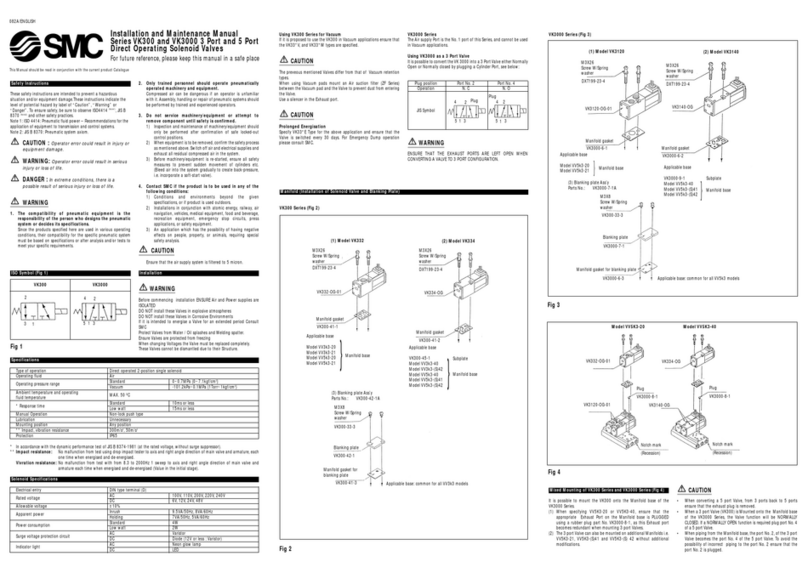

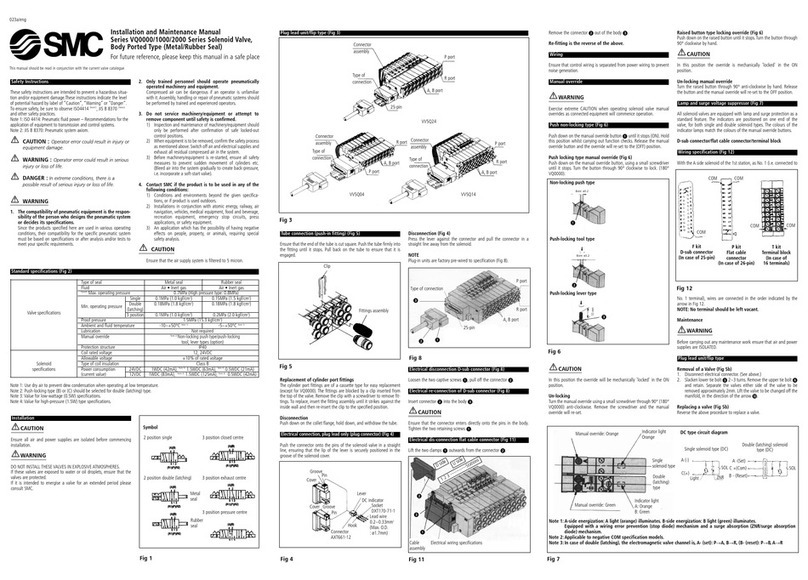

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out

with air (flushing) or washed to remove chips, cutting oil and

other debris from inside the pipe.

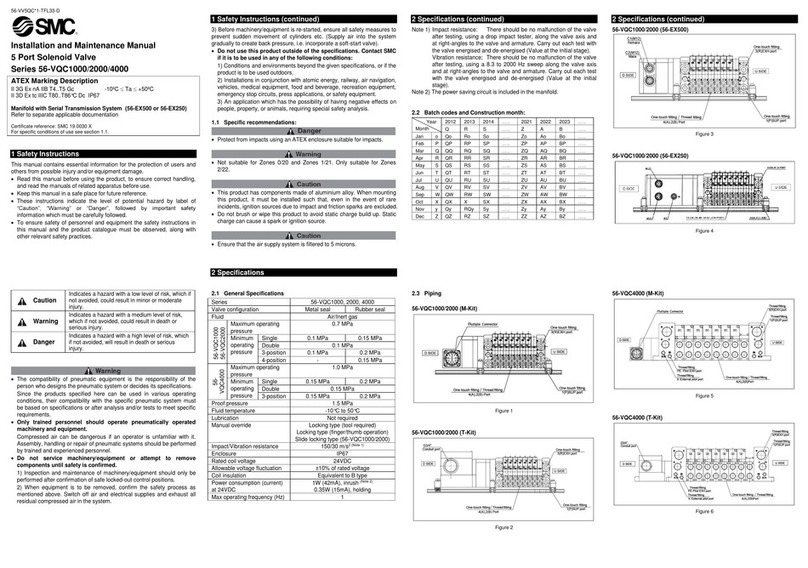

2. Wrapping of pipe tape

When screwing piping or

fittings into ports, ensure that

chips from the pipe threads or

sealing material do not enter

the piping. Also, if pipe tape is

used, leave 1 thread ridges

exposed at the end of the

threads.

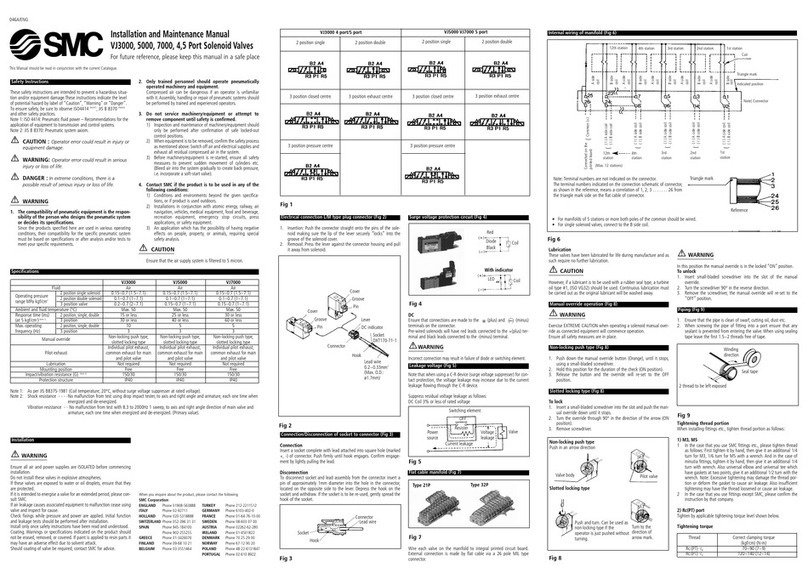

3. Connection of fittings

When screwing fittings into valves, tighten as follows.

Tightening Torque for Piping

Connection thread size (R, NPT)

Proper tightening torque (N·m)

Follow the procedure of the manufacturer when fittings other than

SMC is used.

1) If the fitting is tightened with excessive torque, a large amount

of sealant will seep out. Remove the excess sealant.

2) Insufficient tightening may cause seal failure or loosen the

threads.

3) For reuse

(1) Normally, fittings with a sealant can be reused up to 2 to 3

times.

(2) To prevent air leakage through the sealant, remove any

loose sealant stuck to the fitting by blowing air over the

threaded portion.

(3) If the sealant no longer provides effective sealing, wind

sealing tape over the sealant before reusing. Do not use any

form of sealant other than the tape type of sealant.

(4) Once the fitting has been tightened, backing it out to its

original position often causes the sealant to become

defective. Air leakage will occur.

4. Uni thread fittings

1) First, tighten the threaded portion by hand, then use a suitable

wrench to tighten the hexagonal portion of the body further at

wrench tightening angle shown below. For the reference value

for the tightening torque, refer to the table below.

Connection Female Thread: Rc, NPT, NPTF

Uni thread size

after tightened by hand

Tightening torque

(N·m)

Connection Female Thread: G

Uni thread size

after tightened by hand

Tightening torque

(N·m)

2) The gasket can be reused up to 6 to 10 times. It can be

replaced easily when it has sustained damage. Abroken gasket

can be removed by holding it and then turning it in the same

direction as loosening the thread. If the gasket is difficult to

remove, cut it with nippers, etc. In such a case, use caution not

to scratch the seat face because the seat face of the fitting’s

45° gasket is the sealing face.

5. Piping to products

When piping to a product, refer to the operation manual to

avoid mistakes regarding the supply port, etc.

This is a valve which requires lubrication. Be

sure to lubricate it for operation.

It may cause problems such as damage and

malfunction of the valve if it is not lubricated.

A valve of vacuum specification needs overhaul

for cleaning and addition of grease because it

cannot be lubricated without it. (Refer to page 8.)

1) If a lubricant is used in the system, use class 1 turbine oil (no

additive), ISO VG32.

2) Please contact SMC regarding class 2 turbine oil (with

additives), ISO VG32.

Lubrication amount

If too much oil is supplied, the oil will be accumulated in the

product, causing malfunction or response delay.

1. Use clean air.

Do not use compressed air that contains chemicals, synthetic

oils including organic solvents, salt or corrosive gases, etc., as

it can cause damage or malfunction.

1. Install an air filter.

Install an air filter upstream near the valve. Select an air filter

with a filtration size of 5 ㎛or smaller.

2. Take measures to ensure air quality, such as by

installing an aftercooler, air dryer, or water

separator.

Compressed air that contains a large amount of drainage can

cause malfunction of pneumatic equipment such as valves.

Therefore, take appropriate measures to ensure air quality,

such as by providing an aftercooler, air dryer, or water

separator.

VPA31

5 Series

Precautions for 3 Port Air Operated Valve

Be sure to read before handling.

- 5 - VP3145-OMH0005-D