ipIT®station, or

• there may be 4 lids instead of 2.

Given these variations, use these instructions as a

guide for approach.

These instructions are based on a specific custom-

er’s requirements. Because each Piano Computer

ConferenceTable is made to order, there may be

differences in your hardware and part geometries.

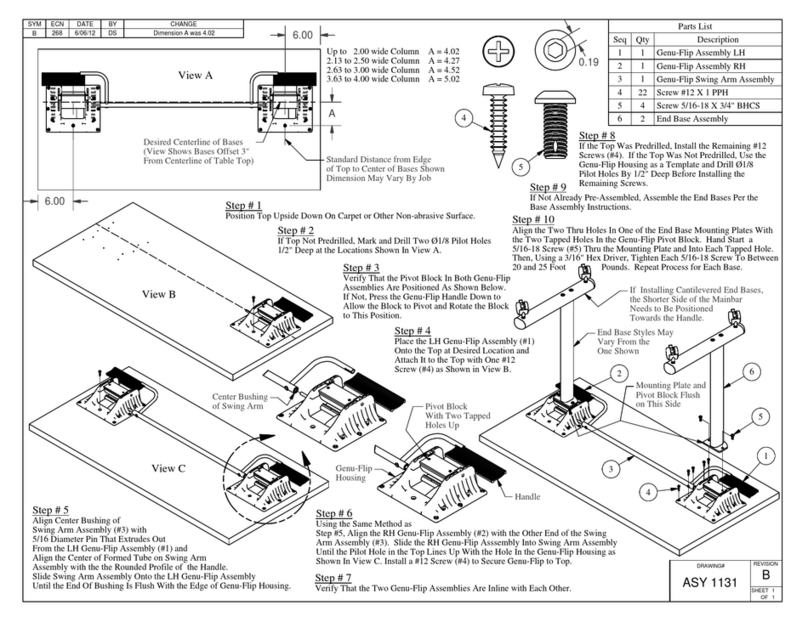

2 People Required

Subassemblies need to be carefully lifted into position and a

second set of hands is needed to stabilize assembly.

Protect the table surfaces.

Assemble in an area protected by carpet, or lay down pack-

ing blankets to prevent scratching table top surfaces.

Assemble the Piano Table First.

Install ipIT®FIH or FIK stations AFTER

Piano is assembled. The weight of the ipIT®mechanics

works against assembling the Piano safely. Consult ipIT®

Installation Instructions for installing ipIT®Stations, but

ignore the instruction to install ipIT®before desk assembly.

This assumes a conventional desk, not the Piano.

Plan Ahead

Know where the table will be positioned in the room. The

table is assembled in sections that are small enough to fit

in most elevators, hallways and doorways. Once fully as-

sembled, the table should not be moved. The table should

be assembled in its final position. Assembled sections may

be lifted and moved together carefully. Have one person per

section lift and move assembled table sections. Connecting

brackets should be installed loosely until fully assembled,

then tightened from one end to the other, leveling & fine

tuning seams for each section.

© 2007 CBT Supply, Inc. dba SMARTdesks. All rights reserved. flipIT®US Patent 7,047,890. Piano Patent D541084 Other patents pending. 1

Based on

Piano 10 Duet