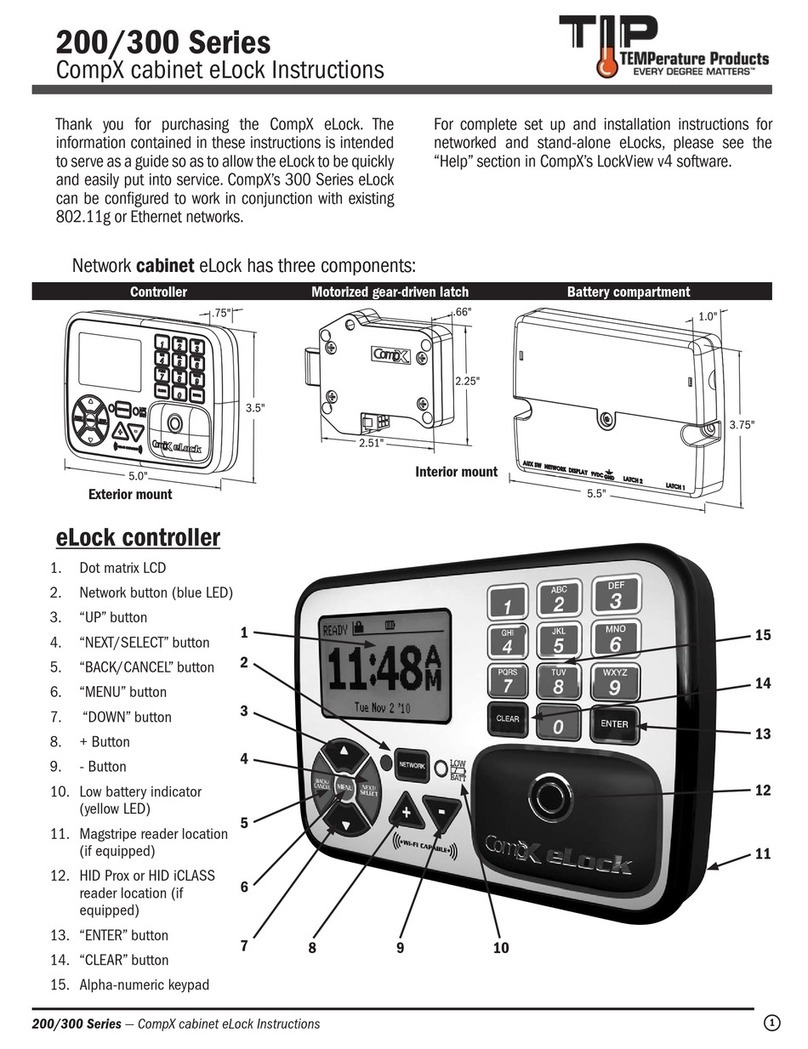

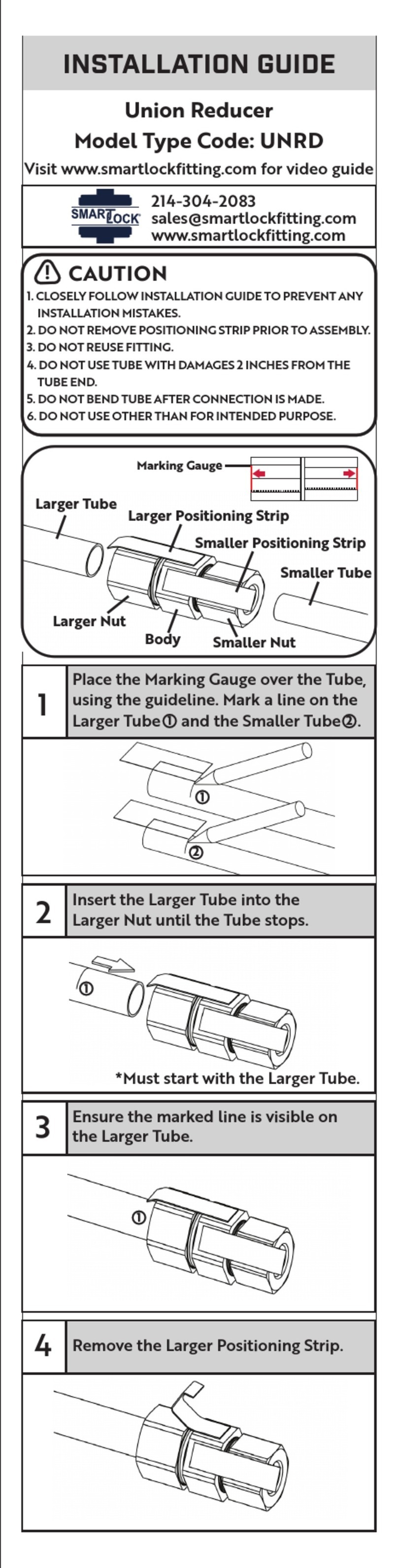

STEP 1

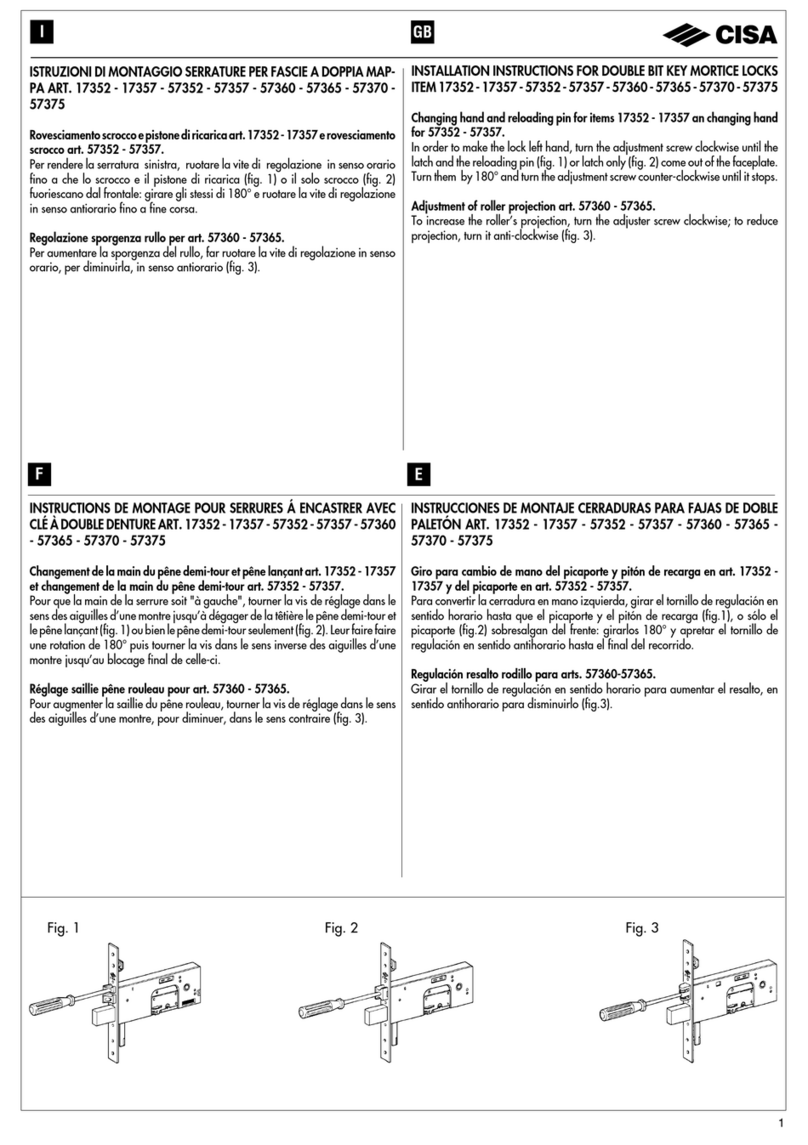

This shows an aluminium door with a

handle up multipoint lock mechanism.

In this instance you lift the handle up to

engage the deadbolts and turn the key

to lock.

STEP 2

Remove all the door hardware from both

sides of the door.

Be sure to perform the compatability test

as per the enclosed sheet before going

any further.

STEP 4

Apply masking tape to the door, fold the

enclosed paper template and align with

the spindle hole. Mark on the tape the

range for the top adjustable xing bolt.

It may be easier to drill a new hole above

the lock case for the cable.

STEP 5

Measure the position of the holes relative

to the centre of the spindle. Also measure

the overall height of the lock case. In this

instance, 55mm, 75mm & 100mm.

Mark these measurements on the mask-

ing tape.

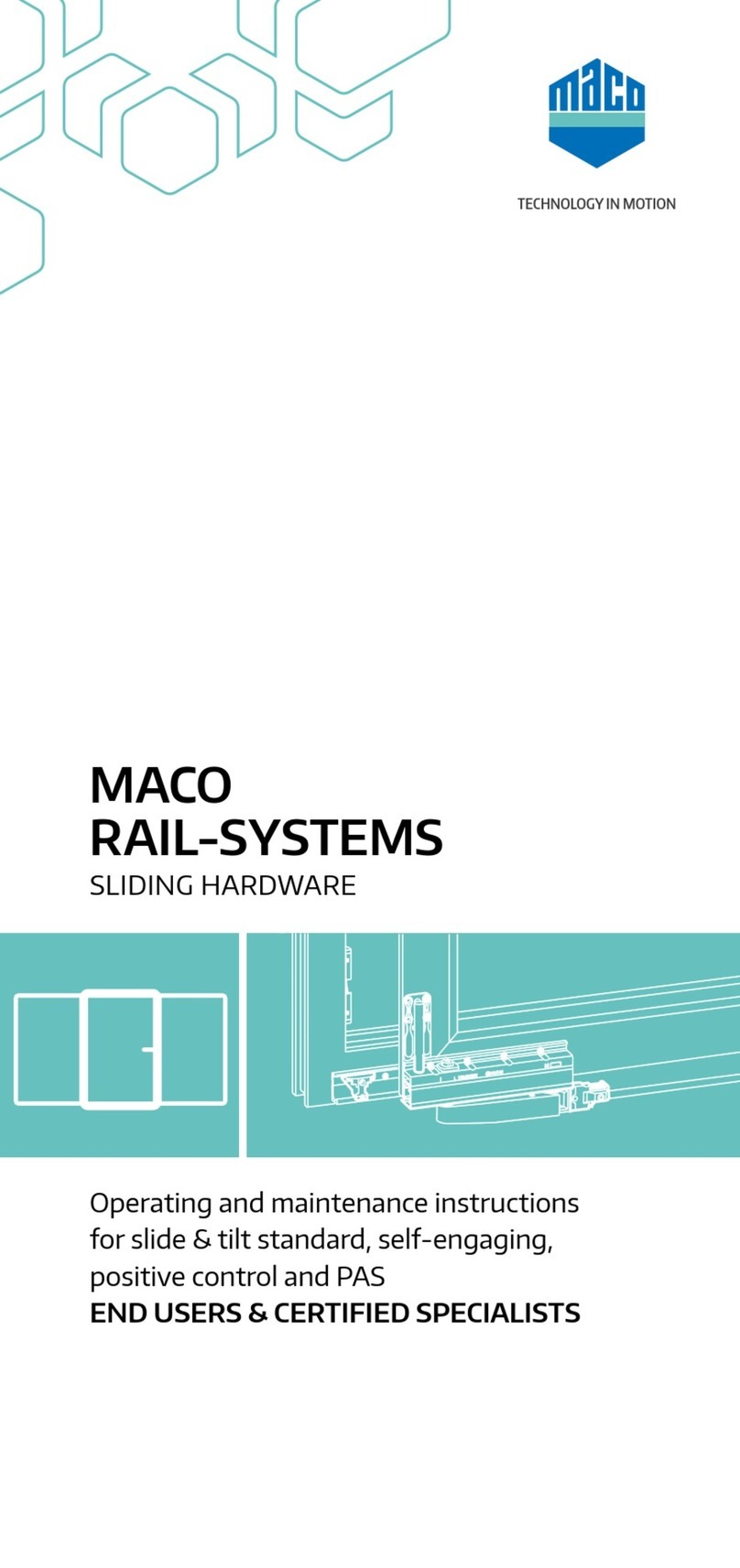

STEP 7

Align the keypad with the spindle. Where

possible the top xing bolt should use

an existing hole in the lock case. In this

example we can use the 55mm hole.

There is no existing hole for the cable so

we will drill a new hole. Mark the cable

hole position on the masking tape.

STEP 8

Mark up the position of the holes on the

other side of the door. Double check the

positions before drilling.

STEP 9

Drill the new holes. We recommend using

a step drill for the larger holes. The rec-

ommended hole diameter sizes are:

Cable: 16mm

Top Bolt: 10mm

Spindle: 25mm - It is important to make

sure that this hole is big enough for the

split pin.

STEP 10

Drill the holes on the inside. Remove the

masking tape. Push the multi-point back

into position and secure with the screws.

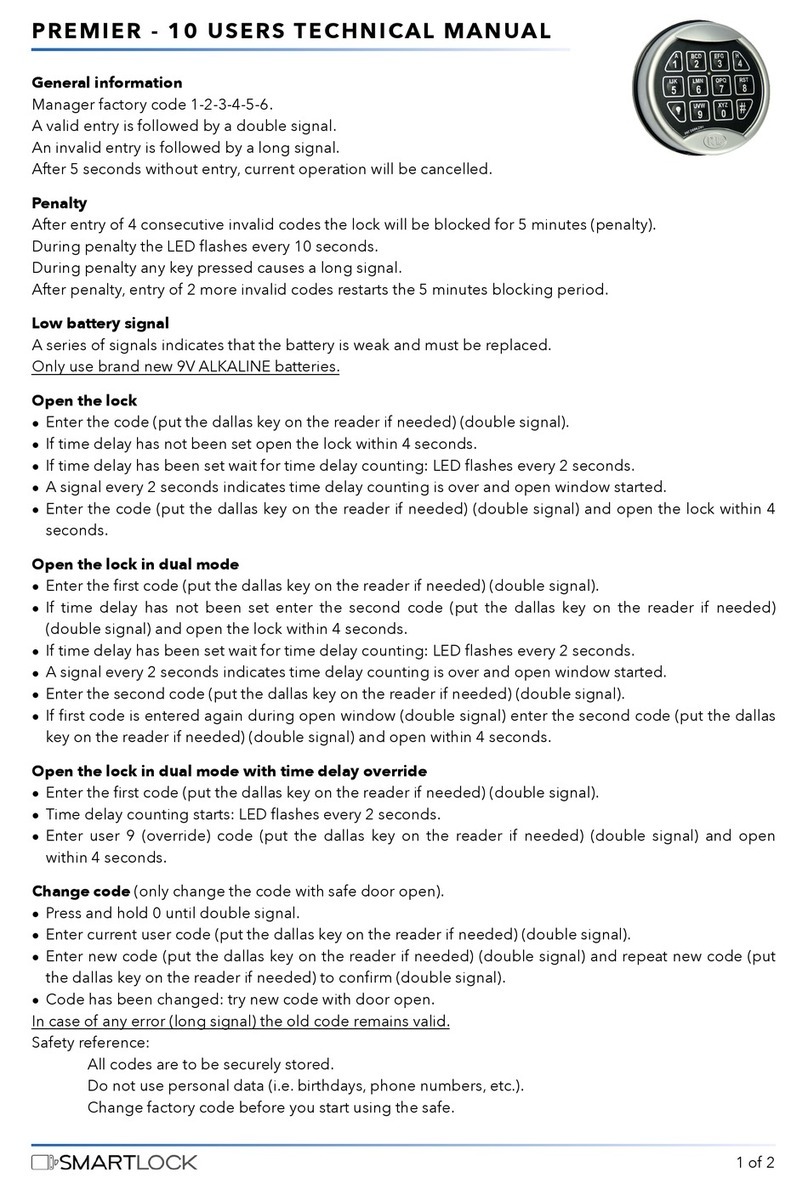

Installation instructions for a

‘handle up’ multi-point lock

mechanism.

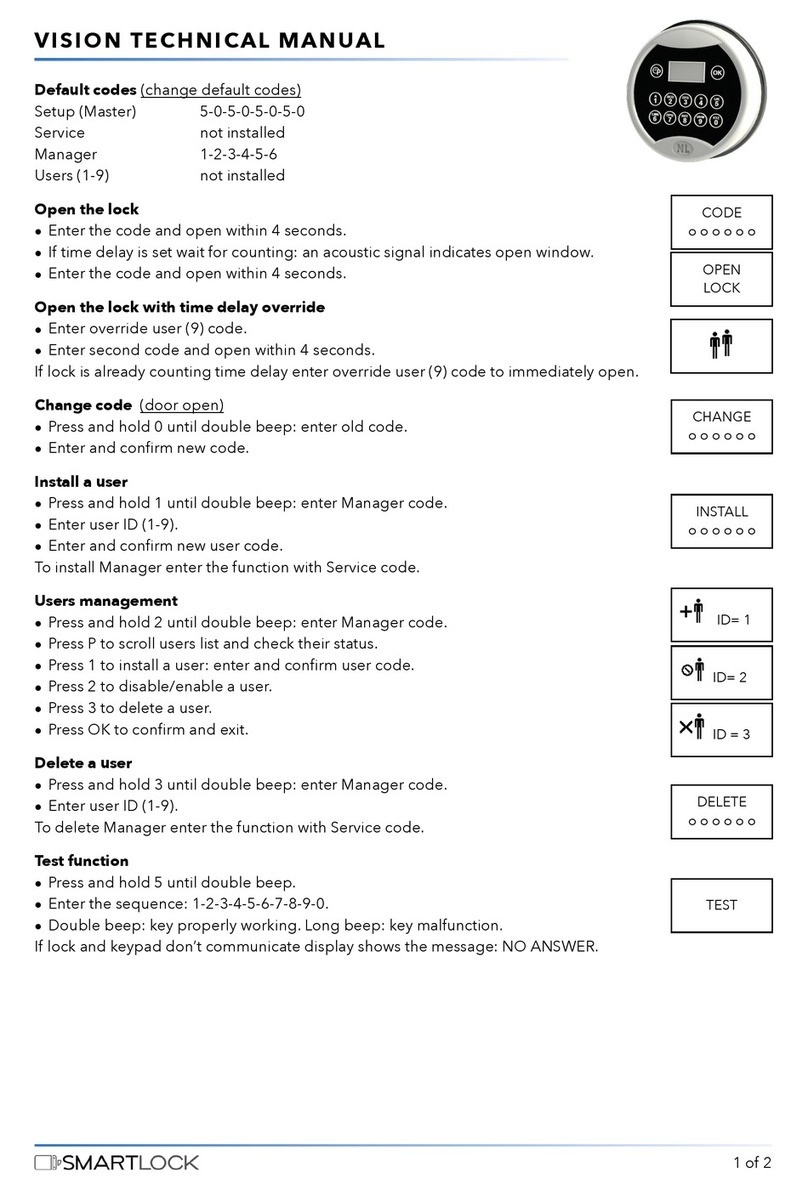

IMPORTANT

There are hundreds of different

types of multi-point lock mecha-

nism, these instructions will apply to

most but not all locks.

Before fitting, carry out the

compatibility test as detailed

in the enclosed A4 sheet.

Please use these instructions

in conjunction with the

enclosed user manual.

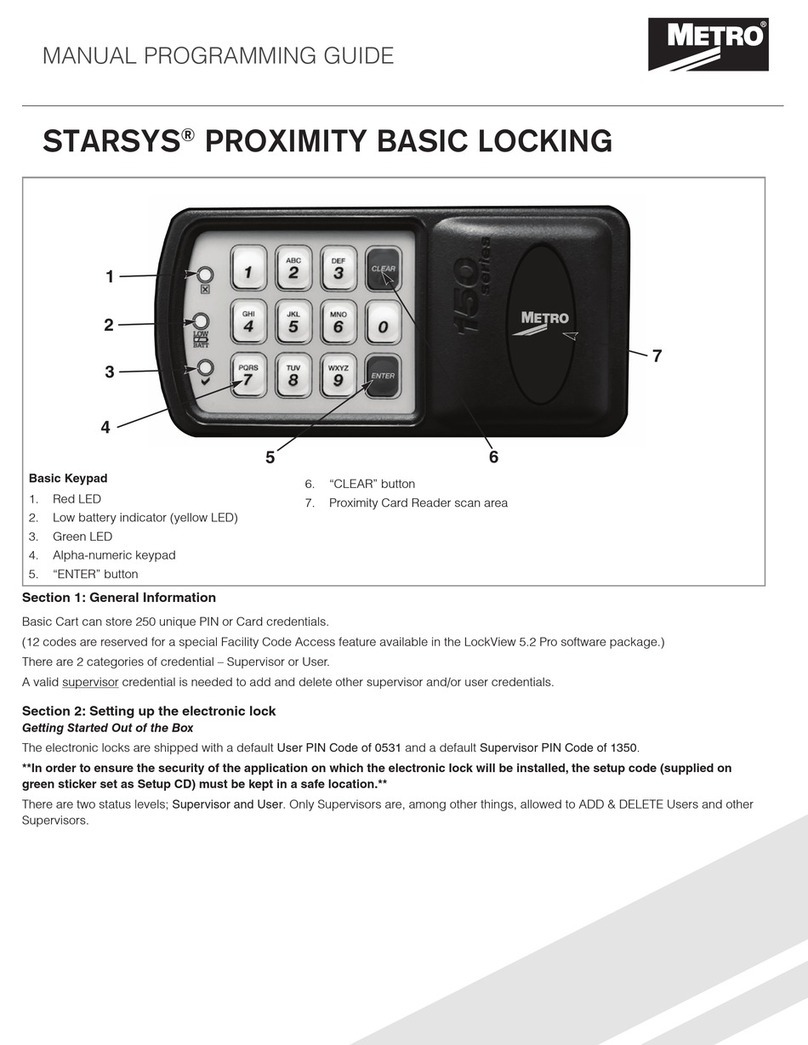

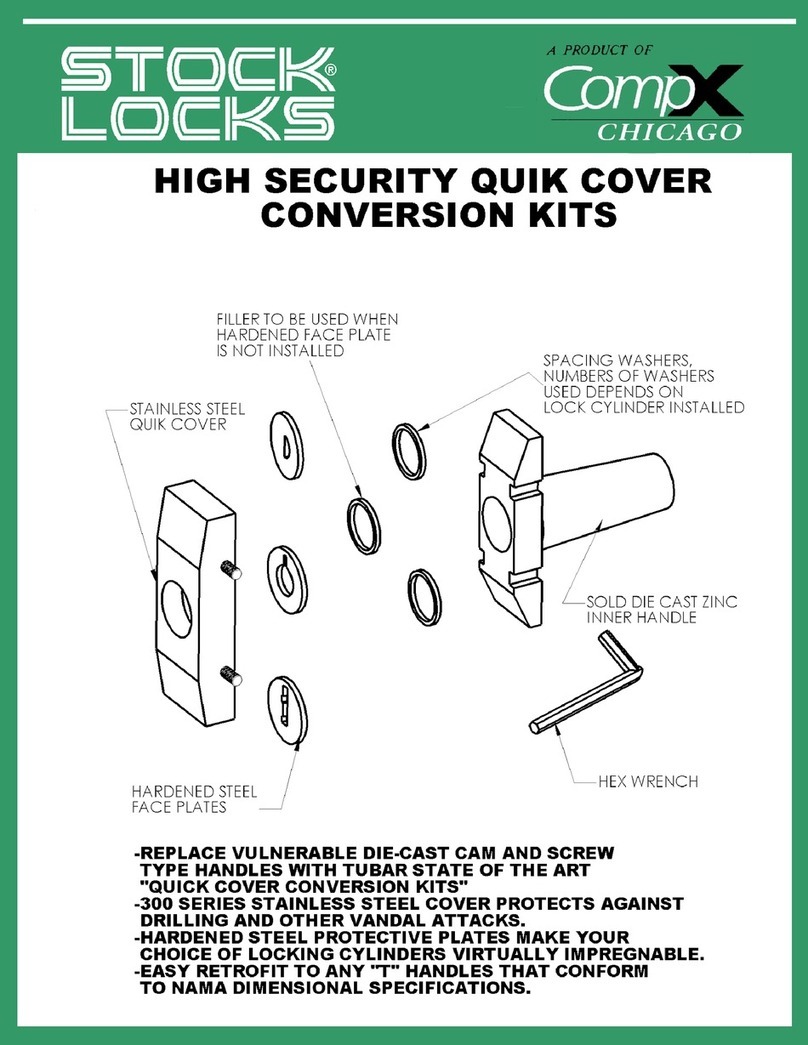

STEP 6

Check that the handles on the both sides

of the lock are facing the correct direc-

tion. If not, insert a Phillips screwdriver

and undo the screw, remove the handle

and ip 180 degrees, push back on and

tighten the screw. Make sure that you t

the two clear plastic washers.

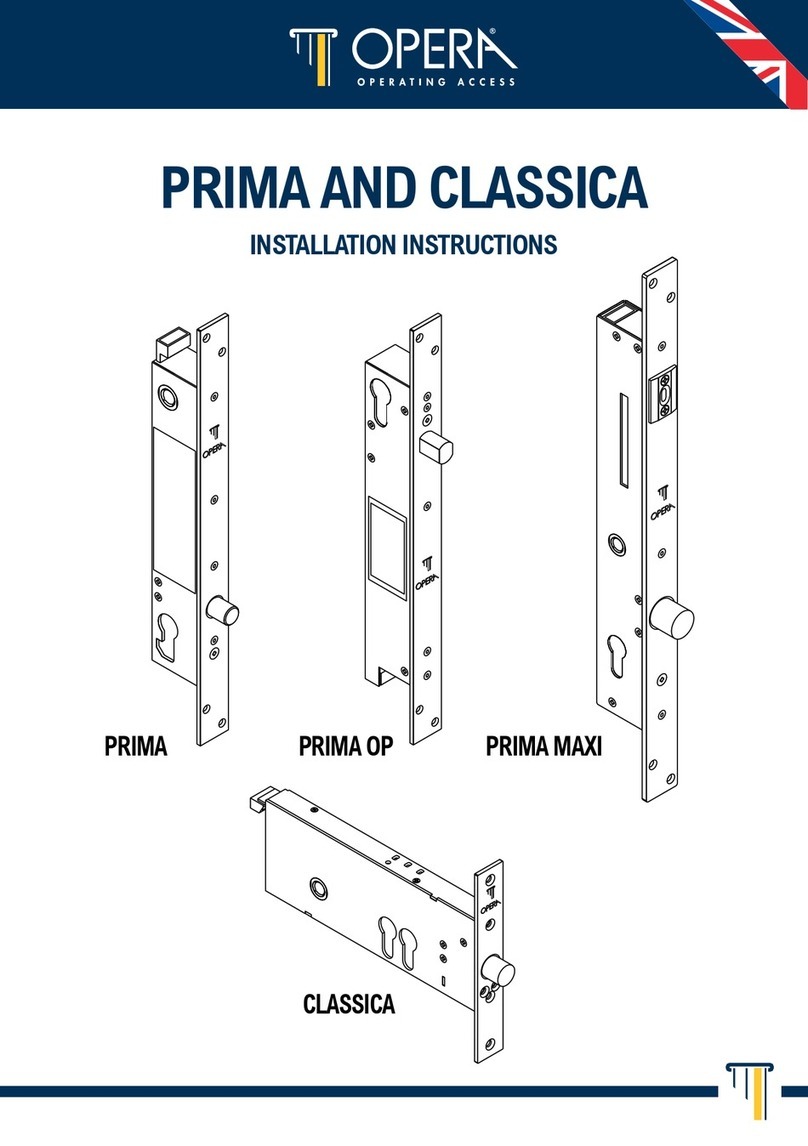

STEP 3

Remove most of the screws that hold the

multipoint in place, or remove

completely. This is so you can deter-

mine the length of the lock case and the

position of any existing holes that can be

used for the xing bolts or cable.

HOLES IN

LOCK CASE

SPINDLE

ALIGN

SPINDLE

FLIP HANDLE

180 DEGREES

NEW HOLE

FOR CABLE

ABOVE

LOCK CASE

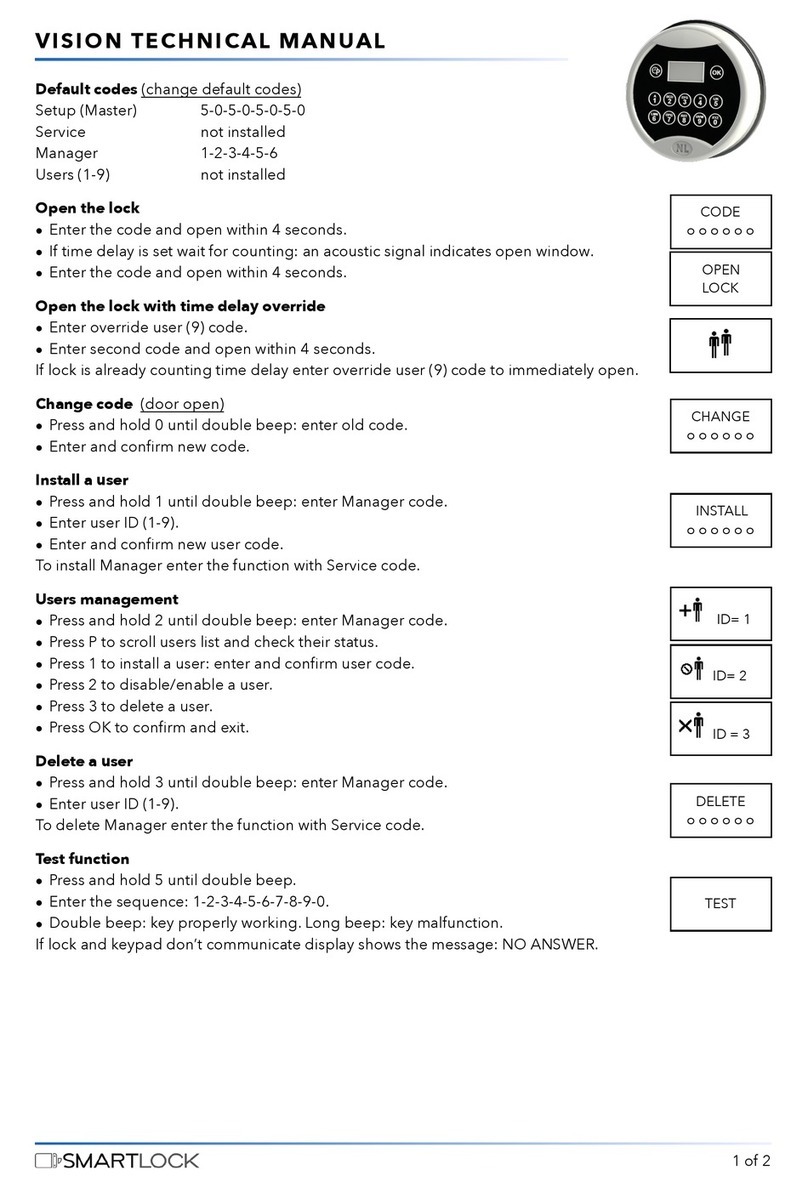

The keypad is secured by two screws

that bolt through the door. The lower

bolt will pass through the existing hole

for the keyed cylinder. The top bolt can

use an existing hole in the lock case or

a new hole can be drilled. A new hole for

the cable may be required and this can

be above the lock case or use an existing

hole. Each multi-point will be different.

LOWER BOLT

SPINDLE

TOP BOLT

CABLE

SLIMLINE UNIVERSAL

3